| Agile Product Lifecycle Management Product Governance and Compliance Supplier Guide Release 9.3.5 E61147-01 |

|

Previous |

Next |

| Agile Product Lifecycle Management Product Governance and Compliance Supplier Guide Release 9.3.5 E61147-01 |

|

Previous |

Next |

A Request For Information (RFI) is the process that a manufacturing company (the buyer) uses to seek compliance data from its suppliers. The buyer uses Agile PG&C to create declarations. When the buyer firm creates a declaration, it specifies a unique declaration name and a single supplier company.

The Default Declarations workflow follows a straightforward process flow, as detailed in the following table.

| Status | Action |

|---|---|

| Pending | Compliance manager (an Agile user who has been assigned the Compliance Manager role) creates new declaration, or modifies an existing declaration by adding new items, manufacturer parts, or commodities. Specifications are added to the declaration, and also an information supplier; is always only one supplier per declaration. |

| Open to Supplier | The declaration requests the supplier (an Agile user who has been assigned the Material Provider role) to confirm whether parts comply with specifications. |

| Submit to Manager | Supplier confirms or denies that the parts that they supply comply with regulations.

The supplier electronically “signs” and submits the declaration back to the compliance manager. |

| Review | The compliance manager and other reviewers verify and approve the contents of the declaration. A reviewer (including a supplier user) can acknowledge a declaration when the user is added as an acknowledger. |

| Released | The compliance manager releases the declaration, thereby publishing the new data about the substances and materials into the product record. Once published, the materials are visible on the Compliance tab of the part or part group, as appropriate.

The “buyer” company can now examine the quantities of all materials in a given top-level assemblies and find out if the assembly is compliant with a set of specifications. |

| Implemented | Once the parts are manufactured and disseminated in the field, the compliance manager implements the declaration, thereby completing the workflow. |

To complete and sign off declarations, declaration recipients for the supplier company have been assigned a role that permits access to the declarations. The default declaration recipient at the supplier company receives an email of notification.

All users at the supplier company who have been assigned the appropriate role can respond to the declaration.

If you have questions about who in your company has been assigned this role, contact your buyer company.

When you are sent a declaration request, you are responsible for completing it. You must disclose whether or not any restricted substances are contained in the component or subassembly it lists, and whether those substances comply with the given specifications.

Once a declaration is opened to a supplier, only the supplier's declaration recipients can edit it (that is, Agile users assigned the "(Restricted) Material Provider” role). For other users, including the compliance manager, the declaration becomes “read-only” until it is returned by the supplier.

This set of default behaviors regards automatic notifications, not user-designated Approvers and Observers.

Declaration Buyer to Supplier - The notification is automatically sent to the supplier. You can add more users to receive notification.

Declaration Supplier to Buyer - The compliance manager is automatically added to the notification list. If no compliance manager was selected, the system add everyone on the Compliance Managers notification list.

Declaration Supplier to Buyer - If there are no compliance managers in the system, the originator is added to the notification list.

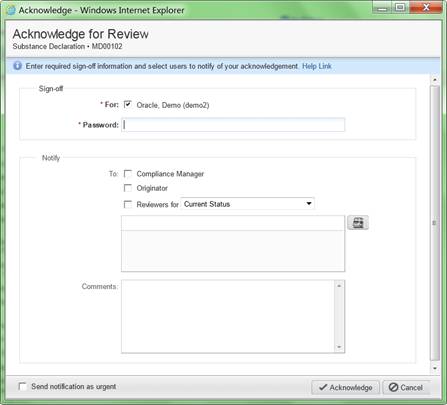

A supplier user can be added as an acknowledger for Declarations. The supplier user with the (Restricted) Material Provider role includes the Acknowledge privilege. These terms are described below:

Acknowledge - A workflow action called 'Acknowledge' is available for Review or Released status.

Acknowledger - A user or user group or job function can be an acknowledger if the Acknowledge privilege is assigned.

The Acknowledge button is visible for supplier users assigned the (Restricted) Material Provider role which contains the Acknowledge privilege.

Acknowledgers then use this dialog to notify users of the acknowledgment:

The Declaration routed for acknowledgment can be seen in Workflow Routings tab, and can be found in Notifications tab or user's Email box. To see the Workflow Routings/Notifications tab, the supplier user must be in Advanced Table Edit mode.

