11g Release 1 (11.1.2)

Part Number E20386-02

Contents

Previous

Next

|

Oracle® Fusion

Applications Order Orchestration Implementation Guide 11g Release 1 (11.1.2) Part Number E20386-02 |

Contents |

Previous |

Next |

This chapter contains the following:

Manage Planning Source Systems

Manage Sourcing Rules and Bills of Distribution

Manage Global Order Promising Profile Options

To populate the order orchestration and planning data repository, you collect data from external source systems, such as external fulfillment source systems and external order capture source systems, and from the Oracle Fusion source system. You manage which source systems are data collection source systems by defining collections parameters and enabling which source systems allow collections.

You manage two categories of source systems for data collections:

External source systems

The Oracle Fusion source system

The following figure illustrates data collections from three source systems. Two of the source systems are external source systems. One of the source systems is the Oracle Fusion source system.

Your business may have many external fulfillment and external order capture source systems. For each external source system from which you need to collect data to include in the order orchestration and planning data repository, define the data collection parameters, and enable the source system for collections. For the Version data collection parameter, the choices are Other or Oracle Fusion.

The order orchestration and order promising processes use data stored in the order orchestration and planning data repository. Some of the data that needs to be in the repository originates in the Oracle Fusion source system. To collect data from the Oracle Fusion source system, include the Oracle Fusion source system as a source system for data collection. Define the data collection parameters for the Oracle Fusion source system, and enable the source system for collections.

For each system from which you intend to collect data to populate the order orchestration and planning data repository, you define and maintain the source system data collection parameters.

For each source system, you complete the following for the data collection parameters:

Specify the time zone.

Specify the version, order orchestration type, and planning type.

Define the number of database connections, parallel workers, rows per processing batch, and cached data entries.

Enable collections allowed.

Enable data cross-referencing.

You must specify the time zone for the source system because the time stamps contained in collected data are converted from the time zone used in the source system to the time zone used for all data stored in the order orchestration and planning data repository. Using the same time zone for all data stored in the order orchestration and planning data repository facilitates correct results when calculations are performed using attributes that store dates. For example, if the source system uses the US Eastern time zone, but the order orchestration and planning data repository stores all data in the US Pacific time zone, then a supply with a due date and time of July 10th 04:00 PM in the source system is stored in the order orchestration and planning data repository with a due date of July 10th 01:00 PM.

You must define one, and only one, source system with the Version attribute equal to Oracle Fusion and the Order Orchestration Type attribute equal to Order Orchestration.

You may define many source systems with the Version attribute equal to Other. For the source systems with the Version attribute equal to Other, the Order Orchestration Type attribute can equal Fulfillment or Order Capture and the Planning Type attribute can equal Fulfillment. Any combination of these values is allowed to describe the purpose of the source system, but you must provide a value for at least one of these type parameters. These parameters do not impact the behavior of the collections process.

Note

Once you have saved a system with the Version attribute equal to Oracle Fusion, you cannot change the value for the Version attribute.

These parameters affect the usage of system resources. The table below defines what each parameter does and provides guidelines for setting it.

|

Parameter |

What the Parameter Does |

A Typical Value for the Parameter |

|---|---|---|

|

Number of Database Connections |

Defines the maximum number of database connections the source server can create during the collection process. This controls the throughput of data being extracted into the Source Java program. |

10 |

|

Number of Parallel Workers |

Defines the maximum number of parallel workers (Java threads) used to process the extracted data. The number here directly impacts the amount of CPU and memory used during a collection cycle. |

30 |

|

Number of Rows per Processing Batch |

Define the number of records to process at a time. The idea is to allow the framework to process data in byte-size chunks. A batch too small may cause extra overhead while a batch too big might peak out memory or network bandwidth. |

10,000 |

|

Cached Data Entries in Thousands |

During data collections, various lookup and auxiliary data are cached in the collection server to support validation. For example, currency rate may be cached in memory. This parameter controls the maximum number of lookup entries cached per lookup to prevent the server from occupying too much memory. |

10,000 |

Before enabling a source system for collections, ensure your definition of the other parameters are complete for the source system. Ensure you have defined values for all applicable attributes, and where applicable, you have enabled organizations for collections or for ATP Web services.

