Purpose: The Interface section of the System Control table defines parameters that control:

• system information

• program names

• program information

For more information: See Point of Sale Integration Overview.

Quick Reference of Interface System Control Values

This table describes briefly each system control value for the point of sale interface and lists the control code, control value, a short definition, other control values to which you should refer in this section, if necessary, and a column where you can indicate the value that you assigned for your company.

If you have more than one company on your system, make a copy of this table for each.

Purpose: Company: ________________________________

|

System Control Value |

Description |

Your Value |

|---|---|---|

|

Defines the number of days to retain processed IL outbound triggers before purging them. |

Number field: |

|

|

Defines whether the system creates triggers in the IL Outbound Trigger table when you add, change, or delete item or SKU information. |

Selected/ Unselected: |

|

|

Defines whether the system creates triggers in the IL Outbound Trigger table when you add, change, or delete vendor information. |

Selected/ Unselected: |

|

|

Defines whether the system creates triggers in the IL Outbound Trigger table when you create or update an invoice. |

Selected/ Unselected: |

|

|

Indicates whether to generate pick download trigger records (file type = PCH). |

Selected/ Unselected: |

|

|

Indicates whether the system creates trigger records for the Outbound Purchase Order API. (file type = POH). |

Selected/ Unselected: |

|

|

Defines whether the system creates a purchase order download (POH) trigger for a purchase order receipt transaction. |

Selected/ Unselected: |

|

|

Indicates whether to create trigger records for the Outbound Return Authorization API (file type = RAD). |

Selected/ Unselected: |

|

|

Indicates whether to create trigger records for the generic inventory integration (file type = ITW) based on changes in inventory levels. |

Selected/ Unselected: |

|

|

Indicates whether to create trigger records for the Generic Customer Outbound API (file type = CST). |

Selected/ Unselected: |

|

|

Indicates whether to generate inventory download trigger records when you create or change a purchase order. |

Selected/ Unselected: |

|

|

Indicates whether to include warehouses whose Allocatable flag is unselected when generating trigger records for the generic inventory integration. |

Selected/ Unselected: |

|

|

Defines whether certain fields are required when creating an item: |

||

|

Defines whether the long SKU division is a required field when you create or change a long SKU department. |

Selected/ Unselected: |

|

|

Defines whether the long SKU department code is required when creating or maintaining an item. |

Selected/ Unselected: |

|

|

Defines whether the long SKU class code is required when creating or maintaining an item. |

Selected/ Unselected: |

|

|

Defines whether the long SKU style code is required when creating or maintaining a SKU. |

Selected/ Unselected: |

|

|

Defines whether an item class is required when creating or maintaining an item. |

Selected/ Unselected: |

|

|

Defines default rules and settings for integration with the Order Broker in Order Broker. |

||

|

Defines whether merchandise locator searches are available for information and to support store pickup order creation. |

Selected/ Unselected |

|

|

Defines whether the distance measurement for merchandise locator or store pickup searches is miles or kilometers. |

Code: |

|

|

Defines whether to submit all brokered backorders on an order in a single Submit Order message. |

Selected/ Unselected |

|

|

Indicates the default search radius, in miles or kilometers, for merchandise locator or store pickup searches. |

Number: |

|

|

Indicates whether to send fulfillment requests for backordered items (brokered backorders) to Order Broker’s Order Broker module. |

Selected/ Unselected: |

|

|

Defines how many minutes to wait before sending a new status inquiry request for to the Order Broker for brokered backorders or for retail pickup, delivery, or store pickup orders. |

Number: |

|

|

Indicates whether backordered items on orders flagged to ship complete are eligible for fulfillment through the Order Broker. |

Selected/ Unselected: |

|

|

Defines the number of days in the future a purchase order’s expected date needs to be before the system requests the Order Broker fulfill a backordered item, or for the system to reject a retail pickup or delivery order. |

Number: |

|

|

Indicates whether backordered items assigned coordinate group codes are eligible for fulfillment through the Order Broker. |

Selected/ Unselected: |

|

|

Indicates whether backordered items on gift orders are eligible for fulfillment through the Order Broker. |

Selected/ Unselected: |

|

|

Defines the account number to specify in Order Broker request messages to identify the Order Broker database. |

System name: |

|

|

Defines the system code to specify in Order Broker request messages to identify the requesting system. |

System name: |

|

|

Defines the default location code to specify in Order Broker request messages to identify the requesting warehouse in Order Management System. |

System name: |

|

|

Defines the location code the Order Broker assigns to a brokered backorder when it cannot find a location to fulfill it. |

System name: |

|

|

Indicates whether to send inventory information to and request orders from Order Broker separately by warehouse, or to aggregate information and to use the OROB Default Location (K51). |

Selected/ Unselected: |

|

|

Defines the code in Order Broker identifying your default integrated point of sale system for assignment of ship-for-pickup or store pickup orders. |

Code: |

|

|

Indicates whether to accept delivery or retail pickup orders assigned by the Order Broker even if they include items that are backordered. |

Selected/ Unselected: |

|

|

Defines the order type to apply to delivery orders assigned by the Order Broker. |

Code: |

|

|

Define the batch number to use for delivery or retail pickup orders in error that are assigned by the Order Broker. |

Number: |

|

|

Indicates whether to update a customer’s email address based on the information received from the Order Broker when it sends delivery or retail pickup orders to Order Management System for fulfillment. |

Selected/ Unselected: |

|

|

Defines the order type to apply to retail pickup orders assigned by the Order Broker. |

Code: |

|

|

Defines the hold reason code to apply to a delivery or retail pickup order when Order Broker indicates that the order has been canceled during pick slip generation in Order Management System. |

Code: |

|

|

Indicates whether to update a customer’s email address based on the information received from the Order Broker when it sends delivery or retail pickup orders to Order Management System for fulfillment. |

Selected/ Unselected: |

|

|

Defines the default source code to apply to delivery or retail pickup orders assigned to Order Management System for fulfillment if no source code was specified in the message from the Order Broker or for the Store Cross Reference record. |

Code: |

|

|

Defines the hold reason code to apply to ship-for-pickup orders if Order Broker returns an error when Order Management System.sends the submit order request during pick slip generation. |

Code: |

|

|

Indicates whether to flag a retail pickup or delivery order to ship complete. |

Selected/ Unselected: |

|

|

Defines the pay type to apply to retail pickup or delivery orders assigned to Order Management System for fulfillment. |

Number: |

|

|

Defines the price override reason code to use for order lines on retail pickup or delivery orders assigned to Order Management System for fulfillment. |

Code: |

|

|

Indicates whether to flag retail pickup or delivery orders as gifts in order to prevent prices from printing on pick slips. |

Selected/ Unselected: |

|

|

Defines the default ship via code to apply to retail pickup or delivery orders assigned to Order Management System for fulfillment if a ship via code is not specified in the message from the Order Broker. |

Number: |

|

|

Indicates whether to calculate freight for store pickup orders that you create in interactive order entry. |

Selected/ Unselected: |

|

|

Indicates whether to send a status update of polled when a delivery or retail pickup order is received from the Order Broker and the order is in error. |

Selected/ Unselected: |

|

|

Defines the order type to assign to store pickup orders. |

Code: |

|

|

Defines the cancel reason code to apply to store pickup orders rejected by Order Broker or by the assigned fulfilling location. |

Code: |

|

|

Defines whether you collect payment for a ship-for-pickup order at the store location rather than billing the order when you ship it from the warehouse. |

Selected/ Unselected: |

|

|

Defines whether to automatically cancel retail pickup, delivery, or special ship-for-pickup orders if their pick slips are voided through the generic pick in API. |

Code: |

|

|

Controls whether to authorize store pickup orders for verification only, or to authorize and bill store pickup orders in Order Management System. |

Selected/ Unselected: |

|

|

Defines whether you can process a return or a negative additional charge for a retail pickup or delivery order. |

Selected/ Unselected: |

|

|

Indicates the field where you store Order Broker’s default product code. |

Code: |

|

|

Indicates whether to map the long SKU division or the item category to the category in Order Broker. |

Code: |

|

|

Select this system control value to use the Order Broker Fulfillment Integration. |

