Transferring Materials Using the Inventory Transfer EIP

The Inventory Transfer EIP reports transfers of stock quantity between material storage locations. The Inventory Transfer EIP is an asynchronous service operation that receives material storage location transfers staged by third-party applications; such as, electronic data collection systems and warehouse management systems. In a Warehouse Management System integration, this data is used by the WMS to modify the inventory status in PeopleSoft Inventory to Open or Hold. The stock quantity is logically transferred to a location with the appropriate status.

See Understanding Electronic Data Collection.

See Four-Wall Warehousing Functions in a WMS Integration.

Setting Up the Inventory Transfer EIP

PeopleSoft delivers the service operations in PeopleSoft Integration Broker with a default status of Inactive. You must activate each service operation before attempting to send or receive data from a third-party source or another PeopleSoft system, such as CRM.

To set up the Inventory Transfer EIP within PeopleSoft Integration Broker and Enterprise Components, use the information in the table below and refer to the setup instructions in the PeopleSoft Supply Chain Management Integrations, "Implementing Integrations", Setting Up Service Operations section.

|

Service Operation |

Direction and Type |

Handlers |

Chunking Available |

Integrates With |

|---|---|---|---|---|

|

INVENTORY_TRANSFER |

Inbound Asynchronous |

Inventory Transfer |

No |

Third-party systems such as electronic data collection systems and warehouse management systems |

See Setting Up Service Operations.

See PeopleTools: Integration Broker

Inventory Transfers Process

The Inventory Transfers process page is used to pick up the inventory transfer transactions in the inbound staging tables, validate them, and then update the appropriate PeopleSoft Inventory tables.

Transaction Handling

If an error is found during the Inventory Transfers process, the system does not process the transaction. The transaction's status on the inbound staging table is changed to Error, and the system inserts a row into the error table for each error message. Use the Transaction Maintenance component to identify and fix the errors before running the Inventory Transfers process again.

Transferring Allocated Stock

PeopleSoft Inventory enables you to transfer stock that has been hard-allocated to a material stock request, sales order, production transfer order, or work order. For more information on transferring allocated stock, see the "Understanding the Transfer of Allocated Stock" section of this topic.

See Understanding the Transfer of Allocated Stock.

Once you have completed the setup of the transferring allocated stock, you can use the transaction codes of 0601 (item transfer) and 0602 (container transfer) to transfer allocated stock. This enables you to transfer warehouse stock and transfer an entire storage container containing some or all allocated stock to another materials storage location. You cannot use the remaining transaction codes of 0603 to 0607 to transfer allocated stock.

The following options are available for the transaction codes of 0601 and 0602 on the Inventory Transfer EIP (service operation), Storage Location Transfer page (transaction page), and the Transaction Maintenance- Inventory Transfer page:

Include Allocated Qty (INCLUDE_ALLOC_FLG)

Select this check box or enter the value of Y (yes) to transfer the selected stock even if the stock has been pre-allocated or lot-allocated to a demand line.

Include Released Qty (INCLUDE_RELSD_FLG)

Select this check box or enter the value of Y (yes) to transfer the selected stock even if the stock has been allocated to a demand line with a pick batch ID.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

IB_MESSAGE_BUILDER |

View the fields to be used by the service operation within PeopleSoft Integration Broker. |

|

|

BCT_INV_REQTRFR |

Establish run control parameters for the Inventory Transfers process and load material storage location transfer data staged by third-party applications using the Inventory Transfer EIP. |

|

|

BCT_CTL_UPD |

View all electronic transactions in the transaction log (inbound staging tables) and access the detail pages that enable you to correct transaction errors. |

|

|

BCT_TRFR_UPD_INV |

View the details of an inventory transfer transaction and correct error messages found during the Inventory Transfers process. |

