Setting Up PeopleSoft Maintenance Management Work Order Parameters

To set up:

Work order types use the Work Order Type (WM_WO_TYPE) component.

Service groups use the Service Group (WM_SRVC_GRP) component.

Work order priorities use the Work Order Priority (WM_PRIORITY) component.

Maintenance types use the Maintenance Type (WM_MAINT_TYPE) component.

Downtime reasons use the Downtime Reason (WM_DWNTIME_RSN) component

Failure impact codes use the Failure Impact (WM_FAILURE_IMPACT) component.

Failure severity codes use the Failure Severity (WM_FAILURE_SEVRTY) component.

Work order alert uses the Work Order Alert (WM_WO_ALERT) component.

Auto assign labor and procurement resources using the Auto Assignment & Dispatch Setup (WM_AUTOASSIG_SETUP) component.

This section provides an overview of work order types, service groups, priorities, maintenance types, and downtime reasons and discusses how to create work order types, create work order service groups, establish work order priority codes, set up asset maintenance types, define asset downtime reasons, define failure impact codes, set up failure severity codes, and set up work order alert.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

Work Order Type Page |

WM_WO_TYPE |

Defines the basic kinds of work that performed in a work order. |

|

WM_SRVC_GRP |

Identifies specific behaviors in a work order. |

|

|

WM_PRIORITY |

Indicates the urgency for completing a specific work order. |

|

|

WM_MAINT_TYPE |

Defines the category of maintenance needed for a selected asset type and subtype. |

|

|

WM_DWNTIME_RSN |

Describes the reason that an asset is not available for use. |

|

|

WM_FAILURE_SEVRTY |

Describes the seriousness of the asset failure to an organization and is required in order to track failure events. |

|

|

WM_FAILURE_IMPACT |

Identifies how the failure of an asset will affect specific organization circumstances or requirements such as hazardous conditions or materials, health issues, safety issues, and more. |

|

|

WM_WO_ALERT_STS |

Configures work order alert setup, such as the list of statuses of the WO for the alert and the group of people that are interested in the alert notification. |

|

|

WM_AUTOASSIG_SETUP |

Define criteria and setup parameters to automatically assign labor and supplier for a Work Order. |

Work order types and service groups are used to categorize work orders, work order data, and work order behavior. Maintenance types and downtime reasons are attributes describing the selected asset.

Work Order Types

Work order types are user-defined and specify in general terms the kind of work performed within the work order. Work order type is an element in each of the default hierarchies defined in the work order business unit. It is used to identify some of the basic functionality of the work order, which includes:

The distribution accounting template that the work order uses.

The distribution template rules setup.

The associate projects setup.

The grace period for closing a work order and work order task.

The use or non-use of chargebacks in a work order.

The default commitment rule for inventoried materials.

The display of project-related fields in the work order.

The work order workflow approval options.

Service Groups

Service groups are used to group work orders by major categories such as Fleet, IT, and Facilities. A service group is required when you create a work order. While a work order business unit is not specifically associated with a service group, it may be used in conjunction with several service groups. A default service group may be set up in a work order business unit. Service groups help define certain work order behaviors, such as:

Triggering the relevant data that displays in the work order at both the task level and the asset lookup level.

Identifying the defaulting ChartField distribution templates in the work order for each of the resource types: labor, parts, materials, and tools.

Note: You set up ChartField distributions to enable you to perform manual allocations to GL to generate accounting entries.

Applying the ChartField distribution template rules to the work order.

Enabling the Project ID default value in the work order based on the setup of the Associate Projects component.

Priorities

You set up priorities for work orders to identify each work order's level of urgency or importance to a scheduler or technician. Examples of priorities are high, medium, and low.

Note: Service request priorities are system-defined values (Critical, Urgent, Standard, and Low). Users cannot define them.

