Setting Definitions for Item Control Values

To define item family routings or item group routings, use the Item Family Routing Assignment component or the Item Group Routing Assignment component.

This topic discusses how to set definitions for Item control values:

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

Brand Names Page |

BRAND_NAMES_INV |

To associate inventory items with brand names that are valid over specific time periods, use the Brand Names (PROD_BRAND_NAME_GBL) component. Brand names that are defined on this page are informational only and are not used by PeopleSoft Inventory. If you select the Item Approval Required option on the Installation Options - Overall/GL (installation options - overall/general ledger) page, items must be approved before you can assign brand names. |

|

CHARGE_CODE_INV |

Define charge codes that define how items should be charged when consumed from a par location. |

|

|

Grades Page |

PRODUCT_GRADE_INV |

To define internal rating levels for items and lots, use the Grades (PRODUCT_GRADE_INV_GBL) component. The information defined on this page is used on the Define Item - General: Classifications page, the Static Item Templates page, and the Lot Control Information page. |

|

Hazard/Disposal Codes Page |

HAZARD_TYPE_INV |

To define hazard codes, use the Hazard/Disposal Codes component (INV_HAZ_TYPES_GBL). Define codes for any special handling instructions. The information that is defined in this page is used on the Static Item Templates page and the Define Item - General: Classifications page. |

|

Item Attributes Group Page |

EN_CHGOVER_GRP |

If you use PeopleSoft Supply Planning, use the Item Attributes Group (EN_CHGOVER_GRP_GBL) component to set up attribute groups. Items that belong to specific attribute groups can be assigned to specific resources (for example, crews, machines, and tools). If you are using PeopleSoft Supply Planning, you must define item attribute groups to assign resource changeover penalties on the Crews - Changeover page, the Machines - Changeover page, or the Tools - Changeover page in the PeopleSoft Manufacturing application. |

|

INV_ITEM_DEFAULTS |

Define item default values to establish item attributes that are automatically assigned to each new item. All inventory items in the SetID can share these attributes. |

|

|

PROD_FAMILY_INV |

Establish item family options. |

|

|

Family Rtg Assignment Page (family routing assignment) |

EN_RTG_FAMILY |

Assign items to item families by using the Item Family Routing (EN_RTG_FAMILY_GBL) component. If you are using PeopleSoft Manufacturing, you can define a routing for each item that you manufacture. To reference another item's routing, use the Define Business Unit Item - Manufacturing: General page. |

|

INV_ITEM_GROUP |

Assign items to item groups to group similar items together. |

|

|

Group Rtg Assignment (group routing assignment) |

EN_RTG_GROUP |

Use the Item Group Routing (EN_RTG_GROUP_GBL) component to assign items to item groups. If you are using PeopleSoft Manufacturing, you can define a routing for each item that you manufacture. |

|

Item Number Control |

ITEM_NBR_CONTROL |

Define item numbering to determine whether new inventory items are sequentially numbered or manually numbered. |

|

Static Item Templates |

INV_ITEM_TEMPLATES |

Establish static item templates to create various sets of item attribute defaults, which are used when defining new items. |

|

Item Types |

INV_ITEM_TYPES |

To group inventory items by function, use the Item Types (INV_ITEM_TYPES_GBL) component. For example, you can group expense, service, or inventory items. The information that is defined on this page is used on the Define Item - General: Classifications page and the Defining Purchasing Item Categories page. |

|

Manufacturers |

MANUFACTURER |

Select a default universal item ID for a manufacturer, and determine whether the manufacturer is locally owned. |

|

MSDS Identifiers (material safety data sheet identifiers) |

MSDS_ID_INV |

To create IDs for items that require a material safety data sheet (MSDS), use the MSDS Identifiers (ITEM_MSDS_ID_GBL) component. PeopleSoft Inventory does not provide standard MSDS documents. Instead, you define an informational code to be used when processing items in the system. The information that is defined here is used on the Define Item - Inventory: Shipping/Handling page. |

|

Packing Codes |

PACKING_CODE_INV |

To create informational codes for items that require special packing routines, use the Packing Codes component (PACKING_CODE_GBL). The information that is defined on this page is used on the Define Item - Inventory: Shipping/Handling page, on the Define Business Unit Item - Inventory: Weight/Volume page, in the Packing Session component (PACK_EST_SHIP_GBL), and on the Static Item Templates page. |

