| Oracle® Retail Advanced Inventory Planning Store and Warehouse Replenishment Planning User Guide for the RPAS Fusion Client Release 14.1 |

|

Previous |

Next |

| Oracle® Retail Advanced Inventory Planning Store and Warehouse Replenishment Planning User Guide for the RPAS Fusion Client Release 14.1 |

|

Previous |

Next |

SRP and WRP generate alerts as a means of indicating possible problems in the supply chain, such as low stock or out of stock, overstocks, or other problems for a store or warehouse. SRP Alerts warn the user about historical or future problems adversely affecting a stores ability to meet sales.

Alerts are notifications that are sent to users about measures whose values are above or below an established acceptance range or threshold. Whenever values for these measures fall outside of this established range, an exception is generated, which causes alerts to be displayed in the Alert Manager window when the user logs on to SRP. This provides a means of easily viewing problem situations on an exception basis and following with the appropriate action.

Alerts are calculated in a nightly batch process. Review of alerts and the management of exceptions is an interactive process that is performed by the user during the day following the batch run.

The process of reviewing alerts and managing exceptions involves the tasks listed in the following table.

| Task | Description |

|---|---|

| Review alerts | The Alert Manager provides notification of any exceptions generated and allows the user to transfer to the appropriate workbooks to research the root cause of the problem. |

| Maintain parameters | Occasionally the SRP and WRP parameters used in the store replenishment planning process may need modification to produce a better plan. |

| Maintain alert parameters | Alerts are triggered based on thresholds, alert horizons, and parameters. These parameters and thresholds may need tuning to control the number and types of alerts. |

| Perform What-if analysis on replenishment plans | What-if analysis can be useful in comparing the current store plan with a What-if plan based on parameter changes. This allows the user the flexibility of analyzing the effect of changed values on the plan without making the changes permanent. |

This chapter provides information on the following topics:

SRP alerts are divided into the following categories.

| SRP Alert Type | Description |

|---|---|

| Historical Availability Alerts |

Provide notification of historical conditions indicating various adverse conditions in a store experienced by a store, such as stock out or low inventory |

| Projected Availability Alerts |

Provide notification of future conditions of forecasted conditions that could cause future stock problems for a store, such as project stock outs or low inventory, along with possible high inventory levels. |

| Other Alerts |

Miscellaneous alerts which provide warning information not necessarily related to stocking levels. |

Historical Availability Alerts provide notification of historical conditions indicating various adverse conditions in a store experienced by a store, such as stock out or low inventory.

The following table lists historical alerts issued by SRP along with a brief description. Details for each alert are addressed in the following sections.

Table 12-1 SRP Historical Alerts

| Alert | Description |

|---|---|

|

Large Consecutive Out of Stocks |

A Large Consecutive Out of Stocks alert is generated when a significant number of stores that have been out of stock for more than a defined number of consecutive days and the amount of lost sales is above a threshold. Only those stores that are Out of Stock (OOS) for the product last night are alerted. |

|

Large Non-Consecutive Out of Stocks |

A Large Non-Consecutive Out of Stocks alert is generated when a significant number of stores that have been out of stock for more than a defined number of non-consecutive of days or the amount of lost sales is above a threshold. Only those stores that are Out of Stock (OOS) for the product last night are alerted. Stores alerted for Large Consecutive Out of Stocks are not alerted. |

|

Large Out of Stocks Last Night |

A Large Out of Stocks Last Night alert is generated when a significant number of stores are out of stock or a significant portion of possible sales yesterday are lost for a specific SKU or when the lost sales for the SKU at the company level is significant. Only those stores that are Out of Stock (OOS) for the product last night are alerted. Stores alerted for Large Consecutive Out of Stocks or Large Non Consecutive Out of Stocks are not alerted. |

|

Day on Day Repeat Out of Stocks |

A Day on Day Repeat Out of Stocks alert is generated when a significant number of stores have been out of stock on the same day in consecutive weeks, and the amount of lost sales is above a threshold. Only those stores that are Out of Stock (OOS) for the product last night are alerted. Stores alerted for Large Consecutive Out of Stocks or Large Non-Consecutive Out of Stocks are not alerted. |

|

Single Store Availability Problems |

A Single Store Availability Problems alert is generated when a single store has been out of stock for more than a specified number of non-consecutive days, and the amount of lost sales is above a threshold. Only those stores that are Out of Stock (OOS) for the product last night are alerted. Stores alerted for Large Consecutive Out of Stocks, Large Non-Consecutive Out of Stocks, Large Out of Stocks Last Night, or Day on Day Repeat Out of Stocks are not alerted. |

|

Historical Availability Summary Alert |

A Historical Availability Summary Alert is raised when any alert in the Historic Availability Alerts Group is generated. The summary allows the user to view any store with historic out of stocks or low stocks. |

Before highlighting the functionality for each of the alerts, it is important to discuss some of the key inputs to these alerts.

Table 12-2 Inputs for Alerts

| Key Inputs for Alerts | Description |

|---|---|

|

Projected Inventory (PI) |

Contains the amount of inventory the store is starting off with at the beginning of the day. The beginning of day inventory on any day is equivalent to the end of day (EOD) inventory of the previous day. This means that at the beginning of the day all supply, demand, sales, and so on of the previous day are accounted for in the inventory, but not the up-coming business day's supply, demand, sales, and so on. |

|

Historical Demand |

Holds yesterday's forecasted demand for a SKU at each store. The historical demand for yesterday should consider the effects of all demand. |

|

Historic Out of Stock |

Historic Out of Stock flag settings for days prior to yesterday are retained and purged in the same manner as other historical measures. Each day the alert calculation is run Out of Stock Yesterday is calculated and saved with the rest of the history. |

|

Out of Stock Yesterday |

A store can be out of stock for a SKU when:

It is difficult to know if a store actually had a stock-out unless a snapshot of inventory taken within the day is 0 or the day ends with no inventory. The former scenario will be captured when running Intra-day replenishment for a SKU/store. In the latter case however, a day may appear to end with inventory though there was insufficient inventory on the shelves. This can happen when a store received a shipment but does not restock shelves until later in the day or night. It is desirable to flag the store as out of stock in this situation. Without detailed store sales analysis it's unclear whether the stock out actually happened but it is sufficient for the planner to know that the stock was excessively low such that a stock-out was likely. |

|

Historic Lost Sales |

Historic Lost Sales for days prior to yesterday are retained and purged in the same manner as other historical measures. Each day the alert calculation is run yesterday's lost sales are calculated and saved with the rest of the history. |

|

Yesterday's Lost Sales |

Lost Sales represents the number of lost sales for a SKU at a particular store due to an out of stock situation. Lost sales are only calculated on OOS days. Because actual sales are only known in the past the lost sales for yesterday can be calculated based on actual sales. Because the actual sales for yesterday are known the lost sales can be determined by finding the difference between the projected demand and the actual sales. If actual sales are greater than demand then there was an excess of sales, compared to expected, therefore lost sales is 0. |

A Large Consecutive Out of Stocks alert is generated when a significant number of stores that have been out of stock for more than a defined number of consecutive days and the amount of lost sales is above a threshold.

Only those stores that are Out of Stock (OOS) for the product last night are alerted.

Large OOS Horizon

Large Consecutive. OOS Number of Days OOS

Large Consecutive OOS Alerting Stores Ratio

Large Consecutive OOS Corp. Lost Sales Volume over horizon

The Large Consecutive Out of Stocks alert is triggered if all of the following conditions are True:

Calculate the number of consecutive days a store is Out of Stock (OOS) over the user-defined alert horizon. The number of consecutive days OOS must be greater than the user-defined threshold, Large Cons. OOS Number of Days OOS. Calculate the ratio of the number of stores consecutive OOS against the number of stores ranged for that SKU. The calculated ratio must be greater than the user-defined threshold, Large Cons. OOS Alerting Stores Ratio.

Count the number of consecutive out of stock days (Store Historical Inventory is 0) starting with and including yesterday, over the alert horizon or when the store is no longer in scope (Store In Scope Indicator is False). The alert horizon is an alert parameter, Large OOS Horizon, defining the number of days over which calculations are performed for this alert. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or Sub-Class/Company level.

