Integrating with an Electronic Data Collection

System

Integrating with an Electronic Data Collection

System

This chapter gives an overview of integrating with third-party systems and discusses how to manage the information in greater detail by integrating PeopleSoft Manufacturing with these third-party systems:

Electronic data collection.

Item content provider.

Manufacturing execution system.

Product data management system.

Product life cycle management applications.

See Also

PeopleSoft Manufacturing Integrations

Integrating with an Electronic Data Collection

System

Integrating with an Electronic Data Collection

System

Today, many manufacturers are minimizing manual data entry on the shop floor. Enhancing the capability to employ data collection devices provides improvements in three very important areas:

|

Error reduction |

You can scan the control data (production, operation, and work center) rather than manually enter it, reducing the probability of errors. |

|

Accuracy |

Data collected during the course of the production activity reflects greater accuracy. |

|

Simplicity |

Depending upon the data collection front-end solution, you can combine several transactions together. |

PeopleSoft Manufacturing and PeopleSoft Flow Production enable you to use a bar code scanner, wedge connected to a PC, or radio frequency device to scan data. You can use electronic data collection with these transactions:

Actual Hours

Completions

Component Issue/Return

Kanban Completions

Kanban Receiving

Kanban Transfers

Kit Issues/Returns

Manual Replenishment Request

Multiple Output Completions

Production Picking

Bar coded labels are available for completed items, Kanban Cards, and Pull Tickets. You can also print bar code-enabled reports.

All bar coded transactions are inserted into a central Transaction Log using PeopleSoft Application Messaging, where a process executes to pick up specific transaction rows for validation. If no errors are found, the system applies the transactions through PeopleSoft Manufacturing and PeopleSoft Flow Production. If errors are found, you can review the transactions and fix the errors on the Transaction Maintenance page.

See Also

Getting Started with PeopleSoft Manufacturing

PeopleSoft Manufacturing Integrations

Integrating to Electronic Data Collection Systems

Processing Picking Plans Using Electronic Data Collection

Processing Kit Issues and Returns Using Electronic Data Collection

Issuing Material Using Electronic Data Collection

Maintaining Kanban Cards and Replenishment Requests

Integrating with an Item Content Provider

Integrating with an Item Content Provider

The proliferation of Web-based catalogs has provided manufacturers with an easy and effective tool to locate components with the desired specifications at the lowest cost. The traditional catalog function now comes in a variety of forms to improve business to business communication between systems. Examples of the types of systems PeopleSoft defines as 'Item Content Providers' include Component Supplier Management (CSM) systems, market site aggregators, independent trading exchanges, and traditional catalog providers with new web interfaces. These systems benefit the design and purchasing of new products by accelerating item location, maximizing design reuse, and reducing acquisition costs.

Item Content Providers provide tools to classify and query item lists. This benefits engineering designs by enabling parametric search capability, maximizing design reuse, preferred parts selection, and efficient parts retrieval. You can use Item Content Providers to help reduce the number of redundant items in an organization.

On the procurement side of your organization, you can use an Item Content Provider to classify parts and vendors, and set up business rules for supplier consolidation, and supplier performance management. It also helps with cost reduction by getting the correct and lowest cost components up front.

PeopleSoft provides several enterprise integration points (EIP) to these systems to maximize ease of importing item data into the PeopleSoft database. Using Application Messaging technology, you can keep this information up to date within the PeopleSoft system by subscribing to XML messages from an Item Content Provider system to the PeopleSoft EIPs:

Item Definition (SetID)

Item Business Unit attributes

Item Revisions

Vendor/Item attributes

Note. For Item Content Providers, PeopleSoft supports inbound messages only.

Understanding Item Content Provider Transactions

Understanding Item Content Provider Transactions

Depending on the Item Content Provider involved, it may include publishing items, revisions, and item pricelist messages. These messages must be formatted into the PeopleSoft XML structure prior to being posted to PeopleSoft.

Note. This translation is third-party specific and isn't performed using the PeopleSoft system.