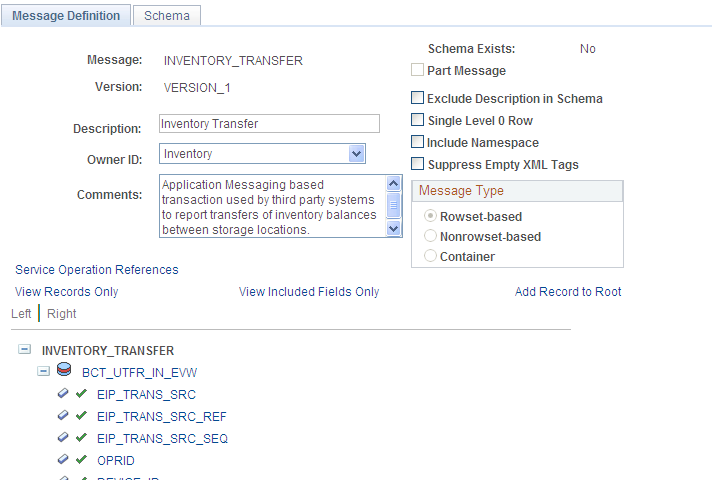

Use the Message Definition page (IB_MESSAGE_BUILDER) to view the fields to be used by the service operation within PeopleSoft Integration Broker. This is a setup step that is not repeated for each transaction request.

Navigation:

This example illustrates the fields and controls on the View the fields included in the message used by the INVENTORY_TRANSFER service operation (1 or 2). You can find definitions for the fields and controls later on this page.

This example illustrates the fields and controls on the View the fields included in the message used by the INVENTORY_TRANSFER service operation (2 or 2). You can find definitions for the fields and controls later on this page.

In order to correctly populate your incoming data, review the message definition. Message definitions provide the physical description of the data that is being sent, including; fields, field types, and field lengths. Messages do not contain any processing logic. All processing logic is defined in service operations, using service operation handlers. In this section, consider some important fields in the INVENTORY_TRANSFER message.

Field or Control |

Description |

|---|---|

TRANSACTION_CODE |

Transaction codes determines the type of action to be performed, including: 0601 - Item Transfer: Transfers loose items from one material storage location to another. This transaction is useful for inventory consolidation in a warehouse where some items are not tracked in containers. For example, you can move the last five cases of inventory so that a received pallet can be put away into the original material storage location. Using this transaction code, you can choose to transfer available stock, allocated stock, or a combination of both. For allocated stock, you can choose the stock to be transferred using the Original Location group box, or select a specific allocation using the Inventory Allocations group box or the Production Allocations group box. When transferring allocated stock, keep in mind, that a partial transfer could occur leaving allocated stock in two separate material storage locations. For example, 20 units of item A could be allocated to order ID 999. A transfer transaction could move 15 allocated units to another location but leave 5 allocated unit in the original location. 0602 - Container Transfer: Transfers a full storage container from one material storage location to another. By moving a container (a full pallet, for example) to another location, you can consolidate inventory in your warehouse. Using this transaction code, you can choose to transfer a storage container that contains stock that has been allocated to a demand line. You can transfer a container with available stock, allocated stock, or a combination of both. When transferring a container with allocated stock, be sure to select the Include Allocated Qty check box for pre-allocated and lot-allocated stock and the Include Release Qty check box for released stock. Using this transaction code, you can choose to transfer a container with available stock, allocated stock, or a combination of both. 0603 - Associate Item to a Cntr (associate an item to a container): Transfers loose items into a storage container. You can build a new container, or you can add items to an existing container. If the container is empty before the new items are added, you can enter the putaway location on the same transaction. If the container already has items in it, use the Container Transfer transaction to move the container to the destination location. You cannot transfer allocated stock into a container. 0604 - DeAssociate Item From a Cntr (deassociate an item from a container): Transfers items from a storage container to a material storage location. You can also use this transaction to move inventory from a storage container in a secondary material storage location to a fixed picking bin location that does not have a storage container. This transaction reverses the associate item to a Container transaction. You cannot transfer allocated stock out of a container. 0605 - Item/Cntr to Item/Cntr (item/container to item/container): Transfers items from one storage container to another. If the destination container is empty, you can add items to the container and move the container to another material storage location simultaneously. For a storage container that already has items in it, use the Container Transfer transaction. You cannot transfer allocated stock using this transaction code. 0606 - Cntr/Cntr Full Transfer (container to container full transfer): Transfers all contents of one storage container into another storage container. You cannot transfer allocated stock using this transaction code. 0607 - Debuild Full Container: Transfers all items from a storage container to a material storage location. You cannot transfer allocated stock using this transaction code. |

Original Location Fields

Enter in information to select the stock from it's original location.