The supplier user can receive notifications:

When the supplier user is required to acknowledge a declaration.

When the supplier user no longer is required to acknowledge a declaration.

When the supplier user is an acknowledger and the declaration is changed to another status.

When the supplier user is an acknowledger and the declaration is signed off by other users.

When the supplier user is an acknowledger, but does not acknowledge the declaration in a specific time period.

When the supplier user is set as an escalator of an acknowledger, and the acknowledger did not acknowledge the declaration in a specific time period.

When a declaration request is opened to an information supplier, the supplier is responsible for completing the declaration and disclosing if any restricted substances are contained in the components and subassemblies it provides and whether those substances comply with specifications.

To complete and sign off on declarations, one or more declaration recipients for the information supplier must be assigned the (Restricted) Material Provider role. If you have questions about who in your supply chain has been assigned this role, see your administrator.

When the material provider changes the status of the declaration from Open to Supplier to Submit to Manager, he must "sign off" the declaration.

The above topic describes how a standard Agile declaration is sent to a supplier and, upon completion, returned to the buyer. The following process sequences describe a range of responses to declarations.

Declaration Opened and Completed in Agile Web Client

Supplier firm’s default recipient receives email notification from buyer firm's Compliance Manager requesting completion of a compliance declaration.

Click link within notification and log into Agile Web Client (Basic mode).

Click Open Requests link and select the particular declaration request.

Fill in your responses directly in Web Client. Currently this is possible only for Supplier Declarations of Conformance.

Complete the Sign off Message and submit response back to the Compliance Manager.

Declaration Opened and Completed in Microsoft Excel-based Client

On the Agile menu in the Microsoft Excel-based Client, select from list of open declarations. The spreadsheet is populated with data from new declaration.

Within Microsoft Excel, enter your responses into the form, and save it.

On the Agile menu in the Excel client, choose Submit Response.

Complete the Sign-off Message and click OK.

Declaration Opened in Web Client and Completed Using Process Extensions

Supplier firm's default recipient receives email notification from buyer's Compliance Manager to complete a compliance declaration.

Click link within notification and log into Agile PLM via Web Client (Basic mode).

Use the Export JGPSSI,Export AXML, Export IPC 2.0, or Export IPC XML process extension. The declaration request data is exported in the appropriate format, and you can open the file.

Enter your responses into the file, and save it.

Use Import JGPSSI,Import AXML,Import IPC 2.0 XML, or Import IPC XML to import the completed declaration data into Agile PLM.

The Declarations classes in Agile PLM were introduced in Declarations. This topic describes additional facts and rules of business logic for the Declarations classes.

This class of declarations is used to ask questions related to parts or part groups. The buyer company wants to send out a questionnaire to assess part compliance with specifications from customers and government agencies. Typical questions could be: What is the maximum re-flow temperature of this part? What type of plating is on this part? Is this part in compliance with a certain specification? No fields are pre-populated in this declaration.

This class of declarations allows a supplier to respond at a substance-group level and at a substance level without being able to add to the Bill Of Substances (BOS). It could be a material compliance declaration in which the buyer company wants you to declare compliance with specifications at the substance level; or, it could be a partial material disclosure declaration in which you are requested to disclose the weight and/or concentration of selected (or all) substances that are contained within the components and subassemblies it sources from your firm (or the firm whose products you are providing compliance information).

A substance declaration supports pre-population of substances and substance groups from associated specifications.

This class of declarations requests statements from suppliers at a supplier level. It is basically a supplier survey. The buyer company wants to send out a questionnaire and receive a declaration from the supplier to assess compliance with specifications from customers and government agencies. Typical questions could be: Do you have a RoHS compliance Initiative going on? When do you anticipate to have 100% compliant Product? Which ISO certifications do you possess. No fields are pre-populated in this declaration. The SDOC does not require association with any items, manufacturer parts, part groups, or even specifications in order to be effective. Adding specifications to this type of class is allowed for reference purposes.

