|

Permission

|

Topic

|

Usage

|

|

Access Admin

|

Admin

|

On the PC, with this permission, the

Admin button on the SIM Login screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Auto-Receive Stores

|

Admin

|

On the PC, with this permission, the

Auto-Receive Stores button on the Store Admin screen is displayed and

enabled.

Without this permission, the button is not displayed.

|

|

Access Buddy Store

|

Admin

|

On the PC, with this permission, the

Buddy Store button on the Store Admin screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Container Lookup

|

Admin

|

On the HH, with this permission, the

Container Lookup menu option on the Lookups menu is displayed.

Without this permission, the menu option is not displayed.

On MAF, with this permission, the user will have access to functionality

within Container Lookups .

Without this permission, the user will not have access to Container Lookup

functions.

On the PC, with this permission, the Container Lookup button on the Lookups

screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

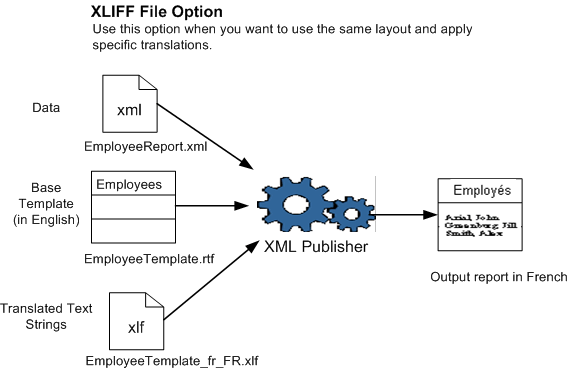

Access Customize Translations

|

Admin

|

On the PC, with this permission, the

Customize Translations button on the UI Config screen is displayed and

enabled.

Without this permission, the button is not displayed.

|

|

Access Extended Attribute

|

Admin

|

On the PC, with this permission, the Ext.

Attribute button on the Setup screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Extended Attribute Dept. Assign

|

Admin

|

On the PC, with this permission, the

Assign to Dept. button on the Extended Attributes screen is displayed and

enabled. Without this permission, the button is not displayed.

|

|

Access Extended Attribute Setup

|

Admin

|

On the PC, with this permission, the

Setup Attributes button on the Extended Attributes screen is displayed and

enabled.

Without this permission, the button is not displayed.

|

|

Access Finisher Lookup

|

Admin

|

On the PC, with this permission, the

Finisher Lookup button on the Lookups screen is displayed and enabled.

Without this permission the button is not displayed.

|

|

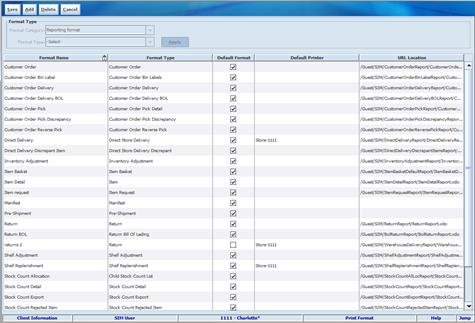

Access Formats

|

Admin

|

On the PC, with this permission, the

Print Format button on the Print Setup screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Hierarchy Format

|

Admin

|

On the PC, with this permission, the

Hierarchy Format button on the Print Setup screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Inventory Adjustment Reason

|

Admin

|

On the PC, with this permission, the Inv.

Adj. Reason button on the Setup screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Inventory Management

|

Admin

|

On the HH, with this permission, the Inv.

Management menu option on the Main menu is displayed.

Without this permission, the menu option is not displayed.

On MAF, with this permission, the user will have access to functionality

within Inventory Management.

Without this permission, the user will not have access to Inventory

Management functions.

On the PC, with this permission, the Inventory Mgmt button on the SIM Login

screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Item Lookup

|

Admin

|

On the HH, with this permission, the Item

Lookups menu option on the Lookups menu is displayed.

Without this permission, the menu option is not displayed.

On MAF, with this permission, the user will have access to functionality within

Item Lookups.

Without this permission, the user will not have access to Item Lookup

functions.

On the PC, with this permission, the Item Lookup button on the Lookups screen

is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Lookup

|

Admin

|

On the HH, with this permission, the

Lookups menu option on the Main menu is displayed.

Without this permission, the menu option is not displayed.

On MAF, with this permission, the user will have access to functionality

within Lookups.

Without this permission, the user will not have access to Lookup functions.

On the PC, with this permission, the Lookups button on the SIM Login screen

is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access MPS Staged Messages

|

Admin

|

On the PC, with this permission, the MPS

Staged Messages button on the Technical Maintenance screen is displayed and

enabled.

Without this permission, the button is not displayed.

|

|

Access MPS Work Types

|

Admin

|

On the PC, with this permission, the MPS

Worker Types button on the Technical Maintenance screen is displayed and

enabled.

Without this permission, the button is not displayed.

|

|

Access Operational Views

|

Admin

|

On MAF, with this permission, the

Operational Viewed menu option in the Drawer/menu is displayed.

Without this permission, the menu option is not displayed.

|

|

Access Print

|

Admin

|

On the PC, with this permission, the

Print button on the SIM Login screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Printers

|

Admin

|

On the PC, with this permission, the

Printers button on the Print Setup screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Product Groups

|

Admin

|

On the PC, with this permission, the

Product Group button on the Admin screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Product Group Schedules

|

Admin

|

On the PC, with this permission, the

Product Group Schedule button on the Admin screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Report

|

Admin

|

On the PC, with this permission, the

Reports button on the SIM Login screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Session Printer

|

Admin

|

On the HH, with this permission, the

Session Printer menu option on the Main menu is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Session Printer button on the Print

Setup screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Setup

|

Admin

|

On the PC, with this permission, the

Setup button on the Admin screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Shipment Reasons

|

Admin

|

On the PC, with this permission, the

Shipment Reason button on the Setup screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Shipping Receiving

|

Admin

|

On the HH, with this permission, the

Shipping/Receiving menu option on the Main menu is displayed.

Without this permission, the menu option is not displayed.

On MAF, with this permission, the user will have access to functionality

within Shipping/Receiving.

Without this permission, the user will not have access to Shipping/Receiving

functions.