|

Demand Priority Family |

PL_PRIO_FAMILY |

Group items in demand priority families by setting up demand priority groups that you can then associate with an item. |

|

Potency Codes |

POTENCY_CODE_INV |

To create informational codes to specify an item's potency, use the Potency Codes (POTENCY_CODE_INV_GBL) component. The information that is defined on this page is used on the Define Item - General: Classifications page. |

|

Replenishment Classes |

INV_REPLEN_CLASS |

To create groupings for items that are subject to automated periodic replenishment within a business unit, use the Replenishment Classes (REPLENISH_CLASS_GBL) component. The information that is defined on this page is used on the Define Business Unit Item - Inventory: Replenishment page, the Replenishment Parameters page, and the Replenishment Options page. |

|

Stock Types |

INV_STOCK_TYPE |

To create ownership information codes for items that are leased or consigned, use the Stock Types (INV_STOCK_TYPE_GBL) component. A stock type must be assigned during putaway of non-owned items. The information that is defined on this page is used on the Define Item - General: Classifications page, the Static Item Templates page, the Define Item - Inventory: Shipping/Handling page, the Manual Staging page, and the Express Putaway page. |

|

Stocking Periods |

STOCK_PERIOD_INV |

Define stocking periods by setting up time-phased safety stock and excess stock levels for PeopleSoft Supply Planning. You can also populate this page by either uploading data from a third-party forecasting system or using PeopleSoft Inventory Planning and Demand Planning. |

|

Storage Rules |

STOR_INSTRUCT_INV |

To define special storage requirements for items, use the Storage Rules (STOR_INSTRUCTION_GBL) component. The information that is defined on this page is used on the Define Item - Inventory: Shipping/Handling page, the Static Item Templates page, and the Putaway Detail page. |

|

Universal Item ID Types |

UPN_TYPE_CD |

Define universal item ID types at the SetID level, and determine whether the ID represents a GTIN. |

|

Utilization Types |

UTIL_TYPE_INV |

Define utilization types define the ABC classifications to use in the environment. For example, you may decide to classify items as A, B, and C, or High, Medium, and Low. The Utilization Type Calculation process assigns utilization types to individual items by business unit and utilization group. On the Perform Physical Accounting pages, utilization types are selected in alphabetical order. |

|

Util Group Inv (utilization group - inventory) |

UTIL_GROUP_INV |

Define utilization groups for each ABC utilization grouping that you want to maintain in the system. For example, establish utilization groups for cycle counting, planning, material handling, or performance reporting. Each utilization group can use different parameters to assign items to a specific utilization type. For example, the inventory control supervisor may consider an item to be a C item because it is a slow mover, but the purchasing department may consider that same item to be a B item because of its lead time. |

Use the Charge Codes page (CHARGE_CODE_INV) to define charge codes that define how items should be charged when consumed from a par location.

Navigation:

The information that is defined on this page is used on the Define Par Location - Line page, the Consumer Usage page, and Consumer Usage Entry page. You can also capture the charge code during material usage tracking and pass it to a third-party billing system.

Use the Item Default Values page (INV_ITEM_DEFAULTS) to define item default values to establish item attributes that are automatically assigned to each new item.

All inventory items in the SetID can share these attributes.

Navigation:

Note: Modification of the item default values do not change existing item data.

Field or Control |

Description |

|---|---|

Item Tracking |

Select a value to define the type of stocking control that is most commonly used by items in this SetID. |

Lot |

Select when inventory items are either produced or otherwise grouped in distinct and identifiable subsections, often referred to as lots. Lots often represent production runs. Default values for items that are not lot-controlled are defined on the Installation Options - Inventory page. |

Serial |

Select when each inventory item in stock is managed in units of one. Default values for items that are not serial-controlled are defined on the Installation Options - Inventory page. |

Ship Serial |

Select when serial tracking is required only at the time of shipment. Ship-serial items can be moved throughout the inventory business unit without serial control, which simplifies transaction processing and entry. Serial numbers are then assigned at the time of shipment to provide serial tracking on products that are shipped to customers, internal locations, and other inventory business units. |

Non-Owned Item |

Select if the majority of the items are maintained in inventory but not owned by the business unit. |