This class of declarations is used against the template for the Japanese Green Procurement format. The Class name in Admin is JGPSSI Declarations. Agile supports only JGPSSI version 2.02. The buyer company wants suppliers to provide a declaration in the JGPSSI format using the JGPSSI supported entities. No substances from specifications are pre-populated in this declaration.

This class of declarations allows a supplier to build a Bill Of Substances (BOS) consisting of four levels: subpart, homogeneous material, substance groups, and substances. It could be a material compliance declaration at the homogeneous material level, or it could be a partial material disclosure declaration to discover the weight and concentration of substances that are contained within the homogeneous materials. This can be effected through an outside application or spreadsheet. No fields are pre-populated in this declaration.

These two Declarations classes support compliance work using the IPC forms for substance declarations (IPC 1752-1) and homogeneous materials declarations (IPC 1752-2). These forms are available in XML and Adobe PDF format. Agile PLM 9.3.2 still supports the use of the PDF forms; however the PDF forms are no longer supported by IPC.

For IPC, we support IPC 175x Version 2.0.

You must download the Scriba1750a_beta06 from http://sourceforge.net/projects/ipc175xutils/.

|

Note: CIPC 1752A represents the latest version of the standard. |

The present Agile PLM Release supports released Version 2.0 of the IPC format. The website for the IPC forms and information about the "1752" standards is http://www.ipc.org/ContentPage.aspx?pageid=Materials-Declaration.

IPC 1752A is supported by XML only; PDF forms are not supported.

IPC 1752-1 and 1752-2 are supported by XML and PDF forms. Please note that while you can use PDF forms, they are no longer supported by IPC in version 2.0.

As you create 1752-1 and 1752-2 declarations, you are given the option to choose the 1752A version. We provided two new process extensions to support IPC 1752A version: Import IPC 2.0 XML and Export IPC2.0 XML. IPC1752-1 and IPC1752-2 declarations can enable the two PXs to implement IPC1752A version. This is described in detail in the Agile PLM Administrator Guide.

We recommend your administrator create one new subclass of IPC 1752-1 Declarations and one new subclass of IPC 1752-2 Declarations using Java Client.

IPC declarations prior to version 2.0 use PDF forms. Adobe Acrobat version 7.x is the minimal requirement, while Acrobat version 8.x is the recommended release for work with the IPC PDF forms. The website for Adobe Software is www.adobe.com.

The IPC1752-2 PDF form allows entry of unstructured substance data. For instance, the user can enter homogeneous material data in a hierarchical structure or in a flat structure. The system also stores the flat structure within the declaration, which can show the user how the data was retrieved from IPC and how PLM converted the data into a hierarchical structure.

The storing of the flat structure is accomplished through four flex-fields, Text01--Text04, on the part Substances tables. They are renamed as IPC Sub-item, IPC Material, IPC Category, and IPC Substance.

By default, these fields are disabled (not visible), and the flat structure is not stored. In order to capture the flat structure of the composition, these fields must be enabled by the administrator. Even with the flexfields enabled, a user must have Modify privilege for those fields; if not, the flat structure is not stored and the user sees an "Insufficient Privilege" error during the import procedure.

Earlier, each IPC declaration carried just one specification and just one part/part group. Now Export IPC 2.0 XML and Import IPC 2.0 XML can support multiple objects.

There is no restriction to the number of specifications or the number of parts/PGs that can be added to IPC declarations. However, if a declaration carries multiple items, manufacturer parts, or part groups and multiple specifications, Export IPC 2.0 XML supports multiple Parts/PGs, indicating that Export IPC 2.0 XML exports all compositions from the declaration's <Parts/PGs> tables. But Export IPC XML will only export one composition from the declaration's <Parts/PGs> tables.

Similarly, Import IPC XML updates only one composition, that of the part that was exported. The system identifies this by the part number, rev, and the first specification in the declaration's Specifications table, which is sorted alphabetically.

Import IPC 2.0 XML updates all compositions, that of the parts that were exported. The system identifies these by the part number, rev, and the related specifications in the declaration's Specifications table, which are sorted alphabetically. As part of Import IPC 2.0 XML support of multiple compositions, for one item with different revisions, the revisions are distinguished by this format: 'NumberId [Rev]'.

The information supplier-user must do the following to complete a declaration.

