Production Scheduling in PeopleSoft Manufacturing

Production Scheduling in PeopleSoft Manufacturing

This chapter discusses:

Production scheduling in PeopleSoft Manufacturing.

Factors affecting scheduling with PeopleSoft Manufacturing.

Factors affecting scheduling with PeopleSoft Supply Planning.

Examples of production scheduling.

Production Scheduling in PeopleSoft Manufacturing

Production Scheduling in PeopleSoft Manufacturing

In PeopleSoft Manufacturing, you can maintain the schedule for production using the PeopleSoft Manufacturing scheduling algorithms or PeopleSoft Supply Planning solvers. Although the PeopleSoft Supply Planning solvers use production data from PeopleSoft Manufacturing to create and maintain a production plan, the production plan derives the schedule based on slightly different factors and scheduling algorithms than those used in PeopleSoft Manufacturing. PeopleSoft Manufacturing schedules each production ID or production schedule quantity independently of other production IDs or production schedules. It does not consider demands put on resources by other production when scheduling the individual production ID or production schedule quantity.

However, PeopleSoft Supply Planning can consider resource requirements across multiple production IDs or production schedules. PeopleSoft Supply Planning schedules and reschedules production, so available capacity is not exceeded in any one day.

Although Oracle recommends that you use the PeopleSoft Supply Planning solvers to schedule or optimize production, times occur when you might need to add or change a production ID or production schedule without running it through the solvers. If capacity is a concern in the environment, the actual start and due dates and times that PeopleSoft Manufacturing determines should be used only as a guideline or estimate.

This chapter describes the factors that are involved in the scheduling of production using PeopleSoft Manufacturing and PeopleSoft Supply Planning.

Factors Affecting Scheduling with PeopleSoft

Manufacturing

Factors Affecting Scheduling with PeopleSoft

Manufacturing

If you are using PeopleSoft Manufacturing to schedule production, in addition to planned lead times, these factors affect the actual start date and time and the actual due date and time of each operation:

Operation overlap, based on a percentage or send ahead quantity.

Whether setup can occur during queue time or at any time after production begins.

Whether setup time is included in scheduling the operation.

Operation intensity.

The work center calendar, if one exists.

The production calendar, if one exists.

The five-day workweek calendar.

Note. If PeopleSoft Supply Planning is installed, you cannot define queue planning lead times. Simultaneous setup and queue is not considered.

You define these factors for each business unit, item, work center, or routing. You can also define these factors when maintaining the operation list if the production is in the Firmed or Released status when an operation list is created.

Maintaining Production Dates and Actual

Dates

Maintaining Production Dates and Actual

Dates

All production IDs and production schedules maintain production date and shift information as well as actual date and time information.

Production date and shift information is defined as the actual working day and shift (or manufacturing day and shift) during which component and production scheduling can be done. You define production dates and shifts through the production calendar or the work center calendars.

Actual date and time is defined as the actual date and time the production is scheduled to begin or end. In most cases, production dates and actual dates are the same. If you have production shifts that span two days, the actual date for production may be different from the production date. The system determines an actual date by the actual time that a production is scheduled to start or end within the production shift.

Defining Production Scheduling Methods

Defining Production Scheduling Methods

You define a production scheduling method when you create a new production ID. When you manually add a production ID, the system schedules it based on whether you know when you want to start production or when the item is due:

If you decide to schedule the production ID based on the completion date and time or the due date and time, it is backward scheduled.

In this case, the system calculates the actual start date and time. The production start date and shift as well as the production due date and shift associated with both the actual start date and time and due date and time are determined.

If you decide to schedule the production ID based on the actual start date and time, it is forward scheduled.

In this case, the system determines when the assemblies will be complete and calculates an actual due date and time. The production start date and shift as well as the production due date and shift associated with both the actual start date and time and due date and time are determined.

PeopleSoft Manufacturing always backward schedules production schedules. When adding a new production schedule, you enter a production due date and production due shift for the production quantity. The system then calculates the production start date and production start shift. The actual start date and time as well as the actual due date and time are also calculated.