Maintenance Types

Maintenance types are defined in PeopleSoft Asset Management. They identify the type of maintenance and maintenance procedures that should be followed for a particular asset. For example, you might establish a Tune Up maintenance code that specifies routine maintenance for an automobile. In PeopleSoft Maintenance Management, you must associate one or more maintenance types with an asset type and subtype in order to define a preventive maintenance loop. You can set up a maintenance type as a default value in the work order business unit, which displays in the Maintenance Type field on the Miscellaneous page of the work order. This field must be entered before you can close preventive maintenance work orders.

Downtime Reasons

You can enter the downtime for an asset and select a reason for the asset downtime for each work order task. When a work order is closed, the Work Order Close process updates the total of downtime hours in the asset maintenance history using the data that you entered on the work order. Work order close does not, however, update the start and end downtimes in PeopleSoft Asset Management.

Note: There is a link to enter downtime on the Actual Task Dates tab of the Technician Workbench.

Failure Tracking Setup

You define failure severity and failure impact codes based on the requirements of your organization. When you perform a failure analysis, you can select failure severity and failure impact codes to search for specific failure events to analyze on the Failure Analysis page. PeopleSoft Maintenance Management delivers sample data that contains examples of these two types of failure codes. You can use this sample data to help you define your own failure codes.

You must set up failure severity codes for your organization before you can track failure events in PeopleSoft Maintenance Management. Each code describes the seriousness of the asset failure to your organization. For example, you could define failure severity codes as critical, high, medium, low, or none or with numerical values. You are required to select a failure severity code on the Work Order Failure Tracking page.

Failure impact codes are useful for identifying how the failure of an asset will affect specific organization circumstances or requirements such as hazardous conditions or materials, health issues, safety issues, and more. You can assign more than one failure impact code to a failure event on the Work Order Failure Tracking page. However, you are not required to set up failure impact codes to complete the Work Order Failure Tracking page.

Work Order Alert Setup

Work Order Alert set up is useful to configure work order alert setup, such as the list of statuses of the WO for the alert and the group of people that are interested in the alert notification depending on the work order type, maintenance type, asset type and sub type, wo priority, asset criticality, problem group and code.

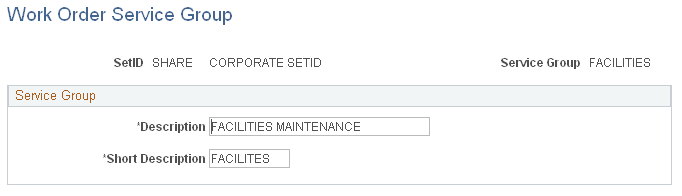

Use the Work Order Service Group page (WM_SRVC_GRP) to identifies specific behaviors in a work order.

Navigation:

This example illustrates the fields and controls on the Work Order Service Group page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Service Group |

Enter and describe each type of service group, such as IT and Facilities, to use for defining specific work order behaviors. |

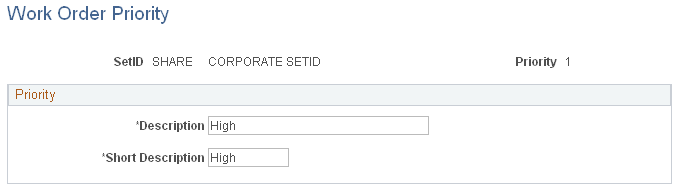

Use the Work Order Priority page (WM_PRIORITY) to indicates the urgency for completing a specific work order.

