Performing a Cost Rollup

You can calculate the cost of makeable items by running the Cost Rollup process.

To calculate product costs:

Verify the cost foundation has been defined for the items. See the topics, "Structuring Your Cost Management System" and "Defining the Cost Foundation for Makeable Items."

See Understanding Cost Structure.

See Understanding the Manufacturing Standard Cost Foundation.

Check the item default values, including the source code, standard cost group (optional), and cost element in the Define Business Unit Item component.

Confirm that the items have a BOM.

If you are rolling up the costs to a configured item, verify that you have a component list on the production ID.

(Optional) Confirm that the items have an item routing.

If you are rolling up the costs to a configured item, verify that you have an operation list on the production ID.

Use the Cost Rollup page to run a cost rollup and calculate the new standard cost for the items.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

Define Business Unit Item - Manufacturing |

MFG_ATTRIB |

Select the source code for each item. The source code determines whether or not an item is included in the Cost Rollup process. |

|

Define Business Unit Item - General |

GEN_ATTRIB_INV |

Enter the cost element for each item. The Cost Rollup process and Update Production process use cost elements to categorize the components of an item's cost. For purchased items that are components of a manufactured item, enter the current purchase cost. This insures that a default price is available for cost rollup. |

|

Manufacturing BOMs - Summary |

EN_BOM_MAINT |

Verify that a BOM exists for the makeable items. |

|

Define Routings - Summary |

EN_RTG_SUMMARY |

Verify that a routing exists for the makeable items. |

|

CE_ROLLUP_REQ |

Run this process to calculate the standard cost for makeable items. Based on the cost type and version, you can rollup any combination of BOM and routing for production, configured, engineering, simulations. The process calculates the cost of co-products and by-products. |

These default values influence the Cost Rollup process.

Source Codes

The item's source code determines how the item is used for the Cost Rollup and Update Production processes. Define each item's source code on the Define Business Unit Item - Manufacturing page. The options are:

Field or Control |

Description |

|---|---|

Buy |

This is a purchased item. No lower-level costs are calculated; therefore, any BOM or routings attached to this item are not used in cost calculations. |

Expense |

This item is expensed when received in an inventory business unit. The cost of this item is never included in the Cost Rollup and Update Production processes. You can specify the item on a BOM to call out the material requirement, but the cost is not included in the standard cost rollup. |

Floor Stock |

This item is expensed when issued to production. The cost of this item is never included in the Cost Rollup and Update Production processes. You can specify the item on a BOM to call out the material requirement, but the cost is not included in the standard cost rollup. |

Make |

This is a manufactured (makeable) item. The Cost Rollup and Update Production processes calculate and post new frozen standard costs for this item. Makeable items are assemblies or subassemblies that are manufactured in house, purchased from a subcontractor, or by a combination of both. |

Planning |

This is an item used only in PeopleSoft Supply Planning. The item is never included in the Cost Rollup and Update Production processes. |

Routing

On the Define Business Unit Item - Manufacturing page, specify which production routing the item uses when the system determines the assembly item's this level labor, material, and overhead costs.

Average Order Quantity

The item's average order quantity indicates the typical batch or lot size that you use to produce this item. Define each item's average order quantity on the Define Business Unit Item - Manufacturing page. This is the quantity that you expect to produce in one production ID or production schedule based on the BOM.

If a BOM quantity on a bill is greater than 1, the component's per order quantity is spread over the BOM quantity. For example, Assembly A has a BOM quantity of 100; Component B used on A has a per order quantity (QPA, or quantity per assembly) of 1500. Therefore, the use of B for a single A is 15 (1500/100). When entering the QPA, the BOM maintenance supports a precision of 4 places to the right of the decimal. You have the option to define the calculated QPA precision that the system maintains when it determines the item's cost. On the Installation Options - Manufacturing page, you select a precision anywhere from 4 to 10 places to the right of the decimal. If the BOM and associated process results in multiple outputs (primary, co-products, and by-products), the BOM quantity must be set to the item's average order quantity.

