Administering Your System

|

You administer your system using the shelf management card command-line interface (CLI) or via Ethernet using the RMCP interface.

This chapter contains the following sections:

IPMI LAN Interface

The IPMI LAN interface is required by the ATCA specification and supports IPMI messaging with the Shelf Manager through the Remote Management Control Protocol (RMCP). A system administrator that uses RMCP to communicate with shelves is able to interact with any ATCA-compliant Shelf Manager. This low-level interface provides access to the IPMI aspects of a shelf, including the ability for the system administrator to issue IPMI commands to IPM controllers in the shelf, using the Shelf Manager as a proxy.

Supported IPMI Commands

The standard IPMI commands are documented in the PICMG 3.0, ATCA specification. TABLE 3-1 shows the IPMI commands implemented by the Shelf Manager. Due to security considerations, the treatment of a given command may be different, depending on whether it is received over the RMCP interface or on IPMB-0.

TABLE 3-1 IPMI Commands Implemented by the Shelf Manager

|

Command

|

NetFn

|

CMD

|

Arriving from RMCP Interface

|

Arriving from IPM Controller

|

|

Get Device ID

|

App

|

01h

|

Supported

|

Supported

|

|

Cold Reset

|

App

|

02h

|

Supported

|

Supported

|

|

Warm Reset

|

App

|

03h

|

Not Supported

|

Not supported

|

|

Get Self Test Results

|

App

|

04h

|

Supported

|

Supported

|

|

Manufacturing Test On

|

App

|

05h

|

Not Supported

|

Not supported

|

|

Set ACPI Power State

|

App

|

06h

|

Supported

|

Supported

|

|

Get ACPI Power State

|

App

|

07h

|

Supported

|

Supported

|

|

Get Device GUID

|

App

|

08h

|

Supported

|

Supported

|

|

Reset Watchdog Timer

|

App

|

22h

|

Supported

|

Supported

|

|

Set Watchdog Timer

|

App

|

24h

|

Supported

|

Supported

|

|

Get Watchdog Timer

|

App

|

25h

|

Supported

|

Supported

|

|

Set BMC Global Enables

|

App

|

2Eh

|

Supported

|

Supported

|

|

Get BMC Global Enables

|

App

|

2Fh

|

Supported

|

Supported

|

|

Clear Message Flags

|

App

|

30h

|

Supported

|

Supported

|

|

Get Message Flags

|

App

|

31h

|

Supported

|

Supported

|

|

Enable Message Channel Receive

|

App

|

32h

|

Not Supported

|

Not supported

|

|

Get Message

|

App

|

33h

|

Not Supported

|

Not supported

|

|

Send Message

|

App

|

34h

|

Supported

|

Supported

|

|

Read Event Message Buffer

|

App

|

35h

|

Not Supported

|

Not supported

|

|

Get BT Interface Capabilities

|

App

|

36h

|

Not Supported

|

Not supported

|

|

Get System GUID

|

App

|

37h

|

Supported

|

Supported

|

|

Get Channel Authentication Capabilities

|

App

|

38h

|

Supported

|

Supported(*)

|

|

Get Session Challenge

|

App

|

39h

|

Supported

|

Not supported

|

|

Activate Session

|

App

|

3Ah

|

Supported

|

Not supported

|

|

Set Session Privilege Level

|

App

|

3Bh

|

Supported

|

Not supported

|

|

Close Session

|

App

|

3Ch

|

Supported

|

Not supported

|

|

Get Session Info

|

App

|

3Dh

|

Supported

|

Supported(*)

|

|

Get AuthCode

|

App

|

3Fh

|

Supported

|

Supported(*)

|

|

Set Channel Access

|

App

|

40h

|

Supported

|

Supported(*)

|

|

Get Channel Access

|

App

|

41h

|

Supported

|

Supported(*)

|

|

Get Channel Info

|

App

|

42h

|

Supported

|

Supported(*)

|

|

Set User Access

|

App

|

43h

|

Supported

|

Supported(*)

|

|

Get User Access

|

App

|

44h

|

Supported

|

Supported(*)

|

|

Set User Name

|

App

|

45h

|

Supported

|

Supported(*)

|

|

Get User Name

|

App

|

46h

|

Supported

|

Supported(*)

|

|

Set User Password

|

App

|

47h

|

Supported

|

Supported(*)

|

|

Activate Payload

|

App

|

48h

|

Not Supported

|

Not supported

|

|

Deactivate Payload

|

App

|

49h

|

Not Supported

|

Not supported

|

|

Get Payload Activation Status

|

App

|

4Ah

|

Not Supported

|

Not supported

|

|

Get Payload Instance Info

|

App

|

4Bh

|

Not Supported

|

Not supported

|

|

Set User Payload Access

|

App

|

4Ch

|

Not Supported

|

Not supported

|

|

Get User Payload Access

|

App

|

4Dh

|

Not Supported

|

Not supported

|

|

Get Channel Payload Support

|

App

|

4Eh

|

Not Supported

|

Not supported

|

|

Get Channel Payload Version

|

App

|

4Fh

|

Not Supported

|

Not supported

|

|

Get Channel OEM Payload Info

|

App

|

50h

|

Not Supported

|

Not supported

|

|

Master Write-Read

|

App

|

52h

|

Not Supported

|

Not supported

|

|

Get Channel Cipher Suites

|

App

|

54h

|

Not Supported

|

Not supported

|

|

Suspend/Resume Payload Encryption

|

App

|

55h

|

Not Supported

|

Not supported

|

|

Set Channel Security Keys

|

App

|

56h

|

Not Supported

|

Not supported

|

|

Get System Interface Capabilities

|

App

|

57h

|

Not Supported

|

Not supported

|

|

Get Chassis Capabilities

|

Chassis

|

00h

|

Supported

|

Supported

|

|

Get Chassis Status

|

Chassis

|

01h

|

Supported

|

Supported

|

|

Chassis Control

|

Chassis

|

02h

|

Supported

|

Supported

|

|

Chassis Reset

|

Chassis

|

03h

|

Not Supported

|

Not supported

|

|

Chassis Identify

|

Chassis

|

04h

|

Not Supported

|

Not supported

|

|

Set Chassis Capabilities

|

Chassis

|

05h

|

Supported

|

Supported

|

|

Set Power Restore Policy

|

Chassis

|

06h

|

Not Supported

|

Not supported

|

|

Get System Restart Cause

|

Chassis

|

07h

|

Not Supported

|

Not supported

|

|

Set System Boot Options

|

Chassis

|

08h

|

Not Supported

|

Not supported

|

|

Get System Boot Options

|

Chassis

|

09h

|

Not Supported

|

Not supported

|

|

Set Front Panel Button Enables

|

Chassis

|

0Ah

|

Not Supported

|

Not supported

|

|

Set Power Cycle Interval

|

Chassis

|

0Bh

|

Not Supported

|

Not supported

|

|

Get POH Counter

|

Chassis

|

0Fh

|

Not Supported

|

Not supported

|

|

Set LAN Configuration Parameters

|

Transport

|

01h

|

Supported

|

Supported(*)

|

|

Get LAN Configuration Parameters

|

Transport

|

02h

|

Supported

|

Supported

|

|

Suspend BMC ARPs

|

Transport

|

03h

|

Supported

|

Supported(*)

|

|

Get IP/UDP/RMCP statistics

|

Transport

|

04h

|

Not Supported

|

Not supported

|

|

Set Serial/Modem Configuration

|

Transport

|

10h

|

Not Supported

|

Not supported

|

|

Get Serial/Modem Configuration

|

Transport

|

11h

|

Not Supported

|

Not supported

|

|

Set Serial/Modem Mux

|

Transport

|

12h

|

Not Supported

|

Not supported

|

|

Get TAP Response Codes

|

Transport

|

13h

|

Not Supported

|

Not supported

|

|

Set PPP UDP Proxy Transmit Data

|

Transport

|

14h

|

Not Supported

|

Not supported

|

|

Get PPP UDP Proxy Transmit Data

|

Transport

|

15h

|

Not Supported

|

Not supported

|

|

Send PPP UDP Proxy Packet

|

Transport

|

16h

|

Not Supported

|

Not supported

|

|

Get PPP UDP Proxy Receive Data

|

Transport

|

17h

|

Not Supported

|

Not supported

|

|

Serial/Modem Connection Active

|

Transport

|

18h

|

Not Supported

|

Not supported

|

|

Callback

|

Transport

|

19h

|

Not Supported

|

Not supported

|

|

Set User Callback Options

|

Transport

|

1Ah

|

Supported

|

Supported(*)