Navigation:

This example illustrates the fields and controls on the Work Order Priority page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Priority Code |

Enter a level of priority such as High, Medium or Low or whatever values are meaningful to your organization. When you create a work order, you select its level of priority in relation to other work orders. |

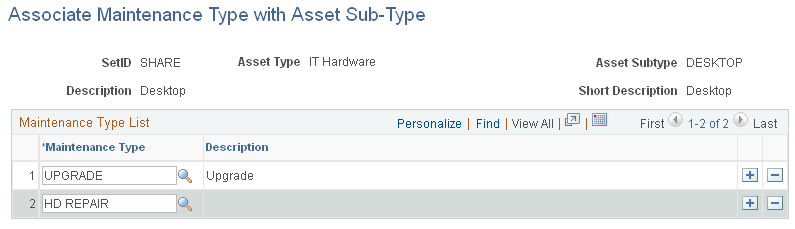

Use the Associate Maintenance Type with Asset Subtype page (WM_MAINT_TYPE) to defines the category of maintenance needed for a selected asset type and subtype.

Navigation:

This example illustrates the fields and controls on the Associated Maintenance Type with Asset Subtype page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

SetID and Asset Type and Asset Subtype and Description and Short Description |

Access the Maintenance Type component, enter the SetID and select the Asset Type and Subtype. |

Maintenance Type |

Add one or more rows of maintenance types to associate with the selected Asset Type and Asset Subtype. |

Use the Downtime Reason page (WM_DWNTIME_RSN) to describes the reason that an asset is not available for use.

Navigation:

Set Up Financials/Supply Chain, Product Related, Maintenance Management, Setup, Downtime Reason

This example illustrates the fields and controls on the Downtime Reason page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Downtime Reason |

Enter the abbreviated reason that an asset is unavailable for use. |

Description |

Provide a longer description of the reason for the asset downtime. |

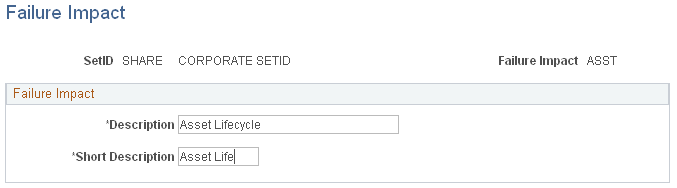

Use the Failure Impact page (WM_FAILURE_IMPACT) to identifies how the failure of an asset will affect specific organization circumstances or requirements such as hazardous conditions or materials, health issues, safety issues, and more.

Navigation:

Set Up Finanicals/Supply Chain, Product Related, Maintenance Management, Setup, Failure Impact, Failure Impact

This example illustrates the fields and controls on the Failure Impact page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

SetID and Failure Impact |

Select a SetID and enter an identifiable code to define a circumstance or requirement that can be impacted by a failure event on the Failure Impact Codes - Add a New Value page such as ASST to represent Asset Life Cycle. |

Description and Short Description |

Enter a long and a short meaningful description of the entered failure impact code such as Asset Life Cycle impact. If you choose to define a failure impact code, these are both required fields. |

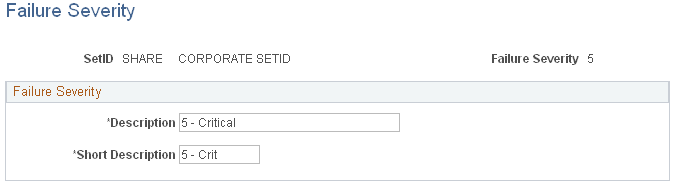

Use the Failure Severity page (WM_FAILURE_SEVRTY) to describes the seriousness of the asset failure to an organization and is required in order to track failure events.

Navigation:

Set Up Finanicals/Supply Chain, Product Related, Maintenance Management, Setup, Failure Severity, Failure Severity

This example illustrates the fields and controls on the Failure Severity page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

SetID and Failure Severity |

Select a SetID and enter a code up to five characters that best represents a level of the severity on an asset failure to your organization on the Add a New Value page. For example 1, 2, 3. |

Description and Short Description |

Enter a meaningful long and short description of this failure severity code such as Critical, High, Medium or a definition of a numerical failure severity code, if you used numbers to define these codes. These are both required fields. |

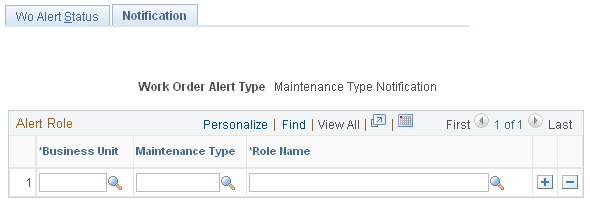

Use the Work Order Alert page (WM_WO_ALERT_STS) to configure work order alert setup, such as the list of statuses of the WO for the alert and the group of people that are interested in the alert notification.