Field or Control |

Description |

|---|---|

INV_ITEM_ID |

Select the item that you are transferring. The field is required for Item Transfer, Associate Item to a Container, Deassociate Item From a Container, and Item/Container to Item/Container transactions. Because Container Transfer, Container/Container Full Transfer, and Debuild Full Container transactions transfer all items in the container, the field is unavailable. The business unit defaults established on the Inventory Display Options page govern whether lot, serial, staged date, and configuration fields are needed for this item. |

STORAGE_AREA, STOR_LEVEL_1, STOR_LEVEL_2, STOR_LEVEL_3, and STOR_LEVEL_4 |

Select the material storage location from which you are removing items. Unless you specify otherwise, the current container location is the default. This field is only available for the Item Transfer and Associate Item to a Container transactions. The business unit's default display options determine how many material storage location levels are available for entry to this message row. |

CONTAINER_ID |

Select a storage container for the original location. |

QTY and UNIT OF MEASURE |

The quantity and UOM for the item to be transferred. This is required fields for all the item-transfer transactions. Because the full-container transactions transfer all items in the storage container, quantity and units of measure are not applicable for these transactions. If the item is serial controlled, the quantity must equal 1. If negative quantities are not allowed, the transfer quantity must be less than or equal to the available quantity at the material storage location. If the UOM Conversion Flag for electronic data collection transactions specifies using the entered UOM, you must use a valid stocking UOM for the item. If the flag is set to convert the UOM to the standard UOM or to convert the UOM to the stocking UOM, you can enter any valid UOM for the item. |

PICK_BATCH_ID and PICKLIST_LINE_NO |

Enter values if you are using a pick batch as the basis for the transaction. When using this field, keep in mind the following information:

|

INCLUDE_ALLOC_FLG |

Enter Y in this field to transfer the selected stock even if the stock has been pre-allocated or lot-allocated (that is, allocated to a demand line without a pick batch ID). This field is only applicable if you have selected the transaction code of 0601 (item transfer) or 0602 (container transfer). The default setting is derived from the Include Pre-Released Allocations check box on the Fulfillment Setup page for this business unit. |

INCLUDE_RELSD_FLG |

Enter Y in this field to transfer the selected stock even if the stock has been allocated to a demand line with a pick batch ID. This field should only be used if you have selected the Allow Transfer of Released Allocations check box on the Inventory Definition- Business Unit Options page and, on this transaction, you have using the transaction code of 0601 (item transfer) or 0602 (container transfer). The default setting is derived from the Include Released Allocations check box on the Fulfillment Setup page for this business unit. |

DEMAND_SOURCE, SOURCE_BUS_UNIT, ORDER_NO, ORDER_INT_LINE_NO, and SCHED_LINE_NBR |

If you are transferring stock that has been allocated to a demand line, you can select the stock to be transferred by entering in information about the allocated order, including the demand source, source business unit, order number, line number, and schedule line number. These fields are only available if you have selected the transaction code of 0601 (item transfer) or 0602 (container transfer). In addition, either the INCLUDE_ALLOC_FLG field or the INCLUDE_RELSD_FLG field must have the value of Y. If the data entered here conflicts with the pick batch ID entered on this same transaction, then the transaction is put in error status. |

PRODUCTION_ID |

If you are transferring stock that has been allocated to a production order demand line from PeopleSoft Manufacturing, you can enter the production ID to select the stock to be transferred. This field is only available if you have selected the transaction code of 0601 (item transfer) or 0602 (container transfer). In addition, the INCLUDE_RELSD_FLG field must have the value of Y. If the production ID entered here conflicts with the pick batch ID entered on this same page, then the transaction is put in error status. |

Destination Location Fields

Enter the destination for the transferred stock or storage container.

Field or Control |

Description |

|---|---|

TO_CONTAINER_ID |

Enter the storage container that is the destination of this transfer. |

TO_STORAGE_AREA, TO_STOR_LEVEL_1, TO_STOR_LEVEL_2, TO_STOR_LEVEL_3, and TO_STOR_LEVEL_4 |

Indicate the destination material storage location. If the destination container is empty and you are conducting an Associate Item to a Container, Item/Container to Item/Container, Container/Container Full Transfer, or Debuild Full Container transaction, this field is required. If the container is not empty, the system adds the new items to the container at its current location. If the destination material storage location is a fixed picking bin, the UOM that you entered must equal the fixed picking bin UOM, unless the UOM Conversion Flag (located on the Define Business Unit Item - Inventory: Shipping/Handling page) is set to convert to the standard UOM, in which case:

|

For more information about messages, see the "Managing Messages" topic of the PeopleTools: PeopleSoft Integration Broker.