Selected/ Unselected: |

|

|

Defines the originating location code for delivery orders that originated in Order Management System and are sent to Order Broker to determine the fulfilling location. |

Code: |

|

|

Defines the order type code the system assigns to delivery orders that originated in Order Management System that Order Broker determined should be fulfilled by Order Management System. |

Code: |

|

|

Defines whether ship-for-pickup orders are sent to Order Broker for fulfillment assignment. |

Code: |

|

|

Order Type for Retail Pickup Orders Originating in OROMS (M35) |

Defines the order type code the system assigns to retail pickup orders that originated in Order Management System that Order Broker determined should be fulfilled by Order Management System. |

Code: |

|

Select this field if you are using Order Broker to process drop ship purchase orders. |

Selected/ Unselected: |

|

|

Defines the number of days added to the date passed to Order Broker to calculate the Expected ship date stored in Order Management System for a drop ship purchase order line. |

Number: |

|

|

Identifies whether or not an external warehouse management system is being used with Order Management System. |

Selected/ Unselected: |

|

|

Defines whether the system automatically advances you to the Work with Customer Profile Screen in order entry and order maintenance for all customers that require customer demographics or only for customers that have an alternate customer number defined. |

Selected/ Unselected: |

|

|

Defines the program that generates the store pickup notification email. |

Program name: |

|

|

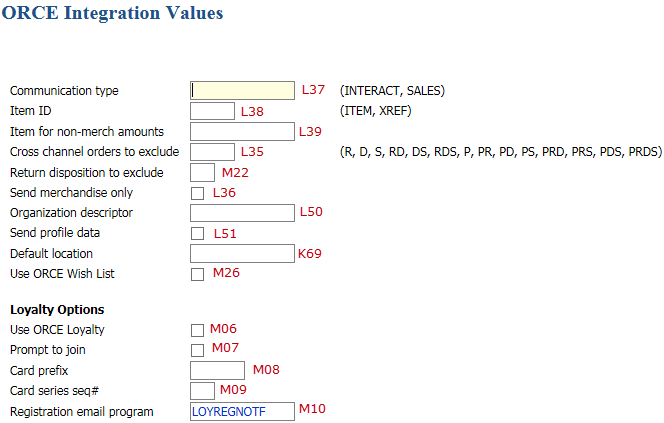

These values control integration with Oracle Retail Customer Engagement. |

||

|

Defines how Order Management System sends customer information to Oracle Retail Customer Engagement. |

Code: |

|

|

Defines how Order Management System identifies items/SKUs for integrations with other systems. |

Code: |

|

|

Defines the item code to include in the Customer Engagement Post POSlog Transaction Message to represent all non-merchandise amounts for an item, such as freight, additional freight, handling and additional charges. |

Code: |

|

|

Defines the types of orders Order Management System excludes in the Oracle Retail Customer Engagement Sales Feed. |

Code: |

|

|

Defines the return disposition code assigned to return (credit) invoices that Order Management System excludes from the Oracle Retail Customer Engagement Sales Feed. In addition, Order Management System does not generate a return confirmation for these returns. |

Code: |

|

|

Defines whether Order Management System includes full invoice totals or only merchandise and tax amounts in the Oracle Retail Customer Engagement Sales Feed. |

Selected/ Unselected: |

|

|

Identifies the Oracle Retail Customer Engagement organization that maps to your Order Management System company. |

Code: |

|

|

Defines whether to include customer profile information when sending new or changed customer information to Oracle Retail Customer Engagement through the interactive customer integration. |

Selected/ Unselected: |

|

|

Indicates the store cross-reference record you use as part of an integration with a point-of-sale system. |

Code: |

|

|

Defines whether you use the Customer Engagement Customer Wish List Integration. |

Selected/ Unselected: |

|

|

Defines whether you use the Customer Engagement Loyalty Integration. |

Selected/ Unselected: |

|

|

Defines whether the system automatically displays the Customer Loyalty Registration Window during Order Entry and Work with Customers (WCST) when the customer is not assigned to a loyalty card in Oracle Retail Customer Engagement. |

Selected/ Unselected: |

|

|

Defines the 5 digit prefix assigned to the Loyalty Card Definition in Oracle Retail Customer Engagement that is used to assign new loyalty cards to sold to customers that join the loyalty program. |

Code: |

|

|

Defines the 2 digit card series number assigned to the Loyalty Card Definition in Oracle Retail Customer Engagement that is used to assign new loyalty cards to sold to customers that join the loyalty program. |

Code: |

|

|

Defines the program used to generate a Loyalty Registration Notification email when a sold to customer joins the loyalty program and is assigned a loyalty card in Oracle Retail Customer Engagement. |

System Name: |

|

|

Defines whether the system retrieves item images and item information from an external image hosting application. |

Selected/ Unselected: |

|

|

Defines the number of days old a periodic process history record should be before it is eligible for purge. |

Number: |

|

|

Defines whether to generate separate pick slips or drop ship purchase orders for ship-for-pickup orders so that each line creates a separate order in Order Broker. |

Selected/ Unselected: |

|

|

Defines the order type to assign to orders you process through the ChannelAdvisor integration. |

Code: |

|

|

Defines the available quantity to report to ChannelAdvisor for drop ship and non-inventory items. |

Number: |

|

|

Defines the offer associated with item and SKU cross-references for ChannelAdvisor. |

Code: |

|

|

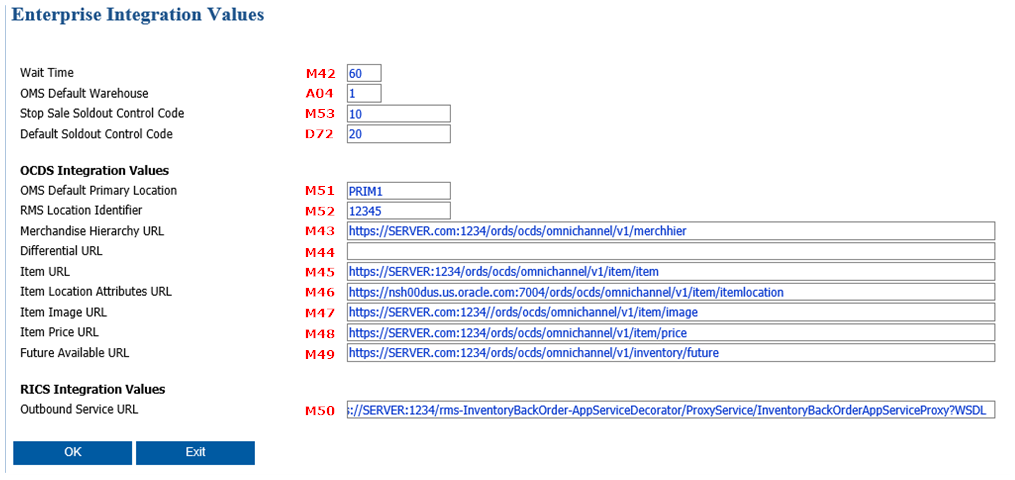

Enterprise Integration Values (M41) These values control integration with integration with Oracle Retail Merchandising Foundation Cloud Service (RMFCS) and Oracle Retail Pricing Cloud Service (RPCS) through Omnichannel Cloud Data Service (OCDS), as well as with RICS. |

||

|

Defines the number of seconds to wait for a response from OCDS for responses to requests for item and related data, and RICS for backorder notification requests. |

Number: |

|

|

Defines the default warehouse to use when importing enterprise foundation data through OCDS. |

Number: |

|

|

Defines the soldout control code to use when Order Management System indicates to sell out an item immediately. |

Code: |

|

|

Defines the soldout control code to assign when creating items or SKUs. |

Code: |

|

|

Defines the location to use when creating item location records through the OCDS import. |

Code: |

|

|

Defines the location identifier to map item and pricing from Oracle Retail Merchandising Foundation Cloud Service (RMFCS) and Oracle Retail Pricing Cloud Service (RPCS) to a company in Order Management System when integrating through OCDS. |

Code: |

|

|

Defines the URL to use when requesting merchandise hierarchy information from OCDS. |

Long: |

|

|

Defines the URL to use when requesting item differential information from OCDS. Not currently implemented. |

Long: |

|

|

Defines the URL to use when requesting item information from OCDS. |

Long: |

|

|

Defines the URL to use when requesting information derived from the ITEM_LOC table in OCDS. |

Long: |

|

|

Defines the URL to use when requesting item image information from OCDS. |

Long: |

|

|

Defines the URL to use when requesting item price information from OCDS. |

Long: |

|

|

Defines the URL to use when requesting future available inventory information from OCDS. |

Long: |

|

|

Defines the URL to use when submitting requests to RICS. |

Long: |

|

|

Specifies the code to include as the Return Warehouse in the RTLOG file for returns that do not affect inventory. |

Code: |

|

|

Defines whether to integrate with Narvar in order to generate shipment information to customers. |

Yes/No: |

|

|

Specifies the URL to use when communicating with Narvar. |

Long: |

|

|

Narvar Non-Deliverable Email Address for Shipment Confirmations (M59) |

Specifies the non-deliverable email address for Narvar to use when the email cannot or should not be sent to the customer’s actual email address. |

Long: |

|

Specifies the prefix of the URL to use for shipment tracking. |

Long: |

|

Generic Integration Values (I13)

Purpose: Use this screen to define the type of information you wish the system to capture for generic download.