Navigation:

This example illustrates the fields and controls on the Work Order Alert page: WO Alert Status tab. You can find definitions for the fields and controls later on this page.

This example illustrates the fields and controls on the Work Order Alert page: Alert Notification tab. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

WO Alert Type |

Select the work order alert type from the following options:

|

Field or Control |

Description |

|---|---|

SetID |

Select the desired ID to set the work order alert status. |

Field or Control |

Description |

|---|---|

Work Order Status |

Select the desired work order status. If WO Status is present, it means the WO Alert type = Maintenance Type. For the other alert types you see the WO task status. |

Field or Control |

Description |

|---|---|

Role Name |

View list of users that are interested in receiving the e-mail notification. |

Field or Control |

Description |

|---|---|

Maintenance Type |

Select the desired type of maintenance. This selection is only available when alert type is Maintenance type. |

Field or Control |

Description |

|---|---|

Business unit |

Select the desired business unit for the required work order alert's notification. This is the business unit in the work order which the user is an interested party. |

Field or Control |

Description |

|---|---|

WO Type |

Select the desired work order type. This field is only available when alert type is WO type. |

Field or Control |

Description |

|---|---|

Asset Type |

Select the desired asset type. This field is only available when alert type is WO type. |

Field or Control |

Description |

|---|---|

Asset SubType |

Select the desired asset sub type. This field is only available when alert type is WO type. |

Field or Control |

Description |

|---|---|

Asset Criticality |

Select the desired asset criticality. This field is only available when alert type is Priority. |

Field or Control |

Description |

|---|---|

Priority |

Select the desired priority of work orders. This field is only available when alert type is Priority. |

Field or Control |

Description |

|---|---|

Problem Group and Code |

Select the desired problem group and code. These fields are only available when alert type is Problem. |

Note: The warranty alert query is run automatically, by the time you save the work order, to notify the proper users (defined in the setup) if the asset is under warranty.