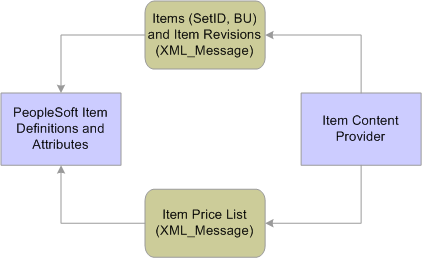

This diagram illustrates the flow of data (using the service operations within PeopleSoft Integration Broker) from an item content provider to PeopleSoft for item definitions, item attributes, and item price lists:

Item Content Provider process

Once XML messages are posted to PeopleSoft , the PeopleSoft subscription process reformats the XML message data and writes the data into PeopleSoft staging tables. The system then initiates an Application Engine process to validate the data. If no errors are found, the process then updates the PeopleSoft item definition tables. If errors are found, you can review the message log and correct errors using the standard Data Definition Maintenance pages.

Note. You can't use Item Content Provider transactions to update transaction related data such as item quantity balances in the PeopleSoft Inventory tables.

Using the Item Master Transaction

The Item Content Provider uses the Item Master EIP to accept detailed updates and new items master information as well as Item business unit specific attributes including Revision data. The Item data includes Master Item, Item Business Unit Attributes, Purchasing Attributes, Item Unit of Measure and Item Revision information.

See PeopleSoft Engineering Overview.

Using the Item Pricelist Transaction

Item Pricelist messages update the system with vendor's item catalogs. This includes detailed item information such as item dimensions, lot and serial control numbers, item groups and families, categories, and statuses. For each item, the system can also receive purchasing data including inspection information, pricing, packing dimensions, and vendor information like vendor catalog number and standard pricing.

See Also

Integrating with a Product Data Management

System

Integrating with a Product Data Management

System

Product Data Management (PDM) systems effectively—and quickly—track and implement new product introductions and product changes. These systems provide engineering-centric software that often pulls together CAD and product documentation, BOM and item information, ECOs, and workflow.

There is a framework in place to enable ongoing, one-way transfer of items, item revisions, and BOMs from the third-party PDM system to PeopleSoft. Using PeopleSoft Application Messaging technology, the third-party system is able to publish messages to the PeopleSoft system.

See Also

PeopleSoft Manufacturing Integrations

Understanding Product Data Management

Understanding Product Data Management

Product Data Management transactions work very much like Item Content Provider transactions. The Product Data Management system publishes item, item revision and bill of material messages. The PeopleSoft subscription process reformats the message data and writes the data into a staging table. The system then initiates an Application Engine process to validate the data. If no errors are found, the process then updates the PeopleSoft Inventory item and BOM tables. If errors are found, you can review the message log and correct errors using the standard Data Definition Maintenance pages.

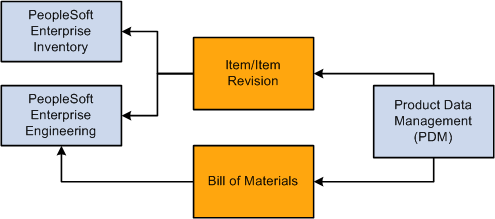

This diagram illustrates the process flow of BOM and item data from the PDM Provider to PeopleSoft Inventory and PeopleSoft Engineering. The PDM Provider publishes new BOMs, updates to existing BOMs, new items, and item revisions:

Data flow from the PDM Provider to PeopleSoft

Using the Bill of Material Transaction

If you are integrating to a third-party Product Data Management (PDM) system, you can subscribe to BOM messages from that system. You typically use PDM systems to manage design aspects of BOMs and BOM changes. You can use them to create new BOMs and then update PeopleSoft Engineering or PeopleSoft Manufacturing. For existing BOMs, you can change components, reference designators, output lists, and substitute items in the PDM and send messages back to the PeopleSoft system. You maintain quantity information in the PeopleSoft applications rather than in the PDM.

See PeopleSoft Engineering Overview.

Using the Item Master Transaction

The Item Content Provider uses the Item Master EIP to accept detailed updates and new items. The Item data includes Master Item, Item Business Unit Attributes, Purchasing Attributes, Item Unit of Measure and Item Revision information. This is an inbound, asynchronous message.

Note. When publishing new items or item revisions in combination with MBOM or EBOM additions or changes, you must publish Item additions prior to publishing BOMs that reference those additions. If not, the BOM transactions may error out due to missing items or revisions which are referenced on the BOMs.