|

|

Get User Callback Options

|

Transport

|

1Bh

|

Supported

|

Supported(*)

|

|

SOL Activating

|

Transport

|

20h

|

Not Supported

|

Not supported

|

|

Set SOL Configuration Parameters

|

Transport

|

21h

|

Not Supported

|

Not supported

|

|

Get SOL Configuration Parameters

|

Transport

|

22h

|

Not Supported

|

Not supported

|

|

Get FRU Inventory Area Info

|

Storage

|

10h

|

Supported

|

Supported

|

|

Read FRU Data

|

Storage

|

11h

|

Supported

|

Supported

|

|

Write FRU Data

|

Storage

|

12h

|

Supported

|

Supported

|

|

Get SDR Repository Info

|

Storage

|

20h

|

Supported

|

Supported

|

|

Get SDR Repository Allocation Info

|

Storage

|

21h

|

Not Supported

|

Not supported

|

|

Reserve SDR Repository

|

Storage

|

22h

|

Supported

|

Supported

|

|

Get SDR

|

Storage

|

23h

|

Supported

|

Supported

|

|

Add SDR

|

Storage

|

24h

|

Supported

|

Supported

|

|

Partial Add SDR

|

Storage

|

25h

|

Supported

|

Supported

|

|

Delete SDR

|

Storage

|

26h

|

Supported

|

Supported

|

|

Clear SDR Repository

|

Storage

|

27h

|

Supported

|

Supported

|

|

Get SDR Repository Time

|

Storage

|

28h

|

Supported

|

Supported

|

|

Set SDR Repository Time

|

Storage

|

29h

|

Supported

|

Supported

|

|

Enter SDR Repository Update Mode

|

Storage

|

6F or 2A (Sun legacy)h

|

Not Supported

|

Not supported

|

|

Exit SDR Repository Update Mode

|

Storage

|

2Bh

|

Not Supported

|

Not supported

|

|

Run Initialization Agent

|

Storage

|

2Ch

|

Not Supported

|

Not supported

|

|

Get SEL Info

|

Storage

|

40h

|

Supported

|

Supported

|

|

Get SEL Allocation Info

|

Storage

|

41h

|

Supported

|

Supported

|

|

Reserve SEL

|

Storage

|

42h

|

Supported

|

Supported

|

|

Get SEL Entry

|

Storage

|

43h

|

Supported

|

Supported

|

|

Add SEL Entry

|

Storage

|

44h

|

Supported

|

Supported

|

|

Partial Add SEL Entry

|

Storage

|

45h

|

Supported

|

Supported

|

|

Delete SEL Entry

|

Storage

|

46h

|

Supported

|

Supported

|

|

Clear SEL

|

Storage

|

47hh

|

Supported

|

Supported

|

|

Get SEL Time

|

Storage

|

48h

|

Supported

|

Supported

|

|

Set SEL Time

|

Storage

|

49h

|

Supported

|

Supported

|

|

Get Auxiliary Log Status

|

Storage

|

5Ah

|

Not Supported

|

Not supported

|

|

Set Auxiliary Log Status

|

Storage

|

5Bh

|

Not Supported

|

Not supported

|

|

Set Event Receiver

|

S/E

|

00h

|

Supported

|

Supported

|

|

Get Event Receiver

|

S/E

|

01h

|

Supported

|

Supported

|

|

Event Message

|

S/E

|

02h

|

Supported

|

Supported

|

|

Get PEF Capabilities

|

S/E

|

10h

|

Supported

|

Supported

|

|

Arm PEF Postpone Timer

|

S/E

|

11h

|

Supported

|

Supported

|

|

Set PEF Configuration Parameters

|

S/E

|

12h

|

Supported

|

Supported

|

|

Get PEF Configuration Parameters

|

S/E

|

13h

|

Supported

|

Supported

|

|

Set Last Processed Event ID

|

S/E

|

14h

|

Supported

|

Supported

|

|

Get Last Processed Event ID

|

S/E

|

15h

|

Supported

|

Supported

|

|

Alert Immediate

|

S/E

|

16h

|

Supported

|

Supported

|

|

PET Acknowledge

|

S/E

|

17h

|

Supported

|

Supported

|

|

Get Device SDR Info

|

S/E

|

20h

|

Supported

|

Supported

|

|

Get Device SDR

|

S/E

|

21h

|

Supported

|

Supported

|

|

Reserve Device SDR Repository

|

S/E

|

22h

|

Supported

|

Supported

|

|

Get Sensor Reading Factors

|

S/E

|

23h

|

Supported

|

Supported

|

|

Set Sensor Hysteresis

|

S/E

|

24h

|

Supported

|

Supported

|

|

Get Sensor Hysteresis

|

S/E

|

25h

|

Supported

|

Supported

|

|

Set Sensor Threshold

|

S/E

|

26h

|

Supported

|

Supported

|

|

Get Sensor Threshold

|

S/E

|

27h

|

Supported

|

Supported

|

|

Set Sensor Event Enable

|

S/E

|

28h

|

Supported

|

Supported

|

|

Get Sensor Event Enable

|

S/E

|

29h

|

Supported

|

Supported

|

|

Re-arm Sensor Events

|

S/E

|

6F or 2A (Sun legacy)h

|

Supported

|

Supported

|

|

Get Sensor Event Status

|

S/E

|

2Bh

|

Supported

|

Supported

|

|

Get Sensor Reading

|

S/E

|

2Dh

|

Supported

|

Supported

|

|

Set Sensor Type

|

S/E

|

2Eh

|

Supported

|

Supported

|

|

Get Sensor Type

|

S/E

|

2Fh

|

Supported

|

Supported

|

|

Get PICMG Properties

|

PICMG

|

00h

|

Supported

|

Supported

|

|

Get Address Info

|

PICMG

|

01h

|

Supported

|

Supported

|

|

Get Shelf Address Info

|

PICMG

|

02h

|

Supported

|

Supported

|

|

Set Shelf Address Info

|

PICMG

|

03h

|

Supported

|

Supported

|

|

FRU Control

|

PICMG

|

04h

|

Supported

|

Supported

|

|

Get FRU LED Properties

|

PICMG

|

05h

|

Supported

|

Supported

|

|

Get LED Color Capabilities

|

PICMG

|

06h

|

Supported

|

Supported

|

|

Set FRU LED State

|

PICMG

|

07h

|

Supported

|

Supported

|

|

Get FRU LED State

|

PICMG

|

08h

|

Supported

|

Supported

|

|

Set IPMB State

|

PICMG

|

09h

|

Supported

|

Supported

|

|

Set FRU Activation Policy

|

PICMG

|

0Ah

|

Supported

|

Supported

|

|

Get FRU Activation Policy

|

PICMG

|

0Bh

|

Supported

|

Supported

|

|

Set FRU Activation

|

PICMG

|

0Ch

|

Supported

|

Supported

|

|

Get Device Locator Record ID

|

PICMG

|

0Dh

|

Supported

|

Supported

|

|

Set Port State

|

PICMG

|

0Eh

|

Supported

|

Supported

|

|

Get Port State

|

PICMG

|

0Fh

|

Supported

|

Supported

|

|

Compute Power Properties

|

PICMG

|

10h

|

Supported

|

Supported

|

|

Set Power Level

|

PICMG

|

11h

|

Supported

|

Supported

|

|

Get Power Level

|

PICMG

|

12h

|

Supported

|

Supported

|

|

Renegotiate Power

|

PICMG

|

13h

|

Not Supported

|

Supported

|

|

Get Fan Speed Properties

|

PICMG

|

14h

|

Supported

|

Supported

|

|

Set Fan Level

|

PICMG

|

15h

|

Supported

|

Supported

|

|

Get Fan Level

|

PICMG

|

16h

|

Supported

|

Supported

|

|

Bused Resource

|

PICMG

|

17h

|

Not Supported

|

Supported

|

|

Get IPMB Link Info

|

PICMG

|

18h

|

Supported

|

Supported

|

|

Get Shelf Power Allocation

|

PICMG

|

19h

|

Supported

|

Supported

|

|

Get Shelf Manager IPMB Address

|

PICMG

|

1Bh

|

Supported

|

Supported

|

|

Set Fan Policy

|

PICMG

|

1Ch

|

Not Supported

|

Not supported

|

|

Get Fan Policy

|

PICMG

|

1Dh

|

Not Supported

|

Not supported

|

|

FRU Control Capabilities

|

PICMG

|

1Eh

|

Supported

|

Supported

|

|

FRU Inventory Device Lock Control

|

PICMG

|

1Fh

|

Supported

|

Supported

|

|

FRU Inventory Device Write

|

PICMG

|

20h

|

Supported

|

Supported

|

|

Get Shelf Manager IP Addresses

|

PICMG

|

21h

|

Supported

|

Supported

|

|

Note - Commands marked by (*) are supported from the IPMB-0 side only if the configuration parameter ALLOW_ALL_COMMANDS_FROM_IPMB is set to TRUE.