On the PC, with this permission, the Shipping/Receiving button on the SIM

Login screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access SIM Managed Store

|

Admin

|

On the PC, with this permission, the SIM

Managed Stores button on the SIM Stores screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access SIM Store

|

Admin

|

On the PC, with this permission, the SIM

Stores button on the Setup screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Store Admin

|

Admin

|

On the PC, with this permission, the

Store Admin button on the Setup screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Store Defaults Admin

|

Admin

|

On the PC, with this permission, the

Store Defaults Admin button on the Setup screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Supplier Lookup

|

Admin

|

On the HH, with this permission, the

Supplier Lookup menu option on the Lookups menu is displayed.

Without this permission, the menu option is not displayed.

On MAF, with this permission, the user will have access to functionality

within Supplier Lookup.

Without this permission, the user will not have access to Supplier Lookup

functions.

On the PC, with this permission, the Supplier Lookup button on the Lookups

screen is displayed and enabled. It also is required to display the Primary

Supplier button on the Item Detail screen.

Without this permission, the button is not displayed.

|

|

Access System Admin

|

Admin

|

On the PC, with this permission, the

System Admin button on the Setup screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Technical Maintenance

|

Admin

|

On the PC, with this permission, the

Technical Maintenance button on the Admin screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Tolerances

|

Admin

|

On the PC, with this permission, the

Tolerances button on the Setup screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Transaction History

|

Admin

|

On the PC, with this permission the Tran

History button on the Lookups screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access UDAs

|

Admin

|

On the HH, with this permission, the View

UDAs menu option is enabled on the Item Lookup menu.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the UDA option button on the Item Lookup

screen is displayed and enabled.

Without this permission, the option button is not displayed.

On the PC, with this permission, the UDA Print Setup button on the Print

Setup screen is displayed and enabled.

Without this permission the screen is not displayed.

On the PC, with this permission, the UDA Detail button on the Item Detail

screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access UI Configuration

|

Admin

|

On the PC, with this permission, the UI

Configuration button on the Technical Maintenance screen is displayed and

enabled.

Without this permission, the button is not displayed.

|

|

Add Extended Attribute Department

|

Admin

|

On the PC, with this permission, the Add

button on the Assign Attributes screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Add Inventory Adjustment Reason

|

Admin

|

On the PC, with this permission, the Add

button on the Inventory Adjustment Reason Maintenance screen is displayed and

enabled.

Without this permission, the button is not displayed.

|

|

Add Shipment Reasons

|

Admin

|

On the PC, with this permission, the Add

button on the Shipment Reason Maintenance screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Create Product Groups

|

Admin

|

On the PC, with this permission, the

Create button on the Product Group List screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Create Product Group Schedules

|

Admin

|

On the PC, with this permission, the

Create button on the Product Group Schedule List screen is displayed and

enabled.

Without this permission, the button is not displayed.

|

|

Create Translations

|

Admin

|

On the PC, with this permission, the

Create button on the Translation Details screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Delete Extended Attribute Department

|

Admin

|

On the PC, with this permission, the

Remove button on the Assign Attributes screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Delete Inventory Adjustment Reason

|

Admin

|

On the PC, with this permission, the

Delete button on the Inventory Adjustment Reason Maintenance screen is

displayed and enabled.

Without this permission, the button is not displayed.

|

|

Delete Product Groups

|

Admin

|

On the PC, with this permission, the

Delete button on the Product Group List screen with be displayed and enabled.

Without this permission, the button is not displayed. If the button is

displayed, the user must also have the necessary data permission for the

product group the user is attempting to delete. If the user is not authorized

for the product group type, User is not authorized to delete this type of

Product Group.

|

|

Delete Product Group Schedules

|

Admin

|

On the PC, with this permission, the

Delete button on the Product Group Schedule List screen is displayed and

enabled.

Without this permission, the button is not displayed. If the button is

displayed, the user must also have the necessary data permission for the

product group that is associated to the product group schedule that is

attempted to be deleted. If the user is not authorized for the product group

type, User is not authorized to delete this type of Product Group Schedule.

|

|

Delete Shipment Reasons

|

Admin

|

On the PC, with this permission, the

Delete button on the Shipment Reason Maintenance screen is displayed and

enabled.

Without this permission, the button is not displayed.

|

|

Delete Staged Messages

|

Admin

|

On the PC, with this permission, the

Delete button on the MPS Staged Message Lookup screen is displayed and

enabled.

Without this permission, the button is not displayed.

|

|

Display Stock Locator

|

Admin

|

On the HH, with this permission, the

Stock Locator option on the Item Lookup menu is displayed and enabled.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Stock Locator button on the Item Lookup

screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Edit Extended Attribute Setup

|

Admin

|

On the PC, with this permission, the Save

and Cancel buttons on the Setup Attributes screen are displayed and enabled.

Without this permission, the buttons are not displayed.

|

|

Edit Product Groups

|

Admin

|

On the PC, with this permission, when a

user double-clicks on an existing Product Group, the Product Group Detail

screen will open. If the user also has the correct data permission for the

product group type, the screen will open in Edit mode.

Without the necessary data permission for the type, the screen will open in

View-only mode. The user must also have this permission for each store that

is included on the product group. If the user does, then the user can edit

the product group; if the user does not, then the screen will open in

View-only mode.

|

|

Edit Product Group Schedules

|

Admin

|

On the PC, with this permission, when a

user double-clicks on an existing Product Group Schedule, the Product Group

Schedule Detail screen will open. If the user also has the correct data

permission for the product group type, the screen will open in Edit mode.

Without the necessary data permission for the type, the screen will open in

View only mode. The user must also have this permission for each store that

is included on the schedule. If the user does, then the user can edit the

schedule; if the user does not then the screen will open in View-only mode.

|

|

Access Customer Details

|

Customer Order

|

On MAF, with this permission, the

Customer Details menu option in the footer menu on the Cust Order Items

Screen is displayed.

Without this permission, the menu is not displayed.

On the PC, with this permission, the Customer button on the Customer Order

Detail screen. This permission is needed to access the customer details such

as name, address for a customer order.

Without this permission, the button is not displayed.

|

|

Access Customer Order

|

Customer Order

|

On the HH, with this permission, the

Customer Orders menu option on the Cust Ord Mgmt menu and Item Lookup menu is

displayed. Without this permission the option is not displayed.

On MAF, with this permission, the Customer Order menu option in the

drawer/menu is available under the Customer Order Mgmt menu. Without

this permission, the option is not displayed.

On the PC, with this permission, the Customer Order button on the Customer

Order Management List screen is displayed and enabled. Without this

permission, the button is not displayed.