See Maintaining Bills of Material.

See Also

Processing Enterprise Integration Points (EIPs)

Integrating with a Manufacturing Execution

System

Integrating with a Manufacturing Execution

System

You can integrate to a Manufacturing Execution System (MES) to enable the optimization of production activities from production order launch to completion of finished goods. MES functions include:

Resource Allocation and Status

Operations/Detail Scheduling

Dispatching Production Units

Document Control

Data Collection/Acquisition

Labor Management

Quality Management

Process Management

Maintenance Management

Product Tracking and Genealogy

Performance Analysis

Overview of Manufacturing Execution System

Transactions

Overview of Manufacturing Execution System

Transactions

Using PeopleSoft Manufacturing's integration, you can:

Communicate production orders and production schedules from PeopleSoft to the MES using the Production Order Update EIP.

Communicate item revision information from PeopleSoft to the MES using the Item Master EIP.

Send operation and order completion and scrap information from the MES to PeopleSoft using the Completions EIP.

Send component item usage from the MES to PeopleSoft using the Edit/Issue EIP.

Analyze production performance in either PeopleSoft or the MES. If you are looking for more detailed operational information, you'll want to use the MES to gather this information.

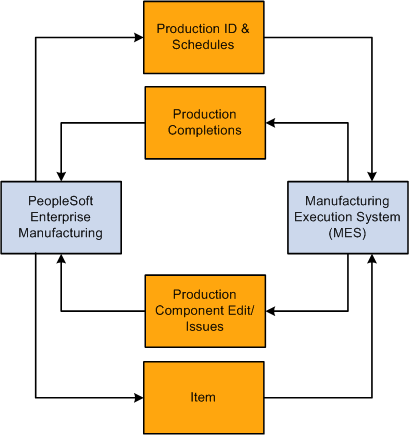

This diagram illustrates the transfer of data between PeopleSoft Manufacturing and any MES, including the transfer of production IDs, production schedules, production completions, production component edits and issues, and item data:

The flow of transfer data between PeopleSoft Manufacturing and any MES

You'll continue to use PeopleSoft Manufacturing for planning, material movement into WIP, validation of completion data, and production costing functions. PeopleSoft is the system of record for setup information, including item masters, bills of material, routings, and creating production orders.

See Also

PeopleSoft Manufacturing Integrations

Using Manufacturing Execution System Transactions

Using Manufacturing Execution System Transactions

When you add or modify production with a status of Firmed or greater, component lists, operation lists, and output lists, the system creates a publish message for the MES to pick up. The system also creates a publish message when changes are made using background programs.

You manage errors for the Completions and Edit/Issues transactions using Transaction Maintenance.

You use the Publish Outbound Transactions page to initiate the outbound publish process for the Production Order Update EIP and the Item Master outbound EIP.

See Understanding SCM Integration.

Using the Item Master Transaction

You can publish item revision information to the Manufacturing Execution System using the Item Master outbound EIP. This is an outbound, asynchronous message. When you create or modify a revision, approve a revision-controlled item, or add business unit attributes to a revision-controlled item, the system publishes an item revision message to the Manufacturing Execution System.

See Maintaining Bills of Material.

Using the Production ID/Production Schedule Manufacturing Execution System Transaction

Use the Production Order Update EIP to export production ID or production schedule changes to an external system. This is an outbound, asynchronous message.

See Maintaining Production Orders and Production Schedules.

Using the Completions Manufacturing Execution System Transaction

Use the Production Completions EIP to import information into PeopleSoft Manufacturing. This is an inbound, asynchronous message.

See Recording Completions and Scrap Using Electronic Data Collection.

Using the Edit/Issues Manufacturing Execution System Transaction

Use the Production Order Issue EIP to import edit or issue component information from a third-party system. This is an inbound, asynchronous message.

See Completing Operations and Recording Scrap.

See Also

Processing Enterprise Integration Points (EIPs)

Integrating with Product Life Cycle Management

Applications

Integrating with Product Life Cycle Management

ApplicationsBy using PeopleSoft Manufacturing, you can send item, revision, and manufacturing bill of material (BOM) information using product life cycle management applications.

See PeopleSoft Manufacturing Integrations.