The days OOS is compared to a second alert parameter, Large Cons. OOS Number of Days OOS. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or Sub-Class/Company level. If the day OOS is greater than this parameter, the store is considered out of stock for consecutive days (OOS store).

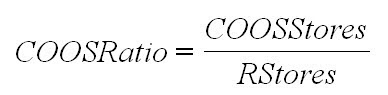

To determine if the number of consecutive OOS stores is significant, a ratio (COOS ratio) is calculated as the number of consecutive OOS stores divided by the total number of ranged stores for that SKU. A store is considered ranged if at least one day in the alert horizon is in scope (Store In Scope Indicator is True).

COOSRatio = Consecutive OOS Ratio

COOSStores = Consecutive OOS Ranged Stores

RStores = Ranged Stores

The consecutive OOS stores are considered significant if the ratio is greater than an alert parameter, Large Cons. OOS Alerting Stores Ratio. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or (SKU/Company) level.

If the OOS ratio is greater than the Large Cons. OOS Alerting Stores Ratio, the first condition for this alert is True.

The total sum of lost sales over the consecutive days that are OOS is greater than a set volume threshold.

First, total the lost sales starting with and including yesterday over the days that are consecutively OOS but do not sum past the alert horizon (Large OOS Horizon parameter) or when the store is no longer in scope (Store In Scope Indicator is False).

The sum of lost sales is compared to an alert parameter, Large Cons. OOS Corp. Lost Sales Volume over horizon (Large OOS volume). This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or (SKU/Company) level.

If the total lost sales for the consecutive OOS stores is greater than the Large OOS volume, this condition is True.

If the SKU was out of stock last night for this store and the store was in scope for last night, condition 3 is True.

A Large Non-Consecutive Out of Stocks alert is generated when a significant number of stores that have been out of stock for more than a defined number of non-consecutive days or the amount of lost sales is above a threshold.

Only those stores that are Out of Stock (OOS) for the product last night are alerted.

Stores alerted for Large Consecutive Out of Stocks are not alerted.

Large OOS Horizon

Large Non-Cons. OOS Number of Days OOS

Large Non-Cons. OOS Alerting Stores Ratio

Large Non-Cons. OOS Corp. Lost Sales Volume over horizon

The Large Non-Consecutive Out of Stocks alert is triggered if all of the following conditions are True:

Calculate the number of non-consecutive days a store is Out of Stock (OOS) over the user-defined alert horizon. The number of non-consecutive days OOS must be greater than the user-defined threshold, Large Non-Cons. OOS Number of Days OOS. Calculate the ratio of the number of stores non-consecutive OOS against the number of stores ranged for that SKU. The calculated ratio must be greater than the user-defined threshold, Large Non-Cons. OOS Alerting Stores Ratio.

Count the number of non-consecutive out of stock days (Store Historical Inventory is 0) starting with and including yesterday, over the alert horizon for each day that is in scope (Store In Scope Indicator is True). The alert horizon is an alert parameter, Large OOS Horizon, defining the number of days over which calculations are performed for this alert. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or Sub-Class/Company level.

The days OOS is compared to a second alert parameter, Large Non-Cons. OOS Number of Days OOS. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or Sub-Class/Company level. If the day OOS is greater than this parameter, the store is considered out of stock for non-consecutive days (OOS store).

To determine if the number of non-consecutive OOS stores is significant, a ratio (COOS ratio) is calculated as the number of non-consecutive OOS stores divided by the total number of ranged stores for that SKU. A store is considered ranged if at least one day in the alert horizon is in scope (Store In Scope Indicator is True).

NCOOSRatio = Consecutive OOS Ratio

NCOOSStores = Consecutive OOS Ranged Stores

NRStores = Ranged Stores

NCOOSRatio = NCOOSStores / RStores

The non-consecutive OOS stores are considered significant if the ratio is greater than an alert parameter, Large Non-Cons. OOS Alerting Stores Ratio. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or (SKU/Company) level.

If the OOS ratio is greater than the Large Non-Cons. OOS Alerting Stores Ratio, the first condition for this alert is True.

The total sum of lost sales over horizon from the SKU/stores that satisfy the non-consecutive OOS threshold is greater than a set volume threshold.

First, total the lost sales starting with and including yesterday over the alert horizon (Large OOS Horizon parameter) for each day that is in scope (Store In Scope Indicator is True) for the non-consecutive OOS stores.

The sum of lost sales is compared to an alert parameter, Large Non-Cons. OOS Corp. Lost Sales Volume over horizon (Large OOS volume). This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or (SKU/Company) level.

If the total lost sales for the non-consecutive OOS stores is greater than the Large OOS volume, this condition is True.

If the SKU was out of stock last night for this store and the store was in scope for last night, condition 3 is True.

If a Large Consecutive Out of Stocks alert was not generated for this SKU/Store, condition 4 is True.

A Large Out of Stocks Last Night alert is generated when a significant number of stores are out of stock or a significant portion of possible sales yesterday are lost for a specific SKU or when the lost sales for the SKU at the company level is significant.

Only those stores that are Out of Stock (OOS) for the product last night are alerted.

Stores alerted for Large Consecutive Out of Stocks or Large Non Consecutive Out of Stocks are not alerted.

Large OOS Last Night Alerting Stores Ratio

Large OOS Last Night Corp. Lost Sales % Possible Sales

Large OOS Last Night Corp. Lost Sales Volume

The Large Out of Stocks Last Night alert is triggered if condition 1 or 2 is True. In all cases, condition 3 and 4 must also be True:

Calculate the ratio of the number of stores out of stock last night (OOS stores) against the number of stores ranged for that SKU. The calculated ratio must be greater than a user-defined threshold.

If the SKU was out of stock last night for this store (Store Historical Inventory is 0 for yesterday), and the store was in scope for last night (Store In Scope Indicator is True), then the store is OOS.

To determine if the number of OOS stores is significant, a ratio (OOS ratio) is calculated as the number of OOS stores divided by the total number of ranged stores for that SKU. A store is considered ranged if yesterday is in scope (Store In Scope Indicator is True). The OOS stores are considered significant if the ratio is greater than an alert parameter, Large OOS Last Night Alerting Stores Ratio. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or SKU /Company level.

OOSLNRatio = OOS Last Night Ratio

OOSLNStores = Number Ranged Stores OOS Last Night

RStores = Ranged Stores

OOSLNRatio=OOSLNStores / RStores

If the OOS ratio is greater than the Large OOS Last Night Alerting Stores Ratio, the first condition for this alert is True.

Calculate the ratio total lost sales yesterday, taking in consideration all stores for the SKU, against their possible sales yesterday. The calculated ratio must be greater than a user-defined percentage.

First, the total lost sales yesterday (total LS yesterday) is calculated as the sum of lost sales yesterday for all stores ranged for that SKU that are considered in scope (Store In Scope Indicator is True).

The total possible sales yesterday (total PS yesterday) is calculated as the sum of Store Historical Lost Sales from yesterday and Daily Sales from yesterday for all stores ranged for that SKU that are considered in scope (Store In Scope Indicator is True).

To determine if the portion of possible sales yesterday is significant, a ratio (PS yesterday ratio) is calculated as total LS yesterday divided by total PS yesterday. The LS yesterday are considered significant if the ratio is greater than an alert parameter, Large OOS Last Night Corp. Lost Sales % Possible Sales. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or (SKU/Company) level.

LSPSRatio = Lost Sales % Possible Sales Ratio

LSYest = Total Lost Sales Yesterday For Ranged Stores

PSYest = Total Possible Sales Yesterday For Ranged Stores

LSPSRatio = LSYest / PSYest

If the PS yesterday ratio is greater than the Large OOS Last Night Corp. Lost Sales % Possible Sales, condition 2 for this alert is True.

The total of lost sales for all SKU/stores out of stock last night from is greater than a set volume threshold.

First, total the lost sales for this SKU at all stores from last night for the OOS stores that are considered in scope (Store In Scope Indicator is True).

The sum of lost sales is compared to an alert parameter, Large OOS Last Night Corp. Lost Sales Volume (Large OOS volume). This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or SKU /Company level.

