Establishing Business Unit Calendars

To define a work week, default production week, or a manufacturing calendar, use the Work Week Definition (MG_WORK_WK_DEFN), Default Production Week (MG_CAL_DEF_WEEK), and Calendar Code Definition (MG_CALENDAR) components.

After you define the shifts in operation for a given day, define the business unit calendars. The five-day work week is also used if the production calendar code isn't yet effective or is obsolete. These calendars define which days the manufacturing business unit is available and the hours of operation for each day. The start and due dates for production and for each operation are determined based on the business unit calendar that you define.

This section discuss how to establish business unit calenders:

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

MG_WORK_WK_DEFN |

Define a five-day, one-shift work week. |

|

|

MG_CAL_DEF_WEEK |

Use to facilitate data entry if you are defining a calendar for a calendar code. |

|

|

MG_CALENDAR |

Define production calendar codes. |

Use the Work Week Definition page (MG_WORK_WK_DEFN) to define a five-day, one-shift work week.

Navigation:

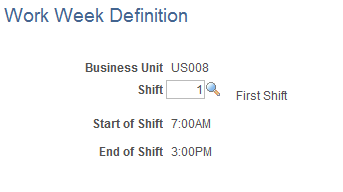

This example illustrates the fields and controls on the Work Week Definition page. You can find definitions for the fields and controls later on this page.

Note: If you don't define at least one calendar code with its associated calendar, or if the production calendar associated with the business unit becomes obsolete, the planning and scheduling functions assume that you are working a five-day work week. The system defines a five-day work week as Monday through Friday, with one shift. Define the specific hours of operation for the shift; the shift must start and end on the same day.

Field or Control |

Description |

|---|---|

Shift Code |

Select only a single shift code. However, if you work more than one shift, the shift code should include all hours of operation for all shifts, as long as the start and end times don't span multiple days. Alternatively, if more than one shift is applicable, or you have a shift that spans multiple days, you may want to define a production calendar. When using a five-day work week for scheduling, define the hours of operation for the five days. Do this by selecting a shift code to associate with the work week. |

Start of Shift and End of Shift |

These fields appear by default from the Shift Codes page. |

Use the Default Prdn Calendar Week page (MG_CAL_DEF_WEEK) to use to facilitate data entry if you are defining a calendar for a calendar code.

Navigation:

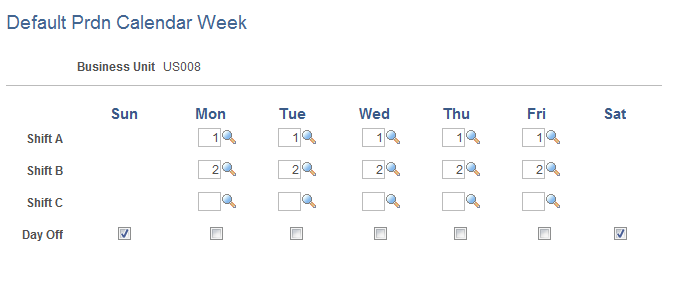

This example illustrates the fields and controls on the Default Prdn Calendar Week page. You can find definitions for the fields and controls later on this page.

When defining a calendar, use this default week to fill each week of a month. This default week should represent a typical production week, including or excluding weekends. Because the system automatically creates the production month using this default week, this page is the preparatory step to defining production months within calendar codes. You can then make changes for individual days within the month on each month's calendar.

For each day in the week, you can assign up to three shifts (Shifts A, B, and C) from among the shifts defined using the Shift Code Definition page. You cannot enter duplicate shifts for the same day, and the shifts that you select for any given day cannot overlap. The shift times must be chronological beginning with the earliest shift listed first and the latest shift listed last. The system does allow shift schedule gaps as long as the shift times remain chronological. The shift times must also be chronological across all days of the week.

If you select the Day Off check box, you are defining the day as a day off; therefore, you cannot define any shift for that day on this page.

However, you can still change each shift or days off for any day of the week when actually defining a monthly calendar.

Once you define the shift codes and default production calendar week for the business units, you can define one or more calendar codes with their associated calendar for each business unit. You can then use these calendar codes within each business unit to set up the calendars for business units, work centers, production resources, and enterprise resources.

You can create calendar codes for an entire year, a partial year, or a few months within the year. You can define a primary production calendar code for a business unit, then create alternate calendar codes to use as exception calendars for work centers and resources.

Keep these in mind when you create calendar codes:

The first calendar code and associated calendar is automatically set to the business unit's default calendar.