Outbound Interface Trigger File Purge Days (I14)

Enter the number of days to retain processed records in the IL Outbound Trigger table before purging them.

An IL outbound trigger is considered processed if the Status field is X.

The Purge IJCT Download periodic function (program name ILR0026) or the Purge option at the Work with Outbound Interface Transactions Screen perform the purge, deleting any records if:

Last processed date is less than the current system date by the number of purge days and Status is X

Example: Today is 2/06 and you have this value set to 1. Any processed record whose Last processed date is earlier than 2/05 or earlier is purged.

If you leave this field set to 0, all processed records are eligible to be purged.

Create Generic Item Download Trigger Records (I15)

Defines whether the system creates item download triggers in the IL Outbound Trigger table when you add, change, or delete item/SKU information. The IL Outbound Trigger table acts as a “to do” list for the item/SKU information that requires download.

Select this field to have the system create item download triggers when you add, change, or delete item or SKU information.

Certain actions in Order Management System trigger the system to create item download triggers in the IL Outbound Trigger table with a File code of SKU; see Item Outbound Trigger Activities.

Additionally, you can also create item download triggers for each item/SKU in your company using the Generating Outbound Interface Triggers (GOIT) menu option.

Leave this field unselected if you do not want the system to create item download triggers when you add, change, or delete item or SKU information or by using the Generate Outbound Interface Triggers menu option.

For more information: See Generic Item Download API.

Create Generic Vendor Download Trigger Records (I16)

Defines whether the system creates vendor download triggers in the IL Outbound Trigger table when you add, change, or delete vendor information. The IL Outbound Trigger table acts as a “to do” list for the vendor information that requires download.

Select this field to have the system create vendor download triggers when you add, change, or delete vendor information.

Certain actions in Order Management System trigger the system to create vendor download triggers in the IL Outbound Trigger table with a File code of VND; see Vendor Outbound Trigger Activities.

Additionally, you can also create vendor download triggers for each vendor in your company using the Generating Outbound Interface Triggers (GOIT) menu option.

Leave this field unselected if you do not want the system to create vendor download triggers when you add, change, or delete vendor information or by using the Generate Outbound Interface Triggers menu option.

For more information: See Generic Vendor Download API.

Create Generic Invoice Download Trigger Records (I17)

Defines whether the system creates invoice download triggers in the IL Outbound Trigger table when you create or update an invoice. The IL Outbound Trigger table acts as a “to do” list for the invoice information that requires download.

Select this field to have the system create invoice download triggers when you create or update an invoice.

Certain actions in Order Management System triggers the system to create invoice download triggers in the IL Outbound Trigger table with a File code of IHD.

Additionally, you can also create invoice download triggers for each invoice in your company using the Generating Outbound Interface Triggers (GOIT) menu option.

Leave this field unselected if you do not want the system to create invoice download triggers when you create or update an invoice or use the Generate Outbound Interface Triggers menu option.

For more information: See Generic Invoice Download API.

Integration with the Sales Audit module of the Oracle Retail Merchandising Foundation Cloud Service: This system control value must be selected in order to use the Integration with the Sales Audit Module of the Oracle Retail Merchandising Foundation Cloud Service. The invoice triggers are required to generate the invoice information to send to the Sales Audit module of the Oracle Retail Merchandising Foundation Cloud Service.

Create Generic Pick Download Triggers (I31)

Indicates whether to create trigger records for the Generic Pick Out API (file type = PCH) when you generate pick slips.

Select this field to generate pick out trigger records when you generate pick slips; see Pick Out Processing for a list of functions that generate a PCH trigger record.

The system also generates printed pick slips unless the Bypass Creation of Pick Forms during WSPS Pick Generation (K55) is also selected and you are using Streamlined Pick Slip Generation (WSPS).

Leave this field unselected if you do not want the system to generate pick out trigger records.

See the Generic Pick Out API for background.

Defines whether the system uses an external warehouse management system and whether PO_OUT XML messages are sent for all purchase orders if Create Generic PO Download Triggers (K26) is selected.

Select this field to use an external warehouse management system with Order Management System, to send a PO_OUT XML message for all purchase orders, and to Create Generic PO Download Triggers (K26).

The following table indicates when purchase order download trigger records are created,

|

Use WMS Integration(K25) |

EDI PO Flag for Vendor |

Results |

|

|---|---|---|---|

|

Selected |

Unselected |

Unselected |

No Purchase Order Download Trigger records are created. |

|

Selected |

Unselected |

Selected |

Purchase Order Download Trigger records are created for EDI Vendors only. |

|

Selected |

Selected |

Selected or Unselected |

Purchase Order Download Trigger records are created for all purchase orders. |

Note: When a Purchase Order Download trigger is created for an EDI vendor, the EDI Date in the Purchase Order Header table is updated with the date when the download trigger was created for both add and change transactions.

If the Create Generic PO Download Triggers (K26) is unselected, no purchase order download triggers are created.

Leave this field unselected if you do not want to integrate an external warehouse management system with Order Management System, generate PO_OUT XML messages, or create purchase order download trigger records.

For more information: See Generic Outbound Purchase Order API for more information on which activities generate trigger records.

Create Generic PO Download Triggers (K26)

Select this field to have the system create a purchase order download (POH) trigger in Working with Outbound Interface Transactions (WOIT) when you print a purchase order, based on the trigger rules defined for the PO Download (PO_OUT) integration layer job. The PO_OUT job monitors for purchase order out download triggers and generates a PO Download XML Message (CWPurchaseOrderOut) to send the purchase order information to a remote system as long as Use WMS Integration (K25) is selected.

Note: An add or change trigger is not generated unless the purchase order is printed. See Purchase Order Download Trigger Activities.

Leave this field unselected if you do not want the system to create purchase order download trigger records.

For more information: See Generic Outbound Purchase Order API for more information on which activities generate trigger records.

Create Generic PO Download Trigger for PO Receipt (K27)

Defines whether the system creates a purchase order download (POH) trigger in Working with Outbound Interface Transactions (WOIT) for a purchase order receipt transaction.

The following identifies when purchase order receipt transactions generate generic purchase order download triggers and when they do not generate generic purchase order download triggers. The valid values are:

• NEVER or blank. Purchase order download triggers are not created for Purchase Order Receipt transactions and never generate a change Purchase Order Download trigger.

• ALWAYS. Purchase order download triggers are created for all Purchase Order Receipt transactions. This means that any and all purchase order receipts generate a change Purchase Order Download trigger.

• CLOSED. Purchase order download triggers are generated only when the purchase order is changed to a closed status as a result of a purchase order receipt. A receipt closes a purchase order either because you received the ordered quantity, or because the Under Receipt % (A62) was met.

Note: If the Create Generic PO Download Triggers (K26) system control value and the Use WMS Integration (K25) system control value are unselected, purchase order receipts do not generate triggers.

For more information: See Generic Outbound Purchase Order API for more information on which activities generate trigger records.