If the total lost sales for the OOS stores is greater than the Last night OOS volume, this condition is True.

If a Large Consecutive Out of Stocks alert and a Large Non-Consecutive Out of Stocks alert were not generated for this SKU/store, condition 4 is True.

A Day on Day Repeat Out of Stocks alert is generated when a significant number of stores have been out of stock on the same day in consecutive weeks, and the amount of lost sales is above a threshold.

Only those stores that are Out of Stock (OOS) for the product last night are alerted.

Stores alerted for Large Consecutive Out of Stocks or Large Non-Consecutive Out of Stocks are not alerted.

Day on Day OOS Horizon

Day on Day OOS Day on Day Count Threshold

Day on Day OOS Alerting Stores Ratio

Day on Day OOS Corp. Lost Sales Volume

The Day on Day Repeat Out of Stocks alert is triggered if all of the following conditions are True:

Calculate the number of stores Out of Stock (OOS) on the same day in consecutive weeks over the user-defined alert horizon for each SKU/store. The number of days OOS must be greater than the user-defined threshold, Day on Day OOS Day on Day Count Threshold. Calculate the ratio of the number of stores OOS against the number of stores ranged for that SKU. The calculated ratio must be greater than a user-defined threshold.

First, count the number of days a store is out of stock (Store Historical Inventory is 0) repeat day on day for yesterday, yesterday - 7, yesterday - 14, over the alert horizon assuming the day is in scope (Store In Scope Indicator is True). The alert horizon is an alert parameter, Day on Day OOS Horizon, that defines the number of days over which calculations are performed for this alert. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or Sub-Class/Company level.

The days OOS is compared to a second alert parameter, Day on Day OOS Day on Day Count Threshold. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or Sub-Class/Company level. If the day OOS is greater than this parameter, the store is considered day on day repeat out of (OOS store).

To determine if the number of OOS stores is significant, a ratio (OOS ratio) is calculated as the number of OOS stores divided by the total number of ranged stores for that SKU. A store is considered ranged if at least one day in the alert horizon is in scope (Store In Scope Indicator is True). The OOS stores are considered significant if the ratio is greater than an alert parameter, Day on Day OOS Alerting Stores Ratio. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU /Store or SKU /Company level.

DDOOSRatio = Day On Day OOS Ratio

DDOOSStores = Day On Day OOS Ranged Stores

RStores = Ranged Stores

DDOOSRatio = DDOOSStores / RStores

If the OOS ratio is greater than the Day on Day OOS Alerting Stores Ratio, the first condition for this alert is True.

The total of lost sales for all Day on Day out of stock SKU/stores over the alert horizon is greater than a set volume threshold.

First, total the lost sales for this SKU at all Repeat Day on Day OOS stores over the alert horizon for each day that is in scope (Store In Scope Indicator is True).

The sum of lost sales is compared to an alert parameter, Day on Day OOS Corp. Lost Sales Volume. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or SKU /Company level.

If the total lost sales for the OOS stores is greater than the Day on Day OOS volume, this condition is True.

If the SKU was out of stock last night for this store and the store was in scope for last night, condition 3 is True.

If a Large Consecutive Out of Stocks alert and a Large Non-Consecutive Out of Stocks alert were not generated for this SKU/store, condition 4 is True.

A Single Store Availability Problems alert is generated when a single store has been out of stock for more than a specified number of non-consecutive days, and the amount of lost sales is above a threshold.

Only those stores that are Out of Stock (OOS) for the product last night are alerted.

Stores alerted for Large Consecutive Out of Stocks, Large Non-Consecutive Out of Stocks, Large Out of Stocks Last Night, or Day on Day Repeat Out of Stocks are not alerted.

Single Store Horizon

Single Store Number of Days OOS

Single Store Corp. Lost Sales Volume over Horizon

A Single Store Availability Problems alert is triggered if all of the following conditions are True:

The number days a store is Out of Stock (OOS), starting with and including yesterday, over the user-defined alert horizon for must be greater than a user-defined threshold.

First, the number of non-consecutive days a store is out of stock (Store Historical Inventory is 0) is counted over the alert horizon assuming the day is in scope (Store In Scope Indicator is True). The alert horizon is an alert parameter, Single Store Horizon, that defines the number of days over which calculations are performed for this alert. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or Sub-Class/Company level.

The days OOS is compared to a second alert parameter, Single Store Number of Days OOS. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or Sub-Class/Company level.

If the day OOS is greater than this parameter, the store is considered out of stock for non-consecutive days (OOS store).

The total sum of lost sales over horizon for the OOS store is greater than a user-defined threshold.

First, total the lost sales starting with and including yesterday through the alert horizon (Single Store Horizon) for each day that is in scope (Store In Scope Indicator is True) for the OOS store.

The sum of lost sales is compared to an alert parameter, Single Store Corp. Lost Sales Volume over Horizon (Single store volume). This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or SKU/Company level.

If the total lost sales for the OOS store is greater than the Single store volume, this condition is True.

If the SKU was out of stock last night for this store and the store was in scope for last night, condition 3 is True.

If Large Consecutive Out of Stocks, Large Non-Consecutive Out of Stocks, Large Out of Stocks Last Night, or Day on Day Repeat Out of Stocks alert were not generated for this SKU/store, condition 4 is True.

A Historical Availability Summary Alert is raised when any alert in the Historic Availability Alerts Group is generated.

The summary alert allows the user to view stores with any historic alerts.

The Historical Availability Summary Alert is triggered if any of the following alerts are raised for a SKU/store:

Large Consecutive Out of Stocks

Large Non-Consecutive Out of Stocks

Large Out of Stocks Last Night

Day on Day Repeat Out of Stocks Alert

Single Store Availability Problems

Projected Availability Alerts provide notification of future conditions of forecasted conditions that could cause future stock problems for a store, such as project stock outs or low inventory, along with possible high inventory levels.

The following table lists projected availability alerts issued by SRP along with a brief description. Details for each alert are addressed in the following sections.

Table 12-3 Projected Availability Alerts

| Alert | Description |

|---|---|

|

|

A High Projected Out of Stock alert is generated when a significant number of stores are projected to be out of stock or a significant portion of demand is projected as lost sales for a specific SKU and the projected lost sales for the SKU at the company level are significant. |

|

|

A High Projected Low Stocks alert is generated when a significant number of stores have net inventory levels below a set threshold. Stores alerted for High Projected Out of Stock are not alerted. |

|

|

A High Planned Orders alert is generated when Planned orders for a single store exceed a threshold. Stores alerted for High Projected Out of Stock are not alerted. |

|

Projected Availability Summary Alert |

A Projected Availability Summary Alert is raised when any alert in the Projected Availability Alerts Alert Group is generated. The summary allows the user to view any store with projected out of stocks or low stocks. |

A store will be considered projected out of stock for a SKU when the next day's BOD PI (equal to that days EOD PI) is 0 or the store inventory is less than the inventory that is needed to meet projected need until a receipt is available that day (note that if no receipt occurs the day will end with 0 inventory if short).

Lost Sales represents the number of lost sales for a SKU at a particular store due to an out of stock situation. Lost sales are only calculated on OOS days. Projected lost sales for today and in the future are projections based on inventory and projected demand.

A High Projected Out of Stock alert is generated when a significant number of stores are projected to be out of stock or a significant portion of demand is projected as lost sales for a specific SKU, and the projected lost sales for the SKU at the company level are significant.

High Projected OOS / Low Stock Horizon

High Projected OOS Number of Projected Days OOS

HighProjected OOS Alerting Stores Ratio

High Projected OOS Corp. Lost Sales % Forecast

High Projected OOS Corp. Lost Sales Volume over horizon

The High Projected Out of Stock alert is triggered if condition 1 or 2 is True and condition 3 is True:

Calculate number of days a store is projected Out of Stock (OOS) over the user-defined alert horizon. The number of days OOS must be greater than the user-defined threshold High Proj OOS Number of Projected Days OOS. Calculate the ratio of the number of stores High Proj OOS against the number of stores ranged for that SKU. The calculated ratio must be greater than a user-defined threshold.