On the PC, with this permission, when a user double-clicks on an existing

customer order on the Customer Order Management List screen, the Customer

Order Detail screen will open. Without this permission, the user is not

allowed to access the transaction.

On the PC, with this permission, the Customer Orders button on the Item

Lookup pop-up search screen is displayed and enabled. Without this permission

the tab will be disabled.

On the PC, with this permission, the Customer Orders button on the Item

Detail screen is displayed and enabled. Without this permission, the button

is not displayed.

|

|

Access Customer Order Delivery

|

Customer Order

|

On the HH, with this permission, the Deliver

Cust Order menu option on the Cust Ord Mgmt menu is displayed.

Without this permission, the option is not displayed.

On MAF, with this permission, the Delivery menu option in the footer menu on

the Cust Order Items Screen is displayed.

Without this permission, the menu is not displayed.

On the PC, with this permission, the Delivery button on the Customer Order

List and Customer Order Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

On the PC, with this permission, when a user double-clicks on an existing

customer order delivery on the Customer Order Management List screen, the

Customer Order Detail screen will open.

Without this permission, when a user double clicks on an existing customer

order on the Customer Order Management List screen, the user is not allowed

to access the transaction.

|

|

Access Customer Order Delivery Attribute

|

Customer Order

|

On the HH, with this permission, the Add

Ext Attribute menu option on the Customer Order Summary menu is displayed.

Without this permission, the menu option is not displayed.

On MAF, with this permission, the Attributes screen on the Item Detail

screen, is displayed.

Without this permission, the screen is not displayed.

On the PC, with this permission, the Ext. Attributes button on the Delivery

Summary screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Customer Order Management

|

Customer Order

|

On the HH, with this permission, the

Customer Order Mgmt menu option on the Main menu is displayed.

Without this permission the option is not displayed.

On MAF, with this permission, the Customer Order Mgmt menu option in the

Drawer/menu is displayed.

Without this permission, the option is not displayed.

On the PC, with this permission, the Customer Order Mgmt button on the SIM

Login screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Customer Order Pick

|

Customer Order

|

On the HH, with this permission, the

Customer Order Pick menu option on the Cust Ord Mgmt menu is displayed.

Without this permission the option is not displayed.

On MAF, with this permission, the Customer Order Picking menu option will be

dislayed in the drawer.

Without this permission, the menu is not displayed.

On the PC, with this permission, the Pick button on the Customer Order

Management List screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Customer Order Reverse Pick

|

Customer Order

|

On the PC, with this permission, the

Reverse Pick button on the Customer Order Detail screen is displayed and

enabled. Without this permission, the button is not displayed.

With this permission, the Reverse Pick button on the Customer Order List

screen is displayed and enabled. Without this permission, the button is not

displayed.

On the PC, with this permission, when a user double-clicks on an existing

customer order reverse pick record on the Customer Order Management List

screen, the Customer Order Detail screen will open.

Without this permission, when a user double clicks on an existing customer

order reverse pick record on the Customer Order Management List screen, the

user is not allowed to access the transaction.

|

|

Cancel Submit Customer Order Delivery

|

Customer Order

|

On the HH, with this permission, the

Cancel Submit menu option on the Delivery Summary menu is displayed.

Without this permission the option is not displayed.

On MAF, with this permission, the Cancel Submit menu option in the footer

menu on the Delivery Items Screen is displayed.

Without this permission, the menu is not displayed.

On the PC, with this permission, the Cancel Submit button on the Customer

Order Delivery Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Confirm Customer Order Pick

|

Customer Order

|

On the HH, with this permission, the

Confirm Now menu option on the Pick Summary menu is displayed.

Without this permission, the option is not displayed.

On MAF, with this permission, the Confirm menu option in the footer menu on

the Pick Items Screen is displayed.

Without this permission, the menu is not displayed.

On the PC, with this permission, the Confirm button on the Customer Order

Pick List Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Confirm Customer Order Reverse Pick

|

Customer Order

|

On the PC, with this permission, the

Confirm button on the Customer Order Reverse Pick Detail screen is displayed

and enabled.

Without this permission, the button is not displayed.

|

|

Create Customer Order Delivery For Pickup

|

Customer Order

|

On the HH, with this permission, the

Create Delivery menu option on the Deliver Cust Order menu is displayed. In

addition, the option will only be available for orders with a Reservation

Type 'Web Orders' and Delivery Type 'Pickup'.

Without this permission, the option is not displayed.

On MAF, with this permission, the Create button on the Delivery List screen

is displayed. In addition, the button will only be available for orders with

a Delivery Type 'Pickup'.

Without this permission, the menu is not displayed.

On the PC, with this permission, the Create button on the Customer Order

Delivery List screen is displayed and enabled. In addition, the button will

only be available for orders with a Reservation Type 'Web Orders' and

Delivery Type 'Pickup'.

Without this permission, the button is not displayed.

|

|

Create Customer Order Delivery for

Shipment

|

Customer Order

|

On the HH, with this permission, the

Create Delivery menu option on the Deliver Cust Order menu is displayed. In

addition, the option will only be available for orders with a Reservation

Type 'Web Orders' and Delivery Type 'Shipment'.

Without this permission the option is not displayed.

On MAF, with this permission, the Create button on the Delivery List screen

is displayed. In addition, the button will only be available for orders with

a Reservation Type 'Web Orders' and Delivery Type 'Shipment'.

Without this permission, the menu is not displayed.

On the PC, with this permission, the Create button on the Customer Order

Delivery List screen is displayed and enabled. In addition, the button will

only be available for orders with a Reservation Type 'Web Orders' and

Delivery Type 'Shipment'.

Without this permission, the button is not displayed.

|

|

Create Customer Order Pick

|

Customer Order

|

On the HH, with this permission, the

Create Pick menu option on the Customer Order Pick menu is displayed.

Without this permission the option is not displayed.

On MAF, with this permission, the Create button on the Pick List Screen is

displayed and enabled. Without this permission, the button is not displayed.

On MAF, with this permission, the Pick menu option in the footer menu on the

Cust Order Items Screen is displayed.

Without this permission, the menu is not displayed.

On the PC, with this permission, the Create button on the Customer Order Pick

List screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Create Customer Order Reverse Pick

|

Customer Order

|

On the PC, with this permission, the

Create button on the Customer Order Reverse Pick List screen is displayed and

enabled.

