Oracle® Retail Store Inventory Management

Implementation Guide, Volume 1 -

Configuration

Release 14.1

E53312-03

July 2015

Oracle® Retail Store Inventory Management Implementation Guide,

Volume 1 - Configuration, Release 14.1

E53312-03

Copyright © 2015, Oracle and/or its affiliates. All

rights reserved.

Primary Author: Bernadette Goodman

This software and related documentation are provided

under a license agreement containing restrictions on use and disclosure and are

protected by intellectual property laws. Except as expressly permitted in your

license agreement or allowed by law, you may not use, copy, reproduce,

translate, broadcast, modify, license, transmit, distribute, exhibit, perform,

publish, or display any part, in any form, or by any means. Reverse engineering,

disassembly, or decompilation of this software, unless required by law for

interoperability, is prohibited.

The information contained herein is subject to change

without notice and is not warranted to be error-free. If you find any errors,

please report them to us in writing.

If this is software or related documentation that is

delivered to the U.S. Government or anyone licensing it on behalf of the U.S.

Government, then the following notice is applicable:

U.S. GOVERNMENT END USERS: Oracle programs, including

any operating system, integrated software, any programs installed on the

hardware, and/or documentation, delivered to U.S. Government end users are

"commercial computer software" pursuant to the applicable Federal

Acquisition Regulation and agency-specific supplemental regulations. As such,

use, duplication, disclosure, modification, and adaptation of the programs,

including any operating system, integrated software, any programs installed on

the hardware, and/or documentation, shall be subject to license terms and

license restrictions applicable to the programs. No other rights are granted to

the U.S. Government.

This software or hardware is developed for general use

in a variety of information management applications. It is not developed or intended

for use in any inherently dangerous applications, including applications that

may create a risk of personal injury. If you use this software or hardware in

dangerous applications, then you shall be responsible to take all appropriate

fail-safe, backup, redundancy, and other measures to ensure its safe use.

Oracle Corporation and its affiliates disclaim any liability for any damages

caused by use of this software or hardware in dangerous applications.

Oracle and Java are registered trademarks of Oracle

and/or its affiliates. Other names may be trademarks of their respective

owners.

Intel and Intel Xeon are trademarks or registered

trademarks of Intel Corporation. All SPARC trademarks are used under license

and are trademarks or registered trademarks of SPARC International, Inc. AMD,

Opteron, the AMD logo, and the AMD Opteron logo are trademarks or registered

trademarks of Advanced Micro Devices. UNIX is a registered trademark of The

Open Group.

This software or hardware and documentation may provide access to or

information about content, products, and services from third parties. Oracle

Corporation and its affiliates are not responsible for and expressly disclaim

all warranties of any kind with respect to third-party content, products, and

services unless otherwise set forth in an applicable agreement between you and

Oracle. Oracle Corporation and its affiliates will not be responsible for any

loss, costs, or damages incurred due to your access to or use of third-party

content, products, or services, except as set forth in an applicable agreement

between you and Oracle.

Value-Added

Reseller (VAR) Language

Oracle Retail VAR Applications

The following restrictions and provisions only apply to

the programs referred to in this section and licensed to you. You acknowledge

that the programs may contain third party software (VAR applications) licensed

to Oracle. Depending upon your product and its version number, the VAR

applications may include:

(i) the MicroStrategy Components developed and

licensed by MicroStrategy Services Corporation (MicroStrategy) of McLean, Virginia to Oracle and imbedded in the MicroStrategy for Oracle Retail Data

Warehouse and MicroStrategy for Oracle Retail Planning & Optimization

applications.

(ii) the Wavelink component developed and licensed

by Wavelink Corporation (Wavelink) of Kirkland, Washington, to Oracle and

imbedded in Oracle Retail Mobile Store Inventory Management.

(iii) the software component known as Access Via™

licensed by Access Via of Seattle, Washington, and imbedded in Oracle Retail

Signs and Oracle Retail Labels and Tags.

(iv) the software component known as Adobe Flex™ licensed

by Adobe Systems Incorporated of San Jose, California, and imbedded in Oracle

Retail Promotion Planning & Optimization application.

You acknowledge and confirm that Oracle grants you use

of only the object code of the VAR Applications. Oracle will not deliver source

code to the VAR Applications to you. Notwithstanding any other term or

condition of the agreement and this ordering document, you shall not cause or

permit alteration of any VAR Applications. For purposes of this section,

"alteration" refers to all alterations, translations, upgrades,

enhancements, customizations or modifications of all or any portion of the VAR

Applications including all reconfigurations, reassembly or reverse assembly,

re-engineering or reverse engineering and recompilations or reverse

compilations of the VAR Applications or any derivatives of the VAR

Applications. You acknowledge that it shall be a breach of the agreement to

utilize the relationship, and/or confidential information of the VAR

Applications for purposes of competitive discovery.

The information contained in this document is for

informational sharing purposes only and should be considered in your capacity

as a customer advisory board member or pursuant to your beta trial agreement

only. It is not a commitment to deliver any material, code, or functionality,

and should not be relied upon in making purchasing decisions. The development,

release, and timing of any features or functionality described in this document

remains at the sole discretion of Oracle.

This document in any form, software or printed

matter, contains proprietary information that is the exclusive property of

Oracle. Your access to and use of this confidential material is subject to the

terms and conditions of your Oracle Master Agreement, Oracle License and

Services Agreement, Oracle PartnerNetwork Agreement, Oracle distribution

agreement, or other license agreement which has been executed by you and Oracle

and with which you agree to comply. This document and information contained

herein may not be disclosed, copied, reproduced, or distributed to anyone

outside Oracle without prior written consent of Oracle. This document is not

part of your license agreement nor can it be incorporated into any contractual

agreement with Oracle or its subsidiaries or affiliates.

The VAR Applications contain trade secrets of Oracle and

Oracle's licensors and Customer shall not attempt, cause, or permit the alteration,

decompilation, reverse engineering, disassembly or other reduction of the VAR

Applications to a human perceivable form. Oracle reserves the right to replace,

with functional equivalent software, any of the VAR Applications in future

releases of the applicable program.