Create Return Download Triggers (K28)

Select this field to have the system create a return authorization download (RAD) trigger in Working with Outbound Interface Transactions (WOIT) when you create, change, or delete a return, based on the trigger rules defined for the Return Authorization Download (RETURN_OUT) integration layer job. The RETURN_OUT integration layer job monitors for return authorization download triggers and generates a Return Authorization Outbound XML Message (CWReturnRAOut) to send the return authorization information to a remote system.

Unselect this field if you do not want the system to create a return authorization download (RAD) trigger when you create, change, or delete a return.

For more information: See:

• Outbound Return API for an overview and the setup required to send return authorization information to a remote system.

• Return Authorization Outbound Trigger Activities for more information on which activities create a return authorization download (RAD) trigger.

• Introducing Return Authorizations (WRTA) for an overview on the Work with Return Authorizations (WRTA) menu option.

• Posting Returns Outside of Work with Return Authorizations for a summary of the other ways you can post a return outside of the Work with Return Authorizations (WRTA) menu option.

Create Generic Inventory Download Triggers (I32)

The IL Outbound Trigger table acts as a “to do” list for the inventory information that requires download.

Select this field to have the system create inventory download triggers when you perform any action that causes an item’s available quantity to exceed or fall below its availability threshold. For example, receiving a purchase order, making an inventory adjustment, or reserving inventory by entering an order detail line are examples of activities that affect an item’s available quantity. The system creates inventory download triggers in the IL Outbound Trigger table with a File code of ITW.

See the Quantity Available Threshold for Inventory Downloads (G36) system control value for more information on how the system determines an item’s availability threshold.

Additionally, you can also create inventory download triggers for each item/SKU in your company using the Generating Outbound Interface Triggers (GOIT) menu option. This option checks the setting of the Include Non-Allocatable Warehouses (I34) system control value to determine whether to create a trigger if an item is stored only in a non-allocatable warehouse.

Leave this field unselected if you do not want the system to create inventory download triggers when you perform actions that affect an item’s availability, or by using the Generate Outbound Interface Triggers menu option.

For more information: See Generic Inventory Download API for an overview.

Create Generic Customer Download Triggers (L12)

Indicates whether to create trigger records for the Generic Customer Download API (file type = CST) when you create, update, or delete a customer.

Select this field to generate customer download trigger records when you create, update, or delete a customer.

Leave this field unselected if you do not want the system to generate customer download trigger records.

See the Generic Customer Download API for background.

Select this field to have the OTHR_ASYNC process create inventory download trigger records whenever you create or update a purchase order that includes an item/SKU whose available quantity is zero or less.

Note:

• This system control value applies only if the Create Generic Inventory Download Triggers (I32) system control value is selected, and the new or updated purchase order is not a drop ship purchase order.

• The system generates a trigger record whenever you maintain a purchase order that includes the item/SKU whose available quantity is zero or less, regardless of the changes you make to the purchase order, as long as the purchase order is not in cancelled status. Any change to the purchase order generates a trigger record.

• Stop and restart the background jobs after changing this system control value in order for your change to take effect.

Leave this field blank if you do not want the system to create inventory download triggers when you create or update purchase orders.

For more information: See Generic Inventory Download API, especially Creating Inventory Download Triggers through Purchase Order Creation or Maintenance, for an overview and more information.

Include Non-Allocatable Warehouses (I34)

Indicates whether to include warehouses whose Allocatable flag is unselected when generating trigger records for the generic inventory integration. See Generic Inventory Download API for more information.

This system control value also controls whether the CAINV periodic function includes quantities in non-allocatable in the available quantity sent to ChannelAdvisor. See Sending Current Inventory Information to ChannelAdvisor for a discussion of this periodic function, and see ChannelAdvisor Integration Overview for background on integrating with ChannelAdvisor.

Note: Stop and restart the background jobs after changing this system control value in order for your change to take effect.

Download Threshold Quantity (G36)

This is the Quantity Available Threshold for Inventory Downloads (G36) system control value; see that system control value for more information.

Purpose: Use this screen to specify whether certain fields are required when creating an item.

Note: If the Use Retail Integration (H26) system control value is selected, the settings of the following system control values under the Item Values (I91) umbrella system control value are ignored.

• Require L/S Department (I92)

Require L/S Division with L/S Department (E85)

Defines whether the long SKU division is a required field when you create or change a long SKU department. See Require Long SKU Division with Long SKU Department (E85) for a complete description of this system control value.

Defines whether the long SKU department code is required when creating or maintaining an item.

Select this field if you wish to require a long SKU department code for each item. If you are using the Order Management System/CWStore integration, requiring entry of long SKU department is required as part of your retail hierarchy in CWStore.

The system requires entry of the long SKU department:

• at the Create Item Screen and Change Item Screen while Performing Initial Item Entry (MITM)

• Change Item Upload Screens (when correcting errors for an item creating through the RI Item Upload Table (RIIUPP)

If you select this field, you must have authority to the Maintain Long SKU Values in MITM (B05) secured feature in order to enter a long SKU department for an item.

Leave this field unselected if you do not wish to require a long SKU department code for each item.

Note: If the Use Retail Integration (H26) system control value is selected, the system ignores the setting of the Require L/S Department (I92) system control value.

Defines whether the long SKU class code is required when creating or maintaining an item.

Select this field if you wish to require a long SKU class code for each item. If you are using the Order Management System/CWStore integration, requiring entry of long SKU class may be required if it is part of your retail hierarchy in CWStore.

The system requires entry of the long SKU class:

• at the Create Item Screen and Change Item Screen while Performing Initial Item Entry (MITM)

• Change Item Upload Screens (when correcting errors for an item creating through the RI Item Upload Table (RIIUPP)

Note: This system control value controls entry of a long SKU class code at the item level, it does not control entry of a long SKU class code at the SKU level.

If you select this field, you must have authority to the Maintain Long SKU Values in MITM (B05) secured feature in order to enter a long SKU class for an item.

Leave this field unselected if you do not wish to require a long SKU class code for each item.

Note: If the Use Retail Integration (H26) system control value is selected, the system ignores the setting of the Require L/S Class (I93) system control value.

Defines whether the long SKU style code is required when creating or maintaining a SKU and validates that the long SKU style code defined at the item level and SKU level are both unique values.

Select this field if you wish to require a long SKU style code for each SKU. If you are using the Order Management System/CWStore integration, requiring entry of long SKU style may be required if it is part of your retail hierarchy in CWStore.

The system requires entry of the long SKU style:

• at the Create SKU 2 of 2 (With Overrides) Screen and Change SKU 2 of 2(With Overrides) Screen while Performing Initial Item Entry (MITM).

• at the Work with SKU Generator Screen while Using the SKU Generator (ESKG).

• Change Item Upload Screens (when correcting errors for an item/SKU created through the RI Item Upload Table (RIIUPP).

In addition, you receive one of the following error messages if the long SKU style you enter at the item level or SKU level is not a unique value:

• L/S Style must be unique

• L/S Style is a duplicate

Note: This system control value controls entry of a long SKU style code at the SKU level, it does not control entry of a long SKU style code at the item level.

If you select this field, you must have authority to the Maintain Long SKU Values in MITM (B05) secured feature in order to enter a long SKU style for an item/SKU.

If the Default SKU Generator L/S Style (J04) system control value is selected, the SKU generator automatically creates a Long SKU style for each SKU created.

• If a long SKU style code is defined for the base item, the system creates a long SKU style code for each SKU using the base long SKU style code + SKU code.

• If a long SKU style code is not defined for the base item, the system creates a long SKU style code for each SKU using the item code + SKU code.

Leave this field unselected if you do not wish to require a long SKU style code for each SKU. In addition, the system does not validate that the long SKU style you define at the item level or SKU level is a unique value.

Note: If the Use Retail Integration (H26) system control value is selected, the system ignores the setting of the Require L/S Style (I94) system control value.

Defines whether an item class is required when creating or maintaining an item. See Require Item Class in Work with Items (F06) for a complete description of this system control value.

