Setting Up Reservation and Backorder Rules

Reservation and backorder rules are used by the Reserve Materials process and online reservations to determine when the demand line of an order is ready to be moved downstream to the releasable state. Backorder rules are also used at shipping time to determine what to do with shortages that cannot be fulfilled. The reservation and backorder rules are:

Field or Control |

Description |

|---|---|

Line-Level Reservation Rule |

Defines the specific criteria that must be satisfied by this individual demand line before the demand line is moved to the releasable state. For example, a line reservation rule might be that the reserved quantity must equal or exceed 90 percent of the requested quantity on the line before it is set to the releasable state. |

Line Reservation-Backorder |

Defines the specific criteria that must be satisfied by a previously backordered demand line before the demand line is moved to the releasable state. For example, a line backorder rule might be that the reserved quantity for an already backordered line must equal or exceed 100 percent of the requested quantity before it is set to the releasable state. If no line backorder rule exists then the system used the line reservation rule for previously backordered lines. |

Order-Level Reservation Rule |

Defines the specific criteria that must be satisfied by the entire order or grouping that this individual demand line is in, before the demand line is moved to the releasable state. For example, an order reservation rule might be that all the lines in an order must reserve 100 percent of their reserved quantity before the order can move downstream. |

Backorder Rule |

There are two parts to this rule:

|

During reservations, the rules are evaluated in the following order:

Line-level reservation rules.

Line Reservation-Backorder rules.

Order-level reservation rules.

Once a demand line has passed the set releasable criteria for the line-level reservation rule, the line must also pass the set releasable criteria for the order-level reservation rule.

Backorder rules at release.

Once a demand line has passed the set releasable criteria of both the line-level reservation rule and the order-level reservation rule, the backorder rule at release determines how any unreserved quantities (shortages) are handled.

Note: If there are no reservation and backorder rules established for the demand line, then the system uses the Partial Qtys Can Ship, Cancel Backorder, and Partial Orders Can Ship check boxes to determine releases and backorders.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

IN_FL_RULE_SETUP4 |

Add, change, or review line-level reservation rules and line reservation-backorder rules. |

|

|

IN_FL_RULE_SETUP5 |

Add, change, or review order-level reservation rules. |

|

|

IN_FL_RULE_SETUPBR |

Add, change, or review the backorder rule at release. |

|

|

IN_FL_RULE_SETUPBS |

Add, change, or review the backorder rule at shipping. Once a shortage (Release as Shortage option on the Backorder Rule-Release page) has been sent downstream to shipping if there is still no quantities to ship, then this rule determines what happens to the demand line. |

Field or Control |

Description |

|---|---|

Rule Code |

Displays the user-defined code that uniquely identifies this rule. |

Rule Type |

Select the type of rule to add, change, or view. Options are:

|

Description |

Displays the user-defined description of this rule. This field is 32 characters long. |

Use the Reservation/Backorder Rules-Reserve Line page (IN_FL_RULE_SETUP4) to add, change, or review line-level reservation rules and line reservation-backorder rules.

These rules define the specific criteria that must be satisfied by an individual demand line before the demand line is moved to the releasable state.

Navigation:

. Select a Rule Type of Line Reservation Rule.

This example illustrates the fields and controls on the Reservation/Backorder Rules-Reserve Line page. You can find definitions for the fields and controls later on this page.

Defines the specific criteria that must be satisfied by an individual demand line before the demand line is moved to the releasable state. For example, a line reservation rule might be that the reserved quantity must equal or exceed 90 percent of the requested quantity on the line before it is set to the releasable state.

This page defines reservation rules to be applied as line-level reservation rules and line reservation-backorder rules. Whether the rule defined here is applied to a backordered demand line or not, depends on where you add this rule code. The rule code defined here can be applied to the Line Reservation Rule field or the Line Reservation-Backorder field on the Setup Fulfillment-Reservation page or the Create/Update Stock Request-Reservation /Backorder Rules page.

Reservation Actions

Select the action to be performed when the criteria are met by the demand line. Within the Reservation Rules and Actions group box, you can select the Add button just below the title bar and add additional action combinations for this Rule Code. Each combination is evaluated independently.