When changing the status for a production ID or production schedule to Firmed or Released, the system copies the item's routing and creates an operation list. As the system creates the operation list, it also determines the actual start date and time and actual due date and time for each operation. When the system creates the operations list, it reschedules each operation any time that it's modified.

Factors Affecting Scheduling with PeopleSoft

Supply Planning

Factors Affecting Scheduling with PeopleSoft

Supply Planning

PeopleSoft Supply Planning considers several factors when determining the actual start and due date and time of production, teardown, or rework orders, as well as the actual start date and time and actual due date and time of each operation. These factors include:

Planning constraints.

Material availability.

Planning labor or machine setup, run, and fixed run times or run rates defined for each operation.

Operation overlap.

Operation intensity.

Work center calendars, if they exist for the work centers associated with each operation.

The production calendar, if one exists.

The five-day workweek calendar.

Note. Although you can maintain calendars in PeopleSoft Supply Planning, you must use the calendars maintained in PeopleSoft Manufacturing. The calendar data is sent to PeopleSoft Supply Planning with other production data when you are creating a PeopleSoft Supply Planning schedule.

You define these factors as you set up manufacturing data for each business unit, item, work center, or routing. You can also define these factors when maintaining the operation list if the production is in Firmed or Released status.

As PeopleSoft Supply Planning generates an optimized production plan, the system considers material and resource requirements across all production. Additionally, if an item's primary routing causes a constraint violation, the system considers an alternate routing. When the routing is selected, PeopleSoft Supply Planning schedules individual operations for new or existing production, again considering all constraints. The system then sends this information (in the form of planning messages) to PeopleSoft Manufacturing. These messages recommend that new production IDs or production schedules be added or existing production IDs and production schedules be rescheduled or canceled.

See Also

PeopleSoft Supply Planning PeopleBook

Examples of Production Scheduling

Examples of Production Scheduling

The following examples illustrate how PeopleSoft Manufacturing creates and maintains operation schedules. These examples illustrate how the system calculates actual start and due dates and times for different operations using forward and backward scheduling.

Note. These examples assume that you are not using the PeopleSoft Supply Planning solvers to schedule production.

The examples use these types of shop floor operations:

Example 1: Operations with no overlap; queue and setup are done sequentially.

Example 2: Operations with no overlap; queue and setup are done concurrently; queue time is less than setup time.

Example 3: Operations with no overlap, queue and setup are done concurrently; setup time is less than queue time.

Example 4: Operations with no overlap; setup is not included.

Example 5: Operation overlap; queue and setup are done sequentially.

These production times are used for all examples:

|

Op |

Queue |

Setup |

Run |

Intransit |

Overlap |

|

10 |

None |

1 hour |

5 hours (.5 hr/unit) |

2 hours |

None |

|

20 |

1 hour |

3 hours |

10 hours (1 hr/unit) |

1 hour |

None |

Note. Even though PeopleSoft Manufacturing calculates start and due dates and times to the minute, hours are used to make it easier to manually calculate these shop floor operation examples.

All examples assume a 24-hour day with an operation start quantity of 10 units. The start of the operation is when setup starts.

Example 1

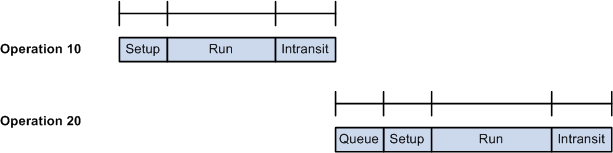

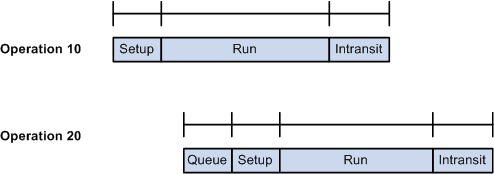

Example 1This diagram shows an example of operations with no overlap and the queue and setup are done sequentially:

Example 1: Queue time is one hour, and setup time is three hours

|

Operation |

Operation Start |

Run Start |

Operation Due |

|

10 |

Day 1, 8:00 a.m. |

Day 1, 9:00 a.m. |

Day 1, 2:00 p.m. |

|

20 |

Day 1, 5:00 p.m. |

Day 1, 8:00 p.m. |

Day 2, 6:00 a.m. |

Forward Scheduling Calculations

Production ID Start Date and Time = Day 1, 8:00 a.m.