If the Store In Scope Indicator is True, count the number of days a store is projected out of stock (Store Alerts Projected Stock Out Indicator) starting with and including today through the alert horizon. The alert horizon is an alert parameter, High Proj OOS / Low Stock Horizon, defining the number of days over which calculations are performed for this alert. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or Sub-Class/Company level.

The projected days OOS is compared to a second alert parameter, High Proj OOS Number of Projected Days OOS. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or Sub-Class/Company level. If the projected days OOS is greater than this parameter, the store is considered projected out of stock (projected OOS store).

To determine if the number of projected OOS stores is significant, a ratio (projected OOS ratio) is calculated as the number of projected OOS stores divided by the total number of stores for that SKU. The projected OOS stores are considered significant if the ratio is greater than an alert parameter, High Proj OOS Alerting Stores Ratio. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or (SKU/Company) level.

If the projected OOS ratio is greater than the High Proj OOS Alerting Stores Ratio, the first condition for this alert is True.

Calculate the ratio total projected lost sales, taking in consideration all stores for the SKU, against their demand forecast over the High Proj OOS / Low Stock Horizon. The calculated ratio must be greater than a user-defined percentage.

First, the total projected lost sales (total projected LS) is calculated as the sum of projected lost sales, starting with and including today, over the alert horizon for all stores ranged for that SKU.

The total Forecasted Demand (total FD) is calculated as the sum of forecasted demand, starting with and including today, over the alert horizon for all stores ranged for that SKU.

To determine if the portion of demand is projected as lost sales is significant, a ratio (projected LS ratio) is calculated as total projected LS is divided by total FD. The projected LS are considered significant if the ratio is greater than an alert parameter, High Proj OOS Corp. Lost Sales % Forecast. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or (SKU/Company) level.

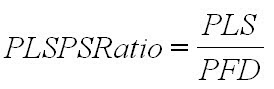

PLSPSRatio = High Proj OOS Corp. Lost Sales % Forecast

PLS = Total Projected Lost Sales

PFD = Total Forecasted Demand

If the projected LS ratio is greater than the High Proj OOS Corp. Lost Sales % Forecast, condition 2 for this alert is True.

The total projected lost sales for all SKU/stores are greater than a set volume threshold.

The total projected LS (calculated above) are compared to an alert parameter, High Proj OOS Corp. Lost Sales Volume over horizon (High Proj OOS volume). This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or SKU /Company level.

If the total projected LS is greater than the High Proj OOS volume, this condition is True.

A High Projected Low Stocks alert is generated when a significant number of stores have net inventory levels below a set threshold.

Stores alerted for High Projected Out of Stock are not alerted.

High Projected OOS / Low Stock Horizon

High Projected Low Stock Low Level Percentage

High Projected Low Stock Number of Low Stock Days

High Projected Low Stock Alerting Stores Ratio

The High Projected Low Stocks alert is triggered if conditions 1 and 2 are True:

Calculate number of days a store is projected Low Stock (LS) over the user-defined alert horizon. The number of days LS must be greater than the user-defined threshold High Proj Low Stock Number of Low Stock Days. Calculate the ratio of the number of stores High Proj LS against the number of stores ranged for that SKU. The calculated ratio must be greater than a user-defined threshold.

If the Store In Scope Indicator is True, determine if a day is projected low stock by calculating the Receipt Up to Level Threshold (RUTL threshold) as RUTL multiplied by the user-defined alert percentage. The alert percentage is an alert parameter, High Proj Low Stock Low Level Percentage. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store level.

HPPct = High Proj Low Stock Low Level Percentage

RUTLPct = Receipt up to Level Percentage

RUTL = Receipt up to Level

RUTLPct(t) = HPPct * RUTL(t).

A day is considered projected low stock if the Net Inventory (NI) is less than the RUTL threshold.

The number of days a store is projected low stock (projected days LS) is counted over the alert horizon. The alert horizon is an alert parameter, High Proj OOS / Low Stock Horizon, defining the number of days over which calculations are performed for this alert. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or Sub-Class/Company level.

The projected days LS is compared to a second alert parameter, High Proj Low Stock Number of Low Stock Days. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or Sub-Class/Company level. If the projected days LS is greater than this parameter, the store is considered projected low stock (projected LS store).

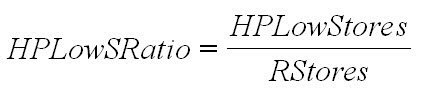

To determine if the number of projected LS stores is significant, a ratio (projected LS ratio) is calculated as the number of projected LS stores divided by the total number of stores for that SKU. The projected LS stores are considered significant if the ratio is greater than an alert parameter, High Proj Low Stock Alerting Stores Ratio. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or (SKU/Company) level.

HPLowSRatio = High Projected Low Stock Ratio

HPLowStores = Number of High Projected Low Stock Ranged Stores

RStores = Ranged Stores

If the projected LS ratio is greater than the High Proj Low Stock Alerting Stores Ratio, the first condition for this alert is True.

If a High Projected Out of Stock alert was not generated for this SKU/store, condition 2 is True.

A High Planned Orders alert is generated when planned orders for a single store on any day in the alert horizon exceed a threshold.

Stores alerted for High Projected Out of Stock are not alerted.

High Planned Orders Def Packs Threshold

High Planned Orders Packs Threshold

High Planned Orders Def Horizon

High Planned Orders Horizon

The High Planned Orders alert is triggered for a SKU/store, which has a release, has a significantly large order quantity.

Only orders with a future release (meaning not in the current overnight batch) are alerted since these are the orders that the user is most likely able to correct. This is not normally an issue since today's orders does not change much from previous plans unless there is a sudden, drastic change in stock on hand. The alert is triggered when all of the following conditions are True:

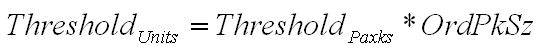

The units ordered is larger than the user specified threshold-converted to units.

Retrieve the receipt plan from today over the user defined alert horizon for On-Supply, alerted SKUs (and the stores in the selected company). The High Planned Orders Horizon defines the maximum number of days over which calculations are performed for this alert. If the receipt's release date is today and the release wave is the overnight wave discard the receipt and move to the next available. Today's overnight-released orders does not trigger alerts.

|

Note: Planned quantities outside of the on-supply dates are not alerted because orders are only generated outside of the on-supply dates for User Specified Allocations. Users should already be aware of these allocated quantities. |

Convert the user defined packs threshold to units by multiplying the threshold by the ordering pack-size.

If the receipt plan (in units) is larger than the units-threshold the first condition is True and the SKU/store is alerted. Subsequent receipts for a SKU/store can be skipped as soon as one receipt has triggered the alert.

A High Projected Out of Stock alert was not triggered.

If a High Projected Out of Stock alert was not generated for this SKU/store, condition 2 is True.

Other Alerts are miscellaneous alerts which provide warning information not necessarily related to stocking levels.

The following table lists other alerts issued by SRP along with a brief description. Details for each alert are addressed in the following sections.

Table 12-4 Other SRP Alerts

| Alert | Description |

|---|---|

|

|

An Overstock alert is generated when Stock Cover and Projected Inventory for a store exceed overstock thresholds. |

|

|

A Forecasting Detail exception is raised when an exception in the Forecasting system has been flagged for a SKU/Store active in the Planning Horizon. |

|

|

A No Like SKU Found exception is raised when there is a Store Like SKU value that is that is pointing to a SKU that is not in that domain. |

|

|

The alert indicates that a SKU/store has repeatedly had a significant amount of markdown sales and waste adjustments compared to its daily sales. |

|

|

The alert indicates that, yesterday, a SKU had significant Dissipation (waste and markdown sales) compared to sales across a significant number of stores. |

An Overstock alert is generated when Stock Cover and Projected Inventory for a store exceed overstock thresholds. The Overstock alert is calculated over the planning horizon.

The Overstock alert is triggered if all of the following conditions are True:

The projected stock cover is greater than a user-defined stock cover days threshold.