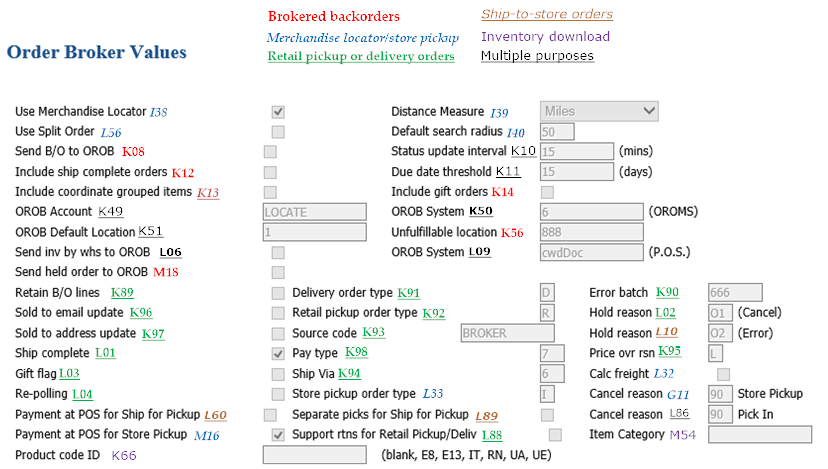

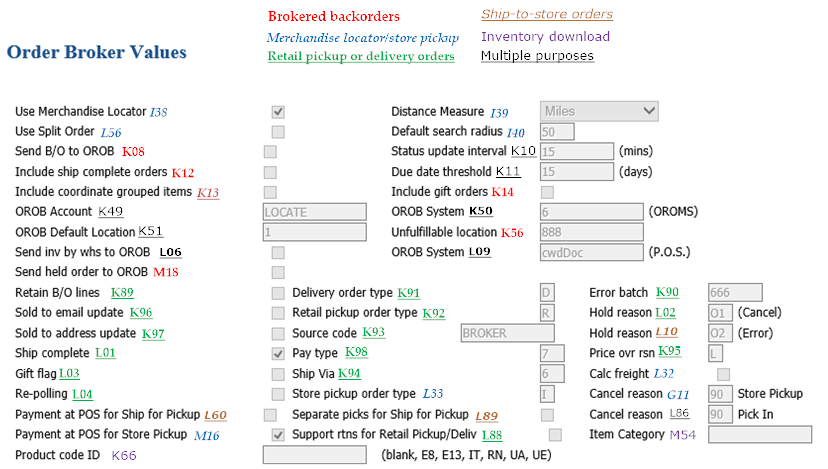

Use this screen to work with values that control the integration between Order Management System and Order Broker’s Order Broker and merchandise locator function. You can use this integration to:

• search for inventory across the enterprise

• automatically have backorders originating in Order Management System fulfilled in an external system, such as Xstore, and prevent selling out backorders unnecessarily

• use Order Management System to fulfill orders originating in a point of sale system, such as Xstore

• send orders from your Order Management System warehouse to a retail store location, where the customer can pick it up

Supplier Direct Fulfillment integration: The integration with Order Broker’s Supplier Direct Fulfillment module uses the OROB System (K50) and OROB Default Location (K51), but none of the other system control values on this screen.

For more information: See:

• the Order Broker Integration Overview for a a high-level discussion of the integration

• the Order Broker Integration for detailed information on integration with the Order Broker

• the Merchandise Locator API for detailed information on searching for items across the enterprise

• Order Broker Configuration for additional setup requirements

Additional system control values related to the Order Broker: See Order Broker Configuration for information on additional system control values that are not included on this screen.

Order Broker values:

• Use Merchandise Locator (I38)

• Merchandise Locator Distance Measurement (I39)

• Default Search Within Radius (I40)

• Order Broker Status Update Interval (K10)

• Order Broker Include Ship Complete Orders (K12)

• Order Broker Due Date Threshold (K11)

• Order Broker Include Coordinate Grouped Orders (K13)

• Order Broker Include Gift Orders (K14)

• OROB Default Location Code for Unfulfillable Orders (K56)

• Send Inventory by Warehouse to OROB (L06)

• Name in OROB for Point of Sale (L09)

• Send Held Orders to OROB (M18)

• Retain Backordered Lines Brokered to OROMS (K89)

• Order Type for Orders Brokered for Delivery (K91)

• Order Broker Error Batch Number (K90)

• Sold to Email Update for Orders Brokered to OROMS (K96)

• Order Type for Retail Pickup Orders Brokered to OROMS (K92)

• Order Broker Hold Reason (Cancel) (L02)

• Sold to Address Update for Orders Brokered to OROMS (K97)

• Order Broker Source Code (K93)

• Hold Reason for Errored Ship for Pickup Orders (L10)

• Ship Complete for Orders Brokered to OROMS (L01)

• Order Broker Payment Type (K98)

• Order Broker Price Override (K95)

• Gift Flag for Orders Brokered to OROMS (L03)

• Calculate Freight for Store Pickup Orders (L32)

• Re-Polling for Orders Brokered to OROMS (L04)

• Store Pickup Order Type (L33)

• Cancel Reason (Rejected Store Pickup Orders) (G11)

• Payment at POS for Ship for Pickup Orders (L60)

• Create Separate Picks for Ship for Pickup Orders (L89)

• Cancel Reason (Pick In) (L86)

• Payment at POS for Store Pickup (M16)

• Suppress Returns for Retail Pickup/Delivery (L88)

• OROB Item Category Value (M54)

Sample screen:

Order Broker Fulfillment values:

Select Order Broker Fulfillment on the Order Broker Values screen to display the system control values related to using Order Broker for fulfillment assignment.

• Use OROB for Fulfillment Assignment (M31)

• Use OROB for Ship for Pickup Fulfillment Assignment (M34)

• Originating Location to Pass to OROB (M32)

• Order Type for Delivery Orders Originating in OROMS (M33)

• Order Type for Retail Pickup Orders Originating in OROMS (M35)

Select this field to have the:

• Merch locator option available to advance to the Merchandise Locator Search Window (Searching for an Item). You can use this window to research an item’s availability in locations where the customer might be able to pick up the item.

• Store Pickup option available to advance to the Merchandise Locator Search Window (Store Pickup) if the Store Pickup Order Type (L33) specifies an order type. You can use this window to find a store location where the customer can pick up the items on the order. If you select a store location, the system converts the order to a store pickup order and sends it to Order Broker in order to notify the store location.

Leave this field unselected if you do not use the merchandise locator or store pickup options.

Merchandise Locator Distance Measurement (I39)

Defines the default unit of measurement for merchandise locator and store pickup searches. Set this field to:

• M = the distances entered at the Merchandise Locator Search Window (Searching for an Item) and Merchandise Locator Search Window (Store Pickup) are in miles

• K = the distances entered at the Merchandise Locator Search Window (Searching for an Item) and Merchandise Locator Search Window (Store Pickup)are in kilometers

The distances displayed at the Merchandise Locator Search Results Screen and the Store Pickup Search Results Screen also use this unit of measure.

Leave this field blank to have the distance of measure default to M (miles), or if you do not use the merchandise locator or store pickup options.

Select this system control value to have Order Management System send all brokered backorders on an order to Order Broker in a single SubmitOrder message.

Leave this field blank to send each backordered line separately.

Note:

• If this system control value is not selected:

• Order Management System does not support canceling individual lines on a store pickup order if, for example, the customer picks up one item on the order but declines to pick up another. See Receiving a Store Pickup Cancellation from Order Broker for a discussion.

• No freight charges are included in the SubmitOrder message to Order Broker.

• This system control value should not be selected if the Create Separate Picks for Ship for Pickup Orders (L89) system control value is selected.

About splitting orders:

• Required Setup for Splitting Orders

• Splitting Brokered Backorders but not Lines

• Splitting Brokered Backorder Lines

• If the Order or Line Splits After Initial Creation in Order Broker

• Status Updates to Order Broker

Required Setup for Splitting Orders

At the Preferences screen in Order Broker, set the Allow Split Order flag consistently with this system control value. Optionally, if you select the Allow Split Order flag in Order Broker, you can also select the Allow Split Line flag. See below for a discussion.

Splitting Brokered Backorders but not Lines

When Order Management System sends one or more brokered backorder lines to the Order Broker and the Allow Split Order flag is selected in Order Broker, but the Allow Split Line flag is not selected:

1. The Order Broker first looks for a single location that can fulfill the complete requested quantity of all submitted lines on the order.

2. If the Order Broker cannot find a single location that can fulfill the complete requested quantity of all lines, it looks for two or more locations that can each fulfill the complete requested quantity of the lines separately.

