11 Holding, Releasing, and Reviewing Orders

This chapter contains the following topics:

11.1 Understanding Order Holds and Releases

In some circumstances, you must hold a customer's order. For example, you might place a customer's order on hold for credit reasons. When the credit issue has been resolved, you use order releases to return the order to the processing cycle or to initiate the sales order process. Or, if you have held a blanket or quote order, you can create sales orders by releasing the blanket order or the quote order.

When the system places an order on hold, the order is taken out of the processing cycle. When you release an order, you return it to the order processing cycle.

11.2 Holding Orders

This section provides an overview of holding orders and discusses how to set processing options for the Batch Credit Hold program (R42542).

11.2.1 Understanding Holding Orders

During order entry, the system can evaluate orders in a variety of ways, including order hold information. When you enable order hold processing, the system evaluates order information to determine whether to place an order on hold. If the system determines that the order should be on hold, it issues an order hold warning to the user before processing the order.

The system can perform credit checking when you enter an order and can place an order on credit hold. Occasionally you might verify a customer's credit limits against existing sales orders and place the orders on credit hold. You can use the Batch Credit Hold program (R42542) to hold existing sales orders that are beyond credit limits. You must set the Highest Next Status processing option for the system to review sales orders with multiple lines at different statuses. If all sales order detail lines are at a status lower than or equal to the value that you enter for this processing option, the entire sales order is put on credit hold.

For example, a sales order includes line one with a Next Status of 590 and line two with a Next Status of 540. You entered 560 for the Highest Next Status processing option. Therefore, the order is not put on hold because the status of line one is higher than the value in the processing option.

11.2.1.1 Record Reservation (Release 9.1 Update)

The JD Edwards EnterpriseOne software provides record reservation capability within the Batch Credit Hold program (R42542). Record reservation helps to ensure the integrity of the data and prevent data loss. To avoid simultaneous processing of the same records, the system reserves (locks) records for processing by any other program. Thus, the system does not allow you to edit a record that has been locked by a different user or application.

When a program that uses record reservation is interrupted, orphaned reservation records might remain in the Business Object Reservation table (F00095). This can occur, for example, when technicians are working with a server, or when a workstation shuts down without warning. If an interruption stops one of the programs in the Batch Credit Hold program (R42542) before it releases the reservations that it creates, you cannot update the records until the orphaned reservations are removed.

You can use the Remove Business Object Reservation program (P00095) to release unwanted record reservations. This program stores reservation information in the Business Object Reservation table (F00095).

11.2.2 Setting Processing Options for the Batch Credit Hold Program (R42542)

Processing options enable you to specify the default values for the Batch Credit Hold program.

11.2.2.1 Defaults

These processing options specify the default values that the system uses to process order holds.

- 1. Status Code - From

-

Enter a value from user-defined code (UDC) 40/AT that specifies the beginning status code range that the system uses to select orders for batch credit hold. The system uses this code with the Status Code - To processing option to define the search criteria range. The combination of Status Code - From and Status Code - To must be a valid combination of last status and next status in the Order Activity Rule table (F40203) for the order type and line type that you are processing.

- 2. Status Code - To

-

Enter a code (UDC 40/AT) to specify the status code range that the system uses to select orders for batch credit hold. The system uses this code with the Status Code - From processing option to define the search criteria range. The combination of Status Code - From and Status Code - To must be a valid last status and next status combination in the F40203 table for the order type and the line type that you are processing.

- 3. Based On Status

-

Specify whether the system uses the Last Status field or Next Status field to determine which orders are processed. Values are:

1: Select orders for which the Last Status value falls within the Status Code From and Status Code To processing option values.

2: Select orders using the Next Status value.

- 4. Override Next Status

-

Enter a code from UDC 40/AT that indicates the next step in the order process. The code that you specify must have been set up in the F40203 table based on the order type and the line type that you are using. The override status is another allowed step in the batch credit hold process and is optional. The combination of the beginning status and the override next status must be a valid last status and next status combination in the F40203 table.

- 5. Prevent Next Status Update

-

Specify whether to prevent the system from updating the next status from the order activity rules. Values are:

Blank: Update the next status from the existing order activity rules.

1: Prevent the system from updating the next status.

- 6. Highest Next Status

-

Enter a code from UDC 40/AT that indicates the highest next status that sales order detail lines can have for the system to apply a credit hold to the sales order. The system does not evaluate orders with next statuses greater than this value for credit holds.

- 7. Hold Orders Code

-

Enter a code from UDC 42/HC that the system uses to automatically compare the credit limit that you set up for the customer in the Customer Master by Line of Business table (F03012) against the order and any outstanding balances in accounts receivable.

You define the conditions that the system uses to place orders on hold in the Order Hold Information program (P42090) and attach those conditions to a hold code. You must specify the hold code in this processing option to activate order hold processing.

11.3 Releasing Held Orders

This section provides an overview of order releases and mobile applications for reviewing and releasing sales held orders, lists prerequisites, and discusses how to:

-

Set processing options for the Release Holds program (P43070).

-

Release orders on hold.

-

Set processing options for the Batch Release Credit Holds program (R42550).

-

Release credit holds in batch.

11.3.1 Understanding Order Releases

You can have orders on hold for several reasons. For example, you can hold orders that do not meet margin requirements, or that exceed a customer's credit limit. When an order is on hold, you must release it back into the processing cycle for any additional processing to take place. You do this using the Release Holds program (P43070) or the Batch Release Credit Holds program (R42550).

You can place a variety of holds on an order, including:

-

Customer holds, such as credit holds.

-

Item holds, such as detail lines that do not meet the margin requirements.

-

Order holds, such as orders that do not meet minimum amounts or that exceed maximum limits.

If you activate the JDESOENTRY workflow process, the system processes the order through order hold checking. After you click OK to accept the order, the system checks the processing options for hold codes and compares the order against the order hold information.

If the system puts the order on hold, it sends an E-mail message to the address book number defined in the hold code as the person responsible. This message indicates that the order is on hold. The person responsible for releasing the orders can use the work center to review messages sent during the workflow process and to access the orders to release. When you release the order, the system sends an E-mail message to the salesperson, defined in the commission fields and the sold to number, indicating that the order is being processed.

You must release an order from hold to return it to the processing cycle. For example, if you enter an order for a customer who has exceeded their credit limit, the system places the order on hold. When the customer makes a payment, their credit status changes and their orders can be filled. However, the system does not process this customer's orders until you release them. You must have appropriate security access to release an order. You can release items and orders for customers as many times as necessary. You can print the Print Held Sales Order report (R42640) to review all sales orders that are on hold.

To speed up the order release process, you can select and release orders based on the parent address book number.

Additionally, you can use the Batch Release Credit Holds program (R42550) to release sales orders on credit hold. The program releases sales orders based on the pick date and customer credit limit. When the customer submits a payment to satisfy outstanding invoices and has a credit balance to apply toward the existing sales order, the program reviews sales order detail lines by pick date. The program releases sales orders from hold using the earliest pick date on the order detail line.

11.3.2 Mobile Applications for Reviewing and Releasing Sales Held Orders (Release 9.1 Update)

The following mobile applications are available, and can be used to review and release the sales held orders on a mobile device:

-

Sales Held Order Release (Smartphone and Tablet)

These applications require system administrator configuration before they are available to individual users. Contact your system administrator to determine whether these applications are available for use.