First, calculate the projected Stock Cover Days as the count of days from the current day until the current day's Projected Inventory (PI) minus Demand (Dmd) is less than or equal to zero. Only count days where demand is greater than 0. If demand is 0 on a particular day pass over that day and do not increment the days of cover count. If the PI minus Dmd is less than zero on the last day, calculate the percent of the last days demand that covers the current day's current day's PI.

The projected Stock Cover Days is compared to an alert threshold, Stock Cover Days Threshold. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or Sub-Class/Company level.

If the projected Stock Cover Days is greater than the Stock Cover Days Threshold, the first condition is True.

The projected inventory in units is greater than the overstock units threshold.

The Projected Inventory (PI) is compared to an alert threshold, Overstock Units Threshold. This parameter is maintained in the SRP Alert Maintenance workbook at the SKU/Store or Sub-Class/Company level.

If the PI is greater than the Overstock Units Threshold, this condition is True.

A Forecasting Detail exception is raised when an exception in the Forecasting system has been flagged for a SKU/Store.

The Sales Forecast Detail Alert is loaded from an external source based on exceptions found in the user's forecasting system. No calculations are performed within SRP but this alert will only be displayed for SKU/Stores that are active within the Planning Horizon.

The Sales Forecast Detail alert is used to give the user visibility of an exception in the forecasting system that could be causing exceptions in SRP. This allows the user to determine if changes are required within the forecasting system or within SRP to resolve the exception.

A No Like SKU Found exception is raised when there is a Store Like SKU value that is that is pointing to a SKU that is not in that domain.

During batch processing, AIP verifies that all Like SKU values are in the current domain. If there is a Store Like SKU value that is not a measure in that domain, an alert flag is triggered against the primary SKU/store.

A High Repeated Dissipation alert is triggered when the number of days a store has high dissipation (Short Code Sales and waste adjustment), compared to daily sales, exceeds the threshold, and the threshold is exceeded at a percentage of stores. Yesterday must be included in one of the total days a store has high dissipation of a SKU.

A High Dissipation Yesterday alert is triggered when a store has high dissipation (short code sales and waste adjustment) compared to daily sales, and the ratio of high dissipation stores to all ranged stores exceeds the threshold. The stores must have high dissipation of the SKU yesterday and not be flagged as High Repeated Dissipation in order to be counted in the ratio and be alerted. Otherwise, the alert triggers if the total dissipation percent of sales yesterday across all ranged stores exceeds the threshold.

WRP alerts are divided into the categories listed in the following table.

| Alert Category | Description |

|---|---|

| Warehouse Stock Shortage Alerts | Provides notification of historical conditions indicating various adverse conditions in a store experienced by a warehouse, such as insufficient stock to fulfill store orders or forecasted demand. |

| Network Exception Alerts | Provides notification of current and future for groups of SKUs at a warehouse. |

| WRP Overstock Alerts | Provides notification of projected overstock situations at stocked and stockless warehouses. |

| Sales Forecast Alerts | Provides notification that a Sales Forecast alert exists that may be the cause of problems in the warehouses replenishment |

Warehouse Stock Shortage Alerts provide notification of historical conditions indicating various adverse conditions in a store experienced by a warehouse, such as insufficient stock to fulfill store orders or forecasted demand.

The warehouse stock shortage alerts can be separated into two groups - sales credit item alerts and demand credit item alerts.

The sales credits alerts are triggered when the warehouses shortage does not cover expected sales at the stores. In other words, the sales credit alerts warn of possible lost sales at the stores.

The demand credits alerts are triggered when the warehouses shortage does not cover forecasted demand at the stores. In other words, the demand credit alerts warn of possible low stock situations at the stores.

The following table lists historical alerts issued by WRP along with a brief description. Details for each alert are addressed in the following sections.

| Alert | Description |

|---|---|

| Sales Credit Multi-Day Stocked Alert | A Sales Credit Multi-Day Stocked alert is generated when the number of days a sales credit exception exists exceeds a sales credit days threshold.

This alert is only triggered for stocked products. |

| Sales Credit Stocked Alert | A Sales Credit Stocked alert is generated when the Sales Credit exceeds a sales credit unit threshold and the percentage sales credit exceeds a sales credit percentage shortage threshold.

This alert is only triggered for stocked products. SKUs alerted for Sales Credit Multi-Day Stocked Alert are not alerted. |

| Sales Credit Multi-Day Stockless Alert | A Sales Credit Multi-Day Stockless alert is generated when the number of days a sales credit exception exists exceeds a sales credit days threshold.

This alert is only triggered for stockless products. |

| Sales Credit Stockless Alert | A Sales Credit Stockless alert is generated when the Sales Credit exceeds a sales credit unit threshold and the percentage sales credit exceeds a sales credit percentage shortage threshold.

This alert is only triggered for stockless products. SKUs alerted for Sales Credit Multi-Day Stockless Alert are not alerted. |

| Sales Credit Summary Alert | The Sales Credit Summary Alert is triggered when any of the Sales Credit Alerts are triggered. |

| Demand Credit Multi-Day Stocked Alert | A Demand Credit Multi-Day Stocked alert is generated when the number of days a demand credit exceeds a demand credit days threshold, demand credit units/case threshold, and a percentage threshold.

This alert is only triggered for stocked products. SKUs alerted for any Sales Credit Alerts are not alerted. |

| Demand Credit Stocked Alert | A Demand Credit Stocked alert is generated when the Demand Credit exceeds a demand credit unit/case threshold and the percentage demand credit exceeds a demand credit percentage threshold.

This alert is only triggered for stocked products. SKUs alerted for Demand Credit Multi-Day Stocked Alert are not alerted. SKUs alerted for any Sales Credit Alerts are not alerted. |

| Demand Credit Summary Alert | The Demand Credit Summary Alert is triggered when any of the Demand Credit Alerts are triggered. |

A Sales Credit Multi-Day Stocked Alert is generated for stocked products when the number of days a sales credit exception exists exceeds the Sales Credit Days Threshold for Stocked Commodity.

The Sales Credit represents the difference between the store's need and the warehouse available inventory position.

The Percentage Sales Credit represents the percent of unsatisfied store sales for a product by a warehouse.

Sales Credit Case Threshold For Stocked Commodity

Sales Credit Unit Threshold For Stocked Commodity

Sales Credit Percentage Shortage For Stocked Commodity

Sales Credit Days Threshold For Stocked Commodity

The Sales Credit Multi-Day Stocked Alert is triggered if all of the following conditions are True:

Calculate the Sales Credit. The negative of the Sales Credit must be greater than a user-defined threshold.

First, the Minimum Sales over Review Time is calculated as the sum of Minimum Sales Stock (MSS), from store destinations only, minus the store net inventory.

The Sales Credit is the warehouse net inventory, minus the Minimum Sales over Review Time. The Sales Credit is capped at zero. The Sales Credit is only calculated within the fixed period.

If set, convert the Sales Credit Case Threshold to Units by multiplying it by the warehouse orderable unit, then select the smaller unit threshold value. If more than one warehouse orderable unit is found for the SKU Group/Warehouse select the largest.

Calculate the Negative Sales Credit as Sales Credit times negative one.

The Negative Sales Credit is compared to the sales credit units threshold.

If the Negative Sales Credit is greater than the sales credit units threshold, the first condition for this alert is True.

Calculate the Percentage Sales Credit. The Percentage Sales Credit must be greater than a user-defined threshold.

First, Calculate the Percentage Sales Credit as the Negative Sales Credit divided by the Minimum Sales over Review Time needed from the warehouse.

The Percentage Sales Credit is compared to an alert parameter, Sales Credit Percentage Shortage for Stocked Commodity. This parameter is maintained in the WRP Alert Maintenance workbook at the SKU/Warehouse, Sub-class or Department level.

If the Percentage Sales Credit is greater than Sales Credit Percentage Shortage for Stocked Commodity, this condition is True.

The number of days a sales credit exception exists is greater than a user-defined threshold.

First, count the number of ATP days the negative of the sales credit exceeds the sales credit unit threshold and the sales credit percentage shortage.

The number of days calculated above is compared to an alert parameter, Sales Credit Days Threshold for Stocked Commodity. This parameter is maintained in the WRP Alert Maintenance workbook at the SKU/Warehouse, Sub-class or Department level.