When you enable a source system for data cross-reference, the data collections from the source system requires additional processing steps to check for and to cross-reference data during collections. These additional processing steps can have a performance impact. For data collected from third-party source systems, it is recommended that any cross-referencing needs be completed externally, before the data is presented for collections.

From the list of organizations for each source systems, you designate which organizations will have their data collected when a collections process collects data from the source system.

To determine which organizations to enable for collections, analyze the sourcing strategies for your company, the type of organization for each organization in the list, and any other business requirements that would determine whether system resources should be expended to collect data from that organization. If the data from that organization would never be used by order promising or order orchestration, no need to collect the data.

For example, consider a scenario where the list of organizations for a source system includes 20 manufacturing plants and 10 distribution centers. Because the business requirements specify that the movements of materials from the manufacturing plants to the distribution centers are to be controlled separately from order orchestration and order promising, there are no sourcing rules that include transferring from one of the manufacturing plants. For this scenario, you would only enable the 10 distribution centers for collections.

You enable the available-to-promise (ATP) Web Service to enable Oracle Fusion Global Order Promising to invoke an external order promising engine to determine a date and quantity available for fulfillment lines to be shipped from a specific organization.

Your business requirements may require you to obtain the available-to-promise dates and available-to-promise quantities from external fulfillment systems for fulfillment lines to be shipped from specific organizations. To implement such a requirement, you enable the ATP Web Service for each organization subject to the requirement.

When a fulfillment line is received with a ship-from organization that is equal to an organization for which ATP Web Service has been enabled, Oracle Fusion Global Order Promising invokes the order promising engine of the applicable external system to determine an available-to-promise date and an available-to-promise quantity. For example, if the ATP Web Service has been enabled for your Lima organization, when fulfillment lines are received with Lima specified for the ship-from organization, an external order promising engine is invoked to provide an available-to-promise date and an available-to-promise quantity for these fulfillment lines.

There are some rare cases where an organization would be enabled for both collections and for ATP Web Service. For example, consider the scenario where there are different sourcing strategies for two items, Item X and Item Y. Item X is only purchased from the Chicago organization, but the Chicago organization can transfer Item X from the Seattle organization, and the sourcing rules have specified that the order promising process should check for inventory at the Seattle organization for Item X when Chicago is out of stock. The Seattle organization must be enabled for collections because the data from the Seattle organization must be included in the Order Orchestration and Planning data repository for use by the order promising process when it needs to check for available supply of Item X at the Seattle organization to transfer to the Chicago organization. Item Y is purchased directly from Seattle, must be made to order, and the order promising process must invoke an external ATP Web service to determine when the Item Y could be made. In this case, you would also enable the Seattle organization for ATP Web service.

No. You cannot add additional source systems when managing source systems for data collections for the order orchestration and planning data repository.

Source systems must first be defined in the Trading Community Model. For the system to be listed as one of the systems from which to choose from when managing source systems, the definition of the system in the Trading Community Model must enable the system for order orchestration and planning.

To define the sources of supply for your supply chains and to define your date-effective sourcing strategies, create sourcing rules and bills of distribution. Within each sourcing rule or bill of distribution, you define one or more supply sources and a combination of rankings and quantity-based sourcing specifications for each source to define priorities across the supply sources. For each source, you also select one of three source types, and you specify the value for the attributes applicable to the selected source type.