Additionally, see the following topic in the JD Edwards EnterpriseOne Applications Mobile Enterprise Applications Implementation Guide:

11.3.3 Prerequisites

Before you complete the tasks in this section, verify that you have:

-

Set up status codes and order activity rules for additional types of orders.

-

Set up the line types related to credit orders and direct ship orders.

11.3.4 Forms Used to Release Held Orders

| Form Name | Form ID | Navigation | Usage |

|---|---|---|---|

| Work With Held Orders | W43070A | Additional Order Processes (G4212), Release Holds | Review orders on hold. |

| Password Confirmation | W43070B | Select an order and select Release from the Row menu on the Work With Held Orders form. | Release orders on hold.

Enter the password to release the order. |

11.3.5 Setting Processing Options for the Release Holds Program (P43070)

Processing options enable you to specify the default values, display settings, versions, and processes that the system performs for the Release Holds program (P43070).

11.3.5.1 Defaults

These processing options specify the default order type and release code.

- 1. Order Type

-

Enter a value from UDC 00/DT that identifies the order type to release.

- 2. Release Code

-

Enter a value from UDC 40/RC that indicates the release code.

11.3.5.2 Display

These processing options specify the information that the system displays.

- 1. Display Sales Orders or Purchase Orders

-

Specify whether the system displays sales orders or purchase orders. Values are:

Blank: Display purchase orders.

1: Display sales orders.

- 2. Display Previously Released Orders

-

Enter Y to display previously released orders.

11.3.5.3 Versions

These processing options specify the versions of programs that the system uses when accessed from the Work With Held Orders form.

- 1. Sales Order Entry (P4210)

-

Enter the version for the Sales Order Entry program (P4210).

If you leave this processing option blank, the system uses ZJDE0001.

- 2. Purchase Order Entry (P4310)

-

Enter the version for the Purchase Order Entry program (P4310).

If you leave this processing option blank, the system uses ZJDE0001.

- 3. Print Pick Slip (R42520)

-

Enter the version for the Print Pick Slip program (R42520).

If you leave this processing option blank, the system uses ZJDE0001.

- 4. Ship and Debit (R45100)

-

Enter the version for the Ship and Debit program (R45100).

If you leave this processing option blank, the system uses ZJDE0001.

- 5. Manufacturing Work Order (P48013)

-

Enter the version for the Manufacturing Work Order program (P48013).

If you leave this processing option blank, the system uses ZJDE0001. This processing option is applicable to the release of sales orders only.

11.3.5.4 Process

These processing options determine processes that the system performs.

- 1. Automatic Printing of Pick Slip

-

Specify whether the system automatically prints pick slips. Values are:

Blank: Do not print pick slips.

1: Automatically print pick slips.

- 2. Release Status Code of Work Order

-

Enter a value from UDC 00/SS that indicates the status of the work order when you release it back into the processing cycle.

- 3. Ship and Debit Processing

-

Specify the ship and debit processing mode. Values are:

Blank: Do not use R45100.

1: Use the subsystem mode.

2: Use the batch mode.

- 4. Parent or Ship To Credit Hold Release Processing (Sales Only)

-

Specify whether the system allows sales orders on credit hold to be released. Values are:

Blank: Do not allow a parent or ship to credit hold release.

1: Allow parent or ship to credit hold release.

Note:

This processing option is available for sales orders on credit hold only.

11.3.5.5 Warehouse

These processing options determine how the system processes items through the warehouse.

- 1. Request Processing Mode

-

Specify the pick request processing mode. Values are:

Blank: Do not indicate a pick request.

1: Generate requests only.

2: Generate requests and process using the subsystem.

- 2. Processing Pick Requests

-

If you are processing pick requests using the subsystem, enter the version of the Location Selection Driver program (R46171) that the system uses.

- 3. Override Next Status

-

Enter a value from UDC 40/AT that indicates the next status for sales order lines for which requests have been generated.

11.3.5.6 Prepayment

These processing options determine the hold codes when you use prepayments.

- 1. Release Authorization Hold and Advance Prepayment Status

-

Enter a value from UDC 42/HC that specifies whether the system releases the authorization hold and advances the status. The system can release the authorization hold only if authorization has been received.

- 2. Release Settlement Hold and Advance Prepayment Status

-

Enter a value from UDC 42/HC that specifies whether the system releases the settlement hold and advances the status. The system releases the settlement hold only when settlement has been received.

11.3.6 Releasing Orders on Hold

Access the Work With Held Orders form.

- Person Responsible

-

Enter the address book number of the person who is responsible for reviewing and releasing orders placed on hold.

- Supplier/Customer

-

Enter a second, 30-character description, remark, or explanation.

- Parent Number

-

Enter the address book number of the parent company. The system uses this number to associate a particular address with a parent company or location. Any value that you enter in this field updates the Address Organizational Structure Master table (F0150) for the blank structure type. This address number must exist in the Address Book Master table (F0101) for validation purposes. Examples of address book records that have a parent number include subsidiaries with parent companies, branches with a home office, and job sites with a general contractor.

- Ship To

-

Enter the address number of the location to which you want to ship this order. The address book provides default values for customer address, including street, city, state, zip code, and country.

11.3.7 Setting Processing Options for the Batch Release Credit Holds Program (R42550)

Processing options enable you to specify the default processing for programs and reports.

11.3.7.1 Defaults

These processing options specify the default order type and release code.

- Status Code - From

-

(Future use) Enter a value from UDC 40/AT that specifies the beginning status code range that the system uses to select orders. The combination of Status Code - From and Status Code - To must be a valid combination of last status and next status in the Order Activity Rule table (F40203) for the order type and the line type that you are processing.

- Status Code - To

-

(Future use) Enter a value from UDC 40/AT that specifies the status code range that the system uses to select orders. The combination of Status Code - From and Status Code - To must be a valid last status and next status combination in the F40203 table for the order type and the line type that you are processing.

- Based On Status

-

(Future use) Specify whether the system selects the Sales Order Detail table (F4211) according to the last status or next status. Values are:

1: Select according to last status.

2: Select according to next status.

- Release Code

-

Enter a code from UDC 40/RC that indicates the identifier of the party responsible for releasing held orders. When the held order is released, the program updates this value to the Held Orders table (F4209).

- Credit Hold Code

-

Enter a value from UDC 42/HC that identifies why an order was placed on hold, for example, credit, budget, or margin standards were exceeded.

- Proof or Final mode

-

(Future use) Specify whether the system runs in proof or final mode. Values are:

Blank: Run in proof mode.

1: Run in final mode.

11.3.7.2 Print

This processing option determines whether the system prints amounts on the report.

- Print Amounts

-

Specify whether the system prints financial amounts on the report. Values are:

Blank: Print financial amounts on the report.

1: Do not print the financial amounts on the report.

11.3.8 Releasing Credit Holds in Batch

You can release orders on credit hold using Batch Release Credit Holds (R42550). The R42550 program releases sales orders held in the Held Orders table (F4209) and removes the order hold code on the order in the Sales Order Header File table (F4201) based on customer credit limit and amount due.

Enter BV in the Fast Path field. Enter R42550 in the Batch Application field on the Available Versions form.

11.3.8.1 Record Reservation (Release 9.1 Update)

The JD Edwards EnterpriseOne software provides record reservation capability within the Batch Release Credit Holds program (R42550). Record reservation helps to ensure the integrity of the data and prevent data loss. To avoid simultaneous processing of the same records, the system reserves (locks) records for processing by any other program. Thus, the system does not allow you to edit a record that has been locked by a different user or application.

