1 Maintenance Module

The Maintenance module allow you to records all maintenance work required on board of the Ship, a cabin or public locations and scheduling of preventive maintenance. The function within the module includes creating a work order, report printing and viewing of past maintenance work.

Work Orders

The Work Orders can be added singly or by batch using the Criteria Add function. Entries of the work order are not limited to Maintenance module and this function is also available in Management module, Front Desk, Add Work Order.

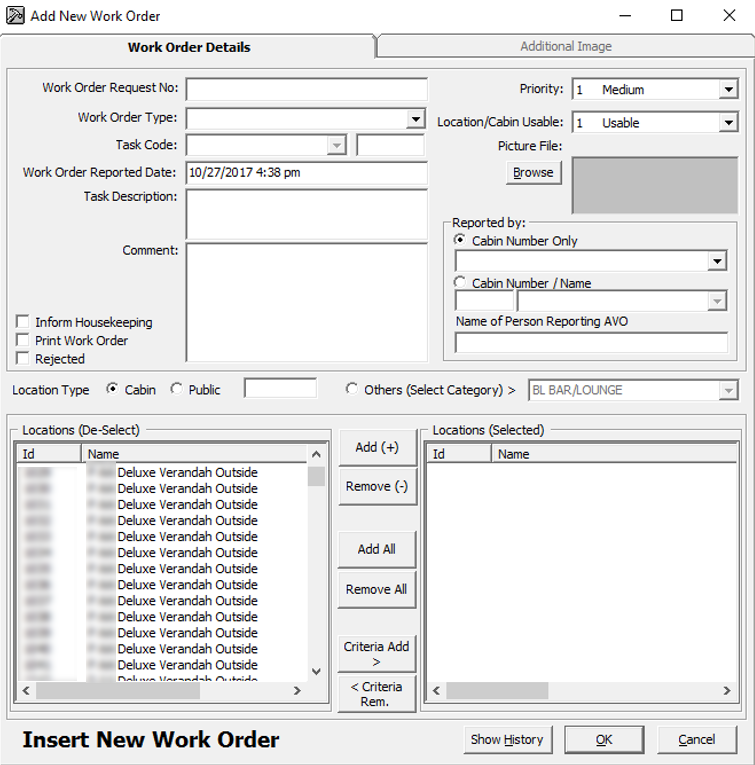

Figure 1-1 Add New Work Order Form

Adding Single Work Order

- From the Work Orders menu, select Add Work Orders.

- In the Add New Work Order form, enter the external document number in Work Order Request No.field, if any.

- Select the Work Order Type and Task Code from the drop-down list.

- Enter the Task Description and Commentin the respective field.

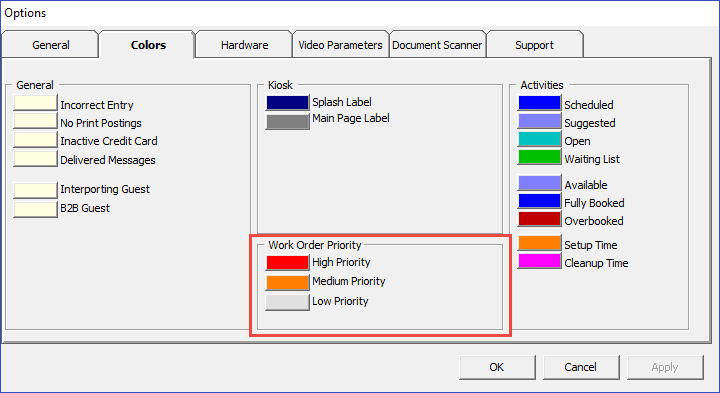

- Select the Priority and Location/Cabin Usable Status from the drop-down list and attach a picture file, if any. You may choose a different Priority and Location Usable Status other than the predefined when adding or editing a work order.

- In the Reported By section, select the Cabin number and enter the Name of Person Reporting AVO.

- In the Location Type, either select Cabin, Public or Others (Select Category)>, then navigate to Location section and select the exact location(s) from the grid.