This table lists the three replenishment source types, the definition of the source type, and the attributes to specify for each source type.

|

Source Type |

Source Type Definition |

Attributes to Specify |

|---|---|---|

|

Buy from |

Sourced from an external supplier. |

Specify the supplier and supplier site. |

|

Make at |

Sourced from an internal organization that manufactures the item. |

Specify the manufacturing organization. |

|

Transfer from |

Sourced through an interorganization transfer. |

Specify the organization from which items will be transferred. |

Note

When you create sourcing rules and bills of distribution, you specify how you will replenish items. You do not specify what items that you will replenish. To specify which sourcing rules or bills of distribution that you will use to replenish what items, you create assignment sets.

You define the following aspects of sourcing rules and bills of distribution to define your sources of supply and your sourcing strategies:

Global sourcing rules

Local sourcing rules

Bills of distribution

Effectivity dates

Source ranks, quantity-based sourcing specifications, and allocation percentages

Tip

When first designing your sourcing rules and bills of distribution, start by envisioning your assignment set. Determine what set of global sourcing rules, local sourcing rules, bills of distribution, or combinations of rules and bills that you need to implement your assignment set while minimizing the number of rules or bills to maintain. For example, you may be able to define a global sourcing rule in such a way that you will need only a few local sourcing rules to assign for exceptions to the global rule.

Global sourcing rules can specify two of the source types: the buy-from or transfer-from source types. Any organization can potentially replenish items by buying from any of the suppliers specified in the buy-from sources, or transferring from any of the organizations specified in the transfer-from sources. For example, if you create a global sourcing rule with a buy-from source with Super Supply Company specified for the supplier, any of your organizations can potentially buy from Super Supply Company.

If you have a source that is applicable to most of your organizations, create a global sourcing rule for that source and local sourcing rules for the organizations for which the source is not applicable. For example, if there are 20 organizations in your company, and 19 of the organizations transfer supply from the Munich organization, create a global sourcing rule specifying transfer-from the Munich organization, and create a local sourcing rule specifying where the Munich organization gets supply from.

Local sourcing rules can specify all three source types. Because a local sourcing rule is applicable to one, and only one, organization, you specify which organization the rule is being created for when you create the rule. The replenishment sources defined in the rule are applicable only to the organization for which the rule was created. For example, if you create a local sourcing rule with M1 as the organization for which the rule is being created, and you add a buy-from source to the rule with XYZ Supply Company specified for the supplier, and you have no other sourcing rules or bills of distribution with XYZ Company specified for the supplier, then only the M1 organization can buy from XYZ Supply Company.

If you have designed multiple local sourcing rules with material flowing through three or more organizations, you can choose to create one bill of distribution to implement the sources instead of creating multiple local sourcing rules. Choosing to create a bill of distribution instead of souring rules is a personal or organizational preference. Any scenario that you can implement by creating a bill of distribution, you can also implement by creating multiple local sourcing rules.

For example, the following sourcing scenario could be implemented by three local sourcing rules or one bill of distribution:

Organization M1 sources items by purchasing from a supplier, XYZ Supply.

Organization M2 sources items by transferring from M1.

Organization M3 sources items by transferring from M2.

Use sourcing effectivity dates to modify sourcing rules and bills of distribution when sources change, such as a new supplier contract is established or a manufacturing facility is shut down. Each rule or bill can have multiple, non-overlapping ranges of effectivity start dates and end dates, with a different set of sources specified for each range. For example, if you have a sourcing rule that currently specifies a buy-from source with Acme Supplier specified for the supplier, but your company has decided to start buying from Winter Widgets instead, you would modify the sourcing rule by specifying the applicable end date, the date you will no longer buy from Acme Supplier, for the current effectivity date range. You add a new effectivity date range, specifying the date when you will start buying from Winter Widgets for the start date, and then you add a buy-from source for the new effectivity date range with Winter Widgets specified for the supplier.

For each source in a sourcing rule or bill of distribution, you designate a rank to specify the order in which the sources within the rule or bill will be considered by order promising when the rule or bill is applied during a supply chain availability search. The source with the lowest number rank will be considered first, and the source with the highest number rank will be considered last. If your sourcing strategy includes using specific sources for specific quantities, you designate a from quantity, a less-than quantity, or both, for one or more sources.