Create Product |

Select when a product ID is to be created the majority of the time. The product ID will be created when you save the Define Item component. |

Item Type |

Select an item type if the majority of the items will use the same value. |

Costing Group |

Select a cost profile group if the majority of the items will use the same value. |

Category Code |

Select a category code if the majority of the items will use the same value. |

Cost Element |

Select a cost element if the majority of the items will use the same value. |

UPN Type Code |

Select a universal item ID type code to be used for entering a global trade item number within a SetID. This value also determines which universal item identifier represents GTIN data when you are publishing to the UCCNet, and the GTIN to use when you are generating RFID tags. |

Use the Item Families page (PROD_FAMILY_INV) to establish item family options.

Navigation:

In PeopleSoft Inventory, you can categorize items by groups and families. No formal relationship exists between item groups and item families, but you can use an item family to further classify an item group. For example, you can define the hardware group as consisting of families of printers and monitors.

The information that is defined on this page is used on the Define Item - General: Common page when you are setting up cycle counting events on the Event Creation Process page, as an alternate search key for item ID, and as a selection criteria when you are running the Inventory Value report, the Cost Profiles report, the Basic Item Listing report, and the Stock Status report.

When you associate an item with a family on the Family Rtg Assignment page or with a group on the Group Rtg Assignment page, you can also associate it with a reference routing item ID. Floor stock, expensed items, and planning items, however, cannot be specified as a reference routing. When this information is defined, you can set up master routings by item family or by item group on the Define Business Unit Item - Manufacturing: General page.

Use the Item Groups page (INV_ITEM_GROUP) to assign items to item groups to group similar items together.

Navigation:

The information that is defined on this page is used on the Define Item - General: Common page as an alternate search key for item ID when you are defining transaction accounting rules and as a selection criterion when you are running the Inventory Value report, the Cost Profiles report, the Basic Item Listing report, and the Stock Status report. In manufacturing environments, item group information can also be specified on the Group Rtg Assignment page.

Use the Item Number Control page (ITEM_NBR_CONTROL) to define item numbering to determine whether new inventory items are sequentially numbered or manually numbered.

Navigation:

If you enable automatic numbering, you can still manually enter item IDs when adding new items. To do so, enter an item ID number and override the value of NEXT. The NEXT value tells PeopleSoft Inventory to create the item ID with the next unique sequential number.

Note: If you do not select the Auto Number Items check box, you must manually enter an ID when defining new inventory items.

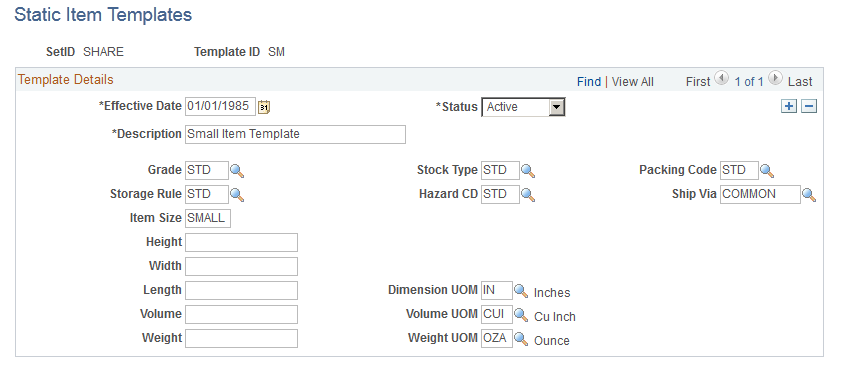

Use the Static Item Templates page (INV_ITEM_TEMPLATES) to establish static item templates to create various sets of item attribute defaults, which are used when defining new items.

Navigation:

This example illustrates the fields and controls on the Static Item Templates page. You can find definitions for the fields and controls later on this page.

Use the static item template to automatically populate a new item with the item attributes defined on the static item template. After entering the required information on the Define Item - General pages, you can select the template ID on the Define Item - General: Classifications page to populate these item attributes in the rest of the component. You can override these default values. Static item template modifications do not change existing item data.

Static item templates provide a few item attributes for new items with limited needs. For a more robust item template, use the configurable item templates. For configurable item templates, see the "Using Configurable Item Templates to Create Items" topic of this product documentation.