Without this permission, the button is not displayed.

|

|

Delete Customer Order Delivery

|

Customer Order

|

On the HH, with this permission, the

Delete Delivery menu option on the Delivery Summary screen is displayed.

Without this permission, the option is not displayed.

On MAF, with this permission, the Delete menu option in the footer menu on

the Delivery Items Screen is displayed.

Without this permission, the menu is not displayed.

On the PC, with this permission, the Delete button on the Customer Order

Delivery List screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Delete Customer Order Pick

|

Customer Order

|

On the HH, with this permission, the

Delete Pick menu option on the Pick Summary screen is displayed.

Without this permission, the option is not displayed.

On MAF, with this permission, the Delete menu option in the footer menu on

the Pick Items Screen is displayed.

Without this permission, the menu is not displayed.

On the PC, with this permission, the Delete button on the Customer Order Pick

List screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Delete Customer Order Reverse Pick

|

Customer Order

|

On the PC, with this permission, the

Delete button on the Customer Order Reverse Pick List screen is displayed and

enabled.

Without this permission, the button is not displayed.

|

|

Dispatch Customer Order Delivery

|

Customer Order

|

On the HH, with this permission, the

Dispatch Now menu option on the Delivery Summary screen is displayed.

Without this permission, the option is not displayed.

On MAF, with this permission, the Dispatch menu option in the footer menu on

the Delivery Items Screen is displayed.

Without this permission, the menu is not displayed.

On the PC, with this permission, the Dispatch button on the Customer Order

Delivery Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Dispatch Incomplete Customer Order

Delivery

|

Customer Order

|

On the HH, with this permission, when the

Dispatch Now has been selected on the Delivery Summary screen and the

customer order is incomplete a warning message is displayed to the user and

allowed to cancel or continue.

Without this permission, when the Dispatch Now has been selected on the

Delivery Summary screen when the customer order is incomplete, an error

message is displayed to the user and the user cannot continue.

On MAF, with this permission, when the Dispatch menu option on the Delivery

Items screen has been selected and the customer order is incomplete, a

warning message is displayed to the user and allowed to cancel or continue.

Without this permission, when the Dispatch menu option has been selected on

the Delivery Items, an error message is displayed and the user cannot

continue.

On the PC, with this permission, when the Dispatch button on the Customer

Order Delivery Detail screen has been selected and the customer order is

incomplete, a warning message is displayed to the user and allowed to cancel

or continue.

Without this permission, when the Dispatch button has been selected on the

Delivery Summary screen when the customer order is incomplete, an error

message is displayed to the user and the user cannot continue.

|

|

Edit Customer Order BOL

|

Customer Order

|

On MAF, with this permission, the Edit

Delivery menu option in the footer menu on the Delivery Items screen is

displayed.

Without this permission, the menu is not displayed.

On the PC, with this permission, the BOL Detail screen will open in Edit

mode. In addition, the View Customer Order BOL permission is required to gain

access to the screen.

Without this permission, the BOL Detail screen is View-only.

|

|

Edit Customer Order Delivery Attribute

|

Customer Order

|

On MAF, with this permission, the Add

Attributes button and Remove Attributes (Trash can) on the Attributes screen

of the Item Detail screen are displayed and enabled.

Without this permission, the button and trash can are not displayed.

On the PC, with this permission, the Apply, Add, Remove and Cancel buttons on

the Extended Attribute Data Entry screen are displayed and enabled.

Without this permission, the buttons are not displayed.

|

|

Edit Customer Order Delivery For Pickup

|

Customer Order

|

On the HH, with this permission, the Edit

Delivery menu option on the Deliver Cust Order menu is displayed. In

addition, the option will only be available for orders with a Reservation

Type 'Web Orders' and Delivery Type 'Pickup'.

Without this permission, the option is not displayed.

On MAF, with this permission, when a user selects on an existing Customer

Order Delivery record, the Delivery Items screen and Item Detail screen will

be editable. In addition, only the orders with a Delivery Type ‘In Store

Pickup' will be editable.

Without this permission, the screen will open in View-only mode.

On the PC, with this permission, when a user double-clicks on an existing

Customer Order Delivery record, the Customer Order Delivery Detail screen

will open. In addition, only the orders with a Reservation Type 'Web Orders'

and Delivery Type 'Pickup' will be editable.

Without this permission, the screen will open in View-only mode.

|

|

Edit Customer Order Delivery For Shipment

|

Customer Order

|

On the HH, with this permission, the Edit

Delivery menu option on the Deliver Cust Order menu is displayed. In

addition, the option will only be available for orders with a Reservation

Type 'Web Orders' and Delivery Type 'Shipment'.

Without this permission, the option is not displayed.

On MAF, with this permission, when a user selects on an existing Customer

Order Delivery record, the Delivery Items screen and Item Detail screen will

be editable. In addition, only the orders with a Delivery Type 'Ship to

Customer' will be editable.

Without this permission, the screen will open in View-only mode.

On the PC, with this permission, when a user double-clicks on an existing

Customer Order Delivery record, the Customer Order Delivery Detail screen

will open. In addition, only the orders with a Reservation Type 'Web Orders'

and Delivery Type 'Shipment' will be editable.

Without this permission, the screen will open in View-only mode.

|

|

Edit Customer Order Pick

|

Customer Order

|

On the HH, with this permission, the

Review Pick menu option on the Pick Summary screen is displayed.

Without this permission, the option is not displayed.

On MAF, with this permission, when the user selects a Customer Order Pick,

the Pick Items screen and the Item Details screen will open in edit mode.

Without this permission, the screens will open in a view-only mode.

On the PC, with this permission, when a user double-clicks on an existing

Customer Order Pick record, the Customer Order Pick Detail screen will open

in an edit mode.

Without this permission, the screen will open in View-only mode.

|

|

Edit Customer Order Reverse Pick

|

Customer Order

|

On the PC, with this permission, when a

user double-clicks on an existing Customer Order Reverse Pick record, the

Customer Order Reverse Pick Detail screen will open in edit mode.

Without this permission, the screen will open in View-only mode.

|

|

Edit Quantity Deliveries

|

Customer Order

|

On MAF, with this permission, the

Delivery quantity field and quantity widget on the Item Detail screen is

enabled.

Without this permission, the field and quantity widget is not enabled and

only scanning is allowed.

|

|

Edit Quantity Picking

|

Customer Order

|

On MAF, with this permission, the Picking

quantity field and quantity widget on the Item Detail screen is enabled.