3. If it is not possible to assign all the order lines to fulfilling locations even by splitting the order and assigning the lines separately, the Order Broker assigns lines when possible to fulfilling locations and assigns each unfulfillable line to the unfulfillable location. In this situation, the unfulfillable order line returns to standard backorder processing in Order Management System.

|

Scenario |

Example |

|---|---|

|

Order with multiple items assigned to a single fulfilling location |

Order includes: • AB100: 1 unit • CD200: 2 units Possible locations that support shipment and are not excluded based on probability rules or distance: • store 10: - 2 units AB100 - 2 units CD200 • store 20: - 100 units AB100 - 1 unit CD200 Store 10 has sufficient inventory of both items, so the Order Broker assigns the entire order to this location. |

|

Order with multiple items assigned to multiple fulfilling locations |

Order includes: • EF300: 1 unit • GH400: 2 units Possible locations that support shipment and are not excluded based on probability rules or distance: • store 10: - 3 units EF300 - 1 unit GH400 • store 20: - 5 units GH400 (EF300 not stocked) Since there is no single location that has sufficient inventory of both items, the Order Broker assigns the first item (EF300) to store 10 and the second item (GH400) to store 20. |

|

One or more items on an order can be assigned to fulfilling location(s), but an item is unfulfillable |

Order includes: • IJ500: 1 unit • KL600: 3 units Possible locations that support shipment and are not excluded based on probability rules or distance: • store 10: - 50 units IJ500 - 1 unit KL600 • store 20: - 2 units IJ500 - 1 unit KL600 The Order Broker assigns the first item (IJ500) to location 10. Since there is no location that has sufficient inventory for KL600, the Order Broker assigns the item to the unfulfillable location; as a result, Order Management System returns the item to standard backorder processing. |

Splitting Brokered Backorder Lines

When Order Management System sends one or more brokered backorder lines to the Order Broker, and both the Allow Split Order flag and the Allow Split Line flag are selected in Order Broker:

1. The Order Broker first looks for a single location that can fulfill the complete requested quantity of all submitted lines on the order.

2. If the Order Broker cannot find a single location that can fulfill the complete requested quantity of all lines, it looks for two or more locations that can each fulfill the complete requested quantity of the lines separately.

3. If it is not possible to assign all the order lines to fulfilling locations even by splitting the order and assigning the lines separately, the Order Broker assigns lines when possible to fulfilling locations and looks for two or more locations that, among them, can fulfill the complete requested quantity of each line that cannot be completely assigned to a single location.

4. If it is not possible to completely assign an order line even by splitting the line across multiple locations, the Order Broker assigns each unfulfillable line to the unfulfillable location. In this situation, the unfulfillable order line returns to standard backorder processing in Order Management System.

Note: If a possible location supports backorders and stocks the item, the Order Broker assigns the entire quantity of the order line to that location rather than splitting the line.

|

Scenario |

Example |

|---|---|

|

An order line on a multi-line order can be fulfilled only by splitting |

An order includes 3 units of item AB100. Possible locations that support shipment, are not excluded based on probability rules or distance, but do not support backorders: • store 10: 2 units • store 20: 2 units The Order Broker assigns 2 units to location 10 and 1 unit to location 20. |

|

An order line on a multi-line order cannot be completely fulfilled even by splitting |

An order includes 5 units of item CD200. Possible locations that support shipment, are not excluded based on probability rules or distance, but do not support backorders: • store 10: 1 units • store 20: 3 units Since it is not possible to assign all 5 units even by splitting the line across locations, the Order Broker assigns the entire order line to the unfulfillable location; as a result, Order Management System returns the item to standard backorder processing. |

If the Order or Line Splits After Initial Creation in Order Broker

It is possible for a selected fulfilling location to reject an assigned order or order line if, for example, the available inventory for the item was overstated in Order Broker. In this situation, the Order Broker “reshops” the rejected order or line, attempting to find one or more possible fulfilling location(s).

|

Settings |

Example |

|---|---|

|

The Allow Split Order is selected, the Allow Split Line flag is not selected |

Single line rejected: An order is assigned to location 10: • AB100: 2 units • CD200: 1 unit Store 10 accepts the line for AB100, but rejects the line for CD200 because the item is not actually available. The Order Broker then assigns the line for CD200 to store 20, where 3 units are available. In this situation, Order Management System has two Order Broker records, both for store 10, when Order Broker initially accepts the order. After it receives a status inquiry response with the updated information, it updates the second Order Broker record with the new assignment of store 20. |

|

Both the Allow Split Order and Allow Split Line flags are selected |

Splitting the line after initial order creation: An order for 3 units of EF200 is assigned to store 20, but the location rejects the order because the requested quantity of the item is not actually available. The Order Broker next assigns the order line across: • store 30: 1 unit • store 40: 2 units In this situation, Order Management System has a single Order Broker record for store 20 and a quantity of 3 when Order Broker initially accepts the order. After it receives a status inquiry response with the updated information, Order Management System: • updates the first Order Broker record with a quantity of 1 and store 30 • creates a new Order Broker record with a quantity of 2 and store 40 A partial line quantity is unfulfillable after initial order creation: An order for 3 units of GH300 is initially assigned to: • store 60: 2 units • store 70: 1 unit Order Management System initially creates an Order Broker record for the 2 units in store 60 and the 1 unit in store 70. Store 70 rejects the order for 1 unit, and there are no additional locations that might fulfill this order line. The Order Broker assigns the 1 unit to the unfulfillable location. When Order Management System receives this update, it changes the status of the Order Broker record for the 1 unit to unfulfillable status and changes the location to the unfulfillable location. The single unit then returns to standard backorder processing once store 60 ships the 2 assigned units. |

Quantity not indicated in order transaction history messages: The order transaction history messages do not specify the quantity affected by the update; however, if you split orders and lines, the quantity affected may be less than the total order line quantity. For example, if the Order Broker splits an order line across two locations for fulfillment, and one of the locations fulfills its assigned quantity, the order transaction history message of Ln#: 2 Shipped by Broker does not indicate the fulfilled quantity.

Note: Oracle recommends that you do not select the Allow Partial Updates preference in Order Broker when integrating Order Broker and Order Management System.

For more information: See the overview in the Order Broker Operations Guide or online help for background on how the Order Broker assigns orders based on whether you use the option to split orders or lines.

Status Updates to Order Broker

When you select the split order setting, all status updates to Order Broker specify the line number to update. The message specifies the new status to apply, plus any other information such as the ship via and tracking number or cancel reason code and description, at the line level.

When you leave the split order setting unselected, all status updates to Order Broker specify information at the request ID level in Order Broker.

See the Order Status Update Cancel Request Message Sample (Brokered Backorder or Store Pickup) and the Order Status Update Sample (Retail Pickup, Delivery, or Ship-for-Pickup, and Fulfilling Orders) for examples and details.

Default Search Within Radius (I40)

Enter the number of miles or kilometers, depending on the Merchandise Locator Distance Measurement, to default at the Merchandise Locator Search Window (Searching for an Item) and Merchandise Locator Search Window (Store Pickup). This field indicates the distance from the customer’s location to search for item availability in stores and warehouses. You can override this default at the search window.

Leave this field blank if you do not want a value to default at the search window or if you do not use the merchandise locator or store pickup options.

Yes/no field: Select this field to have Order Management System submit backordered lines to the Order Broker for fulfillment (brokered backorders), and prevent backordered lines from selling out unnecessarily.

Important: This system control value must be selected if the Use OROB for Fulfillment Assignment (M31) system control value is selected or the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value is set to ALWAYS.

BROKER process: The BROKER process in Working with Integration Layer Processes (IJCT) generates order, status inquiry, and status update request messages to the Order Broker, and receives the response messages.

Leave this field unselected if you are not using the Order Broker to fulfill backordered lines.

See Brokered Backorders for background.

Order Broker Status Update Interval (K10)

Number field: Enter the number of minutes that the BROKER process in Working with Integration Layer Processes (IJCT) should wait between including an order line in a status inquiry list request to Order Broker. Typically, you would set this field to a short interval when you are first implementing the Order Broker integration, then to a longer interval for production purposes. The default interval is 60 minutes.