This table lists the steps that you take to calculate the start and due date and times for the first operation (Operation 10):

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 10 start date and time. |

Production ID's start date and time. |

This calculation assumes that queue cannot occur at the first operation. |

|

2 |

Operation 10 run start date and time. |

Operation start date and time + setup time. |

None. |

|

3a or |

Operation 10 run time (time and unit). |

Operation start quantity × run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of time per unit. |

|

3b |

Operation 10 run time (units/time). |

Operation start quantity and run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of units per time unit. |

|

4 |

Operation 10 due date and time. |

Run start date and time + run time. |

None. |

This table lists the steps that you take to calculate start and due dates and times for the second operation (Operation 20):

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 20 start date and time. |

Previous operation's (Operation 10) due date and time + previous operation's in transit time + current operation's queue time. |

None. |

|

2 |

Operation 20 run start date and time. |

Current operation start date and time + setup time. |

None. |

|

3a, or |

Operation 20 run time (time and unit). |

Operation start quantity × run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of time per unit. |

|

3b |

Operation 20 run time (units/time). |

Operation start quantity and run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of units per time unit. |

|

4 |

Operation 20 due date and time. |

Current operation run start date and time + run time. |

If you have a schedule with more than two operations, repeat steps 1 through 4 in this table until all subsequent operation due dates and times are calculated. |

Backward Scheduling Calculations

Production ID Due Date and Time = Day 2, 6:00 a.m.

This table lists the steps that you take to calculate the start and due date and times for the last operation (Operation 20):

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 20 due date and time. |

Production ID's due date and time − current operation's in transit time. |

None. |

|

2a, or |

Operation 20 run time (time and unit). |

Operation start quantity × run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of time per unit. |

|

2b |

Operation 20 run time (units/time). |

Operation start quantity / run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of units per time unit. |

|

3 |

Operation 20 run start date and time. |

Current operation's due date and time − run time. |

None. |

|

4 |

Operation 20 start date and time. |

Current operation's run start date and time − setup time. |

None. |

This table lists the steps that you take to calculate start and due dates and times for the prior operation (Operation 10):

|

Step |

To calculate |

Use |

Notes |

|

1 |

Operation 10 due date and time. |

Subsequent operation's (Operation 20) start date and time − subsequent operation's queue time − current operation's in transit time. |

None. |

|

2a, or |

Operation 10 run time (time/unit). |

Operation start quantity × run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of time per unit. |

|

2b |

Operation 10 run time (units and time). |

Operation start quantity / run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of units per time unit. |

|

3 |

Operation 10 run start date and time. |

Current operation's due date and time − run time. |

None. |

|

4 |

Operation 10 start date and time. |

Current operation's run start date and time − setup time. |

If you have a schedule with more than two operations, repeat steps 1 through 4 in this table until all previous operation due dates and times are calculated. |

Example 2

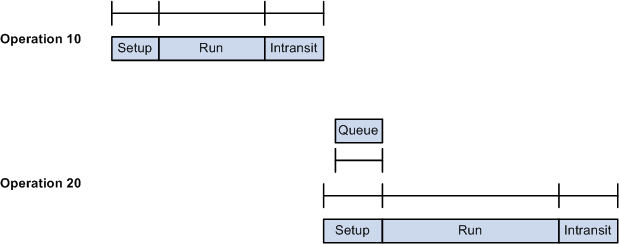

Example 2This diagram shows an example of operations with no overlap and the queue and setup are done concurrently. The queue time is less than the setup time:

Example 2: Queue time is one hour, and setup time is three hours

|

Operation |

Operation Start |

Run Start |

Operation Due |

|

10 |

Day 1, 8:00 a.m. |

Day 1, 9:00 a.m. |

Day 1, 2:00 p.m. |

|

20 |

Day 1, 4:00 p.m. |

Day 1, 7:00 p.m. |

Day 2, 5:00 a.m. |

Forward Scheduling Calculations

Production ID Start Date and Time = Day 1, 8:00 a.m.