For each part, manufacturer part, and part group, fill in the Mass, Mass PPM, and Compliance fields, particularly for substances that are restricted by specifications

Add or remove substances from the Substances tables (under the Items, Manufacturer Parts, and Part Groups tabs) on the declaration as necessary; to do this, they must use process extensions (Export AXML and Import AXML)

Complete other flex fields on the <parts/PG> tables as well as the <parts/PG>Substances tables.

If you are having this problem, request from your buyer company that they set a process extension that can be triggered when moving the declaration to Open to Supplier. The process extension copies the value from Item Number to Mfr Item Number, and from Item Name to Mfr Item Name.

You may experience a mapping issue on the pre-2.0 version IPC forms regarding the attributes Item Number and Manufacturer Part Number (Mfr Item Number), and also Item Name and Mfr Item Name. You may receive a declaration and expect to see (or want to enter) data in Mfr Item Number and Mfr Item Name. The issue is that the fields that must be used are Item Number and Item Name.

This will correct all four fields on the IPC form (after exporting from PLM) to have the values needed by both the Supplier users (in order to complete the form) and the PLM system (for importing back to PLM).

The weight of a part (item or manufacturer part) or assembly, expressed in system wide UOM (unit of measure). Mass in Item Title Block, is a "rev-controlled" attribute.

The Mass Disclosure attribute is found on the Part/PG tabs of declarations (as well as the Composition tab of parts and part groups). It has three values: Fully Disclosed, Partially Disclosed, and Undisclosed. The correct value is generated by the system during composition rollups.

These are the three types of disclosure, and how they are qualified by substance compositions and homogeneous material compositions.

Fully Disclosed composition (Full Disclosure):

A Substance composition is considered to be Fully Disclosed if the difference between the part's mass and the sum of the masses of all the substances is less than or equal to the Mass Tolerance Percentage setting.

A Homogeneous Material composition is Fully Disclosed if this two-step process is satisfied: (1) The difference between a material's mass (that is, the immediate parent of the substances) and the sum of mass of the substances under that material is less than or equal to the Mass Tolerance Percentage setting; and, (2) The difference between the part's mass and the sum of mass of the parents of the substances should be within the Mass Tolerance Percentage.

Partially Disclosed composition (Partial Disclosure):

A Substance composition is Partially Disclosed if the difference is more than the Mass Tolerance Percentage, in which case an "Unreported" substance is added by the system to fill in the missing mass.

A Homogeneous Material composition is Partially Disclosed if one of the following is true:

(1) The difference between a material's mass (that is, the immediate parent of the substances) and the sum of mass of all the substances under that material is greater than the Mass Tolerance Percentage setting; and, (2) the difference between the part's mass and the sum of mass of the parents of the substances is greater than the Mass Tolerance Percentage setting; or

The part's weight is missing, but none of the information is missing in the BOS tree. That is, the Mass and PPM should not be "null" anywhere in the entire BOS tree, including subparts, materials, or substances.

Undisclosed composition (Non Disclosure):

If the mass is missing for the part, substance, or the immediate parent of the substances, it is considered an Undisclosed composition.

Furthermore, a Homogeneous Material composition is Undisclosed if any of these cases are true:

One of the substances in a material does not have Declared Mass and Declared PPM; or,

One of the materials does not have a Declared Mass; or,

One of the materials does not have any substance; or,

One of the subparts does not have any child.

A value can be entered by the information supplier on a declaration or by a regular user on a part or part group. These are used by the compliance manager to ascertain precisely what substance is being referred to by the supplier.

The "Intentionally Added" property acts as the constraint defined in the Joint Industry Guide and the IPC 1752 forms. If, for a substance in the specification, Disallow Intentionally Adding is Yes, when a supplier or other user enters Yes in Intentionally Added, the substance's Calculated Compliance value is Non-compliant. If that substance was not intentionally added (= No), the system can go ahead and check the Threshold PPM of the substance-for-the-spec.

The compliance manager can modify Int.Added in the Pending status of the Default Declarations Workflow. The supplier can modify it in the Open to Supplier status of the same workflow. It cannot be modified in any other status (without administrator impact). If there is no value in Intentionally Added field, the system assumes No when performing rollup calculations.