- Click Add to add the location to Location (Selected) section.

- To deselect the location from the Locations (Selected), select the item to remove and then click Remove(-) or Remove All.

- Click OK to save the work order.

Adding Work Orders by Batch

-

Repeat step 1 to 6 of the above.

-

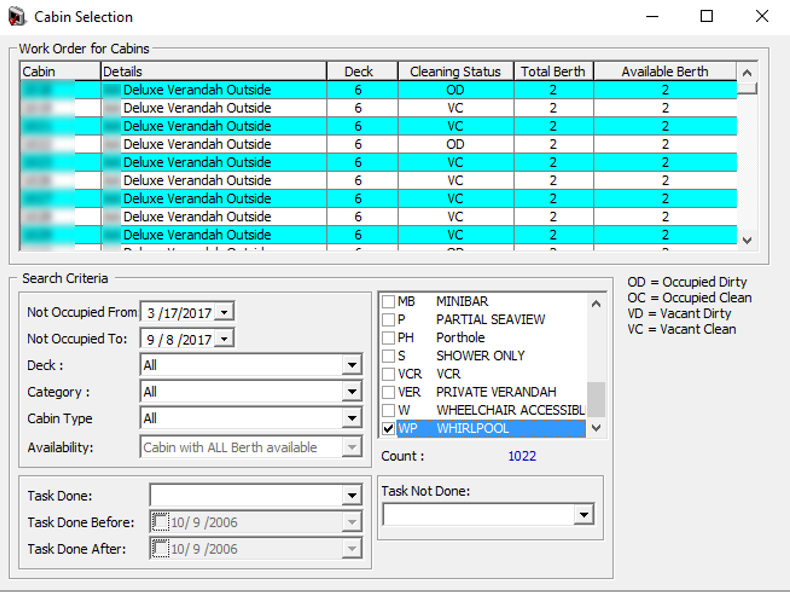

Click Criteria Add>, located between Locations (De-Select) andLocations (Selected) to start the Cabin Selection window.

-

In the Cabin Selection window, navigate to Search Criteria section, select the criteria from the drop-down list, select the required filter, and then click Refresh to update the information in the grid.

Figure 1-2 Cabin Selection Criteria

-

Click OK to add the selection to Locations (Selected).

-

To deselect the location from Locations (Selected), select the item to remove and then click Remove(-) or Remove All.

-

Click OK to complete the work order.