When a program that uses record reservation is interrupted, orphaned reservation records might remain in the Business Object Reservation table (F00095). This can occur, for example, when technicians are working with a server, or when a workstation shuts down without warning. If an interruption stops one of the programs in the Batch Release Credit Holds program (R42550) before it releases the reservations that it creates, you cannot update the records until the orphaned reservations are removed.

You can use the Remove Business Object Reservation program (P00095) to release unwanted record reservations. This program stores reservation information in the Business Object Reservation table (F00095).

11.4 Releasing Backorders

This section provides an overview of backorder releases and discusses how to:

-

Set processing options for the Release Backorders – Online program (P42117).

-

Release backorders online.

-

Set processing options for the Backorder Release and Report program (R42118).

-

Release backorders in batch.

11.4.1 Understanding Backorder Releases

The system can withhold an order or order line from the processing cycle if you do not have the quantity to fill the order or order line. This type of hold is a backorder. When an order or order line is placed on backorder, you must release backorders into the processing cycle when inventory becomes available. When releasing backorders, you can enter a quantity that is greater than the backordered amount.

The system updates the following tables with these amounts:

-

F4201 - Order total.

-

F4211 - Order quantity.

-

F03012 - Customer open order amount.

-

F41021 - Item balance.

If the payment instrument type for the sales order is cash, the system does not update the Customer Master by Line of Business table (F03012).

You can locate backorder information for a specific customer, item, or order before you release a backorder.

11.4.1.1 Releasing Backorders in a Batch

You can release multiple backorders simultaneously using the Backorder Release and Report program (R42118). When inventory becomes available, the system releases backorders until the available inventory is completely committed.

The system automatically establishes the order in which backorders are filled. By default, the system fills the quantity for the order with the earliest date first. To fill an order based on the priority code that you set up in customer billing instructions, you can create an alternative version of the R42118 program and edit the data sequence values. This version fills orders by priority codes first, and then fills orders by request date.

If you use the JD Edwards EnterpriseOne Demand Scheduling Execution system from Oracle, the report displays the Promised Delivery Time (RSDT) information on the report in a column labeled Date/Time.

11.4.1.2 Releasing Backorders for Kits

You can release backorders for the kit parent or for individual kit components. When you release kit components individually, the system displays a warning that you are creating parent and component imbalances. The system flags the record and then uses this information to prevent action on the kit parent that would result in loss of kit integrity such as changing the order quantity on the kit parent item.

The Backorder Release program (P42117) launches the P42055 program when you specify a transaction quantity for the parent and process the line on the sales order. You set the Display Kit Balance Window processing option on the P42117 program to specify how the system performs kit balancing.

You cannot use the Batch Backorder Release program (R42118) to process kit components individually. The system releases components based on the recommended component quantities.

11.4.1.3 Releasing Backorders with Taxed Prices

If you use taxed prices and access the Backorder Release program (P42117) or the Backorder Release and Report program (R42118), the system splits sales order lines and recalculates the taxed extended price and the extended tax amount.

See Taxed Prices

11.4.2 Forms Used to Release Backorders Online

| Form Name | Form ID | Navigation | Usage |

|---|---|---|---|

| Work With Backorders | W42117M | Additional Order Processes (G4212), Release Backorders - Online | Review and select backorders on hold. |

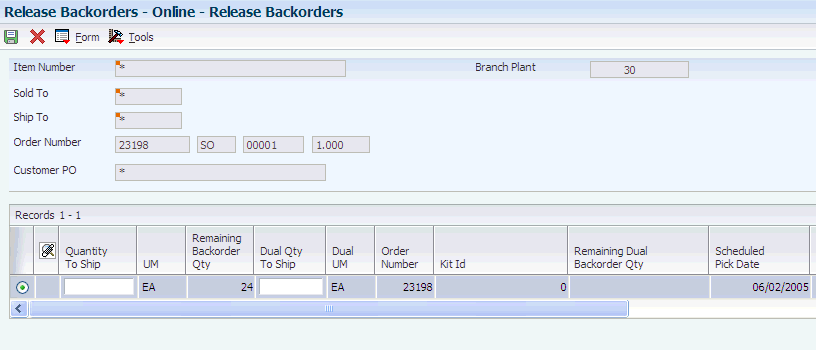

| Release Backorders - Online - Release Backorders | W42117I | Locate the backorders to release and select Release Shown Rows from the Form menu on the Work With Backorders form. | Release all orders displayed. Release a single backorder. |

| Kit Balance Window | W42055A | Confirm shipment or release backorders for kit items. | Revise kit quantities for transactions. |

11.4.3 Setting Processing Options for the Release Backorders - Online Program (P42117)

Processing options enable you to specify the default values, display criteria, versions, and processes that the system performs for Release Backorders - Online program (P42117).

11.4.3.1 Defaults

This processing option determines the next status code for released orders.

- 1. Next Status for Released Orders

-

Enter a value from UDC 40/AT that specifies the line status to be used as the next status on released orders. You must use a status that has been set up in the Order Activity Rules table (F40203) based on the order type and the line type combination.

Note:

If you do not enter a status or enter an invalid status, the system does not update the order status.

11.4.3.2 Display

These processing options specify whether the system displays information.

- 1. Total Fill Only

-

Specify whether the system displays all lines or only lines that can be totally filled. This option works only when you search by item number. Values are:

Blank: Display all lines.

1: Display only lines that can be totally filled.

- 2. Kit Components

-

Specify whether the system displays component lines for kits. When you release backorders for kits, you can manually release the individual components of the kit or have the system release the components when you release the parent item. Values are:

Blank: The system does not display kit component lines. The system automatically releases each component and balances the remaining quantity for each item in the kit.

1: The system displays all kit component lines. You can manually release each component, if necessary.

- 3. Held Orders

-

Specify whether the system displays held orders on the Backorder Release Revisions form. Values are:

Blank: Do not display held orders.

1: Display held orders.

- 4. Next Status to Select

-

Specify a code from UDC 40/AT that indicates the next step in the order flow of the line type.

- 5. Display Kit Balance Window (P42055)

-

Specify whether the system displays the Kit Balancing Window program (P42055) when you are processing a kit item at the parent level. The system always processes manufactured kits at the parent level and performs blind kit balancing. Values are:

Blank: The system displays the Kit Balance Window form only if any exceptions exist. Exceptions include not enough components being available to satisfy the ordered parent quantity and any of the components being previously processed.

1: The system always displays the interactive Kit Balance Window form when processing a kit parent item.

2: The system does not display the interactive Kit Balance Window form. The system performs blind kit balancing, based on the default quantity as defined in the Bill of Material program (P3002).

11.4.3.3 Edits

This processing option determines the allowed lot status codes.

- 1. Enter Allowed Lot Status Group to validate

-

Enter the allowed lot status group to validate.

During sales order processing, the system validates the non-blank lot status codes against the user-defined status code values. If the non-blank lot status codes exist in the Allowed Lot Status table (F41081), the system treats the user-defined lot status codes as blank and the on-hold items continue through the sales order process.

11.4.3.4 Process

These processing options specify whether the system performs specific processes.

- 1. Backorder Quantity as Available Quantity

-

Specify whether the backorder quantity is added to the quantity available. Values are:

Blank: Do not add the backorder quantity to the available quantity.

1: Add the backorder quantity to the quantity available.

