Reviewing Planning Exceptions

Planning exceptions are situations that are in contrast to various parameters defined within the plan, generally caused by changing business rules or manual intervention in the transaction system, or by manual interaction with the planning instance. These exceptions, however, are not directly acted upon by the solvers.

This topic discusses how to define and review Planning Exceptions.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

PL_RVW_EXCP_SUM |

Review exceptions by planning object type. You can navigate to detailed exception information. |

|

|

PL_RVW_EXCP_SEL1 |

Define the filter criteria that you want the system to consider when calculating exceptions. |

|

|

PL_RVW_EXCP_CAL |

Review additional information about the calendar constraints. |

|

|

PL_RVW_EXCP_ORDSZ |

Review additional information about the order sizing exceptions. |

|

|

PL_RVW_EXCP_EFFTV |

Review additional information about the effectivity date exceptions. |

|

|

PL_RVW_EXCP_INVBOM |

Review general and policy violation details. If the Excess Limit Exceeded option is selected then the object name will display as PL_RVW_EXCP_EXCSST. |

Use the Exceptions page (PL_RVW_EXCP_SUM ) to review exceptions by planning object type.

You can navigate to detailed exception information.

Navigation:

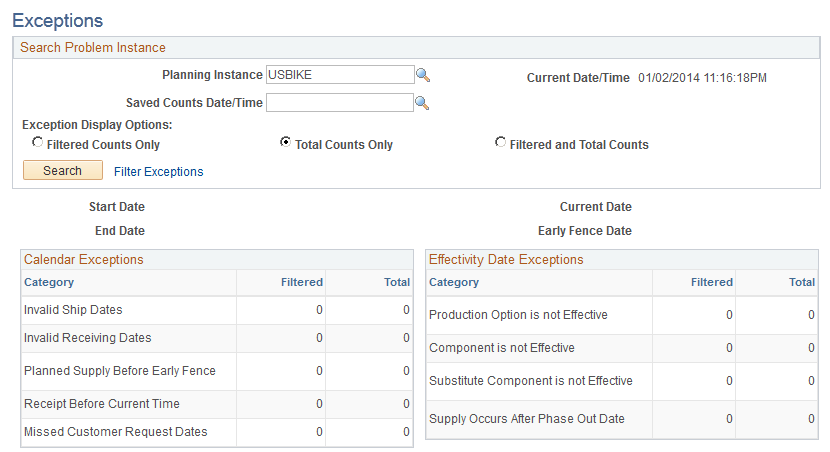

This example illustrates the fields and controls on the Exceptions page (1 of 2). You can find definitions for the fields and controls later on this page.

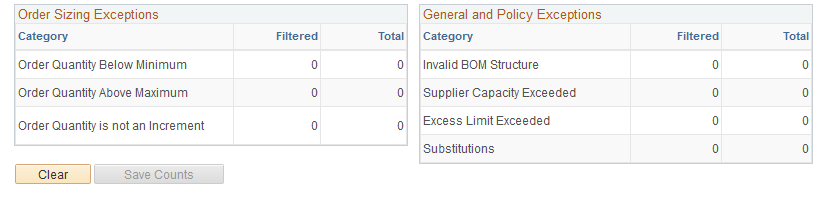

This example illustrates the fields and controls on the Exceptions page (2 of 2). You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Saved Counts Date/Time |

Select a previously saved set of exception counts for review. You can save summary exception counts at any time, including before or after solver runs. When you save exception counts, the system retains the totals only. Additional details for saved counts are not available. |

Exception Display Options |

Indicate how you want the system to calculate and display summary counts. Values are:

If you select Total Counts Only, you can specify the exception type, general, and order type filters criteria, but the system ignores these filters when calculating the total counts. |

Start Date |

The beginning time boundary, before which time does not exist within the planning instance. Used with the end of time, this region defines the time period within which the system recognizes orders and changes. Solvers do not recognize times before the start of time. |

End Date |

The concluding time boundary for the planning instance. Solvers do not recognize orders or changes after this date. |

Current Date |

The current date and time as established for the planning instance. This fence is used to define various time offsets respected by the planning solvers. |

Early Fence Date |

The default early fence for the planning instance. |

Save Counts |

Click to save the summary exception counts to the database for retrieval and review at a later date. Use the Save Counts Date/Time field to select a saved exception count for review. |

Calendar Exceptions

Displays supply and demand that occurs at invalid calendar times. Click any link in the Filtered or Total column to access the Calendar Exceptions page, where you can view additional information about the corresponding constraint.