Field or Control |

Description |

|---|---|

Set releasable when |

Select to change the state of the demand line from Unfulfilled to Releasable when the criteria specified in the rule are met. This action releases the demand line for fulfillment processing. If you use line-level (or order level) reservation rules, it is required that one rule use the Set Releasable action. |

Do not make reservation when |

Select to not reserve inventory stock for this demand line when the criteria specified in the rule are met. The system default is to reserve stock for the demand line even if you cannot yet release the line based on the Set Releasable action. The Do Not Make Reservation action prevents reserving inventory stock when conditions are not yet optimal. For example, you could define a rule to not make reservations if today's date is earlier than the Early Ship Date and the percentage of reservable quantity is less than 90 percent. This prevents stock from being tied up if the condition is not met. |

Notify when |

Select to send a notification to a specific user or role when the criteria specified in the rule is met. Use the Errors and Warnings Framework to define which user or user role to notify and how the notification should be delivered (Workflow, email, or Message Dashboard). For example you might wish to notify the warehouse manager if a demand line has reached the late ship date without being fully reserved. |

Message Text |

If you have selected the action of Notify, enter a specific message to be included in the notification. |

Note: The actions of Set releasable when and Do not make reservation when are mutually exclusive since the system always holds the reservation when the releasable action is taken. The Notify action can be used in combination with the other actions. For example, if you release the demand line, then you might want to notify a customer service representative or other individual.

Rule Sets

Within the Rule Sets group box, you can define one or more List of Criteria group boxes for each rule action by selecting the Add button just below the Rule Set title bar. Each List of Criteria group box is evaluated as an OR condition. For example, if you add two List of Criteria group boxes, the action is taken if criteria 1 or criteria 2 are met. Within an individual List of Criteria group box the separate rows are evaluated as AND conditions; both rows must be met to initiate the action.

Field or Control |

Description |

|---|---|

Field to Compare |

Select the type of comparison to be made. For line-level reservation rules, the options are:

|

Comparison Operator |

Select how the value in the Field to Compare field should be compared to the demand line. If Date is in the Field to Compare field, then your choices are Earlier Than, Earlier or Equal To, Equals, Later Than, or Later or Equal To. If Quantity Reserved is in the Field to Compare field, then your choices are Equal To, Greater or Equal, Greater Than, Less Than, or Less Than or Equal. |

Operand |

Enter a numeric value (days, percentage, or number of units) for the comparison. |

Compare String |

Select the compare value. If Date is in the Field to Compare field, then your choices are Days After or Days Before. If Quantity Reserved is in the Field to Compare field, then your choices are Units in Standard UOM or Percentage of Requested. |

Delete This Rule Set |

Select this link to remove the rule set from this rule. |

For example, the above page shot displays a rule that enables you to release a demand line if it is 3 days before the scheduled ship date and at least 90 percent of the quantity has been reserved or if it is past the scheduled ship date then release whatever quantity is reserved.

Note: If the Use Closure Calendar check box is selected on the Setup Fulfillment- Reservation page, then the system takes closure dates into consideration when comparing today's date to the date on the demand line.

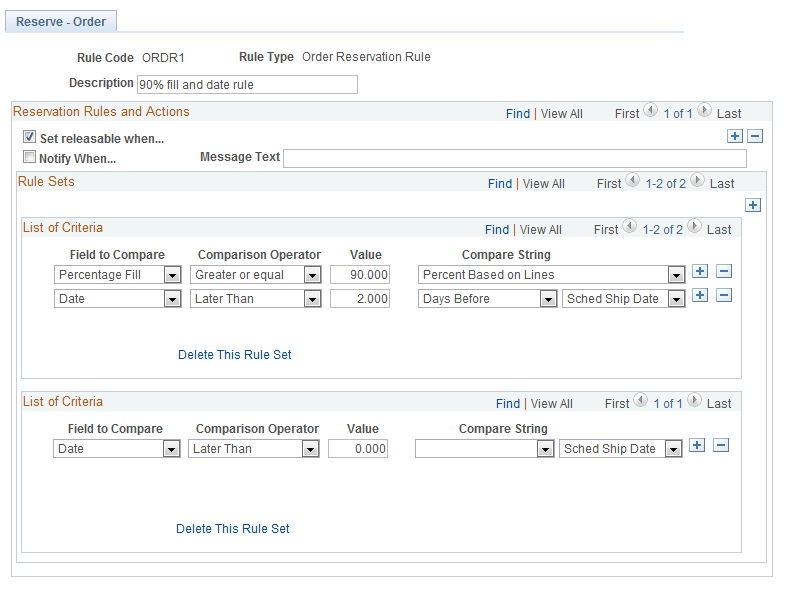

Use the Reservation/Backorder Rules-Reserve Order page (IN_FL_RULE_SETUP5) to add, change, or review order-level reservation rules.