This table lists the steps that you take to calculate the start and due date and times for the first operation (Operation 10):

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 10 start date and time. |

Production ID's start date and time. |

This calculation assumes that queue doesn't occur at the first operation. |

|

2 |

Operation 10 run start date and time. |

Operation start date and time + setup time. |

None. |

|

3a, or |

Operation 10 run time (time/unit). |

Operation start quantity × run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of time per unit. |

|

3b |

Operation 10 run time (units and time). |

Operation start quantity / run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of units per time unit. |

|

4 |

Operation 10 due date and time. |

Run start date and time + run time. |

None. |

This table lists the steps that you take to calculate start and due dates and times for the second operation (Operation 20):

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 20 start date and time. |

Previous operation's (Operation 10) due date and time + prior operation's in transit time. |

This calculation assumes that queue time is less than setup time. |

|

2 |

Operation 20 run start date and time. |

Current operation start date and time + setup time. |

None. |

|

3a, or |

Operation 20 run time (time/unit). |

Operation start quantity × run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of time per unit. |

|

3b |

Operation 20 run time (units and time). |

Operation start quantity / run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of units per time unit. |

|

4 |

Operation 20 due date and time. |

Current operation run start date and time + run time. |

If you have a schedule with more than two operations, repeat steps 1 through 4 in this table until all subsequent operation due dates and times are calculated. |

Backward Scheduling Calculations

Production ID Due Date and Time = Day 2, 5:00 a.m.

This table lists the steps that you take to calculate the start and due date and times for the last operation (Operation 20):

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 20 due date and time. |

Production ID's due date and time − current operation's in transit time. |

None. |

|

2a, or |

Operation 20 run time (time/unit). |

Operation start quantity × run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of time per unit. |

|

2b |

Operation 20 run time (units and time). |

Operation start quantity / run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of units per time unit. |

|

3 |

Operation 20 run start date and time. |

Current operation's due date and time − run time. |

None. |

|

4 |

Operation 20 start date and time. |

Current operation's run start date and time − setup time. |

None. |

This table lists the steps that you take to calculate start and due dates and times for the prior operation (Operation 10):

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 10 due date and time. |

Subsequent operation's (Operation 20) start date and time − current operation's in transit time. |

This calculation assumes that queue time is less than setup time. |

|

2a, or |

Operation 10 run time (time/unit). |

Operation start quantity × run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of time per unit. |

|

2b |

Operation 10 run time (units and time). |

Operation start quantity / run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of units per time unit. |

|

3 |

Operation 10 run start date and time. |

Current operation's due date and time − run time. |

None. |

|

4 |

Operation 10 start date and time. |

Current operation's run start date and time − setup time. |

If you have a schedule with more than two operations, repeat steps 1 through 4 in this table until all previous operation due dates and times are calculated. |

Example 3

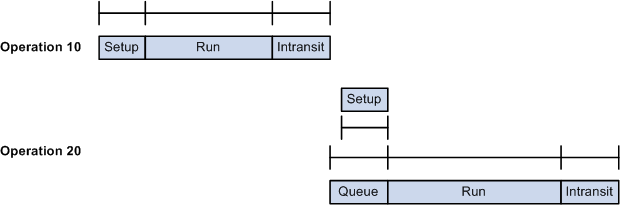

Example 3This diagram shows an example of operations with no overlap, the queue and setup are done concurrently, and the setup time is less than the queue time:

Example 3: Queue time takes three hours and setup takes one hour

|

Operation |

Operation Start |

Run Start |

Operation Due |

|

10 |

Day 1, 8:00 a.m. |

Day 1, 9:00 a.m. |

Day 1, 2:00 p.m. |

|

20 |

Day 1, 6:00 p.m. |

Day 1, 7:00 p.m. |

Day 2, 5:00 a.m. |

Forward Scheduling Calculations

Production ID Start Date and Time = Day 1, 8:00 a.m.

