Reviewing and Correcting PDX Change Order Exceptions

This section provides an overview of change order exceptions.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

EN_PDXECO_EXCP |

Review any incoming change orders that are the result in an error status due to edit checks made on items, revisions, or BOMs. |

|

|

EN_PDX_ERRORS |

View the specific errors associated with the change order. |

|

|

EN_PDX_COMPTRNS |

View the completed change orders. |

|

|

Role Definition Page |

ROLEDEFN |

Define roles. |

|

PDX Alerts Page |

EN_PDX_ALERT_RUN |

Define PDX alert emails, which notify you of load time processing exceptions related to change orders for items and BOMs. |

While the intent is obviously to not have any exceptions, the PDX Change Order Exceptions component is provided to identify and correct any errors that may occur.

This outlines the flow of change order information once it is received into the PeopleSoft Manufacturing system:

Service operations are posted to the PeopleSoft service operation gateway (PDX_MSG), which contains the PDX change order data.

The PDX service operation is processed. It is translated and subscribed to as ITEM_SYNC and BOM_SYNC service operations.

Item sync and BOM sync service handlers write results to new entries by transaction (which relate to the PDX change data) within Data Maintenance as item for items and revisions, and BOM for bill of material changes.

The Daemon defined for the PeopleSoft Process Scheduler determines when to run the PDXJOB defined in "Steps to define and PDX Daemon."

The PDXJOB selects and processes the change order package (by transaction). This job processes the earliest transactions in the system by running the Item Loader and BOM Loader processes in PeopleSoft together sequentially.

Any exceptions processing the PDXJOB are visible within the PDX Change Order Exceptions component defined in this section.

Note: This component provides a special view of the item and BOM data maintenance information in the context of ECO numbers containing Revision information. If the PDX sent contains manufacturing change orders (such as MCOs that have no revision information), these changes are consolidated into a single line within the exception page with the value '***MCO***' if in error. The generic value '***MCO***' is configurable in the Message Catalog utility under message set number 7026 and message number 204.

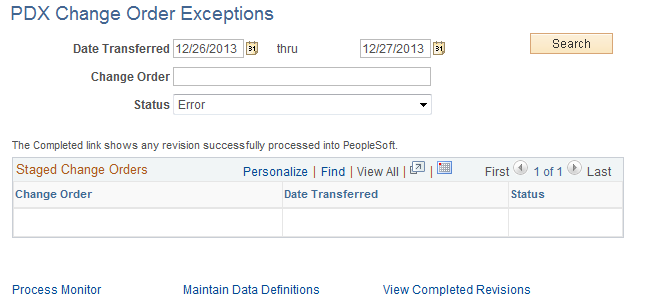

Use the PDX Change Order Exceptions page (EN_PDXECO_EXCP) to review any incoming change orders that are the result in an error status due to edit checks made on items, revisions, or BOMs.

Navigation:

This example illustrates the fields and controls on the PDX Change Order Exceptions page. You can find definitions for the fields and controls later on this page.

This page provides you visibility of incoming staged items and BOMs within the context of change orders only. This page is a view of the information by item or BOM in the Data Maintenance component.

Field or Control |

Description |

|---|---|

Status |

Values include:

When new change orders are being processed, the initial status of each change order appears as New. Note: The details of a change order can include several item and BOM changes that are present in the Maintain Data Definitions component for an initial status of New. If any of the items, revisions, or BOMs related to a change order are processed in error, then the change order will be identified as an Error on this page. |

Error Detail |

Click this link to view the specific errors associated with the change order. Because a change order typically contains multiple items and BOMs, it is possible that some changes were processed successfully while others may have resulted in an error. For example, a new assembly, BOM A123, is sent with four new component items (C1, C2, C3, C4), but one of the new components (C4) was not sent. In this case, three of the components could be successfully processed (C1, C2, C3) as items, but the BOM A123 would fail, because component C4 must exist within PeopleSoft before the manufacturing BOM can be created. If this occurs, the Completed status link appears for that specific change order. |

Completed |

Click this link to view any completed items or BOMs for an error change order. These items have been processed and incorporated into the PeopleSoft Manufacturing system. |