The compliance manager may inform the supplier that the buyer is going to validate the supplier's substances based on the specifications on the Specifications tab. If there are one or more specifications associated with this Substance Declaration (this <type> only), the system automatically prepopulates the substances from those specifications for all the items, manufacturer parts, or part groups in this declaration. If there is no specification associated with this declaration, no substance is prepopulated, even for the substance declaration.

The specifications may concern many substances, including those not used by the parts contained in the declaration. When a substance declaration is opened to the supplier, any substances from the specifications are automatically added to the Substances for <Part/PG> tables. This ensures that you are properly tracking any restricted substances contained in parts listed in the substance declaration.

Specification Intentionally Added

In parts/part groups and declarations, the Substances tables also have an attribute called Spec Intentionally Added. This property points to, on the substance's Specifications > Substances tab, the value of attribute Disallow Intentionally Adding. This read-through attribute is readable and searchable but cannot be modified. For existing customers who do not have an Intentionally Added flag in the Specifications > Substances tab, the system assumes that it is set to No.

There is an Exemption field on a declaration's <Parts/PGs> tabs. Exemptions are set in a specification's General Info page; the values you see for Exemption on a declaration's Parts tab are really coming from the associated specification.

For this reason, Declared Compliance is valid only if there is an associated specification in the declaration. Only when there is a specification, and the spec has exemptions associated (found in the spec's General Info), can you set Declared Compliance to Exempt: when you do, you are then prompted to select an exemption from the list.

This field allows an information supplier to simply declare the compliance state of the substance, either Compliant or Non-Compliant.

"PPM" means Parts Per Million. The Threshold Mass PPM value comes from the Threshold Mass PPM for the corresponding substance in the specification. If enabled, it can be used by the supplier to declare the mass at each level of the BOS.

Substance editing lets you add, remove, and edit substances directly in (unpublished) declarations. The substance editing feature is available on all types of declaration except Supplier Declaration of Conformance and Part Declaration.

Linked to Composition Type Field, the declaration classes in which substance editing works are as follows.

Composition Type = Substance Composition:

Substance, JGPSSI, and IPC 1752-1 declarations

Composition Type = Homogeneous Material Composition:

Homogeneous Material and IPC 1752-2 declarations

The behavior of the Actions are described according to the type of declaration.

"Process extension" is the formal name of items in the Actions menu in declarations (in standard Web Client) or links in the Actions column of declaration rows (in simplified Web Client). Links in the Actions column enable you to perform an operation directly without having to go open the declaration itself.

These are the current process extensions that may be available on declarations. The Agile administrator at the buyer firm may have elected not to use more than the basic Actions found on most Agile objects.

The following process extensions apply to JGPSSI declarations:

Import JGPSSI - This process extension imports data from a text file in JGP Block format for integration with the JGPSSI Excel template

Export JGPSSI - This process extension exports data to a text file in JGP Block format for integration with the JGPSSI Excel template

|

Note: It is possible that when you submit data to Agile from Microsoft Excel, the data may not be successfully imported at the buyer side. Yet you may have received a notification indicating that transmission of the data was successful. The notification is triggered by your submitting the data, not by its successful receipt: the compliance manager may ask you to re-submit the data in these cases. |

The following process extensions apply to Homogeneous Material Declarations, Part Declarations, and Substance Declarations:

Import AXML - "AXML" is Agile XML, an XML representation of Agile's business schema that contains all product content managed in Agile. You use this process extension to export the declaration information in aXML format. The declaration can be completed and re-imported into PLM.

Export AXML - A declaration that was exported using the aXML format and then completed can be imported back into PLM using this process extension

The following process extensions apply to IPC declarations:

Import IPC XML - Imports XML data that is used to complete version 1.1 IPC forms

Export IPC XML - Exports XML data that is used to complete version 1.1 IPC forms

Import IPC 2.0 XML - Imports XML data that is used to complete version 2.0 IPC forms

Export IPC 2.0 XML - Exports XML data that is used to complete version 2.0 IPC forms

Grouping the possible “export” process extensions:

Export JGPSSI exports the declaration in JGP Blocks format

Export AXML exports the declaration in aXML format; this can be used with Part Declarations, Substance Declarations, and Homogeneous Material Declarations

Export IPC XML exports the declaration in XML format that is used to complete version 1.1 IPC forms.