- 2. Commitments

-

Specify whether the system calls the Inventory Commitment program (R42997) to hard-commit released orders to inventory locations. Values are:

Blank: Do not call the R42997 program and soft-commit only orders that are released.

1: Do call the R42997 program to hard-commit released orders to inventory locations.

Note:

If you release amounts over the quantity available, the order can be backordered again. - 3. Release when Quantity to Ship Exceeds Backordered Quantity

-

Specify whether the system allows the release of amounts that are greater than the original quantity. Values are:

Blank: Do not allow the release of amounts that are greater than the original quantity.

1: Allow the release of amounts that are greater than the original backordered quantity.

- 4. Zero On-Hand Quantity

-

Specify whether the system allows the release of orders when the on-hand quantity is zero. Values are:

Blank: Do not allow the release when the on-hand quantity is zero.

1: Do allow the release of orders when the on-hand quantity is zero.

Note:

This processing option can cause inventory levels to become negative quantities, which affects average costing. - 5. Cost Update

-

Specify whether the system updates release orders with the current costs. This processing option enables you to update costs for items that might have changed costs during the interval between the placement of the order and release of the backordered amounts. Values are:

Blank: Do not update the costs.

1: Update released orders with the current costs.

Note:

The system does not change sale price.If you release a backorder for a parent kit item and components have been previously released individually, the system does not change the cost on the parent kit line. The system updates the cost for the component lines that are released from backorder, but does not roll the cost changes up to the parent kit line.

- 6. Ship and Debit Processing

-

Specify whether the system uses the subsystem, batch, or normal processing to identify and adjust ship and debit agreements when you run the P42117 program. Values are:

Blank: Use normal processing.

1: Use the subsystem.

2: Use batch processing with the Assign, Recalculate, and Reassign Agreements program (R45100).

11.4.3.5 Order Holds

These processing options specify credit check and partial order hold codes.

- 1. Credit Check Hold Code

-

Enter a value from UDC 42/HC that identifies the credit hold code that the system uses to automatically compare the credit limit that you set up for the customer in the Customer Master by Line of Business table (F03012) against the order and any outstanding balances in accounts receivable.

You define the conditions that the system uses to place orders on hold in Order Hold Information (P42090) and attach those conditions to a hold code. You must specify the hold code in this processing option to activate order hold processing.

- 2. Partial Order Hold Code

-

Enter a value from UDC 42/HC that identifies the code that the system uses to hold an entire order if quantity is not available to fill an order detail line.

You must enter the partial order hold code for backorder release to release the hold when the order is completely filled. The system can then release and remove the hold according to information in the Customer Billing Instructions, Item Master Information, Item Branch/Plant Information, and Branch/Plant Constants forms. If you do not enter a correct partial hold code, the backorder release does not release the held order.

11.4.3.6 Print

These processing options specify whether the system automatically prints pick slips or invoices.

- 1. Automatic Print

-

Specify whether the system automatically prints invoices. Values are:

Blank: Do not print invoices or pick slips.

1: Print pick slips automatically.

2: Print invoices automatically.

Note:

Use the processing option on the Versions tab to indicate a specific version of the Print Pick Slips program (R42520) or the Print Invoices program (R42565).

11.4.3.7 Versions

These processing options specify the versions of these programs that the system uses.

- 1. Sales Order Entry (P4210)

-

Specify the version of the Sales Order Entry program (P4210) to use to review orders when you select Sales Detail from the Row menu.

- 2. Customer Service Inquiry (P4210)

-

Specify the version of Customer Service Inquiry (P4210) to use to review orders when you select Customer Service Inquiry from the Form menu.

- 3. Item Availability (P41202)

-

Specify the version of Item Availability (P41202) to use to review item information when you select Item Availability from the Form menu.

- 4. Subsystem Print Invoice (R42565)

-

Specify the version of Invoice Print (R42565) that is set up for subsystem processing. Use this processing option if you generate invoices through the subsystem.

Note:

To use this processing option, you must enter 2 for the Automatic Print processing option on the Print tab to automatically print invoices for the P42117 program. - 5. Subsystem Print Pickslip (R42520)

-

Specify the version of Print Pick Slip (R42520) that is set up for subsystem processing. Use this processing option if you generate invoices through the subsystem.

Note:

To use this processing option, you must enter 1 for the Automatic Print processing option on the Print tab to automatically print pick slips for the P42117 program. - 6. Ship and Debit (R45100)

-

Specify the version of subsystem or batch processing (R45100) that the system uses to identify and adjust ship and debit agreements when you run the P42117 program.

11.4.3.8 Warehouse

These processing options specify how the JD Edwards EnterpriseOne Warehouse Management system picks requests.

- 1. Request Processing Mode

-

Specify whether the system creates a pick request in JD Edwards EnterpriseOne Warehouse Management and processes the request through the subsystem. Values are:

Blank: Do not generate pick requests.

1: Create a pick request in JD Edwards EnterpriseOne Warehouse Management.

2: Create a pick request, then process the request through the subsystem in JD Edwards EnterpriseOne Warehouse Management.

You use a pick request to process a suggestion to pick the inventory for an order from a particular location.

- 2. Subsystem Print Pick Request

-

Specify the version of Print Pick Request (P46171) that is set up for subsystem processing. Use this processing option if you generate warehouse management pick requests through the subsystem.

- 3. Override Next Status

-

Enter a value from UDC 40/AT that defines an alternative status in the order process. This must be set up in the order activity rules based on the order type and the line type combination. The combination of the beginning status and the override status must be a valid last status and next status combination in the Order Activity Rules table (F40203).

11.4.4 Releasing Backorders Online

Access the Release Backorders form.

If you use JD Edwards EnterpriseOne Demand Scheduling Execution, when you release the backorder, the system displays the information for the requested delivery time of the order and the scheduled pick time. This information enables you to release the product based on a date and time.

11.4.5 Setting Processing Options for the Backorder Release and Report Program (R42118)

Processing options enable you to specify the default processing for the Backorder Release and Report program (R42118).

11.4.5.1 Defaults

These processing options determine the default next status for the orders that the system releases from backorder.

- 1. Next Status for Released Orders

-

Specify the line status to be used as the next status on released orders. You must use a status that has been set up in UDC table 40/AT of the order activity rules based on the order type and the line type combination.

Note:

If you do not enter a status or enter an invalid status, the system does not update the order status.

11.4.5.2 Edits

This processing option determines the allowed lot status codes.

- 1. Enter Allowed Lot Status Group to validate

-

Enter the allowed lot status group to validate. During sales order processing, the system validates the non-blank lot status codes against the user-defined status code values. If the non-blank lot status codes exist in the F41081 table, the system treats the user-defined lot status codes as blank and the on-hold item continues through the sales order process.

11.4.5.3 Process

These processing options specify whether the system performs specific processes.

- 1. Proof or Final Mode

-

Specify whether you want to run the backorder release report in proof or final mode. Values are:

Blank: Run in proof mode so that no changes are made to any sales order lines and no backorders are filled. Proof mode displays only the sales order lines that you have enough inventory to fill.

1: Run in final mode so that the program updates and fills backordered lines.

- 2. Backorder Quantity as Available Quantity

-

Specify whether the system adds the backorder quantity to the quantity available. This option gives you more quantity available to fill orders. Values are:

Blank: Do not include the backorder quantity in the quantity available.

1: Include the backorder quantity in the quantity available.