The BROKER process “wakes up” to begin the process of evaluating each order line periodically based on the Outbound delay time specified through Working with Integration Layer Processes (IJCT). For example, if the Outbound delay time is set to 600 seconds (10 minutes), the BROKER process waits 10 minutes after finishing its evaluation before it starts the evaluation process again and determines whether to include a line on the order in a status inquiry list request. In evaluating each order line, it checks the latest time when the line was included in a status inquiry list, and determines whether the Order Broker Status Update Interval (K10) has elapsed since then.

Example:

• The Outbound delay time for the BROKER process is set to 600 seconds (10 minutes).

• The Order Broker Status Update Interval (K10) is set to 60 minutes.

• The last time the BROKER process received a status update on an order line was 8:02.

• You start the BROKER process at 8:50. It evaluates the order line and determines that it is not yet eligible for a status inquiry, since less than 60 minutes have elapsed since its last inquiry.

• The BROKER process finishes evaluating orders at 8:55 and “wakes up” again at 9:05 based on the Outbound delay time of 10 minutes.

• This time, the order line is eligible for a status inquiry, since it has been more than 60 minutes since the last inquiry, and it is included in the status inquiry list request.

Order lines evaluated independently: The BROKER process evaluates each order line on a brokered backorder or ship-for-pickup order independently to determine when to include each line in an inquiry request. For example, if one line was last updated at 4:17, and another was last updated at 4:56, the process includes the first line in a request at 5:17, and the second at 5:56, based on a 60-minute status update interval.

This field does not control when Order Management System sends:

• Submit order requests, or status update requests when you cancel or sell out an item or order; there is no built-in delay for sending these requests.

• Status inquiry list requests for Order Broker records whose current status is In Transit, Intransit Polled, Received by Store, or Partial Fulfill; it sends these requests once a day based on the OROB_LIMITED_STATUS_BEG_TIME and OROB_LIMITED_STATUS_END_TIME properties in Working with Customer Properties (PROP) and the setting of the Use OROB for Ship for Pickup Fulfillment Assignment (M34) system control value; see Setting the Daily Status Inquiry Time Window (all versions).

• Fulfillment requests; it sends these messages periodically based on the Outbound delay time specified through Working with Integration Layer Processes (IJCT).

• Status update requests: it sends these messages when the BROKER process “wakes up” after the Outbound delay time.

Leave this field blank if you are not using the Order Broker, or if you want to check for status updates every 60 minutes.

See the Order Broker Integration for background.

Order Broker Include Ship Complete Orders (K12)

Yes/no field: Select this field to have orders that are flagged to ship complete be eligible for submission to the Order Broker as brokered backorders if they meet all the other Rules for Submitting Backorders to Order Broker.

You can review an order’s Ship complete setting at the Display Order Properties Screen.

Leave this field unselected if you want to exclude ship-complete orders from submission to the Order Broker.

See Brokered Backorders for background.

Order Broker Due Date Threshold (K11)

Number field: Enter the number of days you want to wait for receipt of a purchase order rather than using the Order Broker integration for:

• Brokered backorders: If there is an open purchase order that could fulfill the backordered item, and the purchase order is due within the number of days specified here or sooner, then the BROKER process does not send the submit order request message for the brokered backorder. See Brokering Items with Soldout Control Codes for a discussion on how this threshold applies to items flagged with soldout control codes.

• Retail pickup or delivery orders: If the Retain Backordered Lines Brokered to OROMS (K89) system control value is unselected, and you receive a retail pickup or delivery order request that includes a backordered item that is not expected within the number of days specified here, then the BROKER process sends a status update request message to the Order Broker rejecting the order.

|

Example: |

The Due Date Threshold system control value is set to 5 and: 1. There is an open purchase order for the backordered item due in 4 days. Result: • Outbound (brokered backorder) order: Order Management System does not submit the order line to the Order Broker. • Inbound (retail pickup or delivery) order: Order Management System accepts the order. 2. There is an open purchase order for the backordered item due in 6 days. Result: • Outbound (brokered backorder) order: Order Management System submits the order line to the Order Broker. • Inbound (retail pickup or delivery) order: Order Management System rejects the order. 3. There are 2 open purchase orders for the backordered item. One is due in 4 days, and the other is due in 10 days. After you run PO Layering, the full quantity of the first purchase order is accounted for on earlier orders. Result: • Outbound (brokered backorder) order: Order Management System submits the order line to the Order Broker, because based on PO layering, you do not expect receipt of an eligible purchase order for 10 days. • Inbound (retail pickup or delivery) order: Order Management System rejects the order. |

Leave this field set to zero if you are not using the Order Broker or if you would always like to send backordered order lines to the Order Broker for fulfillment (outbound orders) or accept retail pickup or delivery orders from the Order Broker (inbound orders), regardless of when you are expecting receipt of any purchase orders that might be able to fulfill them.

Note: Regardless of the setting of this system control value, drop ship items are always eligible to be retained for fulfillment through Order Management System.

See the Order Broker Integration for background.

Order Broker Include Coordinate Grouped Orders (K13)

Yes/no field: Select this field to have order lines assigned a Coordinate group code be eligible for submission to the Order Broker as brokered backorders if they meet all the other Rules for Submitting Backorders to Order Broker.

You can use coordinate group codes to ensure that certain groups of items, such as set components, ship together.

Leave this field unselected if you want to exclude coordinate-grouped order lines from submission to the Order Broker.

Note: The setting of this system control value is ignored if the Use OROB for Fulfillment Assignment (M31) system control value is selected.

See Brokered Backorders for background.

Order Broker Include Gift Orders (K14)

Yes/no field: Select this field to have gift orders be eligible for submission to the Order Broker as brokered backorders if they meet all the other Rules for Submitting Backorders to Order Broker.

You can review an order’s Gift flag at the Display Order Properties Screen. Flagging an order as a gift order prevents item prices from printing on the pick slip, and generates a gift acknowledgment to the customer sold-to. These options might not be supported when fulfilling the order through the Order Broker.

Leave this field blank if you want to exclude gift orders from submission to the Order Broker.

Note: The setting of this system control value is ignored if the Use OROB for Fulfillment Assignment (M31) system control value is selected.

See Brokered Backorders for background.

System name field: Use this field to specify the name of the Order Broker database, as specified in the account setting at the Order Broker Tenant screen. This account name is passed as the destination in Order Broker requests, Merchandise Locator Searching, and in Supplier Direct Fulfillment Processing.

This field is typically set to LOCATE. Although the account setting at the Tenant screen might be lowercase, the account entry here is not case-sensitive; LOCATE is the same as locate.

Note: This setting is at the Tenant screen in version 5.1 or later of Order Broker. Order Broker versions 4.0 through 5.0 use a setting in the locate-config.properties file on the Order Broker server, and prior versions of Order Broker determine the account setting from an entry in the rms_admin database.

Leave this field blank if you do not use the Order Broker Integration or Merchandise Locator Searching.

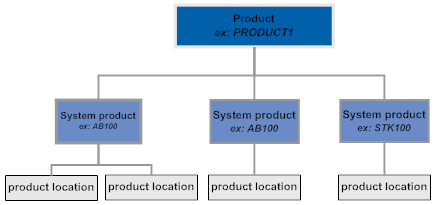

System name field: Use this field to specify the system code identifying your company in Order Broker for Order Broker requests and for Merchandise Locator Searching. The system code must be the same as your Order Management System company number.

This system code is passed as the system_cd in request messages to the Order Broker module, and in the LocateItems request message for Merchandise Locator Searching. For example, if your Order Management System company number is 2, you set this field to 2 (not 002; omit padding zeros unless that is how you created the system code in Order Broker).

Order Broker uses this code not only to identify the requesting system, but also to identify the system product code for the item that is passed in the request message. This identification is important if the system product codes for an item vary in different systems that integrate with Order Broker, such as when you use a different item/SKU code in Order Management System than you use in CWStore.

Example: You call an item AB100 BLUE LRGE in Order Management System, and call the same item 6033 in CWStore. If the OROB System indicated here matches the system code identifying Order Management System in Order Broker, the Order Broker looks for a system product called AB100 BLUE LRGE. Then, if the Order Broker assigns the order to a CWStore location for fulfillment, it sends a notification to the store indicating that item 6033 is required.