Without this permission, the field and quantity widget is not enabled and

only scanning is allowed.

|

|

Item Substitution For Picking

|

Customer Order

|

On the HH, with this permission, the Item

Substitution option on the Pick Detail screen is enabled.

Without this permission, the option is not displayed.

On MAF, with this permission, the Item Substitution menu option in the footer

menu on the Item Detail Screen is displayed.

Without this permission, the menu is not displayed.

On the PC, with this permission, the Item Substitution button on the Customer

Order Pick Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Reject Customer Order

|

Customer Order

|

On MAF, with this permission, the Reject

menu option in the footer menu on the Cust Order Items Screen is displayed.

Without this permission, the menu is not displayed.

On the PC, with this permission, the Reject button on the Customer Order

Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Submit Customer Order Delivery

|

Customer Order

|

On the HH, with this permission, the

Submit menu option on the Delivery Summary screen is displayed.

Without this permission, the option is not displayed.

On MAF, with this permission, the Submit menu option in the footer menu on

the Delivery Items Screen is displayed.

Without this permission, the menu is not displayed.

On the PC, with this permission, the Submit button on the Customer Order

Delivery Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

View Customer Order BOL

|

Customer Order

|

On MAF, with this permission, the BOL

Info menu option in the footer menu on the Delivery Items Screen is

displayed.

Without this permission, the menu is not displayed.

On the PC, with this permission, the BOL button on the Customer Order

Delivery Detail screen is displayed and enabled. The BOL Detail screen will

open in View-only mode.

Without this permission, the button is not displayed.

|

|

Access Adjust Container DSD Receiving

|

DSD Receiving

|

On the HH, with this permission, the

Adjust menu option on the Container Summary screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Adjust button on the DSD Receiving

Container Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Confirm Container DSD Receiving

|

DSD Receiving

|

On the HH, with this permission, the

Confirm menu option on the Container Summary screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Confirm button on the DSD Receiving

Container Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Confirm DSD Receipt

|

DSD Receiving

|

On the HH, with this permission, the

Confirm menu option on the Receipt Summary screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Confirm button on the DSD Receiving Detail

screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Create Container

|

DSD Receiving

|

On the HH, with this permission, the

Create Container menu option on the Receipt Summary screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Create Container button on the DSD

Receiving Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Customer Order

|

DSD Receiving

|

On the PC, with this permission, the

Customer Orders button on the DSD Receiving Detail screen is displayed and

enabled.

Without this permission, the button is not displayed.

|

|

Default Qty in All Containers

|

DSD Receiving

|

On the HH, with this permission, the

Default Qty menu option on the Receipt Summary screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Default Qty button on the DSD Receiving

Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Default Qty in Container

|

DSD Receiving

|

On the HH, with this permission, the

Default Qty menu option on the Receipt Summary screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Default Qty button and the Clear Qty

button on the DSD Receiving Detail Container screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Delete Container

|

DSD Receiving

|

On the HH, with this permission, the

Delete Container menu option on the Container Summary screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Delete button on the DSD Receiving

Container Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Delete Receipt

|

DSD Receiving

|

On the HH, with this permission, the

Delete Receipt menu option on the Receipt Summary screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Delete Delivery button on the DSD

Receiving Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Document DSD Receiving

|

DSD Receiving

|

On the PC, with this permission, the

Document button on the DSD Receiving Container Detail screen is displayed and

enabled.

Without this permission, the button is not displayed.

|

|

Access DSD Receiving

|

DSD Receiving

|

On the HH, with this permission, the DSD

Receiving menu option on the Shipping/Receiving screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the DSD Receiving button on the

Shipping/Receiving screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access DSD Receiving Ext. Attribute

|

DSD Receiving

|

On the HH, with this permission, the Add

Ext Attribute menu option on the Container Summary screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Ext. Attributes button on the DSD

Receiving Container Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Item Receiving

|

DSD Receiving

|

On the HH, with this permission, the Item

Receiving menu option on the Container Summary screen is displayed.

Without this permission, the menu option is not displayed.

|

|

Access Purchase Order

|

DSD Receiving

|

On the HH, with this permission, the

Purchase Order menu option on the DSD Receiving screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Purchase Order button on the

Shipping/Receiving screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Reject Delivery

|

DSD Receiving

|

On the HH, with this permission, the

Reject Delivery menu option on the Receipt Summary screen is displayed. The

menu option is only displayed when applying an ASN to a delivery.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Reject Delivery button on the DSD

Receiving Detail screen is displayed and enable. The button is only displayed

when applying an ASN to a delivery.

Without this permission, the button is not displayed.

|

|

Access Remove Item DSD Receiving

|

DSD Receiving

|

On the HH, with this permission, the

Remove Item menu option on the Container Summary screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Remove Item button on the DSD Receiving

Container Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Review Items

|

DSD Receiving

|

On the HH, with this permission, the

Review Item menu option on the Container Summary screen is displayed.

Without this permission, the menu option is not displayed.

|

|

Add New Item DSD Receiving

|

DSD Receiving

|

On the HH, with this permission, the Add

New Item menu option on the Container Summary screen is displayed.

Without this permission, the menu option is not displayed. An item can

always be added when creating a receipt on the fly.

On the PC, with this permission, an item can be added to the transaction.

Without this permission, an item cannot be added to the transaction from the

DSD Receiving Container Detail screen or Advanced Item Entry screen. An Item

can always be added when creating a receipt on the fly.

|

|

Allow DSD Receiving Without PO

|

DSD Receiving

|

On the HH, with this permission, the

Create Receipt menu option on the DSD Receiving screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Create Receipt menu option on the DSD

Receiving List screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Allow DSD Receiving With PO

|

DSD Receiving

|

On the HH, with this permission, the

Create Receipt menu option on the PO Detail screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Create Receipt button on the Purchase

Order Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Allow Over Receiving for DSD Receiving

|

DSD Receiving

|

On the HH, with this permission, the user

is allowed to over-receive quantities for a DSD Receipt.

Without this permission, the user is not allowed to over-receive quantities

and a message is displayed.

On the PC, with this permission, the user is allowed to over-receive

quantities.

Without this permission, the user is not allowed to over-receive quantities

and will be prompted when damaged and received quantity is larger than the

expected quantity.

|

|

Allow Receiving Damages

|

DSD Receiving

|

On the HH, with this permission, the

Record Damages menu option on the Container Summary screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the damaged column on the DSD Receiving

Container Detail screen is displayed and enabled.