This table lists the steps that you take to calculate the start and due date and times for the first operation (Operation 10):

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 10 start date and time. |

Production ID's start date and time. |

This calculation assumes that queue doesn't occur at the first operation. |

|

2 |

Operation 10 run start date and time. |

Operation start date and time + setup time. |

None. |

|

3a, or |

Operation 10 run time (time/unit). |

Operation start quantity × run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of time per unit. |

|

3b |

Operation 10 run time (units and time). |

Operation start quantity / run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of units per time unit. |

|

4 |

Operation 10 due date and time. |

Run start date and time + run time. |

None. |

This table lists the steps that you take to calculate start and due dates and times for the second operation (Operation 20):

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 20 start date and time. |

Prior operation's (Operation 10) due date and time + prior operation's in transit time + (queue − setup time of current operation). |

This calculation assumes that setup time is less than queue time. |

|

2 |

Operation 20 run start date and time. |

Current operation start date and time + setup time. |

None. |

|

3a or |

Operation 20 run time (time/unit). |

Operation start quantity × run rate (converted to hours) + fixed run (converted to hours). |

Use this calculation if the run rate is in terms of time per unit. |

|

3b |

Operation 20 run time (units and time). |

Operation start quantity / run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of units per time unit. |

|

4 |

Operation 20 due date and time. |

Current operation run start date and time + run time. |

If you have a schedule with more than two operations, repeat steps 1 through 4in this table until all subsequent operation due dates and times are calculated. |

Backward Scheduling Calculations

Production ID Due Date and Time = Day 2, 5:00 a.m.

This table lists the steps that you take to calculate the start and due date and times for the last operation (Operation 20):

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 20 due date and time |

Production ID's due date and time − current operation's intransit time |

None. |

|

2a, or |

Operation 20 run time (time/unit) |

Operation start quantity × run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of time per unit. |

|

2b |

Operation 20 run time (units and time) |

Operation start quantity / run rate (converted to hours) × fixed run (converted to hours) |

Use this calculation if the run rate is in terms of units per time unit. |

|

3 |

Operation 20 run start date and time |

Current operation's due date and time − run time |

None. |

|

4 |

Operation 20 start date and time |

Current operation's run start date and time − setup time |

None. |

This table lists the steps that you take to calculate start and due dates and times for the prior operation (Operation 10):

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 10 due date and time |

Subsequent operation's (Operation 20) start date and time − (queue time - setup time of subsequent operation) - current operation's intransit time |

This calculation assumes that setup time is less than queue time. |

|

2a, or |

Operation 10 run time (time/unit) |

Operation start quantity x run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of time per unit. |

|

2b |

Operation 10 run time (units and time) |

Operation start quantity/ run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of units per time unit. |

|

3 |

Operation 10 run start date and time |

Current operation's due date and time − run time |

None. |

|

4 |

Operation 10 start date and time |

Current operation's run start date and time − setup time |

If you have a schedule with more than two operations, repeat steps 1 through 4in this table until all prior operation due dates and times are calculated. |

Example 4

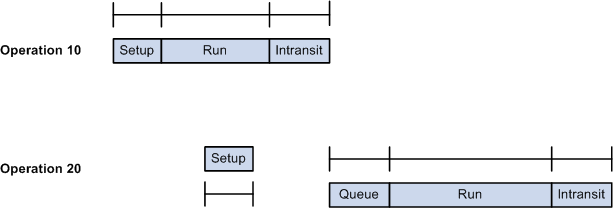

Example 4This diagram shows an example of operations with no overlap and the setup is not included:

Example 4: Queue time is three hours

|

Operation |

Operation Start |

Run Start |

Operation Due |

|

10 |

Day 1, 8:00 a.m. |

Day 1, 9:00 a.m. |

Day 1, 2:00 p.m. |

|

20 |

Day 1, 2:00 p.m. |

Day 1, 5:00 p.m. |

Day 2, 3:00 a.m. |

Forward Scheduling Calculations

Production ID Start Date and Time = Day 1, 8:00 a.m.