Export IPC 2.0 XML exports the declaration in XML format that is used to complete version 2.0 IPC forms

Grouping the possible “import” process extensions:

Import JGPSSI imports a JGP Blocks file (if it was exported via Export JGPSSI) back into the declaration

Import AXML imports an aXML file (if it was exported via Export AXML) back into the declaration

Import IPC XML imports an XML file (if it was exported via Export IPC XML) back into the declaration.

Import IPC 2.0 XML imports an XML file (if it was exported via Export IPC 2.0 XML) back into the declaration.

This task outlines how you might receive an IPC 1752-1 or IPC 1752-2 declaration that was created in Agile at the buyer site. You would complete the declaration working in the IPC PDF.

|

Note: This procedure only applies to the pre-2.0 version of IPC. For IPC 1752A declarations, which were introduced with IPC version 2.0, follow the procedure described in Importing and Exporting Version 2.0 IPC Declarations. |

A typical RFI sequence with an IPC declaration:

The compliance manager at the buyer site creates an IPC declaration in Agile PLM; this is an instance from one of Agile's IPC business classes, IPC 1752-1 Declarations or IPC 1752-2 Declarations. The default workflow for the declaration is moved to the Open to Supplier status.

You, the declaration recipient at the information supplier, log in to Web Client (Basic mode) and see the declaration name. A link in the declaration row activates the Export IPC XML process extension. (Or, if you click the declaration name, all available process extensions are displayed as links on the left navigation pane.) An XML file is saved on your machine.

If you have already downloaded the IPC PDF forms from the IPC web site (http://www.ipc.org/ContentPage.aspx?pageid=Materials-Declaration), open the IPC form in Adobe Acrobat and click Import Data (or File > Form Data > Import Data to Form), then specify the location of the XML file. The XML-contained data is imported to the PDF form.

Enter or modify values in the declaration.

When you have completed the form, the data is exported using Export Data (or File > Form Data > Export Data from Form). The existing XML file is overwritten.

Returning to Web Client, use Import IPC XML process extension to import the modified XML data. Then submit the declaration to the buyer firm.

At the buyer site, the compliance manager opens the completed declaration in Agile to review for possible release.

This task outlines how you can receive an IPC 1752A declaration that was created in Agile at the buyer site.

|

Note: This procedure only applies to the 2.0 version of IPC. For IPC 1752-1and IPC 1752-2 declarations, which were introduced with IPC versions prior to 2.0, follow the procedure described in Importing and Exporting pre-v2.0 IPC Declarations. |

A typical RFI sequence with an IPC declaration:

The compliance manager at the buyer site creates an IPC declaration in Agile PLM; this is an instance from one of Agile's IPC business classes, IPC 1752-1 Declarations or IPC 1752-2 Declarations. The default workflow for the declaration is moved to the Open to Supplier status.

You, the declaration recipient at the information supplier, log in to Web Client (Basic mode) and see the declaration name. A link in the declaration row activates the Export IPC XML process extension. (Or, if you click the declaration name, all available process extensions are displayed as links on the left navigation pane.) An XML file is saved on your machine.

If you have already downloaded the Scriba1750a_beta06 from the web site (http://sourceforge.net/projects/ipc175xutils/),open the IPC form in Scriba and click File > Opendocument, then specify the location of the XML file. The XML-contained data is imported to the Scriba form.

Enter or modify values in the declaration.

When you have completed the form, the data is exported using File > Savedocument. The existing XML file is overwritten.

Returning to Web Client, use Import IPC 2.0 XML process extension to import the modified XML data. Then submit the declaration to the buyer firm.

At the buyer site, the compliance manager opens the completed declaration in Agile to review for possible release.

When your company seeks compliance information about Parts/Part Groups by sending a declaration to a supplier, it may not be convenient for the supplier firm to compile that information directly into the declaration.

One option that is available to the Supplier is to export and import files in a format called aXML. (For more information, see "Importing and Exporting Declarations."

A simpler solution is available in which compliance information that is sought by a Declaration can be collected in a Microsoft Excel spreadsheet, then imported into the Declaration. In this procedure, an Excel template is produced by PG&C.