Note

Because sourcing rules collected from external source systems may include split allocations for planning purposes, there may be multiple sources with the same rank and quantity range, but the allocation percentages must add up to 100 percent. The Order Promising process does not split the desired quantity when checking for availability.

The Order Promising process checks the source with the highest allocation percent first within a group of sources with the same rank. If the source with the highest allocation percent has enough supply, that source is used for the entire requested quantity. If the source with the highest allocation percent does not have enough supply, then the source with the next highest allocation percent will be checked for the entire quantity. Because split allocations are not applicable to order promising sourcing strategies, the examples provided here do not include split allocations.

The following table is an example of a sourcing rule with three ranks. Quantity-based sourcing is not being used in this example. If a supply chain search is conducted using this rule, order promising checks if organization M2 can make the desired quantity first. If organization M2 cannot make the desired quantity, order promising will then check if there is enough quantity at organization V1 for an interorganization transfer. If there is not enough quantity at organization V1, then order promising will check if the desired quantity can be bought from supplier Winter Widgets.

|

Replenishment Source and Applicable Attribute Value |

Rank |

Allocation Percent |

|---|---|---|

|

Make at manufacturing organization M2 |

1 |

100 |

|

Transfer from organization V1 |

2 |

100 |

|

Buy from supplier Winter Widgets |

3 |

100 |

This example illustrates how to define sourcing rules to implement sourcing requirements with quantity-based sourcing specified in the requirements.

You are defining the sources for a set of business requirements that initially include quantity ranges for two suppliers. The requirements change to include a third quantity range and a third supplier.

Your business initially defines the following sourcing requirements:

For quantities less than 100, buy from Supplier A.

For quantities greater than or equal to 100, buy from Supplier B.

Your business adds a new supplier, Supplier C. Your business now defines the following sourcing requirements:

For quantities less than 100, buy from Supplier A, if Supplier A has enough quantity.

For quantities greater than or equal to 100, but less than 200, buy from Supplier B, if Supplier B has enough quantity.

For quantities greater than or equal to 200, buy from Supplier C.

If Supplier A does not have enough supply for a quantity less than 100, or Supplier B does not have enough supply for a quantity between 100 and 199, buy from Supplier C for these quantities.

First, analyze your sourcing requirements to determine how many different sourcing rules you need to create to implement your sourcing requirements. The requirements specified above can be defined within one sourcing rule. After determining how many sourcing rules to define, determine how many sources must be defined for each sourcing rule. First analyze how many replenishment source types have been specified in the requirements. All of the requirements above are for buy-from-a-supplier replenishment source types. Next, analyze how to define the From Quantity, Less Than Quantity, and Rank attributes as needed to implement your sourcing requirements.

For the requirements as initially stated, define two sources with the following values for the Source Type, Supplier, From Quantity, Less Than Quantity, Allocation, and Rank attributes:

Source Type equals Buy from, Supplier equals Supplier A, Less Than Quantity equals 100, Allocation Percent Equals 100, and Rank equals 1

You do not need to specify a value for the From Quantity attribute because the source applies for any quantity less than 100.

Source Type equals Buy from, Supplier equals Supplier B, From Quantity equals 100, Allocation Percent Equals 100, and Rank equals 1.

You do not need to specify a value for the Less Than Quantity attribute because the source applies for any quantity greater than or equal to 100.

For the requirements after the third supplier is added, edit the buy-from-Supplier-B source and add additional sources for Supplier C to define the four sources with the following values for the Source Type, Supplier, From Quantity, Less Than Quantity, Allocation, and Rank attributes:

Source Type equals Buy from, Supplier A, Less Than Quantity equals 100, Allocation Percent Equals 100, and Rank equals 1.

You do not need to specify a value for the From Quantity attribute because the source applies for any quantity less than 100.