If the number of days a sales credit exception exists is greater than Sales Credit Days Threshold For Stocked Commodity, this condition is True

The product is stocked.

A Sales Credit Stocked Alert is generated for stocked products when the Sales Credit exceeds the Sales Credit Unit Threshold and the Percentage Sales Credit exceeds the Sales Credit Percentage Shortage.

SKUs alerted for Sales Credit Multi-Day Stocked Alert are not alerted.

The Sales Credit represents the difference between the store's need and the warehouse available inventory position.

The Percentage Sales Credit represents the percent of unsatisfied store sales for a product by a warehouse.

Sales Credit Case Threshold For Stocked Commodity

Sales Credit Unit Threshold For Stocked Commodity

Sales Credit Percentage Shortage For Stocked Commodity

The Sales Credit Stocked Alert is triggered if all of the following conditions are True:

Calculate the Sales Credit. The negative of the Sales Credit must be greater than a user-defined threshold.

First, the Minimum Sales over Review Time is calculated as the sum of Minimum Sales Stock (MSS), from store destinations only, minus the store net inventory.

The Sales Credit is the warehouse net inventory, minus the Minimum Sales over Review Time. The Sales Credit is capped at zero. The Sales Credit is only calculated within the fixed period.

If set, convert the Sales Credit Case Threshold to Units by multiplying it by the warehouse orderable unit, then select the smaller unit threshold value. If more than one warehouse orderable unit is found for the SKU Group/Warehouse select the largest.

Calculate the Negative Sales Credit as Sales Credit times negative one.

The Negative Sales Credit is compared to the sales credit units threshold.

If the Negative Sales Credit is greater than the sales credit units threshold, the first condition for this alert is True.

Calculate the Percentage Sales Credit. The Percentage Sales Credit must be greater than a user-defined threshold.

First, Calculate the Percentage Sales Credit as the Negative Sales Credit divided by Minimum Sales over Review Time needed from the warehouse.

The Percentage Sales Credit is compared to an alert parameter, Sales Credit Percentage Shortage for Stocked Commodity. This parameter is maintained in the WRP Alert Maintenance workbook at the SKU/Warehouse, Sub-class or Department level.

If the Percentage Sales Credit is greater than Sales Credit Percentage Shortage for Stocked Commodity, this condition is True.

The product is stocked.

The Sales Credit Multi-Day Stocked Alert is not triggered.

A Sales Credit Multi-Day Stockless Alert is generated for stockless products when the number of days a sales credit exception exists exceeds the Sales Credit Days Threshold for Stockless Commodity.

The Sales Credit represents the difference between store's need and the warehouse available inventory position.

The Percentage Sales Credit represents the percent of unsatisfied store sales for a product by a warehouse.

Sales Credit Case Threshold For Stockless Commodity

Sales Credit Unit Threshold For Stockless Commodity

Sales Credit Percentage Shortage For Stockless Commodity

Sales Credit Days Threshold For Stockless Commodity

The Sales Credit Multi-Day Stockless Alert is triggered if all of the following conditions are True:

Calculate the Sales Credit. The negative of the Sales Credit must be greater than a user-defined threshold.

First, the Minimum Sales over Review Time is calculated as the sum of Minimum Sales Stock (MSS), from store destinations only, minus the store net inventory.

The Sales Credit is the warehouse net inventory, minus the Minimum Sales over Review Time. For stockless items, the Sales Credit is not capped at zero. The Sales Credit is only calculated within the fixed period.

If set, convert the Sales Credit Case Threshold to Units by multiplying it by the warehouse orderable unit, then select the smaller unit threshold value. If more than one warehouse orderable unit is found for the SKU Group/Warehouse select the largest.

Calculate the Negative Sales Credit as Sales Credit times negative one.

The Negative Sales Credit is compared to the sales credit units threshold.

If the Negative Sales Credit is greater than the sales credit units threshold, the first condition for this alert is True.

Calculate the Percentage Sales Credit. The Percentage Sales Credit must be greater than a user-defined threshold.

First, Calculate the Percentage Sales Credit as the Negative Sales Credit divided by the Minimum Sales over Review Time needed from the warehouse.

The Percentage Sales Credit is compared to an alert parameter, Sales Credit Percentage Shortage for Stockless Commodity. This parameter is maintained in the WRP Alert Maintenance workbook at the SKU/Warehouse, Sub-class or Department level.

If the Percentage Sales Credit is greater than Sales Credit Percentage Shortage for Stockless Commodity, this condition is True.

The number of days a sales credit exception exists is greater than a user-defined threshold.

First, count the number of days the sales credit exceeds the sales credit unit threshold and the sales credit percentage shortage.

The number of ATP days calculated above is compared to an alert parameter, Sales Credit Days Threshold for Stockless Commodity. This parameter is maintained in the WRP Alert Maintenance workbook at the SKU/Warehouse, Sub-class or Department level.

If the number of days a sales credit exception exists is greater than Sales Credit Days Threshold for Stockless Commodity, this condition is True.

The product is stockless.

A Sales Credit Stockless Alert is generated for stockless products when the Sales Credit exceeds the Sales Credit Unit Threshold and the Percentage Sales Credit exceeds the Sales Credit Percentage Shortage.

SKUs alerted for Sales Credit Multi-Day Stockless Alert are not alerted.

The Sales Credit represents the difference between the store's need and the warehouse available inventory position.

The Percentage Sales Credit represents the percent of unsatisfied store sales for a product by a warehouse.

Sales Credit Case Threshold For Stockless Commodity

Sales Credit Unit Threshold For Stockless Commodity

Sales Credit Percentage Shortage For Stockless Commodity

The Sales Credit Stockless Alert is triggered if all of the following conditions are True:

Calculate the Sales Credit. The negative of the Sales Credit must be greater than a user-defined threshold.

First, the Minimum Sales over Review Time is calculated as the sum of Minimum Sales Stock (MSS), from store destinations only, minus the store net inventory.

The Sales Credit is the warehouse net inventory minus the Minimum Sales over Review Time. For stockless items, the Sales Credit is not capped at zero. The Sales Credit is only calculated within the fixed period.

If set, convert the Sales Credit Case Threshold to Units by multiplying it by the warehouse orderable unit, then select the smaller unit threshold value. If more than one warehouse orderable unit is found for the SKU Group/Warehouse select the largest.

Calculate the Negative Sales Credit as Sales Credit times negative one.

The Negative Sales Credit is compared to the sales credit units threshold.

If the Negative Sales Credit is greater than the sales credit unit threshold, the first condition for this alert is True.

Calculate the Percentage Sales Credit. The Percentage Sales Credit must be greater than a user-defined threshold.

First, Calculate the Percentage Sales Credit as the Negative Sales Credit divided by the Minimum Sales over Review Time needed from the warehouse.

The Percentage Sales Credit is compared to an alert parameter, Sales Credit Percentage Shortage for Stockless Commodity. This parameter is maintained in the WRP Alert Maintenance workbook at the SKU/Warehouse, Sub-class or Department level.

If the Percentage Sales Credit is greater than Sales Credit Percentage Shortage for Stockless Commodity, this condition is True.

The product is stockless.

The Sales Credit Multi-Day Stockless Alert is not triggered.

A Sales Credit Summary Alert is raised if any of the Sales Credit alerts are generated.

The summary allows the user to view any SKU group/warehouse with shortages that do not cover expected sales at the stores.

The Sales Credit Summary Alert is triggered if any of the following alerts are raised for a SKU group/warehouse:

Sales Credit Multi-Day Stocked

Sales Credit Stocked

Sales Credit Multi-Day Stockless

Sales Credit Stockless

A Demand Credit Multi-Day Stocked Alert is generated for stocked products when the demand credit (shortage) exceeds a unit/case threshold, and it exceeds a percentage of the demand, and the number of days that this occurs exceeds the Demand Credit Days Threshold for Stocked Commodity.

The Demand Credit represents the number of units above or below the inventory level required to satisfy forecasted demand thus achieving a projected store inventory at the Receive Up to Level.