Without this permission, the damaged column is not displayed.

|

|

Display Expected Quantity

|

DSD Receiving

|

On the HH, with this permission, the

expected quantity on the Item Detail screen is displayed.

Without this permission, the quantity is not displayed.

On the PC, with this permission, the expected quantity column on the DSD

Receiving Container Detail screen is displayed and enabled.

Without this permission, the column is not displayed.

|

|

Edit Container

|

DSD Receiving

|

On the HH, with this permission, the Edit

Container menu option on the Receipt Summary screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, when the user double-clicks on an existing

Container in the DSD Receiving Detail screen, the DSD Receiving Container

Detail screen will open in edit mode.

Without this permission, the screen will open in view-only mode.

|

|

Edit Container Info

|

DSD Receiving

|

On the HH, with this permission, the

Additional Details option on the Container Summary screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Container Info screen will open in edit

mode.

Without this permission, the screen will open in view-only mode.

|

|

Edit Delivery Info

|

DSD Receiving

|

On the HH, with this permission, the

Additional Details menu option on the Receipt Summary screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Direct Delivery Info screen will open in

edit mode.

Without this permission, the screen will open in view-only mode.

|

|

Edit DSD Receiving

|

DSD Receiving

|

On the PC, with this permission, when the

user double-clicks on an existing Receipt in the DSD Receiving List screen,

the DSD Receiving Detail screen will open in edit mode.

Without this permission, the screen will open in view-only mode.

|

|

Edit DSD Receiving Ext. Attribute

|

DSD Receiving

|

On the PC, with this permission, the

Apply, Add Attributes, Remove Attributes and Cancel buttons on the Extended

Attributes Entry screen are displayed and enabled.

Without this permission, the Close button is displayed and enabled.

|

|

Override Supplier Discrepancies

|

DSD Receiving

|

On the HH, with this permission, the user

can override the supplier discrepancies check during the DSD receipt.

Without this permission, the message “Quantity received is larger than

expected, reduce the quantity received” is displayed.

On the PC, with this permission, the user can override the supplier

discrepancies check during the direct delivery receipt.

Without this permission, the message “Quantity received is larger than

expected, reduce the quantity received” is displayed.

|

|

Receive Direct Delivery on Shop Floor

|

DSD Receiving

|

On the HH, with this permission, the

Receive on Shop Floor prompt on the DSD Receiving Detail screen will be

displayed.

Without this permission the prompt is not displayed.

On the PC, with this permission, the Receive on Shop Floor check box on the

DSD Container Info screen is displayed and enabled.

Without this permission, the check box is not enabled.

|

|

Email Alert - Customer Order Pick

Reminder

|

Email

|

With this permission, the user will be

notified, if the pick list has been created but not actioned.

Without this permission, the user will not be notified.

|

|

Email Alert - Customer Order Receipt

|

Email

|

With this permission, the user will be

notified when customer orders are received.

Without this permission, the user will not be notified.

|

|

Email Alert - Customer Order Reminder

|

Email

|

With this permission, the user will be

notified when the customer order has not been fulfilled.

Without this permission, the user will not be notified.

|

|

Email Alert – Damaged Delivery

|

Email

|

With this permission, the user will be

notified when the delivery includes damaged items.

Without this permission, the user will not be notified.

|

|

Email Alert – Finisher Delivery Unable to

Auto-Receive

|

Email

|

With this permission, the user will be

notified when the finisher delivery UIN qty discrepancy exists on an incoming

ASN during batch processing.

Without this permission, the user will not be notified.

|

|

Email Alert – Finisher UIN Discrepancy

|

Email

|

With this permission, the user will be

notified when a finisher return received quantity does not match the number

of serial numbers on the return.

Without this permission, the user will not be notified.

|

|

Email Alert – Misdirected Container

|

Email

|

With this permission, the user will be

notified when a container has been received in another location.

Without this permission, the user will not be notified.

|

|

Email Alert - New Customer Order

|

Email

|

With this permission, the user will be

notified when customer orders are created.

Without this permission, the user will not be notified.

|

|

Email Alert – Over Received Quantity

|

Email

|

With this permission, the user will be

notified when the number of pre-populated serial numbers exceeds the received

quantity.

Without this permission, the user will not be notified.

|

|

Email Alert – Receiving UIN Discrepancy

|

Email

|

With this permission, the user will be

notified when the number of pre-populated serial numbers does not match the

received quantity.

Without this permission, the user will not be notified.

|

|

Email Alert –RTV Request Expiration

Approaching

|

Email

|

With this permission, the user will be

notified if the supplier return request expiration date is approaching.

Without this permission, the user will not be notified.

|

|

Email

Alert – RTV Unavailable request quantity

|

Email

|

With

this permission, the user will be notified if there is not enough inventory

in the unavailable bucket to send back to supplier from a return request.

Without this permission, the user will not be notified.

|

|

Email

Alert – Shipped Delivery Overdue

|

Email

|

With

this permission, the user will be notified when the shipped delivery has not

been received and has passed the expected date.

Without this permission, the will not be notified.

|

|

Email

Alert – Store Delivery Unable to Auto-Receive

|

Email

|

With

this permission, the user will be notified when a store delivery has

discrepancies and cannot be auto received.

Without this permission, the user will not be notified.

|

|

Email

Alert – Store Receiving Over/Under

|

Email

|

With

this permission, the user will be notified when a store transfer has

over/under received quantities.

Without this permission, the user will not be notified.

|

|

Email

Alert - Transfer Request

|

Email

|

With

this permission, the user will be notified when a transfer request is

created.

Without this permission, the user will not be notified.

|

|

Email

Alert – Transfer Request Approved

|

Email

|

With

this permission, the user will be notified when a transfer request is

approved.

Without this permission, the user will not be notified.

|

|

Email

Alert – Transfer Request Expiration Approaching

|

Email

|

With

this permission, the user will be notified when a transfer request has not

been approved and the request is about to expire. This is based on the not

after date set.

Without this permission, the user will not be notified.

|

|

Email

Alert – Transfer Request Rejected

|

Email

|

With

this permission, the user will be notified when a transfer request is

rejected.

Without this permission, the user will not be notified.

|

|

Email

Alert – Transfer Unavailable Request Quantity

|

Email

|

With

this permission, the user will be notified when the requested quantity is no

longer available at the requested source location.