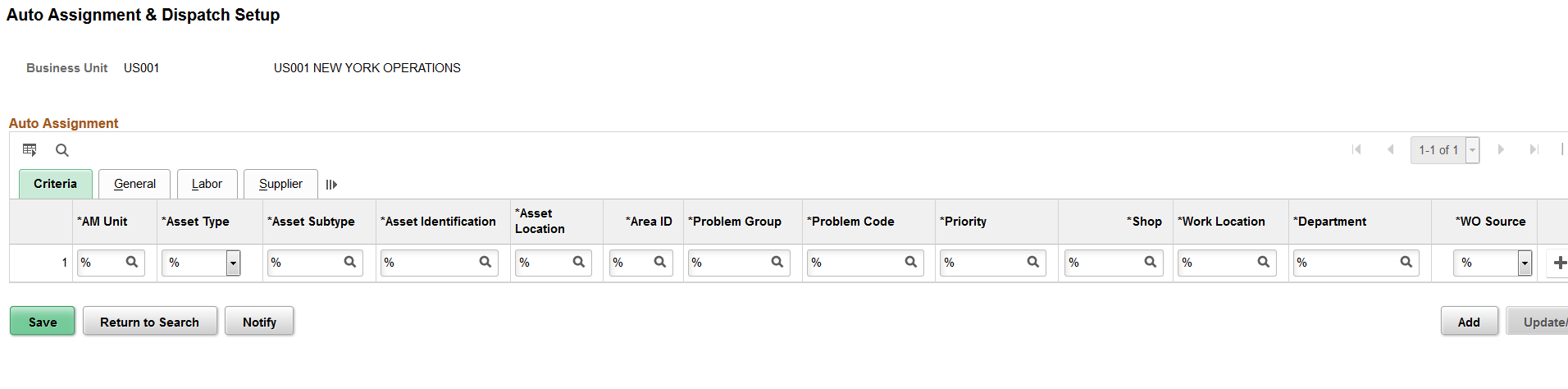

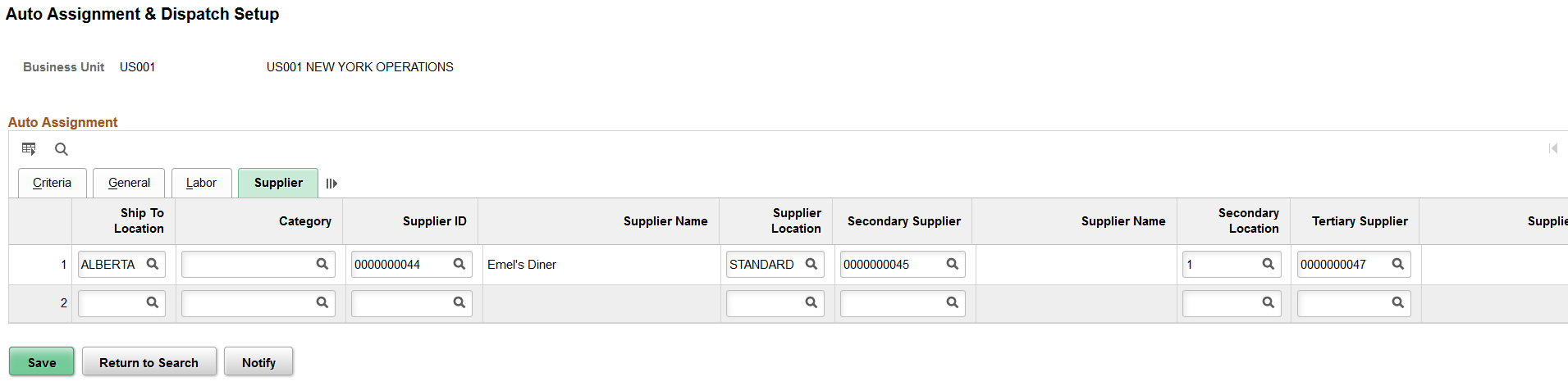

Use the Auto Assignment & Dispatch Setup page (WM_AUTOASSIG_SETUP) to define criteria and setup parameters to automatically assign labor and supplier for a new Work Order.

During auto assignment if any error occurs then it will be displayed on the PM Exception page. User can click the Go to Work Order Workbench link to access the Work Order Workbench and manually assign the Work Order.

Navigation:

This example illustrates the fields and controls on the Auto Assignment & Dispatch Setup - Criteria page. You can find definitions for the fields and controls later on this page.

Auto Assignment — Criteria

Define values for the given parameters such as AM Unit, Asset Type, Area ID, Priority, and Shop to find employee/supplier matching the criteria to auto assign employee/supplier for the Work Order created. You can use % instead of specific value for the given criteria.

The WO Source field lists the different source options such as Preventive Maintenance, Work Order component, and Service Request that you can use for creating a work order. If you want to create an auto assignment criteria for a particular work order, you need to select the specific work order source.

Based on the criteria setup information system will get the best matched resources for the Work Order created.