Work Order Overview

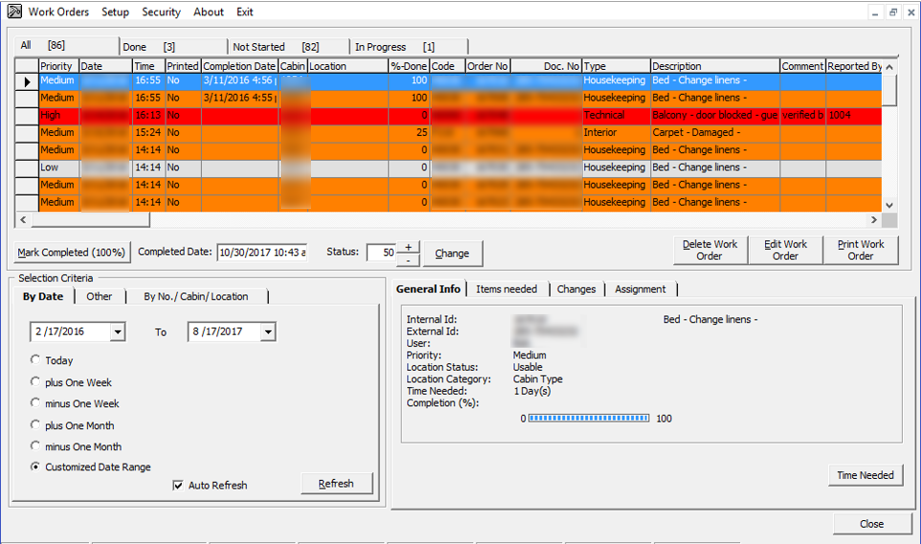

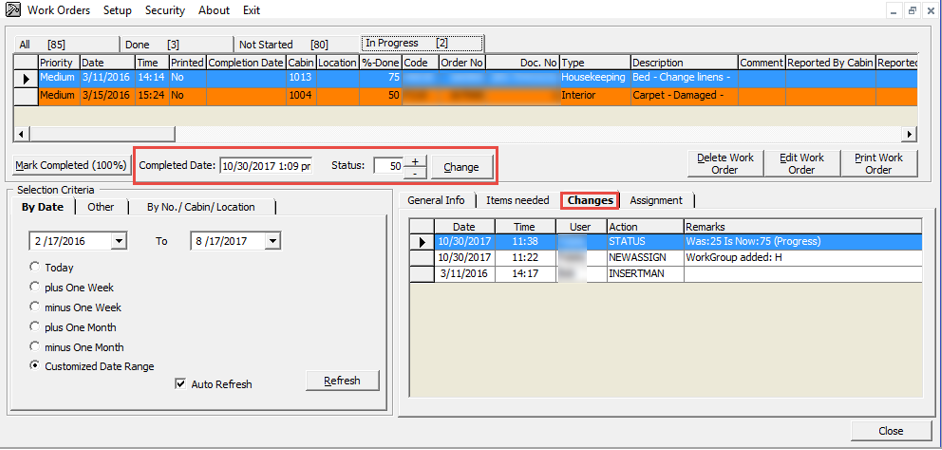

Figure 1-3 Work Order Overview

The Work Order Overview window is comprised of:

-

A grid view of all work orders by status and its corresponding count.

-

Function to Delete, Edit and Print Work Order.

-

A display view by date, others and by No/Cabin/Location.

-

A detailed information of the work order — General info, Items needed, Changes and Work Order Assignment.

Searching for Work Order

-

At the Work Order Overview window, Selection Criteria section, choose the filter from the available tab.

-

Click Refresh to refresh the information on the grid.

-

The information shown on the Overview grid may be sorted by clicking the column header and support columns are Priority, Date, Time, Printed, Completion Date, Cabin Location, %-Done, Code, Order no, Doc. No, Type and Description.

-

Select the Work Order from the grid and click Edit Work Order

. -

In the Update Work Order form, edit the necessary information and click OK to save the changes.

Rejecting a Work Order

-

Select the Work Order from the grid and click Edit Work Order.

-

Select the Rejected check box of the Comment field, then click OK to save. The system places a check mark in the Rejected column on the Overview window.

-

Select the Work Order from the grid and click Delete Work Order.

-

At the confirmation prompt, click Yes to confirm.

-

Enter the reason to delete the work order, and then click OK to proceed.

-

Select the work order from the grid and click Print Work Order.

-

At the Print Job confirmation prompt, click OK to print.

Assigning/Editing/Deleting an Assignment

-

Select the Work Order from the grid and then navigate to Assignment tab window.

-

In the Assignment tab, click Assign Work Order.