This table lists the steps that you take to calculate the start and due date and times for the first operation (Operation 10):

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 10 start date and time |

Production ID's start date and time |

This calculation assumes that queue doesn't occur in the first operation. |

|

2 |

Operation 10 run start date and time |

Operation start date and time + setup time |

Setup is always included at the first operation. |

|

3a, or |

Operation 10 run time (time/unit) |

Operation start quantity x run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of time per unit. |

|

3b |

Operation 10 run time (units and time) |

Operation start quantity / run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of units per time unit. |

|

4 |

Operation 10 due date and time |

Run start date and time + run time |

None. |

This table lists the steps that you take to calculate start and due dates and times for the second operation (Operation 20):

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 20 start date and time |

Prior operation's (Operation 10) due date and time + prior operation's intransit time + current operation's queue time - current operation's setup time |

This calculation assumes that setup can be completed any time after the first operation run has started. The start date and time represent the latest possible time that you should begin setup. |

|

2 |

Operation 20 run start date and time |

Current operation start date and time + setup time |

None. |

|

3a, or |

Operation 20 run time (time and unit) |

Operation start quantity x run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of time per unit. |

|

3b |

Operation 20 run time (units/time) |

Operation start quantity and run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of units per time unit. |

|

4 |

Operation 20 due date and time |

Current operation run start date and time + run time |

If you have a schedule with more than two operations, repeat steps 1 through 4 in this table until all subsequent operation due dates and times are calculated. |

Backward Scheduling Calculations

Production ID Due Date and Time = Day 2, 3:00 a.m.

This table lists the steps that you take to calculate the start and due date and times for the last operation (Operation 20):

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 20 due date and time |

Production ID's due date and time - current operation's intransit time |

None. |

|

2a, or |

Operation 20 run time (time and unit) |

Operation start quantity x run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of time per unit. |

|

2b |

Operation 20 run time (units/time) |

Operation start quantity / run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of units per time unit. |

|

3 |

Operation 20 run start date and time |

Current operation's due date and time - run time |

None. |

|

4 |

Operation 20 start date and time |

Current operation's run start date and time - setup time |

This calculation assumes that setup can be completed any time after the first operation run has started. The start date and time represent the latest possible time that you should begin setup. |

This table lists the steps that you take to calculate start and due dates and times for the prior operation (Operation 10):

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 10 due date and time |

Subsequent operation's (Operation 20) start date and time - subsequent operation's queue time - current operation's intransit time |

The run start date and time is used and setup is not included. The setup at Operation 20 can be completed at the same time the prior operation is being run. |

|

2a, or |

Operation 10 run time (time/unit) |

Operation start quantity x run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of time per unit. |

|

2b |

Operation 10 run time (units and time) |

Operation start quantity / run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of units per time unit. |

|

3 |

Operation 10 run start date and time |

Current operation's due date and time - run time |

None. |

|

4 |

Operation 10 start date and time |

Current operation's run start date and time - setup time |

If you have a schedule with more than two operations, repeat steps 1 through 4 in this table until all prior operation due dates and times are calculated. |

Example 5

Example 5This diagram shows an example of operations overlap. The queue and setup are done sequentially. Assume that operations have overlap expressed as a percent (100% = total overlap, 0% = no overlap) or send ahead quantity. If overlap is expressed as a percentage, assume that all units are available for processing at the start of the run or soon after:

Example 5: 80 percent overlap or a send ahead quantity of 2 units

|

Operation |

Operation Start |

Run Start |

Operation Due |

|

10 |

Day 1, 8:00 a.m. |

Day 1, 9:00 a.m. |

Day 1, 2:00 p.m. |

|

20 |

Day 1, 1:00 p.m. |

Day 1, 4:00 p.m. |

Day 2, 2:00 a.m. |

Forward Scheduling Calculations

Production ID Start Date and Time = Day 1, 8:00 a.m.