These are the three main steps, covered in detail below:

Downloading the MS-Excel spreadsheet template;

Adding substances to the spreadsheet template;

Importing substances from the spreadsheet template.

A declaration has been created, and a specification has been added to it. Parts or Manufacturer Parts or Part Groups are added to the declaration, whose objective is for any substances of concern that are contained in these parts to be declared.

For this compliance information, the declaration may be sent to a supplier, or it may be completed internally by a compliance manager.

To download the MS-Excel template:

In the declaration, click the Actions drop-down menu, select Microsoft Excel > Download Template.

PG&C automatically exports the declaration's attribute information to the Excel spreadsheet. The File Download dialog prompts you to Open or Save the file.

To save the file, browse to a location on your hard drive. You can accept a system-generated filename or enter a new filename.

Close the Get File dialog, which conducted the export of the spreadsheet file.

The importing process is continued in the next topic.

Download and save an MS-Excel spreadsheet.

To add substances to the spreadsheet:

The Excel spreadsheet must be populated with data about the substances being declared for the parts named on the declaration.

These are key fields that must be populated.

|

Important: The column headings must appear exactly as below. Two columns, Parts.Rev/Mfr and Parts.Specification, must appear even if they are not populated. |

CoverPage.Name

CoverPage.Declaration Type

CoverPage.Supplier - note that the Supplier name must be typed exactly as it appears in PG&C

Level - this number reflects the level in the Bill of Substances for the substance in this row.

|

Important: Use the numerical sequence 0, 1, 2, 3 (not 1, 2, 3, 4). The objects are in plural form, and “Homogeneous Materials” are called "Materials" in the spreadsheet. |

0 = Subparts

1 = Materials

2 = Substance Groups

3 = Substances

Parts.Part Type - this and the next several fields could be for a Manufacturer Part or Part Group

Parts.Number

Parts.Rev/Mfr - this column must be in the Excel file, even if there is no value in any of this column's rows

Parts.Specification - this column must be in the Excel file, even if there is no value in any of this column's rows

Substances.Substance

Substances.Mass

Substances.Mass-Measure

Substances.Substance Type - the Substance Type names must be plural, as shown in “Level”, above

When you have completed populating the fields, save the spreadsheet file.

Begin on the Cover Page of the declaration that was created for this process.

This part of the process may be completed by the supplier; or, the supplier may have populated the Excel spreadsheet and sent it to the compliance manager, who can complete the process, as follows.

To import substances from the spreadsheet:

In the declaration, click the Actions drop-down menu, select Microsoft Excel, then select Import from Excel.

Agile Import is opened. In the Import dialog, next to the Import File field, click the Browse button.

In the Choose File dialog, select the Excel file that has been prepared with Substances data in the previous topic, and click Open.

In the Import dialog, click Import.

|

Note: The Import process takes several minutes to complete. You will know it has completed when the Close button appears. |

Before closing the dialog, verify that the Import process has imported the Parts/PGs and the Bill of Substances, which are viewed in the ACCEPTED column.

In the declaration, click the Items, Manufacturer Parts, or Part Groups tab as appropriate. The Substances table (below the list of the parts) lists the substances that have been declared for each part/PG.

This completes the procedure for importing substances into a declaration with MS-Excel.

When the supplier has used the Microsoft Excel-based Client to submit the declaration, it is possible that data may not be successfully imported to the buyer side. There are two stages in which their data is processed. The data is uploaded to the server; upon successful upload, the supplier receives the message that “Your data has been submitted for processing.” The data is then be processed on the server and imported into the system.

If there was a problem with the upload, the supplier is notified immediately; but if the problem occurs at processing or importing on the server side, the system sends an email with the error log as an attachment to the supplier. This means that the declaration remains in Open to Supplier status, and this does not change until the supplier reviews the log in the email notification, makes appropriate changes, and re-submits.

Even if the import on the server side is successful, depending on the size of the declaration, it will take some time for the declaration to move from Open to Supplier to Submitted to Compliance Manager. So if the user checked the declaration immediately after submitting from Excel, they may not see the changes for awhile.

These “under the hood” behaviors are detailed so that you can instruct your suppliers.