The Percentage Demand Credit represents the percent of unsatisfied store demand for a product by a warehouse.

Demand Credit Case Threshold For Stocked Commodity

Demand Credit Unit Threshold For Stocked Commodity

Demand Credit Percentage Threshold For Stocked Commodity

Demand Credit Days Threshold For Stocked Commodity

The Demand Credit Multi-Day Stocked Alert is triggered if all of the following conditions are True:

Calculate the Demand Credit. The negative of the Demand Credit must be greater than a user-defined threshold.

Warehouse Demand for a day is the sum of capped store Unconstrained Receipt Plans (URP) from store destinations only.

For reconciled warehouse-chambers, the Demand Credit is calculated as the Warehouse Demand subtracted from the sum of the CRPs from store destinations only. For unreconciled warehouse-chambers, the Demand Credit is calculated as the Warehouse Demand subtracted from the net inventory which includes planned receipts. The Demand Credit is only calculated on ATP days within the warehouse's fixed period.

Calculate the Negative Demand Credit as Demand Credit times negative one.

If set, convert the Demand Credit Case Threshold to units by multiplying it by the warehouse orderable unit, then select the smaller unit threshold value. If more than one warehouse orderable unit is found for the SKU Group/Warehouse select the largest.

If the Negative Demand Credit is greater than demand credit units threshold, the first condition for this alert is True.

Calculate the Percentage Demand Credit. The Percentage Sales Credit must be greater than a user-defined threshold.

First, Calculate the Percentage Demand Credit as the Negative Demand Credit divided by the sum of unconstrained demand from the stores.

The Percentage Demand Credit is compared to an alert parameter, Demand Credit Percentage Threshold for Stocked Commodity. This parameter is maintained in the WRP Alert Maintenance workbook at the SKU/Warehouse, Sub-class or Department level.

If the Percentage Demand Credit is greater than Demand Credit Percentage Threshold for Stocked Commodity, this condition is True.

The number of ATP days the demand credit units and percentage thresholds are exceeded is greater than a user-defined threshold.

First, count the number of ATP days the demand credit exceeds the demand credit unit threshold and the demand credit percentage threshold.

The number of days calculated above is compared to an alert parameter, Demand Credit Days Threshold for Stocked Commodity. This parameter is maintained in the WRP Alert Maintenance workbook at the SKU/Warehouse, Sub-class or Department level.

If the number of days a demand credit exceeds both thresholds is greater than Demand Credit Days Threshold for Stocked Commodity, this condition is True.

The product is stocked.

No Sales Credit Alerts are generated for this SKU group/warehouse.

A Demand Credit Stocked Alert is generated for stocked products when the Demand Credit exceeds the Demand Credit Unit Threshold and the Percentage Demand Credit exceeds the Demand Credit Percentage Threshold.

SKUs alerted for Demand Credit Multi-Day Stocked Alert are not alerted.

The Demand Credit represents the number of units above or below the inventory level required to satisfy forecasted demand thus achieving a projected store inventory at the Receive Up to Level.

The Percentage Demand Credit represents the percent of unsatisfied store demand for a product at a warehouse.

Demand Credit Case Threshold For Stocked Commodity

Demand Credit Unit Threshold For Stocked Commodity

Demand Credit Percentage Threshold For Stocked Commodity

The Demand Credit Stocked Alert is triggered if all of the following conditions are True:

Calculate the Demand Credit. The Negative Demand Credit must be greater than a user-defined threshold.

Warehouse Demand for a day is the sum of capped store Unconstrained Receipt Plans (URP) from store destinations only.

For reconciled warehouse-chambers, the Demand Credit is calculated as the Warehouse Demand subtracted from the sum of the CRPs from store destinations only. For unreconciled warehouse-chambers, the Demand Credit is calculated as the Warehouse Demand subtracted from the net inventory which includes planned receipts. The Demand Credit is only calculated on ATP days within the warehouse's fixed period.

Calculate the Negative Demand Credit as Demand Credit times negative one.

If set, convert the Demand Credit Case Threshold to Units by multiplying it by the warehouse orderable unit, then select the smaller unit threshold value. If more than one warehouse orderable unit is found for the SKU Group/Warehouse select the largest.

If the Negative Demand Credit is greater than demand credit units threshold, the first condition for this alert is True.

Calculate the Percentage Demand Credit. The Percentage Sales Credit must be greater than a user-defined threshold.

First, Calculate the Percentage Demand Credit as the Negative Demand Credit divided by the sum of unconstrained demand from the stores.

The Percentage Demand Credit is compared to an alert parameter, Demand Credit Percentage Threshold for Stocked Commodity. This parameter is maintained in the WRP Alert Maintenance workbook at the SKU/Warehouse, Sub-class or Department level.

If the Percentage Demand Credit is greater than Demand Credit Percentage Threshold for Stocked Commodity, this condition is True.

The product is stocked.

The Demand Credit Multi-Day Stocked Alert is not triggered and no Sales Credit Alerts are generated for this SKU group/warehouse.

A Demand Credit Summary Alert is raised any of the Demand Credit alerts are generated.

The summary allows the user to view any SKU group/warehouse with shortages that do not cover expected demand at the stores.

The Demand Credit Summary Alert is triggered if any of the following alerts are raised for a SKU group/warehouse:

Demand Credit Multi-Day Stocked Alert Demand Credit Stocked Alert

Network Exception Alerts provide notification of current and future capacity for groups of SKUs at a warehouse.

The following table lists network alerts issued by WRP along with a brief description. Details for each alert are addressed in the following sections.

| Alert | Description |

|---|---|

| Outbound Distribution Capacity Exception |

The Outbound Distribution Capacity Exception is raised when the Warehouse Actual Outbound Volume exceeds the Outbound Distribution Capacity. |

| Warehouse Holding Capacity Exception |

The Warehouse Holding Capacity Exception is raised when the total capacity opening inventory exceeds the Stocking Point Holding Capacity. |

| Stock Cover Exception |

The Stock Cover Exception is triggered when the Projected Stock Cover Actual\Target Difference exceeds the Excessive Stock Cover Threshold for that day. |

| Inbound Day-on-Day Change Exception |

The Inbound Day-on-Day Change Exception is triggered when the percent change between Yesterday's Remaining Week Inbound Plan and Today's Remaining Week Inbound Plan exceeds the Inbound Day-On-Day Change Threshold. |

| Outbound Day-on-Day Change Exception |

The Outbound Day-on-Day Change Exception is triggered when the percent change between Yesterday's Remaining Week Outbound Plan and Today's Remaining Week Outbound Plan exceeds the Outbound Day-On-Day Change Threshold. |

| Stock Cover Day-on-Day Change Exception |

The Stock Cover Day-on-Day Change Exception is triggered when the percent change between Yesterday's Stock Cover and Today's Stock Cover exceeds the Stock Cover Day-On-Day Change Threshold. |

The Outbound Distribution Capacity Exception is raised when the Warehouse Actual Outbound Volume exceeds the Outbound Distribution Capacity.

The Outbound Distribution Capacity Exception is triggered if the following condition is True:

Calculate the projected outbound plan. The projected outbound plan must be greater than a user-defined threshold.

The projected outbound plan is calculated as the sum of demand in cases for all SKUs in the network group for a warehouse.

Demand includes:

All CRPs where the warehouse is the source

Allocations in the Well

Cross-docked CRPs where the warehouse is an intermediate location in the cross-dock route

Each day, the projected outbound plan is compared to an alert parameter, Outbound Distribution Capacity Cases. This parameter is maintained in the WRP Network Threshold Maintenance workbook at the Network Group/Warehouse/Day level.

If the projected outbound plan is greater than the Outbound Distribution Capacity Cases threshold the alert is triggered.

The Warehouse Holding Capacity Exception is raised when the total capacity opening inventory in pallets exceeds the Stocking Point Holding Capacity.

The Warehouse Holding Capacity Exception is triggered if the following condition is True:

Calculate the capacity projected inventory. The capacity projected inventory must be greater than a user-defined threshold.

For each day, the capacity projected inventory is calculated as the sum of Projected Inventory plus Total Held Stock for all SKUs in the network group for a warehouse.