If you use economic order quantities or average order quantities with setup, fixed run, and postproduction times, the system must prorate the cost of these processes over the order quantity to determine a per unit cost. The system determines per unit setup, fixed run, and postproduction cost by dividing the cost of each process by the average order quantity. Typically, the system calculates this at the operation level, then sums it to provide the total cost.

Standard Cost Groups

(Optional) You can use cost groups to select a set of items to process for the Cost Rollup process and the Update Production process (Cost Update/Revalue process page). Enter the group in the Standard Cost Group field on the Define Business Unit Item - General page.

Cost Elements

The Cost Rollup process and Update Production process (Cost Update/Revalue process page) use cost elements to categorize the components of an item's cost. Cost elements are also used when costing a transaction. Enter the cost element for the item's material costs on the Define Business Unit Item - General page. For both purchased and makeable items, enter a cost element in the material cost category.

Used in Manufacturing Check Box

You must identify any items that are used in PeopleSoft Manufacturing. Select the Used in Manufacturing check box on the Item Business Unit Definition - General: Costing page for any item that:

Has a BOM or routing.

Is a component on a BOM or component list.

Is associated with a production area.

Is used on a production ID or production schedule.

The manufacturing bill, engineering bill, or component list determines the structure of the item and therefore the associated lower-level costs.

PeopleSoft Cost Management uses BOM yield or component yield loss to account for the loss of components during the manufacturing process. For costing purposes, the cost of the assembly item can, therefore, take into account the expected loss of components in production. In this instance, the system inflates the cost of the component by the component's yield.

Cost rollups do not include the cost of floor stock, expensed, subcontract supplied, or non-owned items. Consigned items are included in the item's cost as they are considered owned upon consumption.

If you roll up an assembly item that has no owned components, only non-owned and parts supplied by a subcontractor (Subsupply flag is set to Yes), the cost rollup does not calculate any lower-level material costs but still rolls up labor costs for that item.

The production routing, engineering routing, or operation list documents the operations that are necessary to assemble the item. In the Cost Rollup process, the system considers only the routings or operation lists of those items whose source code you have defined as Make.

When calculating conversion costs for an operation, you must consider the crew size of the operation. For example, if the crew assigned to a work center consists of three people, multiply the labor run cost by three.

As it does with crew size, the system multiplies the machine cost of an operation by the number of machines assigned to the work center in which the operation takes place.

When the conversion rate associated with the code assigned to the operation is expressed in terms of a cost per unit, as opposed to a labor or machine rate per hour, you must specify the corresponding costing time type on the routing or operation list in order for the system to include the cost. For example, suppose that you specified a labor run cost of 1.00 per unit in the conversion code associated with the operation. There must be a costing labor run time in the routing or operation list in order for the system to include that 1.00 in the item's cost.

When you specify an operation's costing times and run rates in terms of days, the system factors the rate by the work center's average daily capacity to determine the total number of hours it requires to complete the operation.

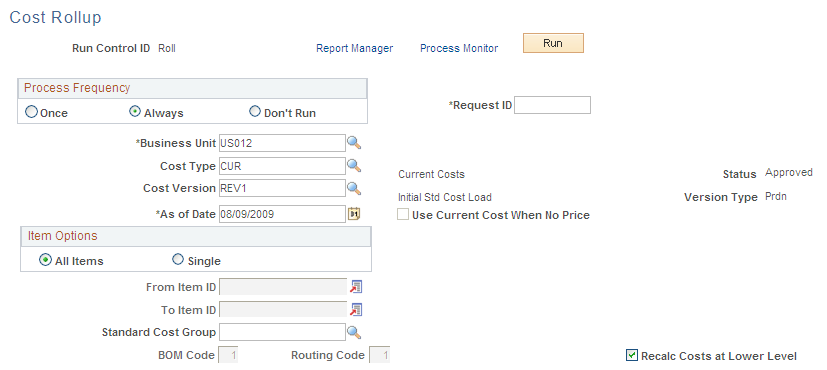

Use the Cost Rollup page (CE_ROLLUP_REQ) to run this process to calculate the standard cost for makeable items.