- 3. Commitments

-

Specify whether the system calls the Inventory Commitment program (R42997) to hard-commit released orders to inventory locations. Values are:

Blank: Do not call the commit program and soft-commit only orders that are released.

1: Call the R42997 program to hard-commit released orders to inventory locations.

Note:

If you release amounts over the quantity available, the order can be backordered again. - 4. Zero On-Hand Quantity

-

Specify whether the system allows the release of orders when the quantity on hand is zero. Values are:

Blank: Do not allow the release of orders when the quantity on hand is zero.

1: Allow the release of orders when the quantity on hand is zero.

Note:

This option can drive inventory levels to negative quantities, which affects average costing. - 5. Cost Update

-

Specify whether the system updates released orders with the current costs. This option enables you to update costs for items that might have changed costs during the interval between the placement of the order and release of the backordered amounts. Values are:

Blank: Do not update costs.

1: Update released orders with the current costs.

Note:

The system does not change sale price. - 6. Ship and Debit Processing

-

Specify the processing method used to identify and adjust ship and debit agreements when you run the Backorder Release program. Values are:

Blank: Do not use subsystem or batch processing.

1: Use the subsystem.

2 Use batch processing (R45100).

11.4.5.4 Order Holds

These processing options activate order hold processing.

- 1. Credit Check Hold Code

-

Enter a value from UDC 42/HC that specifies the credit hold code that the system uses to automatically compare the credit limit that you set up for the customer in the Customer Master by Line of Business table (F03012) against the order and any outstanding balances in accounts receivable.

You define the conditions that the system uses to place orders on hold in the Order Hold Information program (P42090) and attach those conditions to a hold code.

You must specify the hold code in this processing option to activate order hold processing.

- 2. Partial Order Hold Code

-

Enter a value from UDC 42/HC that the system uses to hold an entire order if quantity is not available to fill an order detail line.

You must enter the partial order hold code for backorder release to release the hold when the order is completely filled. The system can then release and remove the hold according to information in the Customer Billing Instructions, Item Master Information, Item Branch/Plant Information, and Branch/Plant Constants forms. If you do not enter a correct partial hold code, the backorder release does not release the held order.

11.4.5.5 Print

These processing options indicate whether the system prints order information for those orders that can be completely filled, orders that are on hold, or components of kits.

- 1. Total Fill Orders

-

Specify whether the system prints only the lines that can be totally filled or all lines. Values are:

Blank: Print all lines.

1: Print only the lines that can be totally filled.

- 2. Print Held Orders

-

Specify whether the system prints held orders and allows the release of the held orders. Values are:

Blank: Do not print held orders.

1: Print held orders and allow the release of the held orders.

- 3. Print Kit Component Lines

-

Specify whether the system prints component lines for kits in backorder release. Values are:

Blank: Do not print kit components.

1: Print kit components in a backorder release.

- 4. Print Error Messages

-

Specify whether the system prints error messages on the report. Values are:

Blank: Print all error messages.

1: Do not print error messages.

11.4.5.6 Versions

These processing options determine the version that the system uses during backorder release processing. If you leave a processing option blank, the system uses the ZJDE0001 version.

- 1. Subsystem Print Invoice (R42565)

-

Specify the version of the Invoice Print program (R42565) that is set up to generate invoices through subsystem processing.

- 2. Subsystem Print Pickslip (R42520)

-

Specify the version of the Print Pick Slip program (R42520) that is set up to generate pick slips through subsystem processing.

- 3. Ship and Debit (R45100)

-

Specify the version of the Assign, Recalculate, and Reassign Agreements program (R45100) that the system uses to identify and adjust ship and debit agreements when you run the R42118 program.

11.4.5.7 Warehousing

You use these processing options with the JD Edwards EnterpriseOne Warehouse Management system.

- 1. Request Processing Mode

-

Specify whether the system generates pick requests and then processes the request through the subsystem. You use a pick request to process a suggestion to pick the inventory for an order from a particular location. If you leave this processing option blank, the system does not generate pick requests. Values are:

Blank: Do not generate pick requests.

1: Generate pick requests only.

2: Generate pick requests and then process the request through the subsystem.

- 2. Subsystem Print Pick Request

-

Specify the version of the Print Pick Request program (P4617) that is set up for subsystem processing if you generate warehouse management pick requests through the subsystem.

- 3. Override Next Status

-

Enter an alternative step in the order process by specifying a value from UDC 40/AT that has been set up in the order activity rules based on the order type and the line type combination. The combination of the beginning status and the override status must be a valid last status and next status combination in the Order Activity Rules table (F40203).

11.5 Releasing Blanket Orders

This section provides an overview of blanket order release and discusses how to:

-

Set processing options for Sales Blanket Order Release (P420111).

-

Release blanket orders.

11.5.1 Understanding Blanket Order Release

You can create sales orders for customers with blanket orders or quotes. You use the Release Blankets program (P420111) to manually deduct item quantities from a blanket order. The system creates a sales order for the quantity that you specify. The system maintains any remaining balance on the blanket order for future orders. The system also indicates when the sales order quantity exceeds the blanket order quantity.

The system consolidates order lines based on sold to, branch/plant, and currency code information. The order numbers that you enter can be consolidated in the same way as the system-generated sales orders. For example, if you select multiple records to release and enter a new order number for the first record only, the system consolidates the orders.

When you release a blanket order, you can specify the sales order number when you verify the release date and quantity. The system checks the order number and line type combinations for duplicates. If duplicates are found, the system stops processing the order and displays an error message that the document number exists. You must assign a unique order number to the order before the system processes the sales order. If you do not enter an order number, the system generates the sales order number using next numbers.

The system lets you release single or multiple blanket orders automatically or manually, and you can specify whether a blanket order is selected by default when multiple blankets meet the identification criteria.

If multiple blanket orders exist for a customer, such as orders received using electronic purchase orders (EDI 850 orders), you can ensure that the system automatically identifies a sales order blanket to be released. To reduce the chances of multiple blankets meeting the processing criteria, you can process blanket orders based on these values:

-

Sold to address and item number.

-

Ship to address and item number.

-

Sold to address, item number, and customer purchase order (PO).

-

Ship to address, item number, and customer PO.

-

Delivered to address and item number.

-

Delivered to address, item number, and customer PO.

You can release multiple blanket orders simultaneously and release the full item quantity in each blanket order without verifying the release quantity and date or specifying a sales order number. To do so, select Release Full Quantity from the Row menu on the Work With Order Blanket Release form. The system generates a sales order for the full quantity and assigns a sales order number through the Next Number Revisions program (P0002).

If you are using the Customer Self-Service version of the P420111 program, you can partially release quantities from multiple blanket orders and from multiple lines on blanket orders if you have set the appropriate processing options. When the system creates the sales orders, you can review each sales order number that results. You can also cancel a single line that has been released, as opposed to having to cancel all of the lines that have been released.

To create a sales order from a blanket order, you must use the unit of measure from the original blanket order. If the units of measure in the sales order do not match the units of measure in the blanket order, the system does not initiate blanket order release.

11.5.1.1 Releasing Blanket Order for Kits

You can release blanket orders using the Sales Blanket Order Release program (P420111) or using the Sales Order Entry programs (P4210 and P42101). If you use the Sales Order Entry programs, you must set the processing options to specify that the system process blanket orders and determine how the system process individual and multiple blanket orders. When you release blanket orders using the Sales Order Entry programs, the system constructs the kit based on the components that you selected when you entered the original blanket order. The system displays the kit components using the Sales Blanket Release program (P42116). You use the Sales Blanket Release program to review and release the blanket order lines. To review the components for the selected kit blanket line, you access the View Kit Components program (P420112) from the Sales Blanket Release program.