|

Get Self Test Results IPMI Command

The Get Self Test Results command returns the results of the POST tests performed by the U-Boot utility when the ShMM is powered up. If all tests are passed, the status code 0x55 is returned. If any tests fail, the device-specific failure code 0x59 is returned and the third byte contains the following bit mask:

|

[7:5]

|

Reserved

|

|

[4]

|

1b = Ethernet test failed

|

|

[3]

|

1b = UART test failed

|

|

[2]

|

1b = U-Boot CRC test failed

|

|

[1]

|

1b = I2C test failed

|

|

[0]

|

1b = Memory test failed

|

IPMI OEM Extension Commands

In addition to the specification-defined IPMI commands listed in TABLE 3-1, the Shelf Manager implements several OEM-defined IPMI commands for the convenience of the System Manager. The Shelf Manager IPMI extension commands are listed in TABLE 3-2 and described in Appendix B.

TABLE 3-2 Shelf Manager IPMI Extension Commands

|

Command

|

NetFn

|

Opcode

|

|

Get Shelf FRU Record Data

|

3Eh

|

1h

|

|

Set Shelf FRU Record Data

|

2Eh

|

05h

|

|

Notify Shelf Manager About an Extracted FRU

|

2Eh

|

2h

|

|

Initiate Shelf Manager Switchover

|

3Eh

|

3h

|

|

Subscribe for Event Notifications

|

2Eh

|

4h

|

Shelf Manager Command-Line Interface

The Shelf Manager command-line interface (CLI) can be used to communicate with the intelligent management controllers of the shelf, with boards, and with the Shelf Manager itself, through text commands. The CLI is an IPMI-based set of commands that can be accessed directly or through a higher-level management application or a script. Administrators can access the CLI through a Telnet connection or the shelf management card serial port. Using the CLI, operators can access information about the current state of the shelf including current FRU population, current sensor values, threshold settings, recent events, and overall shelf health.

Starting the Command-Line Interface

To use the CLI, first log on to the Linux operation system on the shelf management card. Once logged in, run the executable clia from the command line with specific parameters. The first parameter is the command verb. The clia executable is located on the virtual root file system maintained by Linux running on the shelf management card. The clia executable connects to the main Shelf Manager software process, passes the command information to it, and retrieves the results. The Shelf Manager must be running prior to starting the CLI.

For example:

# clia ipmc 20

Pigeon Point Shelf Manager Command Line Interpreter

20: Entity: (d0, 0) Maximum FRU device ID: 20

PICMG Version 2.0

Hot Swap State: M4, Previous: M3, Last State Change Cause: Normal State Change (0)

#

|

If started without parameters, clia enters an interactive mode. In that mode, the program repeatedly issues a prompt to the terminal, accepts user input as the next command with parameters, executes that command, and shows the results on the terminal, until the user types the command exit or quit. For example:

# clia

Pigeon Point Shelf Manager Command Line Interpreter

CLI> ipmc 20

20: Entity: (d0, 0) Maximum FRU device ID: 20

PICMG Version 2.0

Hot Swap State: M4, Previous: M3, Last State Change Cause: Normal State Change (0)

CLI> exit

#

|

Shelf Manager CLI Commands

The Shelf Manager CLI implements the following commands. They are described in detail in Appendix A, Shelf Manager CLI Commands with a subsection for each command, in alphabetical order of the command names.

TABLE 3-3 Shelf Manager CLI Command Summary

|

Command

|

Parameters

|

Description

|

|

activate

|

IPMB address

FRU device ID

|

Activates the specified FRU.

|

|

airfilterreplaced

|

dd.mm.yyyy (optional)

|

Sets a date when the air filter should be replaced.

|

|

alarm

|

alarm type

clear

information

|

Activates or clears Telco alarms. Also displays alarm information

|

|

amcportstate

|

IPMB address

FRU device ID or AMC number (optional)

|

Shows AMC port state information for a specified AMC. If AMC number is not specified, the AMC port state information is reported for all active AMCs for the designated IPM controller.

|

|

board

|

slot number (optional)

|

Shows information about boards.

|

|

boardreset

|

slot number

|

Resets the specified ATCA board.

|

|

busres

|

subcommand, with its parameters

|

Performs the specified operation on the Bused E-Keying-managed resources.

|

|

console

|

slot number

|

Opens a console session on the node board in the specified slot.

|

|

deactivate

|

IPMB address

FRU device ID

|

Deactivates the specified FRU.

|

|

debuglevel

|

new debug level (optional)

|

Gets current debug level for the Shelf Manager or sets a new debug level.

|

|

exit|quit

|

|

Exits from the interpreter in interactive mode.

|

|

fans

|

IPMB address (optional)

FRU device ID (optional)

|

Shows information about fans.

|

|

flashupdate

|

Server IP address

Pathname to firmware image

|

Downloads and updates system firmware on the Sun Netra CP3x60 node boards from the specified server and pathname.

|

|

fru

|

IPMB address (optional)

FRU device ID (optional)

FRU type (optional)

|

Shows information about one or a group of FRUs in the shelf; FRUs are selected by type or by the parent IPM controller.

|

|

frucontrol

|

IPMB address

FRU device ID

Command

Options

|

Sends FRU Control command to the specified FRU.

|

|

frudata

|

IPMB address (optional)

FRU device ID (optional)

block/byte offset (optional)

data (optional)

|

Provides raw access to the FRU Information on the specified FRU.

|

|

frudatar

|

IPMB address

FRU device ID

File name

|

Reads the FRU data area of the specified FRU and stores the data in the specified file.

|

|

frudataw

|

IPMB address

FRU device ID

File name

|

Writes the FRU data in the specified file into the FRU data area of the specified FRU.

|

|

fruinfo

|

IPMB address

FRU device ID

|

Provides user-friendly FRU Information output.

|

|

getacousticlevel

|

ETSI

NEBS-A

NEBS-U

|

Shows the system acoustic level and fan speed.

|

|

getbootdev

|

IPMB address

FRU device ID or AMC address address

|

Shows system boot device parameter

|

|

getfanlevel

|

IPMB address (optional)

FRU device ID (optional)

|

Shows the current level of the fan controlled by the specified FRU.

|

|

getfanpolicy

|

IPMB address (optional)

FRU device ID (optional)

<site-type> (optional)

<site-number> (optional)

|

Retrieves information about Fan Tray(s) control mode and/or FRUs coverage by the specified Fan Tray(s). This command returns two different pieces of data: whether or not the site(s) are enabled/disabled for autonomous control by the Shelf Manager (based on Set Fan Policy commands), and whether or not the FRU site(s) are covered by the fans (according to the Fan Geography record).