Source Type equals Buy from, Supplier B, From Quantity equals 100, Less Than Quantity equals 200, Allocation Percent Equals 100, and Rank equals 1.

Source Type equals Buy from, Supplier C, From Quantity equals 200, Allocation Percent Equals 100, and Rank equals 1.

You do not need to specify a value for the Less Than Quantity attribute because the source applies for any quantity greater than or equal to 200.

Source Type equals Buy from, Supplier C, and Rank equals 2.

You do not need to specify a value for the From Quantity attribute or Less Than Quantity attribute because there is no minimum or maximum value in this case.

This table lists the two sources you define to implement the following sourcing requirements:

Check Supplier A for order quantities less than 100.

Check Supplier B for order quantities greater than or equal to 100.

|

Type |

Supplier |

From Quantity |

Less Than Quantity |

Quantity Unit of Measure |

Allocation Percent |

Rank |

|---|---|---|---|---|---|---|

|

Buy from |

A |

|

100 |

Each |

100 |

1 |

|

Buy from |

B |

100 |

|

Each |

100 |

1 |

This table lists the four sources you define to implement the following sourcing requirements:

Check Supplier A for orders for quantities less than 100.

Check supplier B for quantities greater than or equal to 100 and less than 200.

Check supplier C for quantities greater than 200.

Check supplier C for quantities less than 200 when Supplier A or Supplier B do not have the desired quantity.

|

Type |

Supplier |

From Quantity |

Less Than Quantity |

Quantity Unit of Measure |

Allocation Percent |

Rank |

|---|---|---|---|---|---|---|

|

Buy from |

A |

1 |

100 |

Each |

100 |

1 |

|

Buy from |

B |

100 |

200 |

Each |

100 |

1 |

|

Buy from |

C |

200 |

|

Each |

100 |

1 |

|

Buy from |

C |

|

|

|

100 |

2 |

You create assignment sets to implement the supply chain networks for your sourcing strategies. You implement your supply chain network by selecting the appropriate sourcing assignment level when you assign a sourcing rule or bill of distribution to an assignment set. You create alternative assignment sets, with different sourcing assignments, to model alternative supply chains.

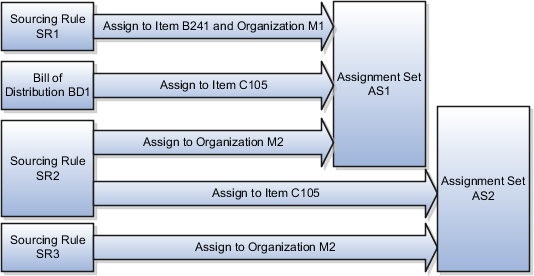

The following figure shows an example where three sourcing rules and one bill of distribution are assigned to two assignment sets:

The first sourcing rule, SR1, is assigned to the first assignment set, AS1, at the item and organization assignment level for item B241 and organization M1.

The bill of distribution, BD1, is assigned to the first assignment set, AS1, at the item assignment level for item C105.

The second sourcing rule, SR2, is assigned to the first assignment set, AS1, at the organization assignment level for organization M2.

The second sourcing rule, SR2, is also assigned to the second assignment set, AS2, but it is assigned to AS2 at the item assignment level for item C105.

The third sourcing rule, SR3, is assigned to the second assignment set AS2, at the organization assignment level for organization M2.

When the supply chain network implemented by assignment set AS2 is followed, Item C105 is replenished according to the sourcing means specified in the sourcing rule SR2. When the supply chain network implemented by assignment set AS1 is followed, Item C105 is replenished according to the sourcing means specified in the bill of distribution BD1.

When you create sourcing rules and bills of distribution, you create descriptions of the means by which you replenish items, but you do not associate these means with any specific items. You create assignment sets to define your supply chain sourcing and transfer links by assigning sourcing rules and bills of distribution to specific items, customers, organizations, categories, demand classes, or regions. For each sourcing assignment within an assignment set, you select the applicable sourcing assignment level to implement the scope of the sourcing rule or bill of distribution for the specific sourcing assignment.