Order Sizing Exceptions

Click any link in the Filtered or Total column to access the Order Sizing Exceptions page, where you can review additional information about the existing orders that do not follow the order minimums, maximums, or increments associated with an item's sourcing definitions.

Effectivity Date Exceptions

Click any link in the Filtered or Total column to access the Effectivity Date Exceptions page, where you can review additional information about orders where exceptions to effectivity dates have been encountered.

General and Policy Exceptions

Click any link in the Filtered or Total column to access the Policy Exceptions page, where you can review additional information about BOM exceptions found while calculating low level codes, planned quantity on hand levels greater than the excess limit, and orders where substitutions have been made.

Use the Exceptions - Filter Exceptions page (PL_RVW_EXCP_SEL1) to define the filter criteria that you want the system to consider when calculating exceptions.

Navigation:

Click the Filter Exceptions link on the Exceptions page.

Exception Type Filters

Select the exception types for which you want to search.

Field or Control |

Description |

|---|---|

Exception Display Options |

Indicate how you want the system to calculate and display summary counts. Values are:

If you select Total Counts Only, you can specify the exception type, general, and order type filters criteria; however, the system ignores these filters when calculating the total counts. |

Calendar Exceptions

Field or Control |

Description |

|---|---|

Invalid Ship Dates |

The system counts a demand order (customer order, transfer, or material stock request) if the ship date is not valid for the business unit's shipping calendar. |

Invalid Receiving Dates |

The system counts a supply order (a PO or a transfer) if the order's receipt date is not a valid receiving date on the business unit's receiving calendar. |

Planned Supply Before Early Fence |

The system counts a planned supply order if the order begins (start date for production, ship date for transfers, and release date for POs) before the items early fence. |

Receipt Before Current Time |

The system counts a supply order (production, purchase, or transfer) if the order's receipt date is before the current date time of the planning instance. |

Missed Customer Request Dates |

The system counts a sales order schedule line, quote or buyers agreement if the planned ship date is after the customer request date. |

Order Sizing Exceptions

Select order sizing exceptions for planned supply orders only.

Field or Control |

Description |

|---|---|

Order Quantity Below Minimum |

The system counts a planned supply order if the order quantity on a supply order is less than the minimum order quantity specified in the sourcing option used to create the planned supply order. |

Order Quantity Above Maximum |

The system counts a planned supply order if the order quantity on a supply order is more than the maximum order quantity specified in the sourcing option used to create the planned supply order. |

Order Quantity Is Not An Increment |

The system counts a planned supply order if the order quantity on a supply order does not match the order increment specified in the sourcing option that is used to create the planned supply order. |

Effectivity Date Exceptions

Field or Control |

Description |

|---|---|

Production Option Is Not Effective |

The system counts a planned production order if the production option (BOM plus routing combination) is invalid at the production end date. |

Component Is Not Effective |

The system counts a component requirement on a planned production order if the production start or end date is invalid because of effective dates. The BOM effectivity option on the planning instance determines whether a component is in effect at the start or end date. |

Substitute Component Is Not Effective |

The system counts a substitute for a component requirement on a planned production order if the production start date or end date is invalid because of substitution effective dates. The BOM effectivity option on the planning instance determines whether a component is in effect at the start or end date. |

Supply Occurs After Phase-Out Date |

The system counts a planned supply order if the order ends (end date for production, arrival date for transfers, and receipt date for POs) after an item's phase-out date. |

General and Policy Exceptions

Field or Control |

Description |

|---|---|

Invalid BOM Structure (invalid bill of material structure) |

The low-level code build detects violations. The system displays the number of items with BOM violations. The system counts an item if its low-level code is set to -1 or 999. |

Supplier Capacity Exceeded |

The system counts a capacity period for a supplier if the plan for an item exceeds the supplier's capacity. |

Excess Limit Exceeded |

The system counts an item if its planned quantity on hand is greater than the specified excess limit at any time between the current time and the late fence. |

Substitutions |

The system counts a component line on a production order if the component is listed as a substitute component, rather than the primary component that would normally be used. |

General Filters

General filters are applicable to all of the exceptions.