To use a different calendar as the production calendar, define that calendar code and use the Manufacturing Options page to change the default production calendar.

You can define only months within alternate calendar codes that are found within the range of the production calendar code.

For example, for 2003, the primary production calendar code M2 has the months of January and July defined. The alternate calendar code may not have August defined, but February or March may be defined, because they fall within the range of the production calendar code (January through July).

Alternate calendar codes function as exception calendar codes to the default production calendar code.

For example, suppose that the production calendar code is defined for the months of January through December and the alternate calendar code is defined for the months of May and July, the system uses the alternate calendar code defined for May and July. The system uses the default dates defined for the production calendar code for all other months.

You cannot delete a month from the production calendar code if it uses the alternate calendar code.

If only one month is left on the production calendar code and you delete it, the system deletes the production calendar code from the Manufacturing Options page.

PeopleSoft Manufacturing then uses the work week definition to schedule production.

If an alternate calendar code is defined for a work center or resource, you cannot delete every month defined for the calendar code.

Once you have added at least one calendar code, you must assign the calendar code to the appropriate business unit. If alternate calendar codes are defined, you can optionally assign those codes to work centers.

If you're using PeopleSoft Supply Planning, you can optionally assign alternate calendar codes to resources.

Important! Before you can assign calendar codes, run the Create Calendars process (MGS3000) to create a version of the calendar—the run time calendar—which is used in the planning and scheduling functions.

Run the Create Calendars process to create a new version of the calendar based on the latest calendar definition if you changed anything relating to the calendar such as:

Changing a shift code's start or end times.

Adding another month or year.

Deleting a month or year.

Changing a non-manufacturing day to a manufacturing day.

If you have enabled PeopleSoft Workflow, any time that you make a change to the calendar code, the system optionally sends a workflow notification to selected roles that you defined. This Production Calendar Change workflow notifies the role, such as a production control manager, that the calendars originally used for scheduling are not in synch with the changes, additions, or deletions that you made to the calendar code, and that you must create a new run-time version of the calendar.

Use the Calendar Code Definition page (MG_CALENDAR) to define production calendar codes.

Navigation:

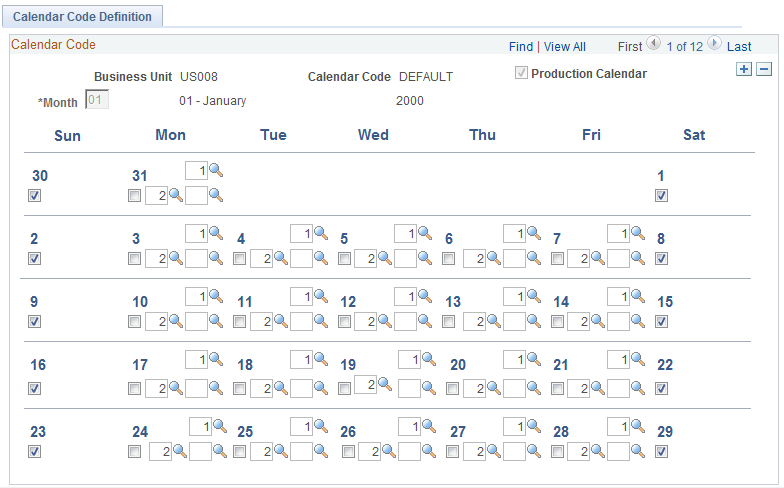

This example illustrates the fields and controls on the Calendar Code Definition page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Production Calendar |

If the calendar code is the default calendar code for the business unit, as defined on the Manufacturing Options page, this check box is selected. |

Mo: (month) |

Create a calendar code with one month, a partial set of months, or 12 months of the year. If you want to create a new monthly calendar, insert a new row, select the month that you want to maintain, and press TAB to move to the next field. The system automatically fills the month with the values previously entered for the default production week. You can then change individual days for the month without affecting the default weekly production calendar. If you have already created the month and you want to change the calendar for an existing month, the Mo. field is unavailable for selection. Use the scroll bar to view the calendar for all existing months for the year. For each day in the week, you can assign up to three shifts from among the shifts defined on the Shift Code Definition page. You cannot enter duplicate shifts for the same day, and the shifts that you select for any given day cannot overlap. The shift times must also be chronological, beginning with the earliest shift listed first and the latest shift listed last. The system does allow shift schedule gaps as long as the shift times remain chronological across all days of the production calendar. Additionally, a shift can begin on one day and end on the next. |

|

Select the Day Off check box in the day's lower left corner, if you want the day to be a non-manufacturing day. |