When you add new replenishment sources, change your strategies for using your existing sources, or you delete replenishment sources, you edit exiting assignment sets, or create new assignment sets, to incorporate these changes into your supply chains. When you edit assignment sets, you add new sourcing assignments to the assignment set, delete exiting sourcing assignments from the assignment set, or make changes to the assignment level and assignment attributes for existing sourcing assignments. You edit assignment sets on the Edit Assignment Set page, or in a worksheet by choosing to edit in worksheet while on the Manage Assignment Sets or Edit Assignment Set pages.

When you design an assignment set, you determine the sourcing assignment level for each sourcing assignment contained within the assignment set. To implement well-designed assignment sets, you must know which sourcing assignment levels take precedence over which other sourcing assignment levels.

Two aspects to understand regarding sourcing assignment levels are:

The sourcing assignment levels and their levels of granularity

Sourcing demand types and the sourcing assignment levels

To determine which sourcing assignments to include in an assignment set, you need to know which assignment levels override which assignment levels. An assignment level that is more granular overrides an assignment level that is less granular.

For example, the Item and Customer and Customer Site assignment level is more granular than the Item and Customer assignment level. If a customer has 12 customer sites, and your sourcing strategy is the same for a specific item at 11 of the 12 customer sites, you only need to add these two sourcing assignments to your assignment set to implement this aspect of your sourcing strategy:

A sourcing assignment at the Item and Customer assignment level to implement which sourcing rule or bill of distribution is applicable for orders placed for the item by the customer at 11 of the customer sites.

A sourcing assignment at the Item and Customer and Customer Site assignment level to implement which sourcing rule or bill of distribution is applicable for orders placed for the item by the customer at the twelfth customer site.

If an order for the item is received for the customer at the twelfth customer site, then the sourcing rule or bill of distribution assigned at the Item and Customer and Customer Site level will be applied. If an order for the item is received for the customer for any of the other eleven sites, then the sourcing rule or bill of distribution assigned at the Item and Customer assignment level will be applied.

The sourcing assignment levels, listed most granular to least granular, are:

Item and customer and customer site: Applies to a specific item for a specific customer at a specific customer site.

Item and customer: Applies to a specific item for a specific customer at all of the customer's sites.

Item and demand class: Applies to a specific item in a specific demand class.

Item and region: Applies to a specific item in a specific region or zone.

Item and organization: Applies to a specific item at a specific organization.

Category and customer and customer site: Applies to all items in specific item category for a specific customer at a specific customer site.

Category and customer: Applies to all items in specific item category for a specific customer at all of the customer's sites.

Category and demand class: Applies to all items in a specific item category for a specific demand class.

Category and organization: Applies to items in a specific item category at a specific organization.

Item: Applies to a specific item in all regions, in all demand classes, and for all customers and all organizations.

Category and region: Applies to all items in a specific item category for a specific region.

Category: Applies to all items in a specific item category in all regions, in all demand classes, and for all customers and all organizations.

Customer and customer site: Applies to a specific customer at a specific customer site for all items.

Customer: Applies a specific customer at all of the customer's sites for all items.

Demand class: Applies to all a specific demand class for all customers and all items.

Region: Applies to a specific region or zone for all demand classes, all customers, and all items.

Organization: Applies to a specific organization for all categories and all items.

Global: Applies to all regions and zones, all demand classes, all customers, all items, and all organizations.

Note

The assignment levels that include category are available only if a category set has been defined for the Sourcing Rule Category Set profile option.

When you create an assignment set, all assignment levels are applicable. When sourcing logic determines which sourcing assignment to use, the type of sourcing need determines what attribute values have been provided, which determines which assignment levels are considered.