-

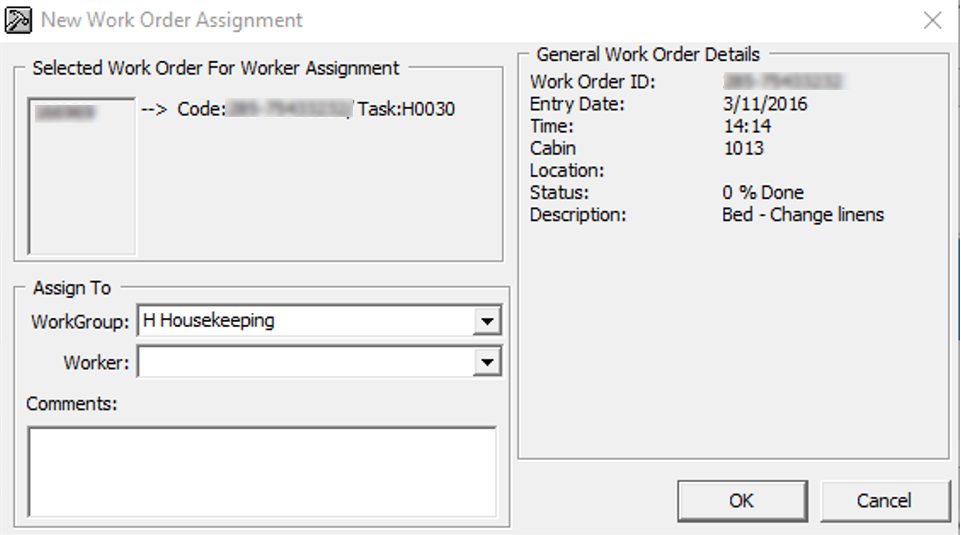

On the New Work Order Assignment form, Assign To section, select the Work Group and/or Worker, from the drop-down list and then click OK to confirm.

Figure 1-4 New Work Order Assignment

-

Status of the assigned work order will now change and appears under In Progress tab. The Date, Time, Assigned By and Worker are also shown in the Assignment tab of the work order.

-

To edit an assignment, select the work order from the Assignment tab, click Edit Assignment, and then click OK to save the changes.

-

To delete an assignment, select the work order from the Assignment tab, and click Delete Assignment.

Adding/Editing/Deleting Items Needed In a Work Order

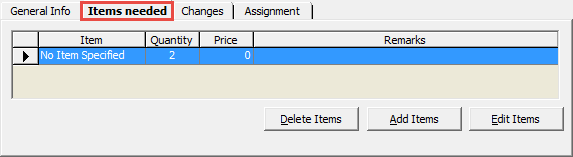

Figure 1-5 Items Needed

-

Select the work order from the Overview tab.

-

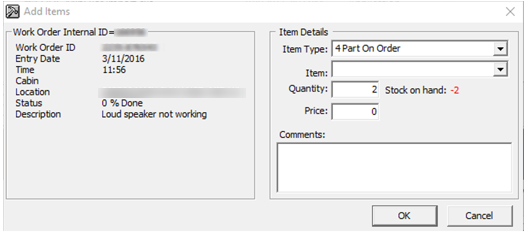

In the Items neededtab, click Add items.

-

Select the Item Type and Item from the drop-down list, enter the required quantity and price, if any.

Figure 1-6 Add Items

-

Click OK to save.

-

To edit the items needed, select the item from the grid, click Edit Items, and then click OK to save the changes.

-

To delete the items needed, select the item from the grid, and click Delete Items.

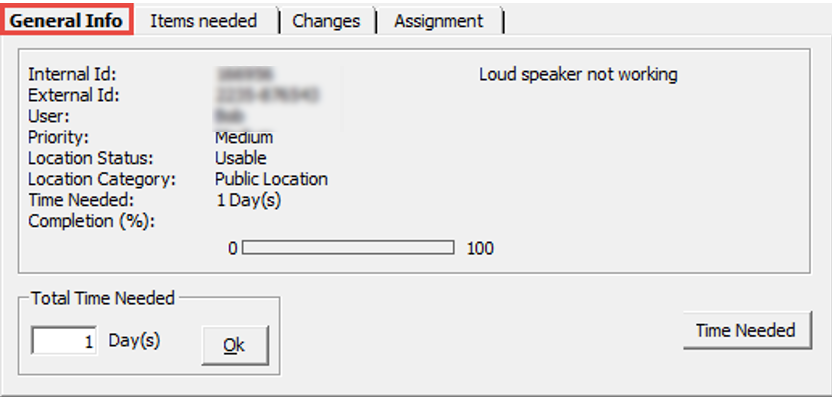

General Information of the Work Order

In the General Info tab of the selected work order, information such as Internal ID, User, Priority Location, Time Needed and Completion % are shown.