|

|

getfruledstate

|

IPMB address (optional)

FRU device ID (optional)

LED ID or ALL (optional)

|

Shows the FRU LED state.

|

|

gethysteresis

|

IPMB address (optional)

sensor name (optional)

sensor number (optional)

|

Shows both the positive and negative hystereses of the specified sensor.

|

|

getipmbstate

|

IPMB address

IPMB link number (optional)

|

Shows the current state of IPMB-0 at the target address. If a link number is specified and the target IPMC is an IPMB switch, information about a specific link is shown.

|

|

getlanconfig

|

channel number

parameter name or number (optional)

set selector (optional)

|

Gets and shows a LAN configuration parameter for a specific channel.

|

|

getmgmtportroute

|

slot number

|

Displays the management port routing configuration.

|

|

getmuxconfig

|

slot number (optional)

|

Gets the multiplexer (MUX) configuration information from the shelf midplane records.

|

|

getpefconfig

|

parameter name or number (optional)

set selector (optional)

|

Gets and shows a PEF configuration parameter.

|

|

getsensoreventenable

|

IPMB address (optional)

sensor name (optional)

sensor number (optional)

|

Shows the current sensor event mask values for the supported events of the specified sensors.

|

|

getthreshold | threshold

|

IPMB address (optional)

sensor name (optional)

sensor number (optional)

|

Shows threshold information about a specific sensor.

|

|

help

|

|

Shows the list of supported commands.

|

|

ipmc

|

IPMB address (optional)

|

Shows information about one or all IPM controllers in the shelf.

|

|

localaddress

|

|

Retrieves the IPMB address of the current Shelf Manager.

|

|

minfanlevel

|

fan level (optional)

|

Shows or sets the minimum fan level.

|

|

mgmtportstate

|

slot

|

Employs the IPMC OEM command get ethernet port access to query the IPMC for management port state or port routing configuration.

|

|

muxstate

|

slot number

|

Querys the IPMC for the current multiplexer (MUX) state and port routing information.

|

|

networkelementid

|

Network Element Identifier (optional)

|

Allows getting or setting the Network Element Identifier.

|

|

poll

|

|

Initiates a poll of the IPM controllers on IPMB-0.

|

|

sel

|

IPMB address (optional)

number of items (optional)

|

Shows several most recent items from the System Event Log maintained on the target IPM controller.

|

|

sendamc

|

IPMB address

AMC address or FRU ID

NetFn

Command Code

Byte1 (optional)

... (optional)

ByteN (optional)

|

Transparently sends an arbitrary IPMI command to an Advanced Management Controller (AMC) that resides behind its correspondent IPM controller in a transparent way.

|

|

sendcmd

|

IPMB address

Network function

Command Code

Byte1 (optional)

... (optional)

ByteN (optional)

|

Transparently sends an arbitrary IPMI command to the target IPMC.

|

|

sensor

|

IPMB address (optional)

sensor name (optional)

sensor number (optional)

|

Shows information about one or a group of sensors; sensors are selected by IPM controller address, number or name.

|

|

sensordata

|

IPMB address (optional)

sensor name (optional)

sensor number (optional)

|

Shows value information for a specific sensor.

|

|

sensorread

|

IPMB address

sensor number

|

Shows raw value information for a specific sensor (ignoring any Sensor Data Record describing the sensor).

|

|

session

|

|

Shows information about active RMCP sessions.

|

|

setacousticlevel

|

ETSI

NEBS-A

NEBS-U

|

Sets the system acoustic level and fan speed.

|

|

setbooddev

|

IPMB address

FRU device ID or AMC address

boot device parameter

|

Sets system boot device parameter.

|

|

setextracted

|

IPMB address

FRU device ID

|

Notifies the Shelf Manager that the specified FRU has been physically extracted from the shelf.

|

|

setfanlevel

|

IPMB address

FRU device ID

level

|

Sets a new level for the fan controlled by the specified FRU.

|

|

setfanpolicy

|

IPMB address

FRU device ID

action to be taken: ENABLE or DISABLE

timeout (optional)

site type (optional)

site number (optional)

|

Enables or disables fan trays for cooling management in addition to the Fan Geography record if this one is presented in the Shelf FRU.

|

|

setfruledstate

|

IPMB address

FRU device ID

LED ID or ALL

LED operation

LED color (optional)

|

Sets the state of a specific LED or all LEDs for the given FRU.

|

|

sethysteresis

|

IPMB address

sensor name or sensor number

hysteresis to be set (pos or neg)

hysteresis value

|

Sets new hysteresis value for the specified sensor.

|

|

setipmbstate

|

IPMB address

IPMB bus name (A or B)

IPMB link number (optional)

action to be taken

|

Disables/enables IPMB-A or IPMB-B (or the specific IPMB link) on the target IPM controller.

|

|

setlanconfig

|

channel

parameter name or number

additional parameters

|

Sets the value of the LAN configuration parameter on the specified channel.

|

|

setlocked

|

IPMB address

FRU device ID

state

|

Sets the Locked bit for the specified FRU to the specified state (0 - unlock, 1 - lock).

|

|

setmgmtportroute

|

slot number

1 or 0

|

Sets the management port route, including front or rear access.

|

|

setmuxconfig

|

slot number

port1:route value

port2:route value

|

Sets the multiplexer (MUX) configuration information into the shelf midplane records for a specific slot. MUX configuration settings take effect during the blade activation.

|

|

setpefconfig

|

parameter name or number

set selector (optional)

parameter value

|

Sets a new value of a PEF configuration parameter.

|

|

setpowerlevel

|

IPMB address

FRU device ID

power level or OFF

Copy

|

Set the power level the specified FRU, turns off power to the FRU, and copies the desired level to the present levels.

|

|

setsensordata

|

IPMB address (optional)

sensor name

assertion events mask (optional)

deassertion events mask (optional)

event_data (optional)

|

Changes the reading, assertion or deassertion mask, or event data bytes for the specified sensor.

|

|

setsensoreventenable

|

IPMB address

sensor name

sensor number

global flags

assertion events mask (optional)

deassertion events mask (optional)

|

Changes the event enable masks for a specific sensor.

|

|

setthreshold

|

IPMB address

sensor name

sensor number

threshold type

threshold value

|

Changes a specific threshold value (upper/lower, critical/non-critical/non-recoverable) for a specific sensor.

|

|

setuserlabel

|

shelf name

slot number name

|

Configures user assigned names for the shelf and the boards. Board names are assigned to slot numbers.

|

|

shelf

|

subcommand, with its parameters

|

Shows general information about the shelf; several subcommands allow setting shelf attributes and getting additional information about specific areas.

|

|

shelfaddress

|

Shelf Address string (optional)

|

Gets or sets the Shelf Address field of the Address Table within Shelf FRU Information.

|

|

shmstatus

|

|

Shows the Shelf Manager Active/Backup status.

|

|

showhost

|

slot number

|

Displays version information about the firmware on certain Sun Netra CP3x60 node boards.

|

|

showunhealthy

|

|

Shows the unhealthy components of the shelf.

|

|

switchover

|

|

Initiates a switchover to the backup Shelf Manager.

|

|

terminate

|

|

Terminates the Shelf Manager without rebooting the shelf management card.

|

|

user

|

subcommand, with its parameters

|

Shows information about the RMCP user accounts on the Shelf Manager and provides a simple way to add, delete and modify user accounts.

|

|

userlabel

|

shelf

slot

slot slot-number (optional)

|

Displays a user assigned name for the shelf and boards. Board names are assigned to slot numbers.

|

|

version

|

|

Shows the Shelf Manager version information.

|

Most informational commands support brief and verbose modes of execution, differing in the amount of information provided. Brief mode is the default (standard); verbose mode is selected by using the option -v in the command line, directly after the command and before the positional arguments. Commands that are executed on the backup Shelf Manager can only access objects (such as sensors, FRUs, IPM controllers) that are local to the backup Shelf Manager.