This table lists the steps that you take to calculate the start and due date and times for the first operation (Operation 10):

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 10 start date and time |

Production ID's start date and time |

This calculation assumes that queue doesn't occur in the first operation. |

|

2 |

Operation 10 run start date and time |

Operation start date and time + setup time |

None. |

|

3a, or |

Operation 10 run time (time/unit) |

Operation start quantity x run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of time per unit. |

|

3b |

Operation 10 run time (units and time) |

Operation start quantity / run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of units per time unit. |

|

4 |

Operation 10 due date and time |

Run start date and time + run time |

None. |

This table lists the steps that you take to calculate start and due dates and times for the second operation (Operation 20):

|

Step |

To Calculate |

Use |

Notes |

|

1a, or |

Operation 20 start date and time; overlap expressed as a percentage |

Prior operation's (Operation 10) start of run + [prior operation's total run time x (1 - overlap percent / 100)] + prior operation's intransit time + current operation's queue time |

None. |

|

1b |

Operation 20 start date and time; overlap expressed as a send ahead quantity |

Prior operation's (Operation 10) start of run + (prior operation's run rate x send ahead quantity, converted to hours) + prior operation's fixed run time + prior operation's intransit time + current operation's queue time |

None. |

|

2 |

Operation 20 run start date and time |

Current operation start date and time + setup time |

None. |

|

3a, or |

Operation 20 run time (time/unit) |

Operation start quantity x run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of time per unit. |

|

3b |

Operation 20 run time (units/time) |

Operation start quantity / run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of units per time unit. |

|

4 |

Operation 20 due date and time |

Current operation run start date and time + run time |

If you have a schedule with more than two operations, repeat steps 1 through 4 in this table until all subsequent operation due dates and times are calculated. |

Backward Scheduling Calculations

Production ID Due Date and Time = Day 2, 2:00 a.m.

This table lists the steps that you take to calculate the start and due date and times for the last operation (Operation 20):

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 20's due date and time |

Production ID's due date and time - current operation's intransit time |

None. |

|

2a, or |

Operation 20 run time (time/unit) |

Operation start quantity x run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of time per unit. |

|

2b |

Operation 20 run time (units/time) |

Operation start quantity/ run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of units per time unit. |

|

3 |

Operation 20 run start date and time |

Current operation's due date and time - run time |

None. |

|

4 |

Operation 20 start date and time |

Current operation's run start date and time - setup time |

None. |

This table lists the steps that you take to calculate start and due dates and times for the prior operation (Operation 10), with an operation overlap expressed as a percentage:

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 10 due date and time, when operation overlap is expressed as a percentage |

Subsequent operation's (Operation 20) start date and time - subsequent operation's queue time - current operation's intransit time + [current operation's total run time x (overlap percent / 100)] |

None. |

|

2a, or |

Operation 10 run time (time/unit) |

Operation start quantity x run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of time per unit. |

|

2b |

Operation 10 run time (units/time) |

Operation start quantity / run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of units per time unit. |

|

3 |

Operation 10 run start date and time |

Current operation's due date and time - run time |

None. |

|

4 |

Operation 10 start date and time |

Current operation's run start date and time - setup time |

If you have a schedule with more than two operations, repeat steps 1 through 4 in this table until all prior operation due dates and times are calculated. |

This table lists the steps that you take to calculate start and due dates and times for the prior operation (Operation 10), with an operation overlap expressed as a send ahead quantity:

|

Step |

To Calculate |

Use |

Notes |

|

1 |

Operation 10 due date and time, when operation overlap is expressed as a send ahead quantity |

Subsequent operation's (Operation 20) start date and time - current operation's intransit time - subsequent operation's queue time + [current operation's run time x (Operation start quantity - send ahead quantity)] |

None. |

|

2a, or |

Operation 10 run time (time and unit) |

Operation start quantity x run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of time per unit. |

|

2b |

Operation 10 run time (units/time) |

Operation start quantity / run rate (converted to hours) + fixed run (converted to hours) |

Use this calculation if the run rate is in terms of units per time unit. |

|

3 |

Operation 10 run start date and time |

Current operation's due date and time - run time |

None. |

|

4 |

Operation 10 start date and time |

Current operation's run start date and time - setup time |

If you have a schedule with more than two operations, repeat steps 1 through 4 in this table until all prior operation due dates and times are calculated. |