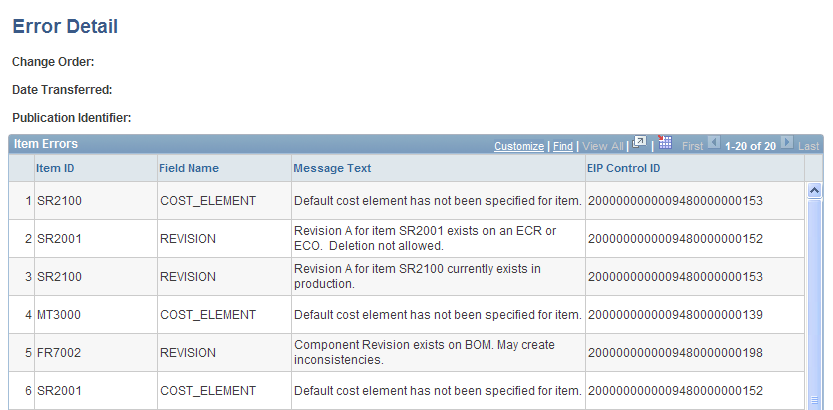

Use the PDX Change Order Exceptions - Error Detail page (EN_PDX_ERRORS) to view the specific errors associated with the change order.

Navigation:

Click the Error Detail link on the PDX Change Order Exceptions page.

This example illustrates the fields and controls on the PDX Change Order Exception - Error Detail page (1 of 2). You can find definitions for the fields and controls later on this page.

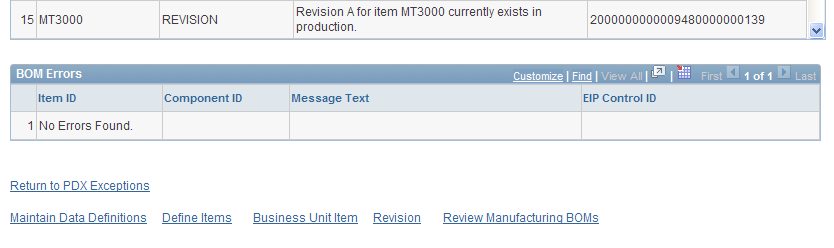

This example illustrates the fields and controls on the PDX Change Order Exception - Error Detail page (2 of 2). You can find definitions for the fields and controls later on this page.

Use the Completed by Change Order page (EN_PDX_COMPTRNS) to view the completed change orders.

Navigation:

Click the Completed link on the PDX Change Order Exceptions page.

This page identifies completed items based solely on the presence of new entries in the item, revision, and BOM production tables within PeopleSoft. This is identified in the system by storing the change order number within the Revision and BOM additional text fields.

It is highly recommended that when there is a BOM processing (data entry) error the error should be corrected within the product life cycle management system and the change order resent to PeopleSoft. In this case, click the Cancel button on the PDX Change Order Exceptions page to cancel all remaining unprocessed and errored entries in the ITEM and BOM staged tables and then resend the entire change order.

Note: Cancel the change order first in PeopleSoft so that subsequent sends of the same change order are not confused with the earlier send, which had an error.

For example, you send two new component items (C1 and C2) and one assembly item (A123), along with one BOM markup for the assembly item A123. It is possible that the two component items process correctly yet the BOM markup fails (for example, a third component (C3) is referenced on BOM A123, but is missing). In this case, canceling the errored change order rows, repairing the change order by adding the third component, and resending the change order to PeopleSoft is a preferred method of correction.

Data Entry Errors

Field or Control |

Description |

|---|---|

BOM error |

Missing required component item in the affected items of the change order caused the BOM to fail because the component item was not present in PeopleSoft. |

Item Error |

|

Engineering Errors to Released and Sent Change Orders

There is no "undo" capability for change orders applied to PeopleSoft. Therefore, you should not make any engineering-type changes to a change order (such as BOM markups) after it has already been sent and processed successfully within PeopleSoft. For example, successfully sending a markup to PeopleSoft and then subsequently unreleasing the change order, changing the markup, and resending the same change order to PeopleSoft is not allowed. Doing so causes both systems to be out of sync.

Note: If additional engineering changes are required to repair a change order, a subsequent change order and release to PeopleSoft is the proper method of correction.

Change Order Errors - Examples

These are some common change order errors that you may encounter:

A component listed on the BOM was mistakenly left off the change order that was corrected within Agile™, and then the change order was resent to PeopleSoft.

In this case, click the Cancel button on the PDX Change Order Exceptions page to cancel all remaining unprocessed and error entries in the item and BOM staged tables and resend the change order.

You sent two new component items (C1 and C2) and one assembly item (A1), along with one BOM markup for the assembly item A1.

It is possible that the two component items processed correctly, but the BOM markup failed (perhaps a third component, C3, is referenced on BOM A1 but is missing).

In this case, canceling the change order rows with an Error status, repairing the change order by adding the third component, and resending the change order to PeopleSoft is a preferred method of correction.