These rules define the specific criteria that must be satisfied by the entire order or grouping of demand lines before the demand lines are moved to the releasable state.

Navigation:

. Select a Rule Type of Order Reservation Rule.

This example illustrates the fields and controls on the Reservation/Backorder Rules-Reserve Order page. You can find definitions for the fields and controls later on this page.

Defines the specific criteria that must be satisfied by an entire order or grouping of demand lines (unit of work) before the individual demand lines are moved to the releasable state. For example, an order-level reservation rule might be that all the lines in an order must reserve 100 percent of their reserved quantity before the order can move downstream. Order-level reservation rules are evaluated after line-level reservation rules. A demand line must pass both rules to be set the releasable state.

Reservation Actions

Select the action to be performed when the criteria are met by the unit of work. Within the Reservation Rules and Actions group box, you can select the Add button just below the title bar and add additional action combinations for this Rule Code. Each combination is evaluated independently.

Field or Control |

Description |

|---|---|

Set releasable when |

Select to change the state of the demand lines in the order or unit of work from Unfulfilled to Releasable when the criteria specified in the rule are met. This action releases the demand lines for fulfillment processing. If you use line level or order-level reservation rules, it is required that one rule use the Set Releasable action. |

Notify when |

Select to send a notification to a specific user or role when the criteria specified in the rule is met. Use the Errors and Warnings Framework to define which user or user role to notify and how the notification should be delivered (Workflow, email, or Message Dashboard). For example you might wish to notify the warehouse manager if an order has reached the late ship date without all lines in the order being fully reserved. |

Message Text |

If you have selected the action of Notify, enter a specific message to be included in the notification. |

Rule Sets

Within the Rule Sets group box, you can define one or more List of Criteria group boxes for each rule action by selecting the Add button just below the Rule Set title bar. Each List of Criteria group box is evaluated as an OR condition. For example, if you add two List of Criteria group boxes, the action is taken if criteria 1 or criteria 2 are met. Within an individual List of Criteria group box the separate rows are evaluated as AND conditions; both rows must be met to initiate the action.

Field or Control |

Description |

|---|---|

Field to Compare |

Select the type of comparison to be made. For line-level reservation rules, the options are:

|

Comparison Operator |

Select how the value in the Field to Compare field should be compared to the demand line. If Date is in the Field to Compare field, then your choices are Earlier Than, Earlier or Equal To, Equals, Later Than, or Later or Equal To. If Order Volume, Order Weight, or Percentage Fill is in the Field to Compare field, then your choices are Equal To, Greater or Equal, Greater Than, Less Than, or Less Than or Equal. |

Operand |

Enter a numeric value (days, percentage, or number of units) for the comparison. |