Without this permission, the user will not be notified.

|

|

Email

Alert – UIN Items on Incoming ASN Failed

|

Email

|

With

this permission, the user will be notified if an Auto Generated SN item is on

the ASN with pre-generated numbers when processing thru the RIB.

Without this permission, the user will not be notified.

|

|

Email

Alert - Unexpected UIN (Store Changed)

|

Email

|

With

this permission, the user will be notified when UINs are discovered at a

store where they should not be.

Without this permission, the user will not be notified.

|

|

Email

Alert – Warehouse Delivery Unable to Auto-Receive

|

Email

|

With

this permission, the user will be notified when the delivery includes

pre-populated serial numbers and cannot be automatically received.

Without this permission, the user will not be notified.

|

|

Access

Notifications

|

Home

Page

|

On

MAF, with this permission, the bell notification icon will be enabled.

Without this permission, it will be disabled.

|

|

Send

Notification

|

Home

Page

|

On

MAF, with this permission, the user will be able to swipe an open transaction

and send a notification.

Without this permission, the notify function will not be available.

|

|

View

Transactions

|

Home

Page

|

On

MAF, with this permission, the user will be able to view all of the open

transactions on the home page (depending on data permissions).

Without this permission, the home page will still display (just without the

transactions listed) allowing for changing the store and the access to

notifications; however the list of open transactions will be empty.

|

|

Access

Inventory Adjustment

|

Inventory

Adjustments

|

On

the HH, with this permission, the Inventory Adjustments menu option on the

Inv. Management menu is displayed.

Without this permission the menu option is not displayed.

On MAF, with this permission, the Inventory Adjustment menu option will

display in the Drawer.

Without this permission, the menu option will not display.

On the PC, with this permission, the Inventory Adjustment button on the

Inventory Management screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access

Inventory Adjustment Attribute

|

Inventory

Adjustments

|

On

the HH, with this permission, the Add Ext Attribute menu option on the

Inventory Adj. Summary menu is displayed.

Without this permission, the menu option is not displayed.

On MAF, with this permission, the Attributes screen on the Inventory

Adjustment Detail screen is displayed and enabled.

Without this permission, the Attributes screen is not displayed.

On the PC, with this permission, the Ext. Attributes button on the Inventory

Adjustment Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Complete

Inventory Adjustment

|

Inventory

Adjustments

|

On

the HH, with this permission, the Confirm Now menu option on the Inventory

Adjustment Summary screen is displayed.

Without this permission, the menu option is not displayed. The Confirm Later

menu option will be available to save the transaction.

On MAF, User must have this permission in order for the Confirm action to

appear on the footer menu on the Inventory Adjustment Detail Screen.

Without this permission, the user will not be able to confirm the

transaction, but only be able to Save the transaction.

On the PC, with this permission, the Confirm button on the Inventory

Adjustment Detail screen is displayed and enabled.

Without this permission, the button is not displayed. The Save button will be

enabled to save the transaction.

|

|

Create

Inventory Adjustment

|

Inventory

Adjustments

|

On

the PC, with this permission, the Create button on the Inventory Adjustment

List Screen will be displayed and enabled.

Without this permission, the button will not be displayed.

On MAF, the permission must exist in order for the Copy action to be

available to the user. This action is available in the footer menu and allows

the user to copy ‘Completed’ adjustments.

On the PC, with this permission, the Create button on the Inventory

Adjustment List screen is displayed and enabled. The Copy button is also

enabled with this permission when the user is copying completed adjustments.

Without this permission, the button is not displayed.

|

|

Delete

Inventory Adjustment

|

Inventory

Adjustments

|

On

the HH, with this permission, the Delete Inv. Adj. menu option on the

Inventory Adj. Summary screen is displayed.

Without this permission, the menu option is not displayed.

On MAF, with this permission, the Delete menu option in the footer menu on

the Inventory Adjustment List screen is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Delete button on the Inventory

Adjustment List screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Edit Inventory Adjustment

|

Inventory Adjustments

|

On the HH, with this permission, the Edit

Inv. Adj. menu option in the Inventory Adj. menu is displayed.

Without this permission, the menu option is not displayed.

On MAF, with this permission, when the user selects an inventory adjustment

it will be editable and the user is allowed to make changes.

Without this permission, the inventory adjustment is view only.

On the PC, with this permission, when the user double-clicks on an existing

Inventory Adjustment in the Inventory Adjustment List screen, the Inventory

Adjustment Detail is editable.

Without this permission, the screen will open in View-only mode.

|

|

Edit Inventory Adjustment Attribute

|

Inventory Adjustments

|

On MAF, with this permission, Attributes

can be added/removed: The Add Attributes and Remove Attributes (Trash can)

buttons will be available on the Attributes screen of the Inventory

Adjustment Detail.

Without this permission, attributes cannot be added or removed.

On the PC, with this permission, the Apply, Add Attributes, Remove Attributes

and Cancel buttons on the Extended Attributes Entry screen are displayed and

enabled.

Without this permission, the Close button is displayed and enabled.

|

|

Edit Quantity

|

Inventory Adjustments

|

On MAF, with this permission, the user

will be able to tap on the item quantity and the quantity widget will open to

edit the quantity.

Without this permission, the quantity is not editable and only scanning is

allowed.

|

|

Access Item Basket

|

Item Basket

|

On the HH, with this permission, the Item

Basket menu option on the Inv. Management menu is displayed.

Without this permission, the menu option is not displayed.

|

|

Add Item to Item Basket

|

Item Basket

|

On the HH, with this permission, the Add

Item option on the Item Basket summary menu is displayed.

Without this permission, the menu option is not displayed.

|

|

Create Item Basket

|

Item Basket

|

On the HH, with this permission, the

Create Item Basket menu option on the Item Basket menu is displayed.

Without this permission, the menu option is not displayed.

|

|

Delete Item Basket

|

Item Basket

|

On the HH, with this permission, the

Delete Item Basket option on the Item Basket summary menu is displayed.

Without this permission, the menu option is not displayed.

|

|

Delete Item from Item Basket

|

Item Basket

|

On the HH, with this permission the

Delete Item option on the Item Basket summary menu is displayed.

Without this permission, the menu option is not displayed.

|

|

Print Item Basket

|

Item Basket

|

On the HH, with this permission, the

Print Ticket option on the Item Basket summary is displayed.

Without this permission, the menu option is not displayed.

|

|

Save Item Basket

|

Item Basket

|

On the HH, with this permission, the Save

Basket option on the Item Basket summary is displayed.