The system determines pricing on the kit sales order based on the price on the original blanket order, regardless of the selected components.

After you create a sales order from the blanket order for the kit parent, the system reflects the changes on the sales order on the original blanket. If you cancel the order, or increase or decrease the order quantity, the system adjusts the open quantity on the original order. The system updates the open order quantity on the components items based on the bill of material and the parent kit. Changes to the individual component lines of a generated sales order do not affect the original blanket order.

11.5.1.2 Releasing Blanket Orders with Taxed Prices

See Taxed Prices

If you use taxed prices and access the Sales Blanket Order Release program, you can release taxed sales orders. The system retrieves the internal tax date from the original blanket order.

Review the following considerations when releasing a blanket order:

-

If you release a taxed blanket order and generate a sales order, the system displays the value in the Use Taxed Prices check box from the original blanket order on the generated sales order.

-

If you release multiple taxed and non-taxed blanket orders before generating the sales order, then the system retrieves the value in the Use Taxed Prices check box from the first released blanket order and uses this value in the generated sales order. Therefore, if the first released blanket is a taxed order, then the generated sales order is a taxed order. If the first released blanket is a non-taxed order, then the generated sales order is a non-taxed sales order.

-

If the generated sales order uses taxed prices and the selected blanket also uses taxed prices, then the system uses the taxed prices from blanket order in the sales order and selects the taxed price override flag in the Sales Order Detail Tax table (F4211TX).

-

If the generated sales order uses taxed prices and the selected blanket does not use taxed prices, then the system uses the non-taxed prices from the blanket order in the sales order and selects the price override flag in the Sales Order Detail table (F4211). The system calculates taxed prices from the non-taxed blanket prices.

-

If the generated sales order does not use taxed prices and the selected blanket uses taxed prices, then the system uses the non-taxed prices from the blanket order in the sales order and selects the price override flag in the F4211 table.

If you select a blanket order with taxed prices, the system displays the following fields on the Work With Order Blanket Release form:

-

Taxed Unit Price

-

Unit Tax Amount

-

Foreign Taxed Unit Price

-

Foreign Unit Tax Amount

If you select a blanket order with taxed prices, the system displays the following fields on the Blanket Order Revisions form:

-

Use Taxed Prices

-

Taxed Unit Price

-

Unit Tax Amount

If you use taxed prices and access the Sales Blanket Release program (P42216) from the Sales Order Entry programs (P4210 or P42101), review the following considerations:

-

If the sales order uses taxed prices and the selected blanket order also uses taxed prices, then system uses the taxed prices from the blanket order in the sales order and selects the taxed price override flag in the Sales Order Detail Tax table (F4211TX).

-

If the sales order uses taxed prices and the selected blanket order does not use taxed prices, then the system uses the non-taxed prices from blanket order in the sales order and selects the price override flag in the Sales Order Detail table (F4211). The system calculates taxed prices from non-taxed blanket prices.

-

If the sales order does not use taxed prices and the selected blanket order uses taxed prices, then the system ignores the taxed prices from blanket order, uses the non-taxed prices from the blanket order in the sales order, and selects the price override flag in the F4211 table.

In the Sales Blanket Release program, you can specify whether to review taxed or non-taxed blanket orders. If you decide to review taxed blanket orders, the system displays the domestic or foreign fields as read-only on the Blanket Release form:

-

Taxed Unit Price

-

Unit Tax Amount

-

Foreign Taxed Unit Price

-

Foreign Unit Tax Amount

If you use taxed prices and access the Sales Order Line Detail program (P42045) from the Sales Blanket Release program (P42216), the system displays either the domestic or foreign fields on the Sales Order Line Detail form:

-

Taxed Unit Price

-

Taxed Extended Price

-

Foreign Taxed Unit Price

-

Foreign Taxed Extended Price

11.5.2 Forms Used to Release Blanket Orders

| Form Name | Form ID | Navigation | Usage |

|---|---|---|---|

| Work With Order Blanket Release | W420111B | Additional Order Processes (G4212), Release Blankets | Review and select blanket orders.

Release all orders by selecting rows and then selecting Release Full Qty (Quantity) from the Row menu. |

| Blanket Order Revisions | W420111A | Select a blanket order on the Work With Order Blanket Release form, and click Select. | Release blanket orders. |

| Blanket Release | W42216A | Sales Order Processing (G4211)

Enter a sales order for an item which exists on a blanket order. |

Release blanket orders during sales order entry. |

| View Kit Components | W420112H | Select a blanket order and select View Kit Components from the Row menu on the Blanket Release form. | Review selected components for a parent kit item on a blanket order. |

11.5.3 Setting Processing Options for the Sales Blanket Order Release Program (P420111)

Processing options enable you to specify the default values, display, versions, and processing for the Sales Blanket Order Release program (P420111).

11.5.3.1 Default

These processing options specify the default values when you create a new blanket order.

- 1. Order Type

-

(Required) Enter a code from UDC 00/DT that specifies the order type to select.

- 2. Outgoing Document Type

-

(Required) Enter a code from UDC 00/DT that specifies the outgoing document type.

- 3. Line Number Increment

-

(Optional) Specify the increment that the system uses to determine new order line numbers when an order line must be split. For example, if order line 1 must be split, and you enter 1 for this processing option, the system creates the new line using line number 2.

11.5.3.2 Display

This processing option determines whether the system displays kit components.

- 1. Hide Kit Component

-

Specify whether the system displays kit component lines on the Blanket Order Release form. Values are:

-

Blank: The system displays the parent kit item and all components.

-

1: The system displays the parent kit item only.

-

11.5.3.3 Version

These processing options enable you to define the version for each application.

- 1. Sales Order Entry

-

Enter the version of the Sales Order Entry program (P4210) that the system uses for releasing blanket orders.

If you leave this field blank, the system uses ZJDE0001.

- 2. Customer Service Inquiry

-

Enter the version of the Customer Service Inquiry program (P4210) that the system uses for releasing blanket orders.

If you leave this field blank, the system uses ZJDE0001.

11.5.3.4 Customer Self Service

These processing options specify whether the system uses customer self-service and determines how the system displays data.

- 1. Customer Self-Service Functionality

-

Specify whether the system activates the Customer Self-Service functionality. Values are:

Blank: Bypass the Customer Self-Service functionality.

1: Activate Customer Self-Service functionality.

- 2. Organization Structure Type

-

Enter the structure type to display addresses for that structure type, or leave blank to display all related addresses.

- 3. Customer Cross Reference Type

-

Enter a code from UDC 41/DT that identifies the customer cross-reference type.

- 4. Display/Hide Change button

-

Specify whether the system displays the change button. Values are:

Blank: Hide the change button.

1: Display the change button.

11.5.4 Releasing Blanket Orders

Access the Blanket Order Revisions form.

When you release a blanket order, you might receive these error messages:

-

Multiple blankets exist.

-

The order line quantity requested is over the amount left on a blanket order.

These errors require you to act, such as select the blanket order from which you want to release the quantity, and reduce the order amount so that it matches the sales order.

- Release Quantity

-

Specify the quantity to release from the open order quantity. This quantity reduces the open order quantity on the original blanket order.

- Request Date

-

Specify the requested date that should be applied to the released line during sales order generation.