Preface................................................................................................................... xv

Audience...................................................................................................................................... xv

Related Documents................................................................................................................... xv

Supplemental Documentation on My Oracle Support............................................. xv

Documentation Accessibility................................................................................................ xvi

Access to Oracle Support................................................................................................ xvi

Customer Support.................................................................................................................... xvi

Review Patch Documentation.............................................................................................. xvi

Improved Process for Oracle Retail Documentation Corrections............................... xvi

Oracle Retail Documentation on the Oracle Technology Network........................... xvii

Conventions............................................................................................................................. xvii

1 Introduction........................................................................................................... 1

Skills Needed for Implementation........................................................................................... 1

Applications.......................................................................................................................... 1

Technical Concepts.............................................................................................................. 2

2 Technical Architecture.......................................................................................... 3

SIM Technology Stack................................................................................................................ 3

Advantages of the Architecture............................................................................................... 3

SIM Technical Architecture Diagrams and Description................................................... 4

Client Tier............................................................................................................................... 4

Middle (Server) Tier............................................................................................................ 5

Database Tier......................................................................................................................... 6

Distributed Topology.................................................................................................................. 6

3 Setup and Configuration....................................................................................... 9

Security........................................................................................................................................... 9

External Authentication/Authorization....................................................................... 9

Internal Authentication/Authorization........................................................................ 9

External/Internal Authentication and Internal Authorization............................... 9

External/Internal Authentication/Authorization................................................... 10

How SIM Associates Menus and Menu Items.................................................................... 12

SIM Permission Definitions............................................................................................. 12

SIM Role Definitions......................................................................................................... 12

External Authentication/Authorization Setup (LDAP)................................................. 14

SIM User Definitions......................................................................................................... 14

SIM User Allowed Stores................................................................................................. 14

SIM User Role Assignments............................................................................................ 14

Oracle Software Security Assurance (OSSA)..................................................................... 15

Setting up LDAP Data for SIM............................................................................................... 15

readme.txt............................................................................................................................ 16

sim_objectclasses.ldif........................................................................................................ 16

sim_add_company.ldif..................................................................................................... 16

sim_add_containers.ldif................................................................................................... 16

sim_data_roles.ldif............................................................................................................ 16

sim_data_stores.ldif.......................................................................................................... 16

sim_data_users.ldif........................................................................................................... 16

sim_data_users_roles.ldif................................................................................................ 16

Using Oracle Virtual Directory to Authenticate SIM....................................................... 17

Internal Authentication/Authorization Setup (SIM)...................................................... 17

SIM User Definitions......................................................................................................... 17

SIM User Allowed Stores................................................................................................. 17

SIM User Role Assignments............................................................................................ 18

External/Internal Authentication/Authorization Setup

(SIM/LDAP)..................... 18

SIM User Definitions......................................................................................................... 18

SIM User Allowed Stores................................................................................................. 18

SIM User Role Assignments............................................................................................ 18

External/Internal Authentication and Internal Authorization

Setup (SIM/LDAP) 18

SIM User Definitions......................................................................................................... 19

SIM User Allowed Stores................................................................................................. 19

SIM User Role Assignments............................................................................................ 19

Time Zones.................................................................................................................................. 19

Defaulting Store Configuration Parameters....................................................................... 19

Data Seeding............................................................................................................................... 19

Data Seeding Components.............................................................................................. 23

Defining Store List............................................................................................................. 24

Executing Data Seeding Scripts...................................................................................... 24

Security FAQ............................................................................................................................... 24

4 Functional Design and

Overviews....................................................................... 25

Store Inventory Management Overview............................................................................. 25

Solution and Business Process Overview............................................................................ 26

Inventory Management........................................................................................................... 27

Inventory Adjustments Functional Overview................................................................... 27

A Summary of Reason Codes and Dispositions......................................................... 28

Wastage Functional Overview....................................................................................... 33

Store Orders Functional Overview................................................................................ 34

Item Requests............................................................................................................................. 35

Price Changes Functional Overview............................................................................. 37

Sequencing Functional Overview.................................................................................. 39

Shelf Replenishment Functional Overview................................................................. 41

Stock Counts Functional Overview............................................................................... 44

Item Basket.......................................................................................................................... 53

Shipping and Receiving Functional Overview.................................................................. 54

Store-to-Store Transfer Functional Overview............................................................ 54

Warehouse Delivery.......................................................................................................... 59

Direct Store Delivery (DSD)............................................................................................ 61

Returns and Return Requests Functional Overview........................................................ 69

Returns.................................................................................................................................. 69

Return Requests.................................................................................................................. 70

Updating Reason Codes................................................................................................... 71

Customer Order Management............................................................................................... 71

Customer Orders................................................................................................................ 72

Customer Order Picking................................................................................................... 73

Customer Order Deliveries.............................................................................................. 73

Customer Order Reverse Picks....................................................................................... 74

Lookups........................................................................................................................................ 75

Item Lookup........................................................................................................................ 75

Supplier Lookup................................................................................................................. 77

Container Lookup.............................................................................................................. 78

Transaction Lookup........................................................................................................... 79

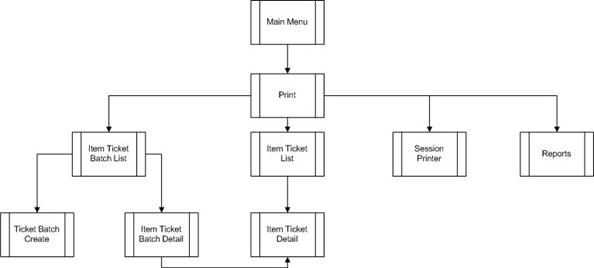

Ticketing Functional Overview...................................................................................... 80

Unique Identification Number (UINs)................................................................................ 83

Functional Overview........................................................................................................ 83

Auto Generated Serial Numbers (AGSNs).................................................................. 84

UIN AutoNumber.............................................................................................................. 85

Auditing............................................................................................................................... 88

UIN Setup............................................................................................................................ 88

UIN Status........................................................................................................................... 89

Resolving UIN Discrepancies......................................................................................... 91

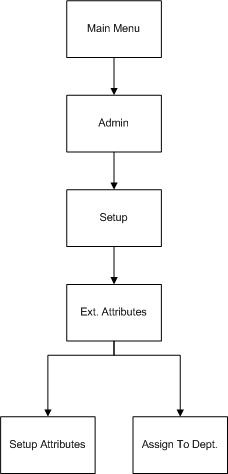

Extended Attributes (including GS1)................................................................................... 93

Functional Overview........................................................................................................ 93

Attributes-Configuration................................................................................................. 95

Attributes-Processing........................................................................................................ 95

5 System and Store

Administration........................................................................ 97

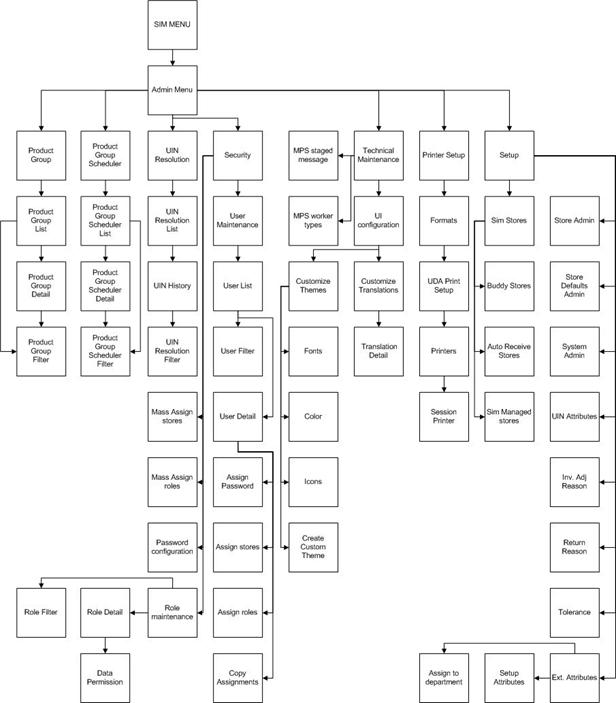

Overview..................................................................................................................................... 97