To help the user to determine whether a specific command is being executed on the active or on the backup Shelf Manager, the following message is issued when a CLI command is executed on the backup Shelf Manager: Running on the Backup Shelf Manager, with limited functionality.

Monitoring Your System

The Shelf Manager CLI provides many commands to monitor your system and display system status. This section describes various ways to monitor your system. See Shelf Manager CLI Commands or Appendix A, Shelf Manager CLI Commands for more information.

Displaying Board and IPMC Information

Board information includes information about each IPM controller in the range of IPMB addresses allocated to ATCA slots, and about each additional FRU controlled by these controllers. The range of IPMB addresses is 82h-A0h for PICMG 3.0 systems, where boards have IPM controllers on them.

Examples for the following tasks are provided showing the commands used and their outputs.

To Display Standard Information About All Boards in the Server

To Display Standard Information About All Boards in the Server

In the example, only the boards in physical slots 3, 4, 5, 7, and 8 are present.

# clia board

Pigeon Point Shelf Manager Command Line Interpreter

Physical Slot # 3

92: Entity: (0xa0, 0x60) Maximum FRU device ID: 0x01

PICMG Version 2.2

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

92: FRU # 0

Entity: (0xa0, 0x60)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “NetraCP-3010”

Physical Slot # 4

8e: Entity: (0xa0, 0x60) Maximum FRU device ID: 0x01

PICMG Version 2.1

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

8e: FRU # 0

Entity: (0xa0, 0x60)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “NetraCP-3060”

8e: FRU # 1

Entity: (0xc1, 0x61)

Hot Swap State: M4 (Active), Previous: M7 (Communication Lost), Last State Change Cause: Normal State Change (0x0)

Device ID String: “SB AMC-HD-A-80X”

Physical Slot # 5

8a: Entity: (0xa0, 0x60) Maximum FRU device ID: 0x00

PICMG Version 2.1

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

8a: FRU # 0

Entity: (0xa0, 0x60)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “NetraCP-3020”

Physical Slot # 7

82: Entity: (0xa0, 0x60) Maximum FRU device ID: 0x01

PICMG Version 2.1

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

82: FRU # 0

Entity: (0xa0, 0x60)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “ATS1160”

82: FRU # 1

Entity: (0xc0, 0x60)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “TM1460A RTM”

Physical Slot # 8

84: Entity: (0xa0, 0x60) Maximum FRU device ID: 0x01

PICMG Version 2.1

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

84: FRU # 0

Entity: (0xa0, 0x60)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “CP3140H-BEG”

84: FRU # 1

Entity: (0xc0, 0x60)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “XCP3040H-RTC”

#

|

To Display Detailed Information About a Board

To Display Detailed Information About a Board

This example shows detailed information about the board in physical slot 14.

# clia board -v 4

Pigeon Point Shelf Manager Command Line Interpreter

Physical Slot # 4

8e: Entity: (0xa0, 0x60) Maximum FRU device ID: 0x01

PICMG Version 2.1

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID: 0x00, Revision: 0, Firmware: 0.210, IPMI ver 1.5

Manufacturer ID: 00006F or 2A (Sun legacy), Product ID: 0bf4, Auxiliary Rev: 00000000

Device ID String: "NetraCP-3060"

Global Initialization: 0xc, Power State Notification: 0xc, Device Capabilities: 0x29

Controller provides Device SDRs

Supported features: 0x29

"Sensor Device" "FRU Inventory Device" "IPMB Event Generator"

8e: Base Interface (0x00), Channel: 1

Link: Enabled Ports: 1

Peer Addr: 0x82, Link Type: PICMG 3.0 Base Interface 10/100/1000 BASE-T, Ext: 0 (10/100/1000 BASE-T)

8e: Base Interface (0x00), Channel: 2

Link: Enabled Ports: 1

Peer Addr: 0x84, Link Type: PICMG 3.0 Base Interface 10/100/1000 BASE-T, Ext: 0 (10/100/1000 BASE-T)

8e: Fabric Interface (0x01), Channel: 1

Link: Enabled Ports: 1

Peer Addr: 0x82, Link Type: PICMG 3.1 Ethernet Fabric Interface, Ext: 0

8e: Fabric Interface (0x01), Channel: 2

Link: Enabled Ports: 1

Peer Addr: 0x84, Link Type: PICMG 3.1 Ethernet Fabric Interface, Ext: 0

8e: FRU # 0

Entity: (0xa0, 0x60)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: "NetraCP-3060"

Site Type: 0x00, Site Number: 04

Current Power Level: 0x01, Maximum Power Level: 0x01, Current Power Allocation: 174.0 Watts

8e: FRU # 1

Entity: (0xc1, 0x61)

Hot Swap State: M4 (Active), Previous: M7 (Communication Lost), Last State Change Cause: Normal State Change (0x0)

Device Type: "FRU Inventory Device behind management controller" (0x10), Modifier 0x0

Device ID String: "SB AMC-HD-A-80X"

Current Power Level: 0x01, Maximum Power Level: 0x01, Current Power Allocation: 21.1 Watts

#

|

To List the Sensors on a Board

To List the Sensors on a Board

In this example, a list of sensors on the board at IPMB address 92 is displayed.

# clia sensor 92

Pigeon Point Shelf Manager Command Line Interpreter

92: LUN: 0, Sensor # 0 ("FRU 0 Hot Swap")

Type: Discrete (0x6f), "Hot Swap" (0xf0)

Belongs to entity: (0xa0, 96) [FRU # 0]

92: LUN: 0, Sensor # 2 ("IPMB Physical")

Type: Discrete (0x6f), "IPMB Link" (0xf1)

Belongs to entity: (0xa0, 96) [FRU # 0]

92: LUN: 0, Sensor # 4 ("CPU1 Temp")

Type: Threshold (0x01), "Temperature" (0x01)

Belongs to entity: (0x3, 96) [FRU # 0]

92: LUN: 0, Sensor # 5 ("CPU2 Temp")

Type: Threshold (0x01), "Temperature" (0x01)

Belongs to entity: (0x3, 96) [FRU # 0]

92: LUN: 0, Sensor # 6 ("Inlet Temp")

Type: Threshold (0x01), "Temperature" (0x01)

Belongs to entity: (0x3, 96) [FRU # 0]

92: LUN: 0, Sensor # 7 ("+12.0V")

Type: Threshold (0x01), "Voltage" (0x02)

Belongs to entity: (0x14, 96) [FRU # 0]

92: LUN: 0, Sensor # 8 ("-12.0V")

Type: Threshold (0x01), "Voltage" (0x02)

Belongs to entity: (0x14, 96) [FRU # 0]

92: LUN: 0, Sensor # 9 ("+5.0V VCC")

Type: Threshold (0x01), "Voltage" (0x02)

Belongs to entity: (0x14, 96) [FRU # 0]

92: LUN: 0, Sensor # 10 ("+3.3V Main")

Type: Threshold (0x01), "Voltage" (0x02)

Belongs to entity: (0x14, 96) [FRU # 0]

92: LUN: 0, Sensor # 11 ("+3.3V StandBy")

Type: Threshold (0x01), "Voltage" (0x02)

Belongs to entity: (0x14, 96) [FRU # 0]

92: LUN: 0, Sensor # 12 ("VBAT")

Type: Threshold (0x01), "Voltage" (0x02)

Belongs to entity: (0x14, 96) [FRU # 0]

92: LUN: 0, Sensor # 13 ("VDD Core0")

Type: Threshold (0x01), "Voltage" (0x02)

Belongs to entity: (0x14, 96) [FRU # 0]

92: LUN: 0, Sensor # 14 ("VDD Core1")

Type: Threshold (0x01), "Voltage" (0x02)

Belongs to entity: (0x14, 96) [FRU # 0]

92: LUN: 0, Sensor # 15 ("VTT 1.25V")

Type: Threshold (0x01), "Voltage" (0x02)

Belongs to entity: (0x14, 96) [FRU # 0]