See the product documentation for PeopleTools: Integration Broker

Use the Storage Location Transfer page (BCT_INV_REQTRFR) to establish run control parameters for the Inventory Transfers process and load material storage location transfer data staged by third-party applications using the Inventory Transfer EIP.

Navigation:

This example illustrates the fields and controls on the Storage Location Transfer process page. You can find definitions for the fields and controls later on this page.

These third-party applications include electronic data collection systems and warehouse management systems.

Field or Control |

Description |

|---|---|

Unit |

Enter the Inventory business unit to receive the transfer transactions. |

Commit Batch |

Enter a commit batch number. This field controls database commit level processing. Enter the number of rows that you want to process before a database update is performed. If you do not want to do intermittent commits, then set the commit batch field to zero (no intermittent commits) or a number that is larger than the normal number of rows that are usually processed. You may need to try different commit batch numbers to achieve the maximum level of performance while minimizing database locking. |

The Storage Location Transfer process verifies that the following criteria are met:

The business unit must be active and cannot be closed to material movement.

If you set up the business unit to generate new storage containers automatically, you can create a new container when you enter a new storage container ID.

If the business unit does not allow the automatic generation of new storage containers and you enter a new container ID, the transaction results in an error.

The originating storage container ID must exist in the system.

The originating and destination locations must both be valid material storage locations that are not closed.

If the item already exists in the location, the item's status fields (status type, available status type, reason code, and retest date) must be identical.

If the status fields are not identical, the item is rejected. The only exception to this rule occurs when either the originating or the destination location is on hold. If either location is on hold for a non-lot-controlled item or a lot-controlled item with an open status, the system moves the item, and the item's status fields change to those of the destination location. Lot-controlled items with a non-open status always retain their status fields no matter where they are moved.

A valid item, lot, serial, and staged date must exist for the original location.

When you add an item to a single-item storage container, the item ID must be the same as that for the container.

If the container has not been assigned a specific item ID, the system verifies that no other items are currently stored in the container. If the system assigned another item ID to the storage container, the transaction results in an error.

If negative quantities are not allowed, the transfer quantity must be less than or equal to the available quantity at the originating location.

A serialized item can never go negative even if negative quantities are allowed.

For Container to Container Full Transfers (0606) and Debuild Full Container (0607) transaction codes, the storage container cannot contain any allocated quantities. For Container Transfers (0602), the container to be moved can contain allocated quantities as long as the Include Allocated Qty or the Include Released Qty flags are selected for the transaction.

If the destination material storage location is a fixed picking bin and the UOM Conversion Flag for electronic data collection transactions is set to use the entered UOM, the entered UOM must equal the fixed picking bin UOM.

If the UOM Conversion Flag for electronic data collection transactions is set to convert the UOM to the standard UOM, the standard UOM must be equal to the fixed picking bin UOM. Similarly, if the UOM Conversion Flag for electronic data collection transactions is set to convert the UOM to the stocking UOM, the default stocking UOM must be equal to the fixed picking bin UOM.

If the UOM Conversion Flag is set to convert the UOM to the standard UOM or to the stocking UOM, you can enter any valid UOM for the item. If the flag is set to use the entered UOM, you must use a valid stocking UOM for the item.

Use the Transaction Maintenance page (BCT_CTL_UPD) to view all electronic transactions in the transaction log (inbound staging tables) and access the detail pages that enable you to correct transaction errors.

Navigation:

The Transaction Maintenance page displays transactions from the inbound staging tables and is used to view the status of the incoming transactions. If errors are found during the Inventory Transfers process, the transaction status in the transaction log is changed to Error, and rows are inserted into error tables for each error message.

Use the Transaction Maintenance- Inventory Transfer page (BCT_TRFR_UPD_INV) to view the details of an inventory transfer transaction and correct error messages found during the Inventory Transfers process.

Navigation:

Click the EIP Control ID link on the Transaction Maintenance page.

Use the Transaction Maintenance- Inventory Transfer page to view, correct, and resubmit inventory transfer transactions. For example, if an inventory transfer transaction is loaded with a material storage location that does not exist, then the file generates an error. Once you have corrected the information and saved the page, the transaction is ready to be reprocessed using the Inventory Transfers process.