Recording Completions Using Electronic Data Collection

This section discusses how to Record Completions Using Electronic Data Collection

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

BCT_MG_CPL |

Record completions and scrap for these transactions:

|

|

|

BCT_MG_MCPL |

Record operation completions for production IDs with multiple outputs using electronic data collection:

|

Use the Completion/Scrap page (BCT_MG_CPL) to record completions and scrap

Navigation:

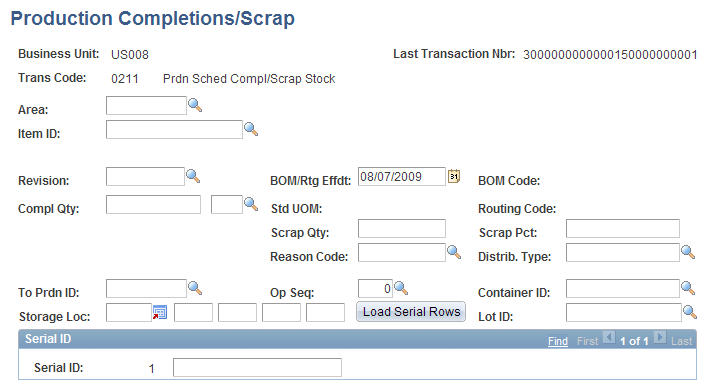

This example illustrates the fields and controls on the Production Completion/Scrap page (for production schedules). You can find definitions for the fields and controls later on this page.

Note: To correct errors, you must use the online completions pages to enter negative completions and reverse completion transactions.

Field or Control |

Description |

|---|---|

Area, Item ID, and BOM/Rtg Effdt (BOM/routing effectivity date) |

Enter values for these fields if you're recording completions for a production schedule using transaction 0211. |

Production ID |

Select values for this field if you're recording completions to stock for a production ID using transaction 0212 or intermediate operations completions using transaction 0213. Item completions are not allowed if the end item (including co-products and recycle by-products) or a component of the end item is on hold. Completions are allowed for waste products with a hold status. Completions are also allowed for rework and teardown orders, but any output of teardown with a hold status prevents teardown completion. |

Use the Multiple Out Completion/Scrap page (BCT_MG_MCPL) to record operation completions for production IDs with multiple outputs using electronic data collection.

Navigation:

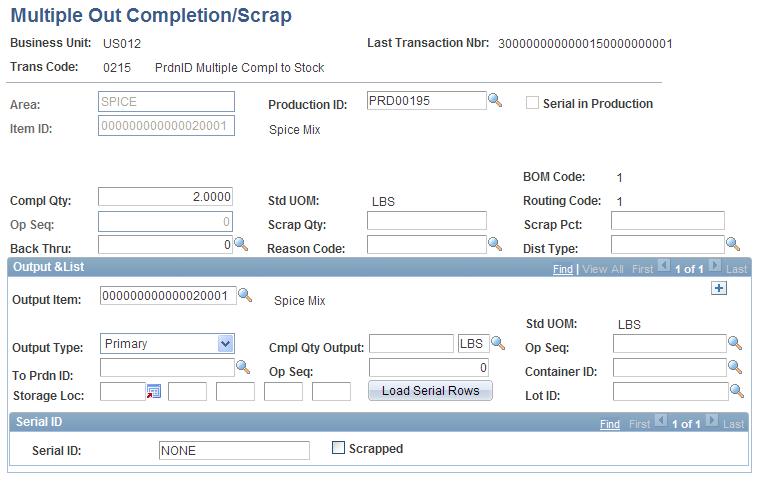

This example illustrates the fields and controls on the Multiple Out Completion/Scrap page (for production IDs). You can find definitions for the fields and controls later on this page.

Note: You can also complete teardown production using multiple output completions transactions, and you can complete teardown outputs at intermediate operations, as well as at the last operation.

Field or Control |

Description |

|---|---|

Area and Item ID |

Select values for these fields if you're recording multiple output completions for a production schedule using transaction 0214. |

Production ID |

Select a value if you're using transaction 0215 or 0216. |

Op Seq (operation sequence) |

Enter any intermediate operation if you're using transaction 0216. |

Back Thru |

Select the operation sequence where you want to record completions. |

Scrap Qty (scrap quantity), Reason Code, and Scrap Pct (scrap percentage) |

Enter values for these fields. |

Distribution Type |

(Optional) Use this field to create specific accounting entries for scrap. |

Output Item |

Select a value. You can enter output items from the outputs designated on the BOM, or you can enter unplanned outputs for recycle or waste by-products. The system includes the amount and type of output items indicated on the end item's BOM. For example, if there were one co-product and two by-products designated on the BOM, there would be four output rows for the co-product, two by-products, and one primary item. |

Cmpl Qty Output (completed quantity output) |

Enter the number of completed items. Based on the completed quantity of the primary item and the co-products, the system calculates the actual completed quantity. |

Load Serial Rows |

If the end item is serial-controlled or being tracked using serial genealogy (serial in production), enter a completed quantity, which should include any scrap quantity, and then click this button. The system then creates as many Serial ID fields as the completed quantity and any scrap quantity, and you can enter the serial IDs for each completed item. The quantity completed and quantity scrapped must be whole numbers for serial-controlled items. You must enter either a completed quantity or scrapped quantity; both values cannot be zero. If the end item is not being tracked using serial genealogy, enter a completed quantity. The system then creates as many serial IDs for the completed quantity. |

Lot ID |

Enter a value if the end item is lot-controlled. |

Serial ID |

Enter the serial IDs for each completed output. If the item is being tracked using serial genealogy, then upon save, the system automatically associates the serial ID with the production ID. |

Scrapped |

(Optional) Select this check box to indicate that the serial ID is being scrapped. |

Note: To correct errors, you must use the online completions pages to enter negative completions and reverse completion transactions.