Product Groups/Scheduler.................................................................................................. 101

Store Administration.............................................................................................................. 102

Set Store Options.............................................................................................................. 102

Store Administration Options Table........................................................................... 103

System Administration.......................................................................................................... 118

Set System Options.......................................................................................................... 118

System Administration Options Tables..................................................................... 119

6 Reporting........................................................................................................... 143

Operational Reports............................................................................................................... 143

Analytical (and Ad Hoc) Reports........................................................................................ 143

Assumptions............................................................................................................................. 143

SIM Reporting Framework................................................................................................... 143

Printing to Local Printers in a Store............................................................................ 143

SIM Operational Reports............................................................................................... 145

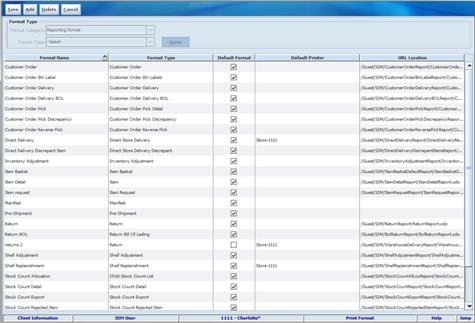

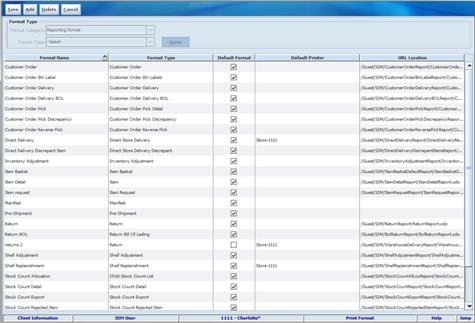

Report Formats................................................................................................................. 147

Configuring a Report Printer in SIM.......................................................................... 165

Defining a Session Printer in SIM................................................................................ 166

Uploading Reports........................................................................................................... 166

Setting up Report Formats in SIM............................................................................... 167

SIM Reports Internationalization................................................................................ 170

Number, Date & Currency Format Support............................................................. 174

Report Engine Functional Specification............................................................................ 176

Functional Requirements............................................................................................... 176

Detailed Report Information........................................................................................ 177

Bill of Lading Report............................................................................................................... 185

Printing the Return Bill of Lading............................................................................... 185

Printing the Transfer Bill of Lading............................................................................ 186

7 Internationalization............................................................................................ 187

Translation................................................................................................................................ 187

DAO Layer................................................................................................................................ 188

Tables.................................................................................................................................. 188

Loading Data.................................................................................................................... 188

Retrieving Translations.................................................................................................. 188

Types of Internationalization............................................................................................... 188

Logging...................................................................................................................................... 188

Text...................................................................................................................................... 188

Numbers............................................................................................................................. 189

Dates (PC).......................................................................................................................... 189

Dates (HH)........................................................................................................................ 189

Money................................................................................................................................. 189

Handheld Device Configuration for Japanese Display.......................................... 189

Brazil-Specific Setup.............................................................................................................. 190

Direct Store Delivery...................................................................................................... 190

Internal Deliveries........................................................................................................... 190

Receiver Unit Adjustments........................................................................................... 191

Unsupported Processes.................................................................................................. 191

A Appendix SIM Permissions............................................................................... 193

B Appendix LDAP Schema.................................................................................... 247

Object Classes........................................................................................................................... 247

Directory Entry Structure..................................................................................................... 249

Configuration File ldap.cfg................................................................................................... 249

Sample LDIF Data Files......................................................................................................... 249

Store.................................................................................................................................... 250

Role...................................................................................................................................... 250

User..................................................................................................................................... 250

User’s Role......................................................................................................................... 251

C Appendix Transfer

Localization........................................................................ 253

Process Requirements............................................................................................................ 253

Transfer Zones.................................................................................................................. 253

Auto Receiving................................................................................................................. 253

Buddy Stores..................................................................................................................... 253

Transfer Force Close Indicator..................................................................................... 254

Receive Entire Transfer Parameter............................................................................. 256

Store Receiving................................................................................................................. 256

Dispatching a Transfer................................................................................................... 256

D Appendix UPC Barcode..................................................................................... 259

Differences Between UPC-A and UPC-E........................................................................... 259

Conversion Between UPC-A and UPC-E.......................................................................... 260

Quick Response Codes........................................................................................................... 261