92: LUN: 0, Sensor # 16 ("VDD 1.2V")

Type: Threshold (0x01), "Voltage" (0x02)

Belongs to entity: (0x14, 96) [FRU # 0]

Belongs to entity: (0x14, 96) [FRU # 0]

92: LUN: 0, Sensor # 17 ("VCC TM 2.5V")

Type: Threshold (0x01), "Voltage" (0x02)

Belongs to entity: (0x14, 96) [FRU # 0]

92: LUN: 0, Sensor # 18 ("VDD +2.5V")

Type: Threshold (0x01), "Voltage" (0x02)

Belongs to entity: (0x14, 96) [FRU # 0]

92: LUN: 0, Sensor # 19 ("VDD +1.5V")

Type: Threshold (0x01), "Voltage" (0x02)

Belongs to entity: (0x14, 96) [FRU # 0]

92: LUN: 0, Sensor # 20 ("System Event")

Type: Discrete (0x6f), "System Event" (0x12)

Belongs to entity: (0xa0, 96) [FRU # 0]

92: LUN: 0, Sensor # 3 ("BMC Watchdog")

Type: Discrete (0x6f), "Watchdog 2" (0x23)

Belongs to entity: (0x3, 96) [FRU # 0]

92: LUN: 0, Sensor # 21 ("RTM Presence")

Type: Discrete (0x6f), "Entity Presence" (0x25)

Belongs to entity: (0xa0, 96) [FRU # 0]

#

|

To Display Data from a Sensor on a Board

To Display Data from a Sensor on a Board

In the example, information about sensor number 3 (CPU2 Temp) on the board at IPMB address 92 is displayed.

# clia sensor 92 9

Pigeon Point Shelf Manager Command Line Interpreter

92: LUN: 0, Sensor # 9 ("+5.0V VCC")

Type: Threshold (0x01), "Voltage" (0x02)

Belongs to entity: (0x14, 96) [FRU # 0]

|

To List All IPMCs in the Server

To List All IPMCs in the Server

This example shows the typical output for the ipmc command.

# clia ipmc

Pigeon Point Shelf Manager Command Line Interpreter

10: Entity: (0xf0, 0x60) Maximum FRU device ID: 0x08

PICMG Version 2.1

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

20: Entity: (0xf0, 0x1) Maximum FRU device ID: 0x08

PICMG Version 2.1

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

82: Entity: (0xa0, 0x60) Maximum FRU device ID: 0x00

PICMG Version 2.1

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

88: Entity: (0xa0, 0x60) Maximum FRU device ID: 0x00

Hot Swap State: M7 (Communication Lost), Previous: M4 (Active), Last State Change Cause: Communication Lost (0x4)

92: Entity: (0xa0, 0x60) Maximum FRU device ID: 0x00

PICMG Version 2.1

Hot Swap State: M4 (Active), Previous: M7 (Communication Lost), Last State Change Cause: Communication Lost (0x4)

96: Entity: (0xa0, 0x60) Maximum FRU device ID: 0x00

Hot Swap State: M7 (Communication Lost), Previous: M6 (Deactivation In Progress), Last State Change Cause: Communication Lost (0x4)

20: Entity: (0xf0, 0x1) Maximum FRU device ID: 0x08

PICMG Version 2.1

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

|

To Display Information About a Specific IPM Controller

To Display Information About a Specific IPM Controller

In the example, basic information about the IPM controller at address 9C is displayed.

# clia ipmc 9c

Pigeon Point Shelf Manager Command Line Interpreter

9c: Entity: (0xd0, 0x0) Maximum FRU device ID: 0x08

PICMG Version 2.0

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

#

|

To Display Detailed Information About the IPM Controller

To Display Detailed Information About the IPM Controller

In the example, detailed information about the IPM controller at address 9C is displayed.

# clia ipmc -v 9c

Pigeon Point Shelf Manager Command Line Interpreter

9c: Entity: (0xd0, 0x0) Maximum FRU device ID: 0x08

PICMG Version 2.0

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID: 0x00, Revision: 0, Firmware: 1.01, IPMI ver 1.5

Manufacturer ID: 00315a (PICMG), Product ID: 0000, Auxiliary Rev: 01ac10ac

Device ID String: "PPS Sentry 6"

Global Initialization: 0x0, Power State Notification: 0x0, Device Capabilities: 0x29

Controller provides Device SDRs

Supported features: 0x29

"Sensor Device" "FRU Inventory Device" "IPMB Event Generator"

#

|

Displaying FRU Information

You can display information about all the FRUs in the system by issuing the clia fru command without any parameters, or you can display information for specific FRU by supplying the FRU’s address, and optionally the FRU ID. See Physical Address to Logical Slot Mapping for a mapping of chassis slot number to physical address to IMPB address.

In the following example, in the line “20: FRU # 1“, 20 is the midplane’s IPMB address and 1 is the FRU device ID.

# clia fru

Pigeon Point Shelf Manager Command Line Interpreter

20: FRU # 1

Entity: (0xf2, 0x60)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: "Shelf EEPROM 1"

|

IPMI FRU Information Layout

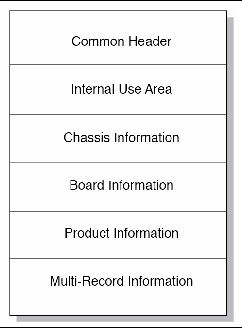

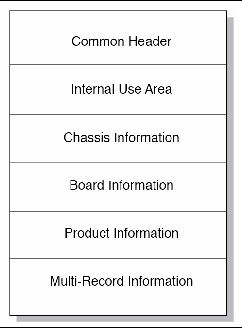

FIGURE 3-1 shows how the IPMI FRU information is organized. Each partition provides specific types of data.

- The Common Header contains area offsets.

- The Internal Use area is used to store proprietary data.

- The Chassis Information area contains chassis type, part number, serial number.

- The Board Information area contains manufacturer timestamp, manufacturer, product name, part/serial number.

- The Product Information area contains manufacturer, product name, part/serial number, version.

- The MultiRecord area contains dynamic data.

FIGURE 3-1 IPMI FRU Information Layout

Environment FRUs

Environment FRUs include midplane, shelf management cards, fans, power entry modules (PEMs), and the shelf alarm panel (SAP). All the environment FRUs have IPMI FRU information only, which are provided and programmed by third-party vendors.

The midplane FRU information includes the Sun part number as well as the third-party part number. Sun also adds additional system information such as slot, vlan, vtag, and other data, in the multirecord area of the midplane FRU information. The midplane FRU information is stored in two identical EEPROMs. Any change in one EEPROM is automatically made in the other EEPROM.

Blade FRUs

The Sun Netra CT900 server switch boards (located in slots 7 and 8) have IPMI FRU information only. The Sun node boards have two separate EEPROMS; one contains IPMI FRU information and the other contains Sun FRU information.

Examples

Examples for the following tasks are provided showing the commands used and their outputs.

To Display Standard Information About All FRUs in the Shelf

To Display Standard Information About All FRUs in the Shelf

This example shows the standard FRU information displayed by the fru command with no arguments.