Delete This Rule Set |

Select this link to remove the rule set from this rule. |

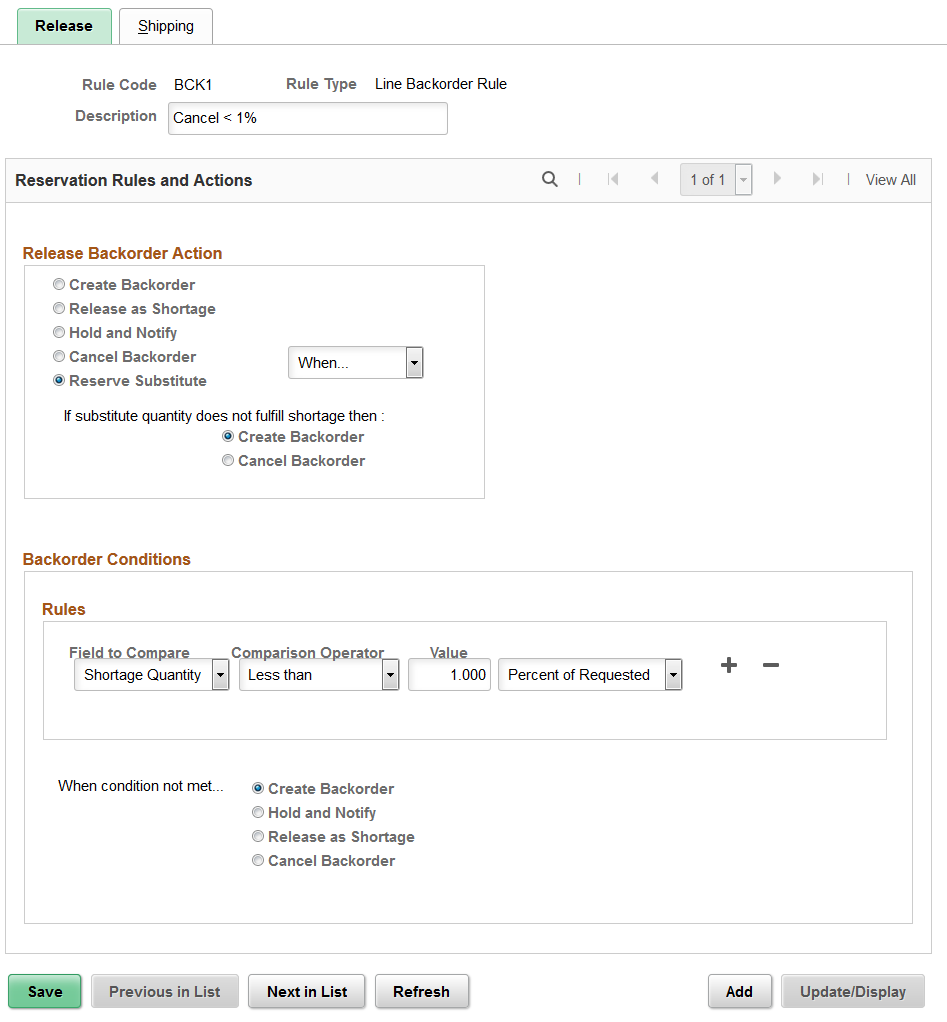

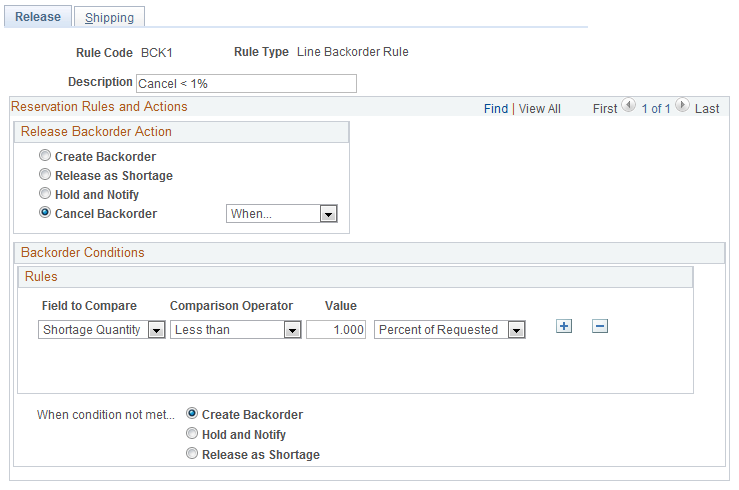

Use the Backorder Rule-Release page (IN_FL_RULE_SETUPBR) to add, change, or review the backorder rule at release.

Once a demand line has passed the set releasable criteria of both the line-level reservation rule and the order-level reservation rule, the backorder rule at release determines how any unreserved quantities are handed.

Navigation:

. Select a Rule Type of Line Backorder Rule.

This example illustrates the fields and controls on the Backorder Rule-Release page. You can find definitions for the fields and controls later on this page.

Once a demand line has passed the set releasable criteria of both the line-level reservation rule and the order-level reservation rule, the backorder rule at release determines how any unreserved quantities are handed.

Release Backorder Action

Select the action to be performed for shortage demand lines being set to releasable status.