Demand for sales orders or forecasts sourcing, also known as independent demand, specifies a value for one or more of the following attributes: item, customer, customer site, demand class. Sales orders always specify item, customer, and customer site. The postal code included in a customer site is used to derive the region. Therefore, for independent-demand sourcing the sourcing logic will consider sourcing assignments where the assignment level includes customer site, customer, item, demand class, or region. A sourcing assignment at the global assignment level will also be considered.

Organization demand specifies a value for the item. The category value is derived from the category the item belongs to. The organization the demand is for defines the organization value. Therefore, for organization-demand sourcing the sourcing logic will consider sourcing assignments where the assignment level includes item, category, or organization. A sourcing assignment at the global assignment level will also be considered.

Note

When sourcing logic is determining where to get the supply from for a specific independent demand, such as the demand specified by a fulfillment line, the answer may be to source it from an organization that doesn't have the supply on hand. At that point, the sourcing logic will use the assignment levels applicable to organization demand to determine how to source the supply for that organization.

Tip

If you are checking the availability for fulfillment line, and you are viewing the pegging tree presented when you view the details of an availability option, you can see the supply chain followed to determine how to source the fulfillment line.

The sourcing assignment levels that you select when you create sourcing assignments in an assignment set formulate a sourcing hierarchy for that assignment set. Order promising uses the sourcing hierarchy to determine which sourcing rule or bill of distribution to follow to find a source for a specific item. Order promising always uses the most specific sourcing rule or bill of distribution that is applicable in the hierarchy.

Note

When order promising conducts a supply chain search, a profile option , the Default Order Promising Assignment Set profile option, designates which assignment set will be applied. Order promising uses the sourcing hierarchy to determine which sourcing rule or bill of distribution to follow from the rules or bills within the designated assignment set.

The position of a sourcing rule or a bill of distribution in the sourcing hierarchy is determined by these two factors:

The assignment level at which you assigned the sourcing hierarchy or bill of distribution to the assignment set.

The rule or bill type which can be global sourcing rule, local sourcing rule, bill of distribution, or source organization. Source organization is the type used to designate when the set of item attribute values is what determines the source instead of a sourcing rule or bill of distribution.

Tip

Understanding and using the power of the sourcing hierarchy in an assignment set can make the designing and managing of sourcing relationships easier.

For example, if a plant initially receives all items belonging to a specific item category, such as the Fasteners item category, from Supplier A, then the sourcing rule to buy from Supplier A can be assigned at the Category assignment level for the Fastener item category.

If you then determine that a specific fastener is to be sourced from a different supplier, Supplier B for example, then you can assign a different sourcing rule to buy from Supplier B at the item level for the specific fastener. The detailed-to-general hierarchy determines that the specific fastener will be sourced from Supplier B, while all other fasteners are still sourced from Supplier A.

The sourcing hierarchy can be envisioned as a detailed-to-general table where each row in the table is a combination of assignment level and rule type. Each row in the hierarchy is more specific than the row below it. The topmost row, the row where a sourcing rule is assigned at the item and customer and customer site assignment level, is the most specific row. The bottommost row, the row where a global sourcing rule is assigned at the global assignment level, is the most general row. You use the sourcing hierarchy to answer which sourcing rule, bill of distribution, or set of item attribute values will be used to find a source for a specific combination of values of these four criteria:

Assignment set

Date

Organization

Item

For the sourcing rules and bills of distribution within the assignment set where the effective date of the sourcing assignment meets the date criteria, each rule or bill is associated with a specific row in the sourcing hierarchy. The sourcing assignment attribute values, such as the item value, determine which of the rules, bills, and set of item attributes are applicable to the specific criteria set. Multiple rules, bills, or item attributes can be applicable; therefore, multiple rows can be applicable. The rule, bill, or set of item attributes associated with the highest row in the hierarchy is the rule, bill, or set of item attributes that will be followed to determine the source.