# clia fru

Pigeon Point Shelf Manager Command Line Interpreter

10: FRU # 0

Entity: (0xf0, 0x60)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “ShMM-500”

12: FRU # 0

Entity: (0xf0, 0x60)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “ShMM-500”

20: FRU # 0

Entity: (0xf0, 0x1)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “PPS BMC”

20: FRU # 1

Entity: (0xf2, 0x60)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “Shelf EEPROM 1”

20: FRU # 2

Entity: (0xf2, 0x61)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “Shelf EEPROM 2”

20: FRU # 3

Entity: (0x1e, 0x0)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “Fan Tray 0”

20: FRU # 4

Entity: (0x1e, 0x1)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “Fan Tray 1”

20: FRU # 5

Entity: (0x1e, 0x2)

Device ID String: “Fan Tray 1” Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “Fan Tray 2”

20: FRU # 6

Entity: (0xa, 0x60)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “PEM A”

20: FRU # 7

Entity: (0xa, 0x61)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “PEM B”

20: FRU # 8

Entity: (0x7, 0x6f)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “SAP Board”

82: FRU # 0

Entity: (0xa0, 0x60)

Hot Swap State: M4 (Active), Previous: M4 (Active, Last State Change Cause: Normal State (0x0)

Device ID String: “NetraCP-3140”

84: FRU # 0

Entity: (0xa0, 0x60)

Hot Swap State: M4 (Active), Previous: M4 (Active, Last State Change Cause: Normal State Change (0x0)

Device ID String: "NetraCP-3140"

8e: FRU # 0

Entity: (0xa0, 0x60)

Hot Swap State: M4 (Active), Previous: M4 (Active), Last State Change Cause: Normal State Change (0x0)

Device ID String: "NetraCP-3010

9a: FRU # 0

Entity: (0xa0, 0x60)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: “NetraCP-3020”

|

To Display Standard Information About All FRUs at Address 9C

To Display Standard Information About All FRUs at Address 9C

In this example, only FRU information is displayed for all FRUs at physical address 9C.

# clia fru 9a

Pigeon Point Shelf Manager Command Line Interpreter

9a: FRU # 0

Entity: (0ad0, 0x60)

Hot Swap State: M4 (Active), Previous: M3 (Activation In Process), Last State Change Cause: Normal State Change (0x0)

Device ID String: "NetraCP-3020"

#

|

To Display Detailed Information About FRU #1 in the Shelf, Address 20

To Display Detailed Information About FRU #1 in the Shelf, Address 20

In this example, detailed FRU information is displayed for FRU device ID 1 on the chassis, physical address 20.

# clia fruinfo 20 1

Pigeon Point Shelf Manager Command Line Interpreter

20: FRU # 1, FRU Info

Common Header: Format Version = 1

Internal Use Area:

Version = 1

Chassis Info Area:

Version = 1

Chassis Type = (23)

Chassis Part Number = 11592-450

Chassis Serial Number =

Board Info Area:

Version = 1

Language Code = 25

Mfg Date/Time = Jun 16 00:00:00 2005 (4973760 minutes since 1996)

Board Manufacturer = Schroff

Board Product Name = ShMM-ACB-III Shelf Manager (Radial IPMB)

Board Serial Number = 0000001

Board Part Number = 21593-251

FRU Programmer File ID = Schroff_11592450_AA.inf

Product Info Area:

Version = 1

Language Code = 25

Manufacturer Name = Schroff

Product Name = 12U 14-Slot ATCA Chassis

Product Part / Model# = 11592-450

Product Version = Dual Star (Radial IPMB)

Product Serial Number = 0000001

Asset Tag =

FRU Programmer File ID = Schroff_11592450_AA.inf

Multi Record Area:

PICMG Shelf Manager IP Connection Record (ID=0x13)

Version = 1

Record Type = Management Access Record

Version = 2

Sub-Record Type: Component Name (0x05)

PICMG Address Table Record (ID=0x10)

Version = 0

PICMG Backplane Point-to-Point Connectivity Record (ID=0x04)

Version = 0

PICMG Backplane Point-to-Point Connectivity Record (ID=0x04)

Version = 0

PICMG Shelf Activation And Power Management Record (ID=0x12)

Version = 0

PICMG Shelf Power Distribution Record (ID=0x11)

Version = 0

PICMG Radial IPMB-0 Link Mapping Record (ID=0x15)

Version = 0

Record Type = 0xf0 OEM Defined Record

Version = 2

Manufacturer ID = 0x303833

|

To Display Detailed Information About FRU #0 on a Node Board at Address 8e.

To Display Detailed Information About FRU #0 on a Node Board at Address 8e.

In this example, detailed FRU information is displayed for FRU device ID 0 on a node board installed at physical address 8e.

# clia fruinfo 8e 0

Pigeon Point Shelf Manager Command Line Interpreter

8e: FRU # 0, FRU Info

Common Header: Format Version = 1

Board Info Area:

Version = 1

Language Code = 25

Mfg Date/Time = Mar 20 00:00:00 2006 (5372640 minutes since 1996)

Board Manufacturer = Sun Microsystems, Inc.

Board Product Name = NetraCP-3060

Board Serial Number = 00000000000000000001

Board Part Number = 00000000000005017313

FRU Programmer File ID = fru-info.inf

Product Info Area:

Version = 1

Language Code = 25

Manufacturer Name = Sun Microsystems, Inc.

Product Name = NetraCP-3060

Product Part / Model# = 00000000000005017313

Product Version = Rev 1.00TEST

Product Serial Number = 00000000000000000001

Asset Tag =

FRU Programmer File ID = fru-info.inf

Multi Record Area:

PICMG Board Point-to-Point Connectivity Record (ID=0x14)

Version = 0

AMC Carrier Information Table Record (ID=0x1a)

Version = 0

AMC Carrier Activation and Current Management Record (ID=0x17)

Version = 0

AMC Carrier Point-to-Point Connectivity Record (ID=0x18)

Version = 0

AMC Carrier Point-to-Point Connectivity Record (ID=0x19)

Version = 0

AMC Carrier Point-to-Point Connectivity Record (ID=0x19)

Version = 0

|

To Display FRU Information in Raw Form

To Display FRU Information in Raw Form

In this example, FRU information is displayed in raw form for all FRUs and for a specific FRU.

# clia frudata

Pigeon Point Shelf Manager Command Line Interpreter

10: FRU # 0 Raw FRU Info Data

FRU Info size: 435

12: FRU # 0 Raw FRU Info Data

FRU Info size: 435

20: FRU # 0 Raw FRU Info Data

FRU Info size: 152

20: FRU # 1 Raw FRU Info Data

FRU Info size: 8192

20: FRU # 2 Raw FRU Info Data

FRU Info size: 8192

20: FRU # 3 Raw FRU Info Data

FRU Info size: 2048

20: FRU # 4 Raw FRU Info Data

FRU Info size: 2048

20: FRU # 5 Raw FRU Info Data

FRU Info size: 2048

20: FRU # 6 Raw FRU Info Data

FRU Info size: 2048

20: FRU # 7 Raw FRU Info Data

FRU Info size: 2048

20: FRU # 8 Raw FRU Info Data

FRU Info size: 2048

20: FRU # 254 Raw FRU Info Data

FRU Info size: 3068

9a: FRU # 0 Raw FRU Info Data

FRU Info size: 512

#

# clia frudata 20 1 0

Pigeon Point Shelf Manager Command Line Interpreter

20: FRU # 1 Block # 0 Raw FRU Info Data

FRU Info size: 8192

01 01 22 24 31 3E 00 49 01 A0 A1 A2 A3 A4 A5 A6

A7 A8 A9 AA AB AC AD E0 E1 E2 E3 E4 E5 E6 D0 D1

|

To Display FRU Information in User-Friendly Format

To Display FRU Information in User-Friendly Format

This example shows a user-friendly version of the FRU information.