Use the Demand Priority Family page (PL_PRIO_FAMILY) to group items in demand priority families by setting up demand priority groups that you can then associate with an item.

Navigation:

After you define the demand priority family, you can use it to group like items for independent demand prioritization purposes. You assign the demand priority family to each item using the Define Item - General: Common page. After you assign a demand priority family to a group of items, you can set demand priorities by family priority grouping using the Demand Prioritization page in PeopleSoft Supply Planning.

Use the Stocking Periods page (STOCK_PERIOD_INV) to define stocking periods by setting up time-phased safety stock and excess stock levels for PeopleSoft Supply Planning.

You can also populate this page by either uploading data from a third-party forecasting system or using PeopleSoft Inventory Planning and Demand Planning.

Navigation:

Note: The information on this page supersedes any stocking level information that you enter when you set up item attributes at the business unit level.

Field or Control |

Description |

|---|---|

Multiple |

Displays the stock-keeping unit of measure for the item. |

Start Date and End Date |

Enter the dates that determine the period for which the corresponding safety stock and excess stock is established within PeopleSoft Supply Planning. |

Safety |

Enter the preferred level to which you want to increase stock when you pass the Safe Limit (safety stock level). For example, if stock falls below 45, then you might want to create enough supply to bring the level up to 100. |

Safe Limit |

Enter the lowest quantity that stock should not surpass. This is the safety stock. |

Excess |

Enter the preferred level to which you want to decrease stock when you pass the Ex. Limit (excess stock limit). For example, if stock goes above 10,000, you can bring it down to 7,500. |

Ex. Limit (excess stock limit) |

Enter the highest quantity that stock should not surpass. |

Stock limits must always be equal to or less than the preferred stocking levels. In addition, safety stock levels must be less than or equal to excess stocking levels.

Note: If you use PeopleSoft Supply Planning, the quantities that you enter on this page should be in multiples of the quantity that is defined in the Order Multiple fields on the Define Business Unit Item - Planning: Order Modifiers page.

If you use PeopleSoft Demand Planning or Inventory Policy Planning, you can populate this page using a two-step process:

Create a flat file by running the Inventory Policy Export process in PeopleSoft Inventory Policy Planning.

Upload the file using the Forecast/Replenishment process in PeopleSoft Demand Planning.

If you use PeopleSoft Inventory, you can upload forecast data from a third-party forecast planning application.

Use the Utilization Types page (UTIL_TYPE_INV) to define utilization types define the ABC classifications to use in the environment.

Create utilization types to define the ABC classifications to be used in the environment. Utilization types can be used to classify inventory items for numerous reasons including cycle counting, planning, material handling, or performance reporting. For example, you may decide to classify items as A, B, and C, or High, Medium, and Low. The Utilization Type Calculation process assigns utilization types to individual items by business unit and utilization group.

Utilization types that are assigned to an item ID can be viewed on the Define Business Unit Item - Inventory: Utilization Types page.

Navigation:

Use the Util Group Inv (utilization group - inventory) page (UTIL_GROUP_INV) to define utilization groups for each ABC utilization grouping that you want to maintain in the system.

For example, establish utilization groups for cycle counting, planning, material handling, or performance reporting. Each utilization group can use different parameters to assign items to a specific utilization type. For example, the inventory control supervisor may consider an item to be a C item because it is a slow mover, but the purchasing department may consider that same item to be a B item because of its lead time.

Navigation:

Field or Control |

Description |

|---|---|

For Cycle Count |

Select to make this the default utilization group for cycle counting. Anytime that you change the default, the system updates the Counting Event Utilization Types table (COUNT_UTIL_INV). Note: If you use the Due to Count cycle-counting method, you must define a default cycle count group; otherwise, you receive an error message on the Counting Event - Utilization Types page. |

For Planning |

Select to make this the default utilization group for inventory planning. You can override this default on the Define Business Unit Item - Inventory: Utilization Types page. |

Build Group Items |

Click to add all items that meet the criteria that is defined in the Utilization Group Details group box to this utilization group. This link adds the appropriate items to the Business Unit Item Utilization Code table (BU_ITEM_UTIL_CD). If you click the link for an existing utilization group, the system replaces all items with items that meet the criteria that is specified here. |