List of Figures

Figure: SIM Technical

Architecture.. 4

Figure: SIM

Deployment.. 7

Figure: Data

Seeding Technical Architecture.. 20

Figure: Business

Process Flow – Inventory Adjustments PC.. 32

Figure: Business

Process Flow - Inventory Adjustment Reason Maintenance PC 33

Figure: Business

Process Flow (non-sale bases). 34

Figure: Store

Orders Business Process Flow – PC.. 35

Figure: Item

Requests Business Process Flow – PC.. 37

Figure: Price

Changes Business Process Flow – PC.. 39

Figure: Sequencing

Business Process Flow – PC.. 41

Figure: Shelf

Replenishment Business Process Flow – PC.. 44

Figure: Business

Flow (Unit, Problem Line, Unit and Amount and Third Party) 50

Figure: Business

Flow – Ad Hoc (PC only). 51

Figure: Business

flow – Third Party.. 52

Figure: Business

Flow - Future Stock Count.. 53

Figure: Store to

Store Transfers Business Process Flow – PC.. 55

Figure: Transfer

Request to Transfer Receipt.. 58

Figure: Warehouse

Receiving Business Process Flow – PC.. 60

Figure: Direct

Store Delivery (new created) Business Process Flow – PC.. 64

Figure: DSD

Multiple Available ASNs Business Process Flow – PC.. 65

Figure: DSD

Updating and Defaulting Cost Business Process Flow – PC.. 66

Figure: Return

Requests Business Process Flow – PC.. 70

Figure: Customer

Order Management Business. 73

Figure: Item Lookup

Business Process Flow – PC.. 76

Figure: Supplier

Lookup Business Process Flow – PC.. 77

Figure: Container

Lookup Business Process Flow – PC.. 78

Figure: Transaction

HIstory Lookup Business Process Flow – PC.. 79

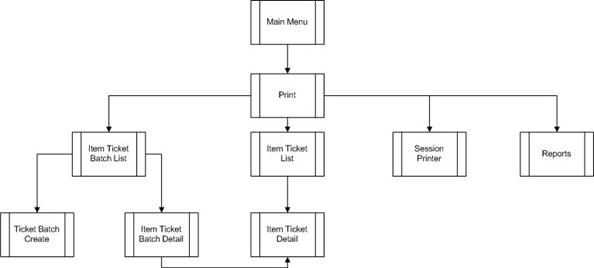

Figure: Ticketing

Business Process Flow – PC.. 82

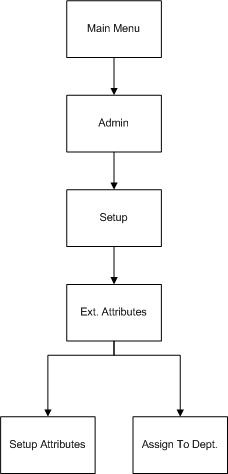

Figure: Extended

Attribute Setup PC Screen Flow – PC.. 93

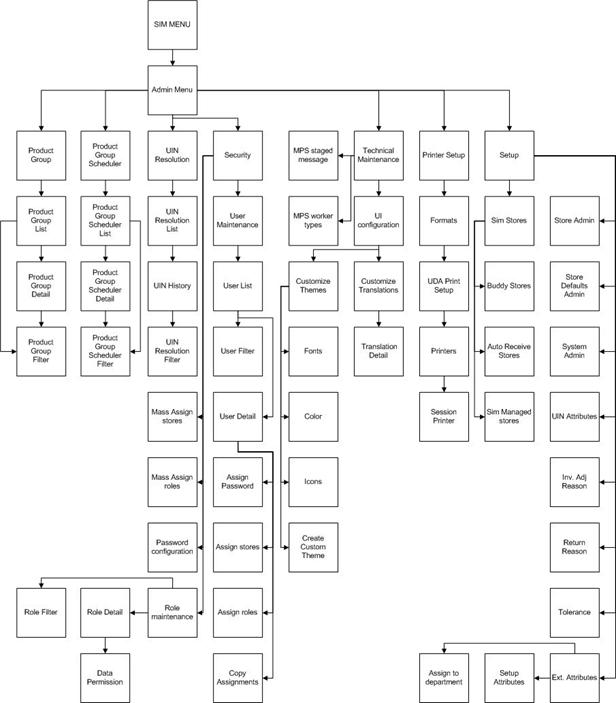

Figure: Store

Administration PC Screen Flow... 98

Figure: The Store

Admin Window... 100

Figure: The System

Admin Window... 116

Figure: Local

Printing in a Store.. 142

Figure: BolReturnReport.. 145

Figure: BolTransferReport.. 146

Figure: CustomerOrderBinLabelReport.. 146

Figure: CustomerOrderDeliveryBOLReport.. 147

Figure: CustomerOrderDeliveryReport.. 147

Figure: CustomerOrderPickDiscrepancyReport.. 148

Figure: CustomerOrderPickReport.. 148

Figure: CustomerOrderReport.. 149

Figure: CustomerOrderReversePickReport.. 149

Figure: DirectDeliveryDiscrepantItemsReport.. 150

Figure: DirectDeliveryReport.. 151

Figure: InventoryAdjustmentReport.. 152

Figure: ItemBasketDefaultReport.. 152

Figure: ItemDetailReport.. 153

Figure: ItemRequestReport.. 154

Figure: ReturnReport.. 155

Figure: ShelfReplenishmentReport.. 156

Figure: StockCountAllLocReport.. 157

Figure: StockCountRejectedItemReport.. 158

Figure: StockCountReport.. 159

Figure: StoreOrderReport.. 160

Figure: TransferReport.. 161

Figure: WarehouseDeliveryReport.. 162

Figure: ShelfAdjustmentReport.. 163

Figure: Report

Formats Screen.. 166

Figure: Oracle BI

Publisher Desktop Options in Word.. 168

Figure: TransferReport.rtf. 169

Figure: Localize the

Template.. 169

Figure: Extract

Text for Export to XLIFF File.. 170

Figure: Save the

XLIFF File.. 170

Figure: Template

and Placeholder of the XML Tag.. 172

Figure: Text Form

Field Options Window... 172

Figure: Form Field

Help Text Window... 173

Figure: UPC-A and

UPC-E Differences. 257

Oracle Retail Store Inventory

Management, Implementation Guide,

Volume 1 - Configuration, Release 14.1

Oracle welcomes customers' comments and suggestions on the

quality and usefulness of this document.

Your feedback is important, and helps us to best meet your needs

as a user of our products. For example:

§

Are the implementation steps correct and complete?

§

Did you understand the context of the procedures?

§

Did you find any errors in the information?

§

Does the structure of the information help you with your tasks?

§

Do you need different information or graphics? If so, where, and

in what format?

§

Are the examples correct? Do you need more examples?

If you find any errors or have any other suggestions for

improvement, then please tell us your name, the name of the company who has

licensed our products, the title and part number of the documentation and the

chapter, section, and page number (if available).

Note:

Before sending us your comments, you might like to check that you have the latest

version of the document and if any concerns are already addressed. To do this,

access the Online Documentation available on the Oracle Technology Network Web

site. It contains the most current Documentation Library plus all documents

revised or released recently.

Send your comments to us using the electronic mail address: retail-doc_us@oracle.com

Please give your name, address, electronic mail address, and

telephone number (optional).

If you need assistance with Oracle software, then please contact

your support representative or Oracle Support Services.

If you require training or instruction in using Oracle software,

then please contact your Oracle local office and inquire about our Oracle

University offerings. A list of Oracle offices is available on our Web site at www.oracle.com.

The Oracle Retail Store Inventory Management

Implementation Guide, Volume 1– Configuration provides detailed

information that is important when implementing SIM. The Oracle

Retail Store Inventory Management Implementation Guide, Volume 1– Configuration

provides the following information and more:

§

System and store administration

Details the SIM system and store options. System option

parameters allow a user to change the parameter for the entire system and all

stores. Store option parameters are only specific to the store the current user

is logged in to.

§

Functional design and overview

Provides detailed information concerning the various aspects of

the SIM functional areas.

This document is intended for the Oracle Retail Store Inventory

Management application integrators and implementation staff, as well as the

retailer’s IT personnel.

For more information, see the following documents in the Oracle

Retail Store Inventory Management Release 14.1 documentation set:

§

Oracle Retail Store Inventory Management

Implementation Guide, Volume 2 – Integration with Oracle Retail Applications

§

Oracle Retail Store Inventory Management

Implementation Guide, Volume 3 – Mobile Store Inventory Management

§

Oracle Retail Store Inventory Management

Implementation Guide, Volume 4 – Extension Solutions

§

Oracle Retail Store Inventory Management

Installation Guide

§

Oracle Retail Store Inventory Management

Operations Guide

§

Oracle Retail Store Inventory Management

Release Notes

§ Oracle Retail Store Inventory Management User Guide

The following document

is available through My Oracle Support. Access My Oracle Support at the

following URL:

http://support.oracle.com/

Enterprise Integration Guide (Located in the Oracle Retail Integration

Suite Library on the Oracle Technology

Network)

The Enterprise Integration Guide is an HTML document that

summarizes Oracle Retail

integration. This version of the Integration Guide is concerned with the two integration styles that

implement messaging patterns: Asynchronous JMS Pub/Sub Fire-and-Forget and Web Service Request

Response. The Enterprise Integration Guide

addresses the Oracle Retail Integration Bus (RIB), a fully distributed

integration infrastructure

that uses Message Oriented Middleware (MOM) to integrate applications, and the Oracle Retail Service

Backbone (RSB), a productization of a set of

Web Services, ESBs and Security tools that standardize the deployment.