# clia fruinfo 20 1

Pigeon Point Shelf Manager Command Line Interpreter

20: FRU # 1, FRU Info

Common Header: Format Version = 1

Internal Use Area:

Version = 1

Chassis Info Area:

Version = 1

Chassis Type = (23)

Chassis Part Number = 11592-450

Chassis Serial Number =

Board Info Area:

Version = 1

Language Code = 25

Mfg Date/Time = Jun 16 00:00:00 2005 (4973760 minutes since 1996)

Board Manufacturer = Schroff

Board Product Name = ShMM-ACB-III Shelf Manager (Radial IPMB)

Board Serial Number = 0000001

Board Part Number = 21593-251

FRU Programmer File ID = Schroff_11592450_AA.inf

Product Info Area:

Version = 1

Language Code = 25

Manufacturer Name = Schroff

Product Name = 12U 14-Slot ATCA Chassis

Product Part / Model# = 11592-450

Product Version = Dual Star (Radial IPMB)

Product Serial Number = 0000001

Asset Tag =

FRU Programmer File ID = Schroff_11592450_AA.inf

Multi Record Area:

PICMG Shelf Manager IP Connection Record (ID=0x13)

Version = 1

Record Type = Management Access Record

Version = 2

Sub-Record Type: Component Name (0x05)

PICMG Address Table Record (ID=0x10)

Version = 0

PICMG Backplane Point-to-Point Connectivity Record (ID=0x04)

Version = 0

PICMG Backplane Point-to-Point Connectivity Record (ID=0x04)

Version = 0

PICMG Shelf Activation And Power Management Record (ID=0x12)

Version = 0

PICMG Shelf Power Distribution Record (ID=0x11)

Version = 0

PICMG Radial IPMB-0 Link Mapping Record (ID=0x15)

Version = 0

Record Type = 0xf0 OEM Record

Version = 2

UNKNOWN Manufacturer ID = 0x303833

|

Displaying Shelf Information

You can use the clia shelf command with one of its valid parameters to display FRU information for key shelf FRUs. You can also get current operating data for the shelf and modify some fields in the Shelf FRU information. The valid shelf parameters are:

- cooling_state or cs

- fans_state or fs

- address_table or at

- power_distribution or pd

- power_management or pm

- pci_connectivity or pcic

- ha_connectivity or ha

- h110_connectivity or h1110c

- point-to-point_connectivity or ppc

See Display Shelf FRU Information for more information.

Examples

Examples for the following tasks are provided showing the commands used and their outputs.

To Display Shelf Cooling Status

To Display Shelf Cooling Status

This example shows the commands and outputs for displaying the shelf’s cooling status.

# clia shelf cooling_state

Pigeon Point Shelf Manager Command Line Interpreter

Cooling state: "Normal"

# clia shelf -v cooling_state

Pigeon Point Shelf Manager Command Line Interpreter

Cooling state: "Normal"

Sensor(s) at this state: (0x9a,4,0) (0x9a,5,0) (0x10,2,0) (0x9a,3,0)

(0x20,120,0) (0x20,121,0) (0x20,122,0) (0x20,123,0)

(0x20,200,0) (0x20,201,0) (0x20,240,0) (0x20,241,0)

(0x20,242,0)

|

To Display Shelf Fan Status

To Display Shelf Fan Status

The commands to display the fan status and the outputs are in this example.

# clia shelf fans_state

Pigeon Point Shelf Manager Command Line Interpreter

Fans state: "Normal"

# clia shelf -v fans_state

Pigeon Point Shelf Manager Command Line Interpreter

Fans state: "Normal"

Sensor(s) at this state: (0x10,7,0) (0x10,8,0) (0x10,9,0) (0x10,10,0)

(0x10,11,0) (0x10,12,0)

#

|

To Display Address Table

To Display Address Table

This example shows the command and output for displaying the shelf address table.

# clia shelf address_table

Pigeon Point Shelf Manager Command Line Interpreter

PICMG Address Table Record (ID=0x10)

Version = 0

Shelf Address = 1

Address Table Entries# = 16

Hw Addr: 41, Site # 7, Type: "AdvancedTCA Board" 00

Hw Addr: 42, Site # 8, Type: "AdvancedTCA Board" 00

Hw Addr: 43, Site # 6, Type: "AdvancedTCA Board" 00

Hw Addr: 44, Site # 9, Type: "AdvancedTCA Board" 00

Hw Addr: 45, Site # 5, Type: "AdvancedTCA Board" 00

Hw Addr: 46, Site # 10, Type: "AdvancedTCA Board" 00

Hw Addr: 47, Site # 4, Type: "AdvancedTCA Board" 00

Hw Addr: 48, Site # 11, Type: "AdvancedTCA Board" 00

Hw Addr: 49, Site # 3, Type: "AdvancedTCA Board" 00

Hw Addr: 4a, Site # 12, Type: "AdvancedTCA Board" 00

Hw Addr: 4b, Site # 2, Type: "AdvancedTCA Board" 00

Hw Addr: 4c, Site # 13, Type: "AdvancedTCA Board" 00

Hw Addr: 4d, Site # 1, Type: "AdvancedTCA Board" 00

Hw Addr: 4e, Site # 14, Type: "AdvancedTCA Board" 00

Hw Addr: 08, Site # 1, Type: "Dedicated ShMC" 03

Hw Addr: 09, Site # 2, Type: "Dedicated ShMC" 03

|

To Display Power Management Information

To Display Power Management Information

An example of the command and its output are shown in this example.

# clia shelf pm

Pigeon Point Shelf Manager Command Line Interpreter

PICMG Shelf Activation And Power Management Record (ID=0x12)

Version = 0

Allowance for FRU Activation Readiness: 20 seconds

FRU Activation and Power Description Count: 19

Hw Address: 41, FRU ID: 0xfe, Maximum FRU Power Capabilities: 200 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

Hw Address: 42, FRU ID: 0xfe, Maximum FRU Power Capabilities: 200 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

Hw Address: 43, FRU ID: 0xfe, Maximum FRU Power Capabilities: 200 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

Hw Address: 44, FRU ID: 0xfe, Maximum FRU Power Capabilities: 200 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

Hw Address: 45, FRU ID: 0xfe, Maximum FRU Power Capabilities: 200 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

Hw Address: 46, FRU ID: 0xfe, Maximum FRU Power Capabilities: 200 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

Hw Address: 47, FRU ID: 0xfe, Maximum FRU Power Capabilities: 200 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

Hw Address: 48, FRU ID: 0xfe, Maximum FRU Power Capabilities: 200 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

Hw Address: 49, FRU ID: 0xfe, Maximum FRU Power Capabilities: 200 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

Hw Address: 4a, FRU ID: 0xfe, Maximum FRU Power Capabilities: 200 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

Hw Address: 4b, FRU ID: 0xfe, Maximum FRU Power Capabilities: 200 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

Hw Address: 4c, FRU ID: 0xfe, Maximum FRU Power Capabilities: 200 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

Hw Address: 4d, FRU ID: 0xfe, Maximum FRU Power Capabilities: 200 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

Hw Address: 4e, FRU ID: 0xfe, Maximum FRU Power Capabilities: 200 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

Hw Address: 44, FRU ID: 0xfe, Maximum FRU Power Capabilities: 200 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

Hw Address: 45, FRU ID: 0xfe, Maximum FRU Power Capabilities: 200 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

Hw Address: 08, FRU ID: 0xfe, Maximum FRU Power Capabilities: 24 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

Hw Address: 09, FRU ID: 0xfe, Maximum FRU Power Capabilities: 24 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

Hw Address: 20, FRU ID: 0xfe, Maximum FRU Power Capabilities: 100 Watts

Shelf Manager Controlled Activation: Enabled

Delay Before Next Power On: 0.0 seconds

#

|

To Display Power Distribution Information

To Display Power Distribution Information

The example shows the command and output for getting the shelf’s power distribution information.

# clia shelf pd

Pigeon Point Shelf Manager Command Line Interpreter

PICMG Shelf Power Distribution Record (ID=0x11)

Version = 0

Feed count: 8

Feed 00:

Maximum External Available Current: 25.0 Amps

Maximum Internal Current: 25.0 Amps

Minimum Expected Operating Voltage: -40.5 Volts

Actual Power Available: 1012.500 Watts

Currently Used Power: 30.000 Watts

Feed-to-FRU Mapping entries count: 3

FRU Addr: 49, FRU ID: 0xfe

FRU Addr: 4b, FRU ID: 0xfe

FRU Addr: 4d, FRU ID: 0xfe

Feed 01:

Maximum External Available Current: 25.0 Amps

Maximum Internal Current: 25.0 Amps

Minimum Expected Operating Voltage: -40.5 Volts

Actual Power Available: 1012.500 Watts

Currently Used Power: 30.000 Watts

Feed-to-FRU Mapping entries count: 3

FRU Addr: 49, FRU ID: 0xfee

FRU Addr: 4b, FRU ID: 0xfe

FRU Addr: 4d, FRU ID: 0xfe

Feed 02:

Maximum External Available Current: 25.0 Amps