Based on the cost type and version, you can rollup any combination of BOM and routing for production, configured, engineering, simulations. The process calculates the cost of co-products and by-products.

Navigation:

This example illustrates the fields and controls on the Cost Rollup page. You can find definitions for the fields and controls later on this page.

Use the Cost Rollup page to perform a cost rollup for a single item, a range of items, a group of items, or all items for any BOM and routing combination within a business unit, as well as for any cost type and cost version.

When rolling up one or all items, consider these points:

When rolling up all items, the system determines the costs of all outputs and all lower level buy items.

If rolling up a single item and the single item specified is a primary item on the BOM code selected, it is costed and updated along with any co-products whose associated primary BOM item is the primary product selected.

You can select a co-product as the single item to roll up.

In this instance, the system determines the BOM on which the co-product is made by looking at the co-product's associated primary BOM. Using this BOM, the co-product's cost is calculated. However, the Primary Product's cost is not calculated nor updated.

The details for yield by operation transactions are captured by calculating yield loss costs at the operation-sequence level, maintaining extended precision cost fields, and storing detailed cost rollup calculations

Field or Control |

Description |

|---|---|

Cost Type and Cost Version |

Select the combination that you want to calculate. The cost type and version determine the set of labor, machine, and overhead rates or costs, plus the purchase costs and additional costs PeopleSoft Cost Management uses in the cost calculation. |

Version Type |

On the Cost Versions page, you select a version type. The version type that you select has a direct impact on the Cost Rollup page. If the version type is Prdn (production), the system changes to the primary BOM and Routing Codes for all levels and the BOM Code and Routing Code fields appear. If the version type is Eng (engineering) or Sim (simulation), then select any combination of BOM and routing codes and the system rolls up the cost for reporting and comparison only. |

As of Date |

Determines which of the assembly's components to include on the item's bill when the system calculates the item's material and lower-level costs. The rollup includes any component that is effective on the bill as of the date specified. The as of date also refers, in a multiple output scenario, to by-product effectivity dates. Configured items do not use the as of date but use the components that are on the component list. |

Use Current Cost When No Price |

Select to ensure that all purchased items have a cost. If the method of calculating the cost of purchased items results in zero or a nonexistent price, then zero is replaced with the current purchase price. |

Recalc Costs at Lower Level (recalculate costs at lower level) |

Select to recalculate all lower-level costs of any subassemblies. This recalculated cost is rolled up into the standard cost of the manufactured item. If you do not select this check box, then the Cost Rollup process uses the current cost for the lower level items based on the cost type and cost version combination. If a lower level subassembly is included in the list of items to be rolled up, then the lower level subassembly's new value is used even though this check box has not been selected. |

Recalc Config Items & Levels (recalculate configured items and levels) |

If PeopleSoft Product Configurator is installed, select to rollup costs for configured items that use configured costing. If multiple production IDs, and therefore, multiple component and operation lists exist for the same item ID and configuration code combination, then the system uses the latest production ID to determine the cost. |

These errors can occur during the Cost Rollup process. Use the Cost Rollup Audit page to check for these errors:

An invalid BOM code or routing code exists.

A co-product is to be rolled up, but a BOM or routing code does not exist for the primary product.

For example, suppose that you try to roll up a co-product with BOM code 2 and routing code 2. However, if its associated primary item does not have a BOM and routing code combination of 2, 2, then an error occurs and the rollup does not take place.

The cost element for a recycle by-product does not exist on the Define Business Unit Item component.

No BOM exists for a Make item.

A cost type's Purchase Cost Used is Forecasted or Last Price, and you did not enter a forecast price or last price paid for a buy item.

An error occurs and the rollup does not take place.