Field or Control |

Description |

|---|---|

Create Backorder |

Select to create a backorder for the shortage quantity. If the entire demand line cannot be reserved then the demand line is backordered. If the demand line can be partially reserved, then the demand line is split into two demand lines. For example, if you have ordered 100 units of an item but only 80 units are available, the system creates a second demand line for the order to put 20 units on backorder. Demand line number 1, for 80 items, is moved into the releasable state where it can be picked and shipped. Demand line number 2, for 20 units, remains in the unfulfilled state until additional quantity becomes available. If you later put away 25 units of the ordered item, the second demand line is be reserved and set to the releasable state as long as the backordered demand line passes the line-level and order-level reservation rules. |

Release as Shortage |

Select to enable the demand line with a shortage to flow downstream through the fulfillment process. The shortage demand line is visible on the order release pick plan and shipping pages, enabling the warehouse to fulfill the shortage when stock becomes available. If the shortage cannot be fulfilled, then, at shipping time, the backorder rule for shipping creates a backorder or cancels a backorder for this demand line. |

Hold and Notify |

Select to hold the demand line with a shortage in the unfulfilled state and send a notification to the user that a backorder decision needs to be made. The demand line is not picked back up again by the Reserve Materials process or online reservations. The demand line stays on hold until a manual decision to release or backorder is made using the Shortage Workbench. Use the Errors and Warnings Framework to define which user or user role to notify and how the notification should be delivered (Workflow, email, or Message Dashboard). The message text will read A backorder decision is required for this demand line and includes the demand key information. |

Cancel Backorder |

Select to cancel a backorder for the shortage quantity. Cancel backorder has two options:

|

Reserve Substitute |

Select to reserve substitutes for the shortage quantity. Reserve Substitute has two actions:

Currently, you can automatically reserve the substitute items when:

Note: If there is an inventory shortage, the system checks for all the eligible substitute items. The substitute items are considered in the order of priority, that is, from the lowest priority number to the highest. The process continues with multiple substitutes in sequence, until the demand is met. If the demand still remains unfulfilled, the backorder for the main original item is either created or cancelled based on the reservation rule set up. |

Backorder Conditions

If you have selected Cancel Backorder using the When option, then enter the criteria to determine when the Cancel Backorder action should be taken.

Field or Control |

Description |

|---|---|

Field to Compare |

Shortage Quantity: Compare the shortage quantity on the demand line to a percentage of the requested quantity or a static value expressed in the item's standard UOM. For example, if the shortage quantity is greater than 90 percent of the requested quantity and/or the shortage quantity is greater than 3 units of the item in its standard UOM. |

When condition not met |

Select the action that should be taken when a shortage demand line does not meet the criteria to cancel backorder. |

Use the Backorder Rule-Shipping page (IN_FL_RULE_SETUPBS) to add, change, or review the backorder rule at shipping.

Once a shortage (Release as Shortage option on the Backorder Rule-Release page) has been sent downstream to shipping if there is still no quantities to ship, then this rule determines what happens to the demand line.

Navigation:

. Select a Rule Type of Line Backorder Rule. Select the Shipping tab.

This example illustrates the fields and controls on the Backorder Rule-Shipping page. You can find definitions for the fields and controls later on this page.

Once a shortage (Release as Shortage option on the Backorder Rule-Release page) has been sent downstream to shipping if there is still no quantities to ship, then this rule determines what happens to the demand line.

Ship Backorder Action

Select the action to be performed for shortage demand lines at shipping.

Field or Control |

Description |

|---|---|

Create Backorder |

Select to create a backorder for the shortage quantity. If the entire demand line cannot be shipped then the demand line is backordered. If a partial quantity on the demand line can be shipped, then the demand line is split into two demand lines. |

Cancel Backorder |

Select to cancel a backorder for the shortage quantity. Cancel backorder has two options:

|

Summary

Field or Control |

Description |

|---|---|

Field to Compare |

Shortage Quantity: Compare the shortage quantity on the demand line to a percentage of the requested quantity or a static value expressed in the item's standard UOM. For example, if the shortage quantity is less than 1 percent of the requested quantity and/or the shortage quantity is less than 3 units of the item in its standard UOM. |