From the Manage Assignment Sets page, you can select the View Sourcing Hierarchy button to view a table containing rows of the sourcing hierarchy. The most specific, most granular, row is the top row. The least specific, least granular row, is the bottom row.

|

Assignment Level |

Sourcing Rule Type |

|---|---|

|

Item and organization |

Sourcing rule |

|

Item and organization |

Source Organization |

|

Category and organization |

Sourcing Rule |

|

Item |

Bill of Distribution |

|

Item |

Sourcing rule |

|

Category |

Bill of Distribution |

|

Category |

Sourcing Rule |

|

Organization |

Sourcing Rule |

|

Organization |

Source Organization |

|

Global |

Bill of Distribution |

|

Global |

Sourcing rule |

Tip

You can view the sourcing hierarchy and initiate a search to ask "Where does this organization get this item on this date?" If you need to analyze why the order promising process returned results that were different than what you expected, you can view and search the sourcing hierarchy to determine which sourcing rule would be used for your set of criteria.

When managing or editing assignment sets, you use the Edit in Spreadsheet button to use a spreadsheet to add, edit, or delete the sourcing rule or bill of distribution assignments for an assignment set. If you are managing assignment sets, you must select an assignment set before you can choose to edit in spreadsheet.

Set profile options to specify the following for Oracle Fusion Global Order Promising:

The sourcing assignment set and lead time multiplier used by the Check Availability process, as well as whether the Check Availability process can invoke external order promising web services

The number of minutes that the results from the Check Availability process remain valid on the Check Availability page, as well as whether the check availability page displays analytics

The number of default display days for the Review Supply Availability page, as well as the organization calendar to be used for supply buckets in the Supply Availability report

The category set used when assignment sets are created

This table lists the profile options that affect the Check Availability process. If the profile option does not have a default value, the Default Value column in the table is blank.

|

Profile Option Display Name |

Default Value |

Effect |

|---|---|---|

|

Order Promising Sourcing Assignment Set |

|

Defines which sourcing assignment set will be used by the supply allocation and check availability processes |

|

Supplier Capacity Accumulation Lead Time Multiplier |

1 |

Defines the multiplier of the approved supplier list lead time to be used to determine the date when to begin the accumulation of supplier capacity |

|

External ATP Web Service Enabled |

No |

If enabled, allows the Check Availability process to invoke external order promising web services |

This table lists the profile options that affect the Check Availability page.

|

Profile Option Display Name |

Default Value |

Effect |

|---|---|---|

|

Timeout for Check Availability Results |

10 |

Sets the number of minutes that the results returned by the Check Availability process will remain valid on the Check Availability page |

|

Analytics for Check Availability Page Enabled |

Yes |

If enabled, the Check Availability page will display analytics |

|

Fulfillment Line Distribution Analytic Days for First Date Range |

2 |

Sets the number of days for the first lateness range in the Fulfillment Line Distribution analytic |

|

Fulfillment Line Distribution Analytic Days for Second Date Range |

7 |

Sets the number of days for the second lateness range in the Fulfillment Line Distribution Analytic |

|

Fulfillment Line Distribution Analytic Days for Third Date Range |

14 |

Sets the number of days for the third lateness range in the Fulfillment Line Distribution Analytic |

This table lists the profile options that affect the Review Supply Availability page and the Supply Availability report. If the profile option does not have a default value, the Default Value column in the table is blank.

|

Profile Option Display Name |

Default Value |

Effect |

|---|---|---|

|

Default Display Days in Review Supply Availability Page |

21 |

Sets the number of horizon days for the Review Supply Availability page if end date was not entered on the ATP Check Availability page |

|

Organization Calendar for Supply Buckets in Supply Availability Report |

|

Defines the organization calendar to use for the weekly and period supply buckets in the Supply Availability report |

This table lists the Sourcing Rule Category Set profile option. There is no default value for the Sourcing Rule Category Set profile option. You must define a value for the Sourcing Rule Category Set profile option to have the assignment levels that include category available as choices for assignment level when creating assignment sets.

|

Profile Option Display Name |

Effect |

|---|---|

|

Sourcing Rule Category Set |

Determines which category set is used when defining assignment sets |