For information about Oracle's commitment to accessibility, visit

the Oracle Accessibility Program website at http://www.oracle.com/pls/topic/lookup?ctx=acc&id=docacc.

Oracle customers that have purchased support have access to

electronic support through My Oracle Support. For information, visit http://www.oracle.com/pls/topic/lookup?ctx=acc&id=info

or visit http://www.oracle.com/pls/topic/lookup?ctx=acc&id=trs

if you are hearing impaired.

To contact Oracle Customer Support, access My Oracle Support at

the following URL:

https://support.oracle.com

When contacting Customer Support, please provide the following:

§

Product version and program/module name

§

Functional and technical description of the problem (include

business impact)

§

Detailed step-by-step instructions to re-create

§

Exact error message received

§

Screen shots of each step you take

When you install the application for the first time, you install

either a base release (for example, 14.1) or a later patch release (for

example, 14.1.1). If you are installing the base release and additional patch

releases, read the documentation for all releases that have occurred since the

base release before you begin installation. Documentation for patch releases

can contain critical information related to the base release, as well as

information about code changes since the base release.

To more quickly address critical corrections to Oracle Retail

documentation content, Oracle Retail documentation may be republished whenever

a critical correction is needed. For critical corrections, the republication of

an Oracle Retail document may at times not be attached to a numbered software

release; instead, the Oracle Retail document will simply be replaced on the

Oracle Technology Network Web site, or, in the case of Data Models, to the

applicable My Oracle Support Documentation container where they reside.

This process will prevent delays in making critical corrections

available to customers. For the customer, it means that before you begin

installation, you must verify that you have the most recent version of the

Oracle Retail documentation set. Oracle Retail documentation is available on

the Oracle Technology Network at the following URL:

http://www.oracle.com/technetwork/documentation/oracle-retail-100266.html

An updated version of the applicable Oracle Retail document is

indicated by Oracle part number, as well as print date (month and year). An

updated version uses the same part number, with a higher-numbered suffix. For

example, part number E123456-02 is an updated version of a document with part

number E123456-01.

If a more recent version of a document is available, that version

supersedes all previous versions.

Documentation is packaged with each Oracle Retail product

release. Oracle Retail product documentation is also available on the following

Web site:

http://www.oracle.com/technetwork/documentation/oracle-retail-100266.html

(Data Model documents are not available through Oracle Technology

Network. These documents are packaged with released code, or you can obtain

them through My Oracle Support.)

Documentation should be available on this Web site within a month

after a product release.

The following text conventions are used in this document:

|

Convention

|

Meaning

|

|

boldface

|

Boldface type indicates graphical user interface elements

associated with an action, or terms defined in text or the glossary.

|

|

italic

|

Italic type indicates book titles, emphasis, or

placeholder variables for which you supply particular values.

|

|

monospace

|

Monospace type indicates commands within a paragraph,

URLs, code in examples, text that appears on the screen, or text that you

enter.

|

1

Oracle Retail Store Inventory Management (SIM) empowers store

personnel to sell, service, and personalize customer interactions by providing

users the ability to perform typical back office functionality on the store

sales floor. The results are greatly enhanced customer conversion rates,

improved customer service, lower inventory carrying costs, and fewer markdowns.

SIM delivers the information and flexible capabilities that store employees

need to maintain optimal inventory levels and to convert shoppers into buyers.

The SIM solution does the following:

§

Improves perpetual inventory levels by enabling floor-based

inventory management through handheld devices and store PCs.

§

Minimizes the time needed to process receipt and check-in of

incoming merchandise.

§

Receives, tracks, and transfers merchandise accurately,

efficiently, and easily.

§

Reduces technology costs by centralizing hardware requirements.

§

Guides users through required transactions.

§

Allows customizations to the product through an extensible

technology platform.

The retailer’s modifications are isolated during product

upgrades, lowering the total cost of ownership.

The implementer needs an understanding of the applications and

technical concepts described in this chapter.

|

Note

See the Oracle Retail Store Inventory

Management Installation Guide for a list of the Oracle Retail

applications that are certified with this version of SIM.

|

The implementer should understand the interface requirements of

the integrated applications (with or without Retail Integration Bus (RIB) and

data sources for the foundation data. Depending on the version of SIM that you

are using, SIM might be deployed either as:

§

Standalone (that is, without RIB)

§

With Oracle Retail Merchandising System (RMS), Oracle Retail

Price Management (RPM) and Oracle Retail Integration Bus (RIB)

§

With Oracle Retail Merchandising System, Oracle Retail Price

Management, Oracle Retail Warehouse Management System (RWMS) and Oracle Retail

Integration Bus

§

With Oracle Retail Point-of-Service (ORPOS) alone

§

With Oracle Retail Merchandising System, Oracle Retail Price

Management, Oracle Retail Warehouse Management System, Oracle Retail Integration

Bus, and Oracle Retail Point-of-Service

The implementer needs functional knowledge of the following

applications:

§

RMS

§

RIB

§

RPM

§

ORPOS

§

RWMS

The implementer should understand the following technical

concepts:

§

UNIX system administration, shell scripts, and job scheduling

§

Web Logic application server (for Oracle Retail deployments)

§

Performance constraints based on the retailer’s infrastructure

§

Technical architecture, deployment options with load balancer

§

Retailer’s hierarchical (SKU/store/day) data

§

Knowledge of Enterprise-Java including web services, PL/SQL

§

LDAP setup and usage

§

BIPublisher (Oracle printing engine) and Internet printing

protocol

2

This chapter describes the technical architecture for Oracle Retail

Store Inventory Management.

SIM has an n-tier architecture consisting of a client tier, a

middle (server) tier, and a data tier. The client tier contains a PC client (a

Java desktop application) and handheld devices. The middle (server) tier

contains the SIM server (deployed as a J2EE application inside the Oracle

Application Server) and the Wavelink server (a standalone server for the

handheld devices). The data tier consists of an Oracle 11g database and an LDAP

directory.

SIM’s robust distributed computing platform enables enhanced

performance and allows for scalability.

The n-tier architecture of SIM allows for the encapsulation of

business logic, shielding the client from the complexity of the back-end

system. Any given tier need not be concerned with the internal functional tasks

of any other tier.

The following list is a summary of the advantages that accompany

SIM’s use of an n-tier architectural design.

§

Scalability: Hardware and software can be added to meet retailer

requirements for each of the tiers.

§

Maintainability: The separation of presentation, business logic,

and data makes the software cleaner, more maintainable, and easier to modify.