The capacity projected inventory is compared to an alert parameter, Stocking Point Holding Capacity. This parameter is maintained in the WRP Network Threshold Maintenance workbook at the Network Group/Warehouse level.

If the capacity projected inventory in pallets is greater than the Stocking Point Holding Capacity threshold the alert is triggered.

The Stock Cover Exception is triggered when the Projected Stock Cover Actual\Target Difference exceeds the Excessive Stock Cover Threshold for that day.

The Stock Cover Exception is triggered if the following condition is True:

For each day, calculate Projected Stock Cover Days. Projected Stock Cover represents the number of days that the Opening Inventory on a certain planning day satisfies the Projected Outbound Plan.

Each day, the Projected Outbound Plan (POP) is calculated as the sum of the day's demand in cases for all SKUs in the network group for a warehouse.

Demand includes:

All CRPs where the warehouse is the source

Allocations in the Well

Calculate the capacity projected inventory as the sum of Projected Inventory minus Back Orders, plus Total Held Stock for all SKUs in the network group for a warehouse.

Calculate the Projected Stock Cover Days Count as the count of days from the current day until the current day's Capacity Projected Inventory (CPI) minus Projected Outbound Plan (POP) is equal to zero. Note that the number of stock covers days may include a partial day.

If the Capacity Projected Inventory (CPI) minus Projected Outbound Plan (POP) is less than zero on the last day, only a portion of this day is covered, calculate the stock cover for a portion of the last day.

If the remaining Capacity Projected Inventory minus Projected Outbound Plan is greater than zero on the last day of the planning horizon the stock cover days will remain equal to the number of days between the current day and the end of the planning horizon.

Projected Stock Cover Days equals the count of days covered plus the percent of the last day's cover.

Calculate the Stock Cover Target/Actual Difference as the relative percentage difference between the Projected Stock Days cover and Target Stock Cover.

Target Stock Cover is an alert parameter maintained in the WRP Network Threshold Maintenance workbook at the Network Group/Warehouse/Day level.

Stock Cover Target/Actual Difference is calculated as (projected stock cover minus target stock cover) divided by target stock cover.

The Stock Cover Target/Actual Difference is compared to an alert parameter, Excessive Stock Cover Global Threshold. This parameter is maintained in the WRP Network Threshold Maintenance workbook at the global level.

If Stock Cover Target/Actual Difference is greater than the Excessive Stock Cover Global Threshold for any day, the alert is triggered.

The Inbound Day-on-Day Change Exception is triggered when the percent change between Yesterday's Remaining Week Inbound Plan and Today's Remaining Week Inbound Plan exceeds the Inbound Day-On-Day Change Threshold.

Calculate the percent change between yesterday and today's remaining week inbound plans. The percent change must be greater than a user-defined threshold.

Calculate today's remaining week inbound plan as the sum of the constrained planned receipts from today through the end of the current week for all SKUs in the network group for a warehouse.

Today's remaining week inbound plan becomes yesterday's remaining week inbound plan on the following day.

Calculate the percent change by taking the difference between today's and yesterday's remaining week inbound plans and divide the difference by yesterday's remaining week inbound plan.

The percent change is compared to an alert parameter, Inbound Day-on-Day Change Threshold. This parameter is maintained in the WRP Network Threshold Maintenance workbook at the Network Group/Warehouse/Day level.

If the percent change is greater than Inbound Day-on-Day Change Threshold the alert is triggered.

The Outbound Day-on-Day Change Exception is triggered when the percent change between Yesterday's Remaining Week Outbound Plan and Today's Remaining Week Outbound Plan exceeds the Outbound Day-On-Day Change Threshold.

The Outbound Day-on-Day Change Exception is triggered if the following condition is True:

Calculate the percent change between yesterday and today's remaining week outbound plans. The percent change must be greater than a user-defined threshold.

First, calculate the Projected Outbound Plan (POP) as the sum of demand for all SKUs in the network group for a warehouse.

Calculate today's remaining week outbound plan as the sum of the Projected Outbound Plan from today through the end of the current week for all SKUs in the network group for a warehouse

Today's remaining week outbound plan becomes yesterday's remaining week outbound plan on the following day.

Calculate the percent change by taking the difference between today's and yesterday's remaining week outbound plans and divide the difference by yesterday's remaining week outbound plan.

The percent change is compared to an alert parameter, Outbound Day-on-Day Change Threshold. This parameter is maintained in the WRP Network Threshold Maintenance workbook at the Network Group/Warehouse/Day level.

If the percent change is greater than Outbound Day-on-Day Change Threshold the alert is triggered.

The Stock Cover Day-on-Day Change Exception is triggered when the percent change between Yesterday's Stock Cover and Today's Stock Cover exceeds the Stock Cover Day-On-Day Change Threshold.

The Stock Cover Day-on-Day Change Exception is triggered if the following condition is True:

Calculate the percent change between yesterday's stock cover and today's stock cover. The percent change must be greater than a user-defined threshold.

For each day calculate the Projected Outbound Plan (POP) as the sum of the day's demand in cases for all SKUs in the network group for a warehouse.

Calculate the capacity projected inventory as the sum of Projected Inventory plus Total Held Stock for all SKUs in the network group for a warehouse.

Calculate the Projected Stock Cover Days Count as the count of days from the current day until the current day's Capacity Projected Inventory (CPI) minus Projected Outbound Plan (POP) is equal to zero. Note that the number of stock covers days may include a partial day.

If the Capacity Projected Inventory (CPI) minus Projected Outbound Plan (POP) is less than zero on the last day, only a portion of this day is covered, calculate the stock cover for a portion of the last day.

If the remaining Capacity Projected Inventory minus Projected Outbound Plan is greater than zero on the last day of the planning horizon the stock cover days will remain equal to the number of days between the current day and the end of the planning horizon.

Projected Stock Cover Days equals the count of days covered plus the percent of the last day's cover.

Calculate the percent change by taking the difference between today's projected stock cover days and yesterday's projected stock cover days and divide the difference by yesterday's projected stock cover days.

The percent change is compared to an alert parameter, Stock Cover Day-on-Day Change Threshold. This parameter is maintained in the WRP Network Threshold Maintenance workbook at the Network Group/Warehouse/Day level.

If the percent change is greater than Stock Cover Day-on-Day Change Threshold the alert is triggered

The following table provides information about the available WRP Overstock alerts.

| Alert | Description |

|---|---|

| WRP Overstock Alert | The WRP Overstock Alert is generated when projected number of days stock cover exceeds the Projected Stock Cover Days Threshold Exception and the projected inventory exceeds the Overstock Threshold Exception. |

| Stockless Surplus Alert for Multiple Days Alert | The Stockless Surplus Alert for Multiple Days is generated for stockless products when the Demand Credit exceeds the Stockless Surplus Threshold, the Demand Credit less the demand over the Stockless Surplus Days Threshold is greater than zero, and the number of days a Stockless Surplus alert exists exceeds the Stockless Surplus MultiDay Threshold. |

| Stockless Surplus Alert for a Single Day Alert | A Stockless Surplus Alert for a Single Day is generated for stockless products when the Demand Credit exceeds the Demand Credit Unit Threshold and the demand over the Stockless Surplus Days Threshold is greater than zero. |

| Overstock Summary Alert | Triggered when any of the overstock item alerts is triggered. |

The WRP Overstock Alert is generated when projected number of days stock cover exceeds the Projected Stock Cover Days Threshold Exception and the projected inventory exceeds the Overstock Threshold Exception. The Overstock alert is calculated over the planning horizon.

The WRP Overstock Alert is triggered if all of the following conditions are True:

Calculate Projected Stock Cover Days. Projected Stock Cover represents the number of days that the Projected Inventory on a certain planning day satisfies the Projected Demand. The Projected Stock Cover Days must be greater than the Projected Stock Cover Days Threshold.

Calculate the Projected Stock Cover Days Count as the count of days from the current day until the current day's Projected Inventory minus Forecast Demand is less than or equal to zero. Only count days where demand is greater than 0. If demand is 0 on a particular day pass over that day and do not increment the days of cover count. Note that the number of stock cover days may include a partial day.