Also used for the Supplier Direct Fulfillment integration: The integration with Order Broker’s Supplier Direct Fulfillment module also uses this system control value to determine the requesting_system_cd. See the Drop Ship Integration Values (H20).

Leave this field blank if you do not integrate with Order Broker.

System name field: Use this field to specify the location for:

• Periodic inventory updates and interactive item availability responses to Order Broker: If the Send Inventory by Warehouse to OROB (L06) system control value is unselected, this code is used as the location representing the Order Management System warehouse in Order Broker when creating or update a product location with current inventory information. When other external systems submit a merchandise locator request or order to Order Broker, the response message indicates that the product is stocked in this location.

• Brokered backorder requests to Order Broker: This code is passed as the originating location in the Order Broker request message for brokered backorders if the Use OROB for Fulfillment Assignment (M31) system control value is unselected, regardless of the setting of the Send Inventory by Warehouse to OROB (L06) system control value. If the Use OROB for Fulfillment Assignment (M31) system control value is selected, the system passes the location in the Originating Location to Pass to OROB (M32) system control value to Order Broker.

Order Broker uses this code to track history for the Order Broker request, and to avoid assigning an Order Broker order to the requesting location, even if Order Broker’s most current inventory information indicates that the requesting location has the requested item in stock. This code is passed as the requesting location_cd in the SubmitOrder request message.

• Store pickup requests to Order Broker: This code is passed as the originating location in the Order Broker request message for store pickup orders regardless of the setting of the Send Inventory by Warehouse to OROB (L06) system control value. Order Broker uses this code to track history for the Order Broker request. This code is passed as the requesting location_cd in the SubmitOrder request message.

• Merchandise locator requests to Order Broker: This code is passed as the requesting location_cd in the LocateItems request regardless of the setting of the Send Inventory by Warehouse to OROB (L06) system control value. See Merchandise Locator API for an overview.

• Fulfillment request to Order Broker: If the Send Inventory by Warehouse to OROB (L06) system control value is unselected, this code is passed as the requesting location_cd in the fulfillment request for newly assigned retail pickup or delivery orders assigned to Order Management System for fulfillment. See Order Broker Integration for an overview.

• Status update and inquiry requests to Order Broker: If the Send Inventory by Warehouse to OROB (L06) system control value is unselected, this code is passed as the requesting location_cd in the status inquiry and update requests for retail pickup, delivery, or ship-for-pickup orders. See Order Broker Integration for an overview.

• Ship-for-pickup requests to Order Broker:

• If the Send Inventory by Warehouse to OROB (L06) system control value is unselected, this code is passed as the requesting location_cd in the submit order request for ship-for-pickup orders.

• This code is always passed as the location_cd when submitting a ship-for-pickup order for a drop ship item. See Order Broker Integration for an overview.

Note: If you are generating ship-for-pickup orders for drop ship items, you need to specify a valid Order Broker location in this system control value; otherwise, Order Broker returns an error indicating that the requesting location is invalid.

Using a default requesting location relieves you of the requirement of setting up all of your allocatable warehouses as locations in Order Broker, even if you ordinarily ship merchandise from multiple warehouses.

For example, you might use Order Management System’s warehouse list functionality to reserve and ship orders from five warehouses; however, you can set this field to 1 in order to always specify a location_cd of 1 in a request message, so that you do not need to set up the additional four warehouses as locations in Order Broker.

The location code you enter here must be a valid location code in Order Broker in the system indicated in the OROB System (K50) system control value, and should be uppercase if it is not numeric. If you use Order Broker’s Product, Product Location, and Incremental Inventory Import Process, the process creates a product location record for each item in this location, provided the item is flagged as OROB eligible in Order Management System.

Also used for the Supplier Direct Fulfillment integration: The integration with Order Broker’s Supplier Direct Fulfillment module also uses this system control value to determine the requesting_location_cd for the CreateDSOrder message to send a drop ship purchase order to Order Broker. See the Drop Ship Integration Values (H20).

Leave this field blank if:

• you do not integrate Order Management System with Order Broker, or

• if you do not integrate with Order Broker’s Supplier Direct Fulfillment module, if you have the Send Inventory by Warehouse to OROB (L06) system control value selected, and if you:

• do not use the merchandise locator search, store pickup, or brokered backorder options in Order Management System, and

• have specified a OROB location for each warehouse that maps to a location in Order Broker

See the Order Broker Integration for background.

OROB Default Location Code for Unfulfillable Orders (K56)

System name field: Use this field to identify the Default Unfulfillable Location set up in Order Broker. Your entry here must match the Default Unfulfillable Location you have set up in Order Broker, which is where the Order Broker assigns order lines it cannot fulfill. When Order Management System receives a response from the Order Broker indicating that a brokered backorder is assigned to this location, it indicates that the Order Broker is unable to fulfill the order. In this case, Order Management System returns the order line to standard backorder and fulfillment processing.

Note: Prior to Order Broker 5.3, the Default Unfulfillable Location is labeled the Default Shipping Location at the Preferences screen.

Leave this field blank if you do not send brokered backorders to the Order Broker.

See Brokered Backorders for background.

Send Inventory by Warehouse to OROB (L06)

Yes/no field: Indicates whether:

• Order Broker’s Product, Product Location, and Incremental Inventory Import Process and Item Availability Updates should separate inventory information by warehouse, or aggregate information across warehouses and use the OROB Default Location (K51) as the location representing the distribution center in Order Management System.

• When polling for newly assigned retail pickup or delivery orders, to send a separate fulfillment request message to the Order Broker by warehouse, or to send a single request for the OROB Default Location (K51).

Note: The BROKER process polls for retail pickup or delivery orders only if you specify an order type in the Order Type for Orders Brokered for Delivery (K91) or in the Order Type for Retail Pickup Orders Brokered to OROMS (K92) system control value.

• When sending a status update or inquiry request, whether the requesting location is the OROB location for the warehouse shipping the order, or to specify the OROB Default Location (K51).

If this value is:

Selected = Order Management System sends:

• product location information for each OROB eligible item in each warehouse that has an OROB location specified.

• a separate fulfillment request message for each warehouse that has a OROB location specified. The requesting location code is the OROB location.

• a status update or inquiry request message identifying the warehouse’s OROB location as the requesting location.

Note: If this system control value is selected but the OROB location is not defined for the warehouse, Order Management System does not send inventory information for each item flagged as OROB eligible if it has a record in this warehouse when a system import is initiated in Order Broker, and does not send fulfillment request messages for the warehouse.

Unselected = Order Management System sends:

• product location information for the OROB Default Location (K51), summing up information across all allocatable warehouses.

• a single fulfillment request message, using the OROB Default Location (K51) as the requesting location.

• a status update or inquiry request message identifying the OROB Default Location (K51) as the requesting location.

See Order Broker’s Product, Product Location, and Incremental Inventory Import Process and Retail Pickup (including Ship-for-Pickup) or Delivery Orders for more information and examples.

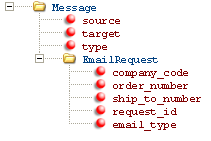

Name in OROB for Point of Sale (L09)

Code field: Use this code to identify the code representing your default point of sale system in Order Broker for ship-for-pickup or store pickup orders.

Important: Your entry here must be a valid system code in Order Broker and the case must match exactly.

Override: You can use the System Code specified for a Store Cross Reference to override the default system name. For example, if you use the Store Connect module for pickup orders in some store locations, but use a point-of-sale system for other locations that support ship-for-pickup orders, you might set this system control value to the code identifying your point-of-sale system, and enter the code for your Store Connect system for the Store Cross Reference records used for Store Connect locations. When submitting a store pickup or ship-for-pickup order to Order Broker, Order Management System uses the System Code, if any, from the Store Cross Reference record; otherwise, it uses the system code from this system control value.

Ship-for-pickup orders: If you specify a code here, the Store option is available at the Create One Time Ship To Address Screen in order entry, so that you can select the store where the customer wants to pick up a ship-for-pickup order. Otherwise, if this field is blank, you cannot create ship-for-pickup orders in order entry.

Store pickup orders: If you do not specify a code here or for the Store Cross Reference record, Order Management System cannot successfully submit a store pickup order to Order Broker.