Without this permission, the menu option is not displayed.

|

|

Access Item Request

|

Item Requests

|

On the HH, with this permission, the Item

Requests menu option on the Inv. Management menu is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Item Request button on the Inventory

Management screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Add Items To Item Request

|

Item Requests

|

On the HH, with this permission, the

Add/Edit Item menu option on the Item Requests Summary screen is displayed.

Without this permission, the menu option is not displayed.

This permission does not apply when creating an Item Request. Add/Edit Item

menu is always available when creating.

On the PC, with this permission and the Edit Item Requests permission, the

Add Item button on the Item Request Detail Screen is displayed and enabled

when editing an existing Item Request.

Without this permission, the button is not displayed.

This permission does not apply when creating an Item Request. Add Item

button is always available when creating.

|

|

On the HH, with this permission, the

Add/Edit Item menu option on the Item Requests Summary screen is displayed.

Without this permission the menu option is not displayed when editing an Item

Request.

On the HH, with this permission, the message “Item is not on the request.

Would you like to add it?” and the Yes and No menu options are displayed.

Without this permission, the message screen is not displayed. This permission

does not apply when creating an item request. Users will always be able to

add and edit items when creating an item request.

On the PC, with this permission and the Edit Item Requests permission, the

Add Item button on the Item Request Detail screen is displayed and enabled

when editing an existing Item Request.

Without this permission, the button is not displayed. This permission does

not apply when creating an Item Request. Add Item button will always be

available when creating.

|

|

Create Item Request

|

Item Requests

|

On the HH, with this permission, the

Create Item Request menu option on the Item Requests menu is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Create button on the Item Request List

screen is displayed and enabled. The Add Items button will also be enabled on

the Item Request Detail screen.

Without this permission, the button is not displayed.

|

|

Delete Item Request

|

Item Requests

|

On the HH, with this permission, the

Delete Item Request menu option on the Item Requests menu is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Delete button on the Item Request List

screen is displayed and enabled. Without this permission, the button is not

displayed.

With this permission, the Item Remove button on the Item Request Detail

screen is displayed and enabled. Without this permission, the button is not

displayed.

|

|

Edit Item Request

|

Item Requests

|

On the HH, with this permission, the Edit

Item Request menu option on the Item Requests menu is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, when the user double clicks on an existing

Item Request in the Item Request List screen, the Item Request Detail screen

will open in edit mode.

Without this permission, the screen will open in View-only mode.

|

|

Request Items

|

Item Requests

|

On the HH, with this permission, the

Request Item Request menu option on the Item Requests menu is displayed.

Without this permission the menu option is not displayed.

On the HH, with this permission, the Request Now menu option on the Item

Requests Summary screen is displayed. Without this permission the menu option

is not displayed.

On the PC, with this permission, the Request button on the Item Request

Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Item Ticket

|

Item Tickets

|

On the HH, with this permission, the

Ticket Printing menu option on the Main menu is displayed.

Without this permission, the menu option is not displayed.

On the PC, with this permission, the Item Ticket button on the Print Menu

screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Item Ticket Batch

|

Item Tickets

|

On the PC, with this permission, the Item

Ticket Batch button in the Print Menu screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access Item Ticket Price Override

|

Item Tickets

|

On the HH, with this permission the

Ticketing Price Override menu is displayed and the user can override the

price on the Ticket Detail screen.

Without this permission, the menu is not displayed and the user cannot

override the price.

|

|

Create Item Ticket

|

Item Tickets

|

On the PC, with this permission, the

Create button on the Item Tickets List screen and the Add Ticket button on

the Item Ticket Batch Detail screen are displayed and enabled.

Without this permission, the buttons are not displayed.

|

|

Create Item Ticket Batch

|

Item Tickets

|

On the PC, with this permission, the

Create Batch button on the Item Ticket Batch List screen and Generate Tickets

button on the Add Transaction screen are displayed and enabled.

Without this permission, the button is not displayed.

|

|

Delete Item Ticket

|

Item Tickets

|

On the PC, with this permission, the

Delete button on the Item Tickets List, Item Ticket Batch List screens and

the Remove Ticket button on the Item Ticket Batch Detail screens are

displayed and enabled.

Without this permission, the buttons are not displayed.

|

|

Edit Item Ticket

|

Item Tickets

|

On the PC, with this permission, when the

user double clicks on an existing Item Ticket in the Item Ticket List or Item

Ticket Batch Detail screen, the Item Ticket Detail screen will open in edit

mode.

On the PC, with this permission, when the user double clicks on an existing

item ticket batch on the Item Ticket Batch List screen, the Item Ticket Batch

Detail screen will open in edit mode.

Without this permission, the screens will open in View-only mode.

|

|

Print Item Tickets

|

Item Tickets

|

On the PC, with this permission, the

Print Tickets button on the Item Ticket List, Item Ticket Detail, Item Ticket

Batch List and Item Ticket Batch Detail screens are displayed and enabled.

Without this permission, the button is not displayed.

|

|

Update Format Item Ticket

|

Item Tickets

|

On the PC, with this permission, the

Update Format button on the Item Ticket List, Item Tickets Batch List and

Item Ticket Batch Detail screens are displayed and enabled.

Without this permission, the buttons are not displayed.

|

|

Update SOH Item Ticket

|

Item Tickets

|

On the PC, with this permission, the

Refresh Qty button on the Item Tickets List, Item Ticket Batch List and Item

Ticket Batch Detail screens are displayed and enabled.

Without this permission, the buttons are not displayed.

|

|

Access Price Change

|

Price Changes

|

On the PC, with this permission, the

Price Change button on the Inventory Management screen is displayed and

enabled.

Without this permission, the button is not displayed.

|

|

Create Price Change

|

Price Changes

|

On the PC, with this permission, the

Create button on the Price Change List screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Print Item Tickets For Price Changes

|

Price Changes

|

On the PC, with this permission, the Item

Tickets button on the Price Change List screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Print Shelf Labels For Price Changes

|

Price Changes

|

On the PC, with this permission, the

Shelf Labels button on the Price Change List screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Accept RTV

|

RTV

|

On the PC, with this permission, the

Accept button on the RTV Detail screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Access RTV

|

RTV

|

On the PC, with this permission, the RTV

button on the Shipping/Receiving screen is displayed and enabled.

Without this permission, the button is not displayed.

|

|

Add Items To RTV

|

RTV

|