§

Platform independence: The code is written once, but can run

anywhere that Java can run.

§

Cost effectiveness: Open source market-proven technology is

utilized, while object-oriented design increases reusability for faster

development and deployment.

§

Ease of integration: The reuse of business objects and function

allows for faster integration to enterprise subsystems. N-tier architecture has

become an industry standard.

§

High availability: Middleware is designed to run in a clustered

environment or on a low-cost blade server.

§

Endurance: Multi-tiered physically distributed architecture

extends the life of the system.

§

Flexibility: The system allocates resources dynamically based on

the workload.

This section provides a high-level overview of SIM’s technical

architecture. The figure below illustrates the major pieces of the typical

three-tiered SIM implementation.

Figure: SIM Technical

Architecture

SIM can be deployed on a wide variety of clients, including a

desktop computer, a hand-held wireless device, and so on. The GUI is

responsible for presenting data to the user and for receiving data directly

from the user through the front end. The presentation tier only interacts with

the middle tier (as opposed to the database tier). To optimize performance, the

SIM PC front end facilitates robust client-side processing.

The PC side of SIM is built upon a fat client architecture, which

was developed using Swing, a toolkit for creating rich graphical user

interfaces (GUIs) in Java applications.

The handheld communication infrastructure piece, known as the

Oracle Retail Wireless Foundation Server, enables the handheld devices to

communicate with the SIM server. The handheld devices talk to the Oracle Retail

Wireless Foundation Server, which in turn makes calls as a client to the SIM server.

By providing the link between the SIM client and the database,

the middle tier handles virtually all of the business logic processing that

occurs within SIM’s multi-tiered architecture. The middle tier is comprised of

services, most of which are related to business functionality. For example, an

item service gets items, and so on. Within SIM, business objects are beans

(that is, Java classes that have one or more attributes and corresponding

set/get methods) that represent a functional entity. Most business objects have

very few operations; in other words, business objects can be thought of as data

containers, which by themselves have almost no business functionality.

Although the PC client and the handheld client use the middle

tier’s functionality differently, the middle tier is the same for both clients.

For example, the handheld device, used on the fly, performs frequent commits to

the database, while the PC performs more infrequent commits. The application is

flexible in that it accommodates the different styles of client-driven

processing.

The middle tier is designed to operate in a stateless manner,

meaning it receives whatever instruction it needs to access the database from

the client and does not retain any information between client calls. Further,

SIM has failover abilities; if a specific middle tier server fails, processing

can roll over to another SIM server for continued processing.

If the workload warrants, SIM can be vertically scaled by adding

additional application servers. Because SIM servers are running on multiple

application servers in a stateless system, work can be seamlessly distributed

among the servers. The result of this feature is that SIM clients do not need

to know that additional application servers have been added to help with the

workload. SIM application servers can contain multiple containers, each of

which is related to a unique Java Virtual Machine (JVM). Each container

corresponds to a specific SIM instance. Introducing multiple instances of a

container allows SIM retailers to more effectively distribute the processing

among several containers and thereby horizontally scale the platform. As the

request load for a service increases, additional instances of the service are

automatically created to handle the increased workload.

The middle tier consists of the following core components, which

allow it to make efficient and reliable calls to the SIM database:

§

Server services contain the pertinent business logic.

§

DAO classes handle database interaction.

§

Databeans contain the SQL necessary to retrieve data from and

save data to the database.

|

Note

There is at least one databean for every table and view

in the database, but there may be more, used for different specific purposes.

|

Data Access Objects (DAO)

§

DAOs are classes that contain the logic necessary to find and

maintain data persistence. They are used by services when database interaction

is required.

Java Database Connectivity (JDBC)

DAOs communicate with the database through the industry standard

JDBC protocol. In order for the SIM client to retrieve the desired data from

the database, a JDBC connection must exist between the middle tier and the

database. JDBC facilitates the communication between a Java application and a

relational database. In essence, JDBC is a set of Application Programming

Interfaces (APIs) that offer a database-independent means of extracting and/or

inserting data to or from a database. To perform those insertions and

extractions, SQL code also resides in this tier facilitating create, read,

update, and delete actions.

The database tier is the application’s storage platform,

containing the physical data used throughout the application. The database

houses data in tables and views; the data is used by the SIM server and then passed

to the client. The database also houses stored procedures to do data

manipulation in the database itself.

One of SIM’s most significant advantages is its flexible

distributed topology. SIM offers complete location transparency because the

location of data and/or services is based upon the retailer’s business

requirements, not upon technical limitations. SIM’s client server communication

is an EJB call (which uses RMI). Because the server does not have to be in the

same store as the in-store clients, the clients log onto the server over the

wire.

SIM’s client code makes use of helper and framework classes that

contain the logic to look up remote references to EJBs on the server and make

calls to them. These helper and framework contain no business logic but contain

only enough code to communicate with the server.

For example, if a helper class is called by the client to perform

the method update shipment, the helper class appears to have that capability,

though in reality it only behaves as a passage to the EJB remote reference,

which is looked up from the server. The EJB remote reference communicates

across the network with the server to complete the business-logic driven

processing. The server performs the actual update shipment business logic and

returns any return values or errors to the client.

Connectivity between the SIM client and the middle tier is

achieved through the Java Naming and Directory Interface (JNDI), which the SIM

client accesses with the necessary IP address and port. JNDI contains the means

for the client to look up services available on the application server.

The figure below illustrates SIM’s deployment.

Figure: SIM Deployment

3

|

Note

For information about Oracle Single Sign-On and Oracle

Retail Store Inventory Management, see the Oracle Retail

Store Inventory Management Installation Guide.

|

SIM provides role-based user access control in order to manage

application functionality and data available to users.

This role-based user access control allows security to be managed

in a way that corresponds closely to the organization’s structure.

This model provides improved support for customization,

maintenance, and management of security in SIM, simplifying customer

implementations while maintaining a high degree of control and flexibility.

Security is handled by assigning privileges (permissions) to a

role in SIM. These roles are assigned to stores and users (in LDAP or SIM). If

the user does not have permission, the feature will not be available for user.

At this time, SIM secures buttons and drop down values on the PC

and menu options on the handheld.

To allow flexibility on how security is implemented, four modes

of deployment exist:

An external system controls security (LDAP). Users and role/store

assignments are administered in LDAP. Roles are set up in SIM and need to match

those set up in LDAP. Authentication is performed in LDAP. Note that Oracle

LDAP (for example, OID) is the only supported LDAP. This is the default and

recommended model of deployment.

SIM controls all aspects of security. Users, roles,

user/role/store assignments are all administered in SIM. Authentication is

performed in SIM.

A hybrid approach will be used for authentication. Each time a

user is successfully authenticated in an external system, the user information

in SIM will be updated, including password. Then if the external security

system is temporarily unavailable, SIM will try to authenticate the user

internally with the password that was used during the last successful

authentication.SIM will be able to authenticate internally created users as

well in this mode. Note that this is only meant to be used as exception

mechanism and not a permanent deployment model. Also, this is not a two-way

process flow. It is uni-directional from LDAP to internal.