Field or Control |

Description |

|---|---|

Business Unit |

The system selects only the exceptions for the specified business unit. |

From Item ID and To Item ID |

The system selects only the exceptions with item codes in the specified range. |

From Item Configuration Code and To Item Configuration Code |

A non-active field that is related to a deprecated product. |

Category |

The system selects only the exceptions for items associated with the specified category ID. |

Family |

The system selects only the exceptions for items associated with the specified family. |

Utilization Type |

The system selects only the exceptions for items associated with the utilization type. |

Planner Code |

The system selects only the exceptions for items associated with the specified planner code. |

Customer |

The system includes only those customer orders for the specified customer in the exception count. |

Supplier ID |

The system includes only the purchase transactions for the selected supplier in the exception count. |

From Date and To Date |

The system selects only the exceptions in the specified date range. For effectivity date violations and calendar violations, the system counts the exception if the exception date falls in the date range. For inventory policy violations, the system counts the exception only if the occurrence of the error falls within the date range for the corresponding item. For order sizing violations, the system counts the exception, if the receipt date is in the date range. |

Planned By |

The system selects only the exceptions for items associated with the specified planned-by types. |

Default All |

Click to reset the exceptions filter values to include all of the exception conditions for all of the order types over the widest possible date range. |

Order Type Filters

Select the order types that you want the system to include when checking for exceptions.

Note: Forecasts and extra demand order types are not included here; these order types do not generate types of exceptions.

Field or Control |

Description |

|---|---|

Search |

When you have defined the selection criteria, click to access the Exceptions Summary page, where you can review the results of the search. |

Default All Values |

Click to reset the exceptions filter values to include all of the exception conditions for all of the order types over the widest possible date range. |

Use the Exceptions - Calendar Exceptions page (PL_RVW_EXCP_CAL) to review additional information about the calendar constraints.

Navigation:

Click any link in the Filtered or Total column in the Calendar Exceptions group box on the Exceptions page.

Field or Control |

Description |

|---|---|

Item ID |

Click any value in this column to access the Material Workbench - Summary page, where you can analyze the material plan for the item and resolve item violations manually. |

Order Date/Time |

Displays the ship date or receipt date, depending on the type of exception. |

Order Type |

Displays the type of order with a calendar exception. |

Order ID |

Click any value in this column to access the corresponding Refine Plan Details page for the order type. For example, suppose that the order type is Material Stock Request, you can click the Order ID value to access the Refine Plan - Stock Requests page, where you can maintain information about internal and external demand orders on an inventory business unit, such as planning parameters, dates, and quantities. |

Frozen |

Select to indicate that the status of the order is frozen; the system does not reschedule frozen orders when solving for material plans. |

Priority Rank |

Displays a numeric value ranging from 1 (highest priority) to 999 (lowest priority) used by the planning engine to determine the order in fulfilling the demand. The system reserves 0 as a priority value. |

Destination Unit |

If the order is a transfer order, this column displays the destination business unit. |

Use the Exceptions - Order Sizing Exceptions page (PL_RVW_EXCP_ORDSZ) to review additional information about the order sizing exceptions.

Navigation:

Click any link in the Filtered or Total column in the Order Sizing Exceptions group box on the Exceptions page.

Field or Control |

Description |

|---|---|

Item ID |

Click any value in this column to access the Material Workbench Summary page, where you can analyze the material plan for the item, navigate to the order maintenance page for the corresponding order, and resolve item violations manually. |

Start Date/Time and End Date/Time |

|

Order Type |

Displays the type of supply order. |

Order ID |

Click any value in this column to access the corresponding Refine Plan Details page for the order type. For example, suppose that the order type is Material Stock Request, you can click the order ID value to access the Refine Plan - Stock Requests page, where you can maintain information about internal and external demand orders on an inventory business unit, such as planning parameters, dates, and quantities. |

Frozen |

If selected, indicates that the status of the order is frozen; the system does not reschedule frozen supply orders when solving for material plans. |

Min Order Quantity (minimum order quantity) |

Displays the minimum amount that can be placed on the order. |

Max Order Quantity (maximum order quantity) |

Displays the maximum amount that can be placed on the order. |

Order Multiple |

Displays the multiple that the system uses to determine an order quantity. For example, suppose that you