- New Order Number

-

(Optional) Specify an order number that the system uses to create the sales order. This order number becomes the generated number of the sales order after the sales order generation.

11.6 Releasing Quote Orders

This section provides an overview of quote order release and discusses how to release quote orders.

11.6.1 Understanding Quote Order Release

You release a quote order in the same manner that you release a blanket order; you use the Release Blankets program (P420111) to release any of the items on a quote order and to create a sales order. If you release only part of the quantity or some items on the quote order, the system maintains the balance remaining on the original quote order. The next time that you display the quote order, you see the adjusted quantity.

If you have multiple orders for the same customer and item, all orders appear on the Work With Order Blanket Release form. The quantity fields do not contain values. You must enter the quantity for the appropriate order.

When you release a quote order, you can specify the sales order number when you verify the release date and quantity. The system checks the order number and document type combinations for duplicates. If duplicates are found, the system stops processing the order and displays an error message that the document number exists. You must assign a unique order number to the order before the system processes the sales order. If you do not enter a unique order number, the system generates the sales order number.

The system consolidates order lines based on sold to, branch/plant, and currency code information. The order numbers that a user enters can be consolidated in the same way as the system-generated sales orders. For example, if you select multiple records to release and enter a new order number for the first record only, the system consolidates the orders.

If you have created a quote order and the customer authorizes the purchase of the quoted items, you can use the quote to create a sales order. You use this method to create a sales order that reflects all or most of the quantities and items on a quote order.

You can release multiple quote orders simultaneously by selecting Release Full Quantity from the Row menu of the Work With Order Blanket Release form.

The system releases the full item quantity in each quote order and attempts to consolidate multiple order selections to a single order if possible. To create a sales order from a quote order, you must use the unit of measure in the original quote order. If the unit of measure in the sales order does not match the unit of measure in the quote order, the system does not initiate quote order release. To generate the sales order, select SO Generation from the Form menu.

11.6.1.1 Quote Order Release for Kits

You can release quote orders manually using the Sales Blanket Order Release program (P420111), or automatically using the Sales Order Entry programs (P4210 and P42101). If you use the Sales Order Entry programs, you must set the processing options to specify that the system process quote orders and determine how the system processes individual and multiple quote orders. When you release quote orders automatically, the system constructs the kit based on the components that you selected when you entered the original quote order. The system displays the kit components using the Sales Blanket Release program (P42116). You can use the Sales Blanket Release program to review and update the quote order lines for release.

The system determines pricing on the kit sales order based on the price on the original quote order, regardless of the selected components.

11.6.2 Mobile Enterprise Applications for Quote Review and Release (Release 9.1 Update)

The following mobile applications are available, and can be used to review and release sales order quotes on a mobile device:

-

Quote Review and Release (Smartphone and Tablet)

These applications require system administrator configuration before they are available to individual users. Contact your system administrator to determine whether these applications are available for use.

Additionally, see the following topics in the JD Edwards EnterpriseOne Applications Mobile Enterprise Applications Implementation Guide:

11.6.3 Forms Used to Release Quote Orders

| Form Name | Form ID | Navigation | Usage |

|---|---|---|---|

| Work With Order Blanket Release | W420111B | Additional Order Processes (G4212), Release Quotes | Review and select quote orders. |

| Blanket Order Revisions | W420111A | Select a record, and click Select to release a quote order. | Release quote orders. |

| Blanket Release | W42216A | Sales Order Processing (G4211)

Enter a sales order for an item which exists on a quote order. |

Release blanket orders during sales order entry. |

| View Kit Components | W420112H | Select a quote order and select View Kit Components from the Row menu on the Blanket Release form. | Review selected components for a parent kit item on a quote order. |

11.6.4 Releasing Quote Orders

Access the Blanket Order Revisions form.

To release the entire quantity on an order:

-

Select the row for the quote order to release.

-

Select Release Full Qty (Quantity) from the Row menu.

To release a partial quantity for an order:

-

Select the row for the quote order you want to release.

-

Click Select.

-

Complete the Release Quantity field on the Blanket Order Revisions form with the quantity to release from the quote order.

After you release the quantity from the quote, you must generate the sales order. To generate the sales order:

-

Select SO Generation from the Form menu on the Work With Blanket Order Release form.

The system automatically creates a sales order and displays the order number and document type.

-

Click the Added Order link to access the new sales order.

11.7 Reviewing Item Information

This section provides overviews of item information and supply and demand, lists a prerequisite, and discusses how to:

-

Set processing options for the Check Price and Availability program (P4074).

-

Review standard price and availability information.

-

Set processing options for the Item Availability program (P41202).

-

Locate quantity information.

-

Review availability calculations.

-

Set processing options for the Supply and Demand Inquiry program (P4021).

-

Review supply and demand information.

11.7.1 Mobile Enterprise Applications for Reviewing Customer Order Information (Release 9.1 Update)

The following mobile applications are available, and can be used to review customer order information on a mobile device:

-

Customer Order Overview (Smartphone and Tablet)

These applications require system administrator configuration before they are available to individual users. Contact your system administrator to determine whether these applications are available for use.

Additionally, see the following topic in the JD Edwards EnterpriseOne Applications Mobile Enterprise Applications Implementation Guide:

11.7.2 Understanding Item Information

You can accurately plan for future stocking needs by reviewing information that the system provides about both the item and the quantity. For example, you can:

-

Access information about the stock items.

-

Access summary and detailed information about on-hand, committed, and available items.

-

Access and monitor supply-and-demand information to help you plan for future stocking needs.

-

Access item information about previous sales, current inventory quantities, and future receipts.

-

Review balance forward records for a specific fiscal year.

-

Reconcile inventory balances with the general ledger (GL) and access detailed item transaction information.

-

Compare the inventory balances after one period with the same period end for the GL.

11.7.3 Understanding Supply and Demand

Use the Supply/Demand Inquiry form to review demand, supply, and available quantities for a specific item. You can review general product and item performance for a given branch/plant, past sales performance, current demand, and other item information. The information is based on inventory, purchasing, and sales history.

The highlighted available-to-promise (ATP) lines on the Supply/Demand Inquiry form indicate the company's uncommitted available inventory. Available-to-promise inventory is available for sale or distribution within a specified period.

The demand quantities are presented by date and can include safety stock, quantities on sales orders, work order parts lists, planned order demand for lower levels, and interplant and forecasted demand. The supply quantities are presented by date and can include on-hand inventory and quantities on purchase orders, manufacturing work orders, planned orders, and rate schedules. Supply quantities without a date or order information represent current availability by branch/plant storage location.

11.7.4 Prerequisite

Before you review item information, you must define the item availability calculation in the Branch/Plant Constants program (P41001).

11.7.5 Forms Used to Review Item Information

| Form Name | Form ID | Navigation | Usage |

|---|---|---|---|

| Customer Service Inquiry | W4210E | Sales Order Inquiries (G42112), Customer Service | Copy both header and detail information from an existing sales order to a new sales order. |

| Manage Existing Order | W42101C | Sales Order Processing (G4211), Update Sales Order - Header First | Click Copy or Convert to copy both header and detail information from an existing sales order to a new sales order. |

| Check Price and Availability | W4074C | Sales Order Inquiries (G42112), Advanced Check Price & Availability | Check price and availability. |

| Work With Price and Availability | W41261A | Sales Order Inquiries (G42112), Standard Check Price & Availability | Review standard price and availability information. |

| Work With Item Availability | W41202A | Sales Order Inquiries (G42112), Summary Availability | Locate quantity information. |

| Detail Availability | W41202C | Select Detail Avail from the Row menu on the Work With Item Availability form. | Review availability calculations. |

| Work With Supply and Demand | W4021B | Sales Order Inquiries (G42112), Supply/Demand | Review supply and demand information. |

11.7.6 Setting Processing Options for the Check Price and Availability Program (P4074)

Processing options enable you to specify the default processing for the Check Price and Availability program (P4074).