All users and roles are kept in SIM only, but the password can be

handled externally. The external password can be cached in case of connection

failure, but LDAP retains the master password configuration. SIM will check the

password externally. If it cannot be found, SIM will look internally. If LDAP

rejects the password, then the assumption is that the password is externally

controlled. SIM will be able to authenticate internally created users as well

in this mode.

|

Table: LDAP and SIM Process Control

|

|

Mode of Deployment

|

Application Control

|

Process Control

|

|

|

Internal Authentication/ Authorization

|

|

SIM:

§ User

§ Role

§ Store

§ Password

§ Login

|

|

|

External Authentication/ Authorization

|

|

LDAP:

§ User

§ Role

§ Store

§ Password

§ Login

|

|

|

External/Internal Authentication and Internal

Authorization

|

LDAP control

|

LDAP:

§ User

§ Role

§ Store

§ Password

§ Login

SIM:

§ Login (use cache in

case LDAP is not reachable)

|

|

|

External/Internal Authentication and Internal

Authorization

|

SIM & LDAP control

|

LDAP:

§ User

§ Password

§ Login

SIM:

§ User

§ Role

§ Store

§ Login (use cache in

case LDAP is not reachable)

|

|

|

External/Internal Authentication and Internal

Authorization

|

SIM Control

|

SIM:

§ User

§ Role

§ Store

§ Password

§ Login

|

|

|

External/Internal Authentication/ Authorization

|

LDAP control

|

LDAP:

§ Password

§ Login

§ User

§ Role

§ Store

SIM:

§ Login (use cache in

case LDAP is not reachable)

|

|

|

External/Internal Authentication/ Authorization

|

LDAP & SIM control

|

LDAP:

§ Password

§ Login

§ User

§ Role

§ Store

SIM:

§ Role

§ Store

§ Login (use cache in

case LDAP is not reachable)

|

|

|

External/Internal Authentication/ Authorization

|

SIM Control

|

SIM:

§ User

§ Role

§ Store

§ Password

§ Login

|

|

Definition of process controls:

§

User – user create

§

Role – role user assignment

§

Store – store user assignment

§

Password – password creation/maintenance

§

Login – user authentication control

Menus and buttons on the PC are defined in the PC_MENU_ITEM

table. In order to add a new button, a new row must be put into the

PC_MENU_ITEM table.

For more information, see "Update the PC Screen" in Oracle Retail Store Inventory Management Implementation Guide –

Volume 4, Extension Solutions.

The permissions used in SIM are stored in the SECURITY_PERMISSION

table. Permissions are identified by a unique name, which is used by the

application to control user access and in the navigation.xml file to associate

menus with permissions.

Permissions can be associated with a device type (PC, handheld,

server) which is used to retrieve a user’s authorized permissions during log

in. When a user logs in on the PC client, only permissions with a device type

of PC (or no device type) are available to the user.

Permissions can be associated with a permission group, which are

stored in the SECURITY_PERMISSION_GROUP table. Permission groups are sets of

permissions that allow permissions to be filtered by category during role creation

or searches.

For more information, see Appendix A, "SIM Permissions".

A role is a named collection of permissions. Roles are created

and edited in SIM using the security administration screens, and are stored in

the SECURITY_ROLE, SECURITY_ROLE_PERMISSION tables. When using external

security, the role header information is also stored in LDAP as a simRole,

although only the roleName is used by SIM and the role information is retrieved

from the SIM database. Roles can contain any combination of available

permissions and can overlap with other roles.

Roles are associated with a role type, which is defined in the

SECURITY_ROLE_TYPE table. The default role types include Store and Corporate.

Role types are used to control which roles a user is allowed to assign based on

their permissions. A user with permission to assign store roles is not allowed

to assign corporate roles without additional permissions.

The role detail screen also allows the assignment of data

permissions, which control access to specific types of data. For example, data

permissions can be used to control access to specific inventory adjustment

reason codes, item request timeslots, role types, or product group types.

In case external/internal authentication/authorization is used,

LDAP will only need to store those roles assigned to users that are controlled

by LDAP.

Technical Overview

The following describes the technical overview.

User

This class represents the header information for a user. This

includes information such as:

§

username

§

first name

§

last name

§

locale

§

user type

§

user status

§

start/end dates

§

default store ID

§

other state information

User objects are used to hold both internal and cached user data.

Users are primarily identified by their username instead of their database ID.

UserPassword

This class represents a user password. It contains information

for an individual password record such as date and status. It is used for both

current passwords and password history. User password objects are used to hold

both internal and cached password records.

UserRole

This class represents a role assignment for a user. It includes

information such as start/end date, store ID, and other state information. User

role objects are used to hold both internal and cached assignments. A role

assignment with no specified store ID applies to all available stores.

UserStore

This class represents a store assignment for a user. Store

assignments do not exist for super users as they have implicit access to all

stores. User store objects are used to hold both internal and cached

assignments.

Permission

This class represents an individual permission. It is mostly used

when managing roles as it contains additional information used for assignment

to roles, such as description, device type, and permission group. Permissions

with no device type apply to all devices. Permissions are primarily identified

by their name instead of their database ID.

PermissionGroup

Permission groups are used to categorize and filter permissions

for filtering and display purposes. It is mostly used for security management

operations.

PermissionSet

This class represents a set of permissions and any associated

parameters. It is used to hold the set of permissions that have been assigned

to a role. Permission sets are also used to hold the union of permissions for

multiple roles that a user has been authorized to access. This class includes

methods to test for the presence and absence of permissions in the set.

Role

This class represents the header information for a role. It

contains the role name, description, role type, and whether an end date is

required for assignment to a user. It is mostly used for security management

operations. Roles are primarily identified by their name instead of their

database ID.

RoleType

This class represents a role type that has been defined in the

database. Role types are used for filtering and display purposes but are also

used with data permissions to restrict access to functionality for certain

types of roles. It is mostly used for security management operations.

The external security model uses LDAP. In this mode LDAP is the

only responsible application for all security control (with exception of assigning

permissions to roles). LDAP will need to be set up before users can login.

Users are defined in LDAP as simUser records.

User records contain information such as:

§

user name

§

status

§

user type

§

default store

§

locale

§

other data defined by the schema

To log in to SIM, a user must have an active status (0). Users can be assigned start or end dates to restrict

their authorization by date.

Users are assigned stores to which they are allowed access. To

log in to a store, the user must first be assigned to that store. The user’s

allowed stores also restrict which stores the user can be assigned roles for.

Users that are defined as super users are allowed access to all

stores, but still require role assignments in order to gain permissions.

Store assignments are stored in LDAP as userStores attributes in

simUser records.

When a user logs into SIM using the PC client, their default

store is automatically selected. The user can change stores by selecting one of

their allowed stores from the combo box on the main screen.