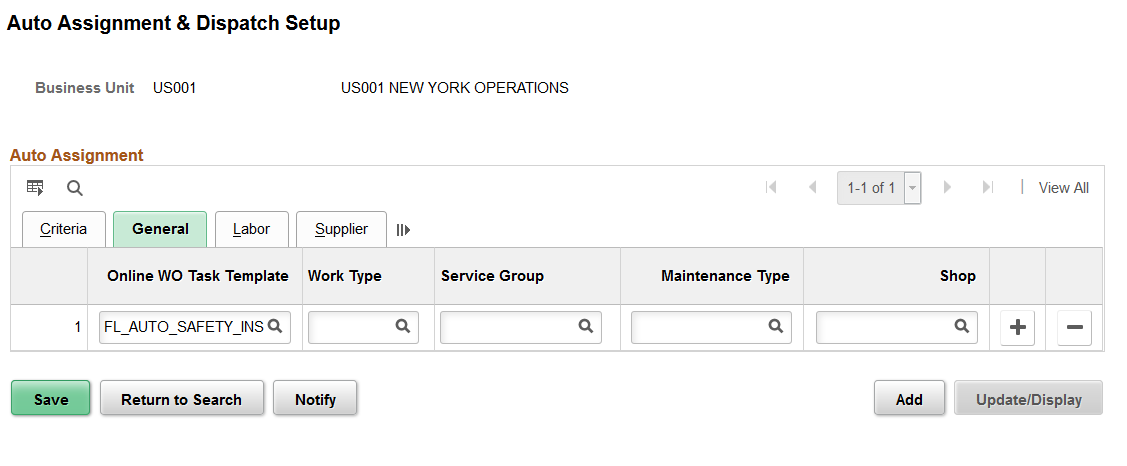

Auto Assignment — General

This example illustrates the fields and controls on the Auto Assignment & Dispatch Setup - General page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Online WO Task Template |

Select the default Work Order task template that will be used to automatically populate the task requirements based on the criteria defined. This field is applicable only for Work Order created online. |

Work Type |

Select appropriate Work Type. This field is applicable only for those Work Orders that are created through a component interface. |

Service Group |

Select appropriate Service Group. This field is applicable only for those Work Orders that are created through a component interface. |

Maintenance Type |

Select appropriate Maintenance Type. This field is applicable only for those Work Orders that are created through a component interface. |

Shop |

Select appropriate value for Shop. This field is applicable only for those Work Orders that are created through a component interface. |

Auto Assignment — Labor

This example illustrates the fields and controls on the Auto Assignment & Dispatch Setup - Labor page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Empl ID |

Select employee ID for the system to automatically assign Work Order based on the criteria defined. |

Secondary Employee |

Select required employee to assign the Work Order. You can select secondary employee if the selected primary Employee ID is not valid. |

Tertiary Employee |

Select required employee to assign the Work Order. You can select tertiary employee if the selected primary Employee ID is not valid. |

Shop Primary Scheduler |

Select the Shop Primary Scheduler check box to automatically assign the work order to the primary shop scheduler defined on the Define Shop - Resources page. When you create a new work order, the Work Order- Schedules page automatically displays the shop scheduler’s details, who is the primary scheduler. If you select this check box, all other fields become disabled. |

Crew Leader |

Select the Crew Leader check box to automatically assign the work order to the crew leader defined for the shop on the Define Crew page. When you create a new work order, the Work Order- Schedules page automatically displays the crew leader’s details. If you select this check box, all other fields become disabled. |

Auto Assignment — Supplier

This example illustrates the fields and controls on the Auto Assignment & Dispatch Setup - Supplier page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Supplier ID |

Select Supplier ID for the system to automatically assign and dispatch Work Orders based on the criteria defined. |

Secondary Supplier |

Select required supplier to assign and dispatch the Work Order. You can select secondary supplier if the selected primary Supplier ID is not valid. |

Tertiary Supplier |

Select required supplier to assign and dispatch the Work Order. You can select tertiary supplier if the selected primary Supplier ID is not valid. |

Ship To Location |

Select the Ship To Location to automatically dispatch the Work Order. |

Supplier Location |

Select the Supplier Location to automatically dispatch the Work Order. |

Category |

Select required Category. This value will be considered only if item ID is not specified for the Work Order. |