Figure 1-7 General Info Tab

The total time needed is adjustable by clicking the Time Needed button, then update the day(s) field and click OK to save.

Updating Work Order Progress Status

Figure 1-8 Updating Progress / Completion Status

- From the Progress tab, select the work order to update.

- In the middle section of the Overview window, enter the completed date, then set the Status using the (+/-) and click Change or click the Mark Completed (100%). A work order that is marked as complete is listed in the Done tab.

- The percentage of completion is logged in Changes tab.

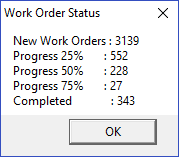

Work Order Status

Figure 1-9 Work Order Status Count

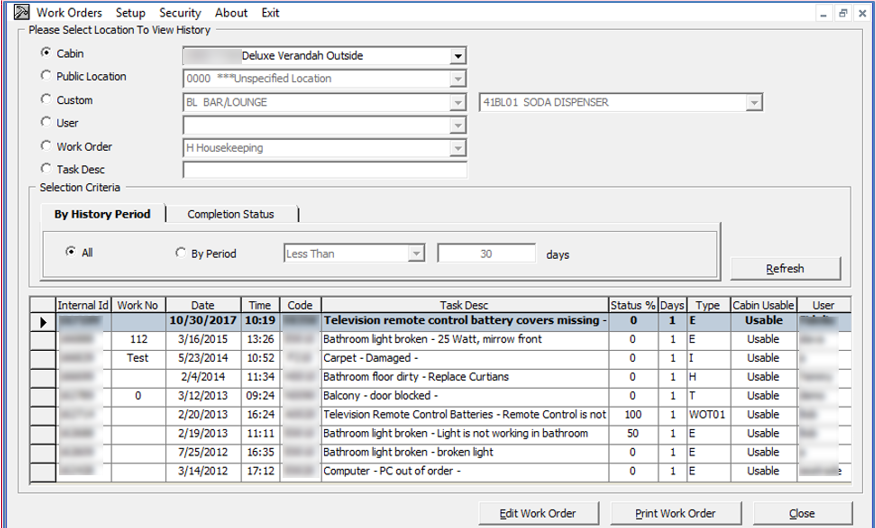

View Location History

Figure 1-10 View Location History Window

- In the View Location History window, select one of the options from the drop-down list.

- Choose from the Selection Criteria section and click Refresh to populate the information on the window.

- Select the work order and click Edit Work Order opens the Update Work Order window. This function does not work if the selected work order is marked as complete.

Reports

- To view the available reports, click Reports.

- To print a report, select the report, and then click Print.

- To view a report, select the report, and then click on Preview tab.

- To export a report, select the report, and then click on Export

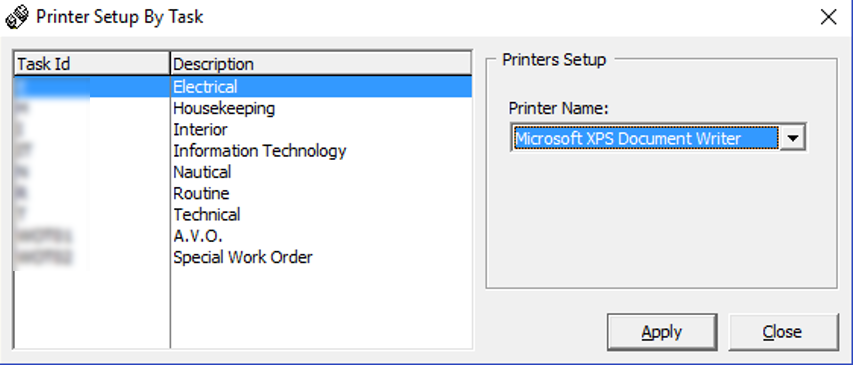

Task Printers

Figure 1-11 Task Printer Assignment

- From the Main window, select Setup and then Task Printer.

- Select the Task ID and then choose the printer name from the drop-down list.

- Click Apply to save.