Users are given permissions by assigning roles to users.

Permissions are never directly assigned to users. A user can be assigned

multiple roles, producing a combined permission set that is the union of the

role permissions.

Role assignments are stored in LDAP for an external model as

simUserRole records, which are child nodes of simUser records. Role assignments

can have start or end dates to restrict their validity by date. The

userRoleStores attribute of the simUserRole record specifies which stores are

valid for the role assignment. If no store is specified then the role

assignment applies to all stores available to the user.

When a user logs into SIM they are given permissions for all

valid role assignments for the store that was selected.

Sensitive information such as user credentials must be encrypted

and stored in a secure location, known as password stores or wallets. These

password stores are secure software containers that store the encrypted user

credentials.

SIM has implemented using wallet alias names in the following

areas:

§

LDAP connection credentials

§

RIB service credentials (publish and subscribe)

§

BIP service credentials

§

Web service consumer credentials (OMS, manifest)

§

WebLogic user credentials (batch, server, wireless users)

SIM uses external secure password stores for the SIM client to

look up SIM remote services:

§

SIM stores the database password in a secure password store for

the database standalone program which invokes sqlplus or sqlldr.

§

SIM stores the application remote login password in a secure

password store for java application programs.

SIM also modifies programs to use security alias names for

accessing database or remote applications:

§

The data seeding (import) program passes the user and password

when invoking the sqlplus and sql loader (sqlldr) inside the program.

§

Any other data import utility or adhoc batch program uses SIM

standard java wrapper to call the stored procedure; if using java wrapper is

not applicable, and if connecting to the database through a database client

utility such as sqlplus or sqlldr, then the secure pass store is used and

tnsalias for database connection credential stored in the wallet must be used.

For more information, see “Appendix: Setting Up Password Stores

with Oracle Wallet” in Oracle Retail Store Inventory

Management Installation Guide.

SIM is intended to work with any Lightweight Directory Access

Protocol (LDAP) product. Out of the box, SIM ships sample .ldif files that can

be used to create data in an LDAP system. We expect customers to use these

files as examples to create their own data load files and hook into their own

pre-existing corporate LDAP authentication system.

Once an LDAP server has been installed, the SIM data schema

(SIM.schema) must be loaded on top of the default LDAP core schema

(core.schema) supplied by the server. The following sample LDIF files are

included in this release at SIM_INSTALL_DIR/sim/application/sim14/ldap. For

more information, see Appendix B, "Appendix: LDAP Schema".

|

Note

The following scripts and configuration files are

provided as examples only. Variations will be necessary to match the data

setup in SIM and the LDAP server that is chosen and installed.

|

Descriptions of the files in the directory and an overview of how

the data needs to be structured in LDAP.

The objectclasses that are used and required by SIM. This file

can be used directly to create the required objectclasses in your LDAP

directory.

The base company container. This file must be modified before it

is imported into your LDAP system.

The containers for holding users, stores, and roles. This file

must be modified before it is imported into your LDAP system.

Sample role data. This file must be modified before it is

imported into your LDAP system.

Sample store data. This file must be modified before it is

imported into your LDAP system.

Sample user data. This file must be modified before it is

imported into your LDAP system.

Sample user role assignment data. This file must be modified

before it is imported into your LDAP system.

|

Note

A simUser can have more than one simStore by simply

repeating the userStores line, but should only have one defaultStore. A

simUserRole can also have more than one simStore by repeating the

userRoleStores line.

|

|

Note

Any user store entry for the user object must have

corresponding Store data populated in the SIM Oracle database to allow a

successful login (table STORE). Any simUserRole object must have

corresponding role and store data populated in the SIM Oracle database.

|

This document explains how to use the Oracle Virtual Directory

(OVD) to authenticate Oracle Retail Store Inventory Management.

The following document is available through My Oracle Support

(formerly MetaLink).

Access My Oracle Support at the following URL:

https://support.oracle.com

Oracle Retail Store Inventory Management: Using Oracle Virtual

Directory to Authenticate Oracle Retail Store Inventory Management (Doc ID: 840179.1).

The default security model in SIM is LDAP authentication

(external authentication). To change the security model to use internal

security, run the following SQL script:

update CONFIG_SYSTEM set CONFIG_VALUE = '0' where config_key =

'SECURITY_AUTHENTICATION_METHOD';

Users are defined in SIM through the UI.

User records contain information such as:

§

user name

§

status

§

user type

§

default store

§

locale

§

other data defined by the UI

To log in to SIM, a user must have an active status. Users can be

assigned start or end dates to restrict their authorization by date.

Users are assigned stores to which they are allowed access. To

log in to a store, the user must first be assigned to that store. The user’s

allowed stores also restrict which stores the user can be assigned roles for.

Users that are defined as super users are allowed access to all

stores, but still require role assignments in order to gain permissions. New

stores are automatically assigned to this user, but role assignments are not.

When a user logs into SIM using the PC client their default store

is automatically selected. The user can change stores by selecting one of their

allowed stores from the combo box on the main screen.

Users are given permissions by assigning roles to users in the

SIM UI. Permissions are never directly assigned to users. A user can be

assigned multiple roles, producing a combined permission set that is the union

of the role permissions.

Role assignments can have start or end dates to restrict their

validity by date.

Since users can have different roles at different stores (for

example, a manager in Store One, but sales associate in Store Two), roles and

stores are assigned as a pair to a user. This allows for very specific setup in

SIM.

When a user logs into SIM they are given permissions for all

valid role assignments for the store that was selected.

This hybrid setup will cache external user role and store

assignment as well as password information. This allows users to continue to

log in when LDAP is down. SIM Internal assigned stores/roles will be added to

the external user assigned roles/stores. In case the user is fully internal to

SIM, SIM password information will be used to authenticate.

It is optional to create a user in SIM, or assign roles and

stores in SIM.

Users are defined in SIM through the UI or in LDAP. If a user at

some point will have SIM-assigned roles/stores, and corporate-assigned

roles/stores, the user needs to be first created in SIM, before that user has

logged in to LDAP. Once cached information is pulled down into SIM, the user

can no longer be created in SIM. The password initially assigned to the user

will be trumped by the password assigned in LDAP.

Users can be created externally, internally or exist both in SIM

and LDAP.

Can be assigned in SIM or in LDAP, or both.

Roles are assigned to SIM or LDAP, or both.

This hybrid setup will only cache password information. Users,

stores and role assignment information are all handled inside of SIM.

This allows corporate control on which users can log in, but

detailed authorization assignments can be controlled by a different group of

users (for example, Store manager). The user will also continue to be able to

log in when LDAP is down.

In case the user is fully internal to SIM, SIM password

information will be used to authenticate.

Users are defined in SIM through the user interface and in LDAP.

The user has to be first created in SIM, before they should log in. The password

initially assigned to the user will be replaced by the password assigned in

LDAP.

Users have to exist both in LDAP and SIM, since LDAP

authenticates and SIM authorizes.