11.7.6.1 Process

These processing options specify the preference processing and price review information.

- 1. Version of Sales Order Entry (P4210)

-

Enter a version of the Sales Order Entry program (P4210) that controls the preference profile.

If you leave this field blank, the system uses the ZJDE0001 version.

- 2. Allow Price History of a Receipt line with associated landed cost, to be updated

-

Specify whether the system allows price history entries for receipts that are updated from the Price Review application (P40G200). The system supports the option to disallow updates of price history entries for receipts, when the receipt has associated landed cost entries. Values are:

0: Allow update of price history entries for receipt lines with associated landed cost entries. This is the default value.

1: Disallow update of price history entries for receipt lines with associated landed cost entries.

11.7.7 Reviewing Standard Price and Availability Information

Access the Work With Price and Availability form.

The system calculates item availability and quantity information based on the options that you select for the branch/plant.

To obtain quantity cost-break information, check the Work With Price and Availability form for a sales order detail line.

You can review standard price adjustment information, such as inventory pricing rules.

- Contract Pricing

-

Click to search for contract prices.

- Lvl (level)

-

Enter an alphanumeric code that determines the sequence in which the system displays the rules within the pricing group. You define levels when you set up the pricing groups.

- Up to Qty (up to quantity)

-

Enter the volume or quantity breaks commonly used in pricing tables. If the quantity on the first level of a rule is 5, then the pricing logic on this level applies only to sales of five or fewer items. If the quantity in the next level is 10, then the pricing logic applies to sales of 6 through 10 items. A value of 99,999,999 indicates all quantities.

- Override Unit Price

-

Enter a price. Any price that you enter here overrides all other rules or prices.

- Factor

-

Enter the discount that the system uses when it calculates the price of an item attached to this inventory pricing rule. Discounts can be expressed as multipliers, additional amounts, or deductible amounts. For example, a 10 percent discount would be expressed as 0.90. You can use the same factor for markups over cost. For example, a 10 percent markup would be expressed as 1.10.

- Type

-

Enter a code that indicates whether the factor value is a multiplier (percent) or an additional or deductible cash amount when applied to an order's price.

- Contract Flag

-

Enter a code that indicates a special pricing relationship between the item and one or more of the customers. The inventory pricing rule code for a contract is the item number. Values are:

Blank: No contract.

C: Contract price.

If you indicate that a pricing type is a contract, you must enter the quantity that can be sold at this contract price and the contract number, if one exists.

You must also attach the contract pricing rule to the customer or customer group for the rule to become effective.

11.7.8 Setting Processing Options for the Item Availability Program (P41202)

Processing options enable you to specify the default processing for the Item Availability program (P41202).

11.7.8.1 Versions

These processing options enable you to specify the versions for various programs that you access from the P41202 program. Versions control how the system processes and displays information. Therefore, you must set the processing option to meet the company's specific needs.

- 1. Item Master

-

Enter the version that the system uses when you access the Item Master program (P4101). If you leave this processing option blank, the system uses version ZJDE0001.

- 2. Item Notes

-

Enter the version that the system uses when you access the Item Notes program (P40163). If you leave this processing option blank, the system uses version ZJDE0001.

- 3. Item Search

-

Enter the version that the system uses when you access the Item Search program (P41200). If you leave this processing option blank, the system uses version ZJDE0001.

- 4. Purchase Order Inquiry

-

Enter the version that the system uses when you access the Purchase Order Inquiry program (P430301). If you leave this processing option blank, the system uses version ZJDE0001.

- 5. Customer Service Inquiry

-

Enter the version that the system uses when you access the Customer Service Inquiry (Misc. Windows) program (P42045). If you leave this processing option blank, the system uses version ZJDE0001.

- 6. Open Work Orders

-

Enter the version that the system uses when you access the Open Work Orders program (R31400). If you leave this processing option blank, the system uses version ZJDE0001.

- 7. Supply and Demand

-

Enter the version that the system uses when you access the Supply and Demand Inquiry program (P4021). If you leave this processing option blank, the system uses version ZJDE0001.

- 8. Bill of Material

-

Enter the version that the system uses when you access the Bill of Material Inquiry program (P30200). If you leave this processing option blank, the system uses version ZJDE0001.

- 9. Lot Availability

-

Enter the version that the system uses when you access the Lot Master Availability program (P41280). If you leave this processing option blank, the system uses version ZJDE0001.

- 10. Item Ledger

-

Enter the version that the system uses when you access the Item Ledger Inquiry (CARDEX) program (P4111). If you leave this processing option blank, the system uses version ZJDE0001.

- 11. Branch/Plant Item Information

-

Enter the version that the system uses when you access the Branch/Plant Constants program (P41001). If you leave this processing option blank, the system uses version ZJDE0001.

- 12. Location Master

-

Enter the version that the system uses when you access the Location Master program (P4100). If you leave this processing option blank, the system uses version ZJDE0001.

- 13. Item Location Information

-

Enter the version that the system uses when you access the Item Location Type program (P41023). If you leave this processing option blank, the system uses version ZJDE0001.

11.7.8.2 Display

These processing options enable you to specify whether the system displays certain types of information and how the system calculates data.

- 1. Grade Information

-

Specify whether the system displays grade information. Values are:

Blank: Do not display grade information.

1: Display grade information.

- 2. Potency Information

-

Specify whether the system displays potency information. Values are:

Blank: Do not display potency information.

1: Display potency information.

- 3. Quality Management

-

Specify whether the system displays information from the JD Edwards EnterpriseOne Quality Management system from Oracle. Values are:

Blank: Do not display quality management information.

1: Display quality management information.

- 4. Quantity - Primary Units of Measure

-

Specify whether the system displays quantity information in primary units of measure. Values are:

Blank: Do not display quantities in primary units of measure.

1: Display quantities in primary units of measure.

- 5. Truncate/Round

-

Specify the manner in which the system truncates or rounds the information in the detail area. Values are:

Blank: Round the information in the detail area. The system uses normal mathematical rounding. For example, with no display decimals specified, 2.3 remains 2 and 2.6 is rounded up to 3.

1: Truncate the information in the grid. The system always removes additional positions. For example, with no display decimals specified, 2.3 and 2.6 are both truncated to 2.

2: Round up the information in the grid. The system always rounds to the next higher number. For example, with no display decimals specified, 2.3 and 2.6 are both rounded up to 3.

- 6. Customer Self-Service

-

Specify whether the system uses the standard mode or customer self-service functionality. Values are:

Blank: Bypass customer self-service functionality and use the standard mode.

1: Activate customer self-service functionality.

11.7.8.3 Lot Options

These processing options enable you to specify whether the system displays fields for advanced lot processing and to specify the default date for calculating the number of days until a lot expires.

- 1. Display Percent of Life Remaining

-

Enter a value to display the Percent of Life Remaining field. If you leave this processing option blank, the system does not display the Percent of Life Remaining field.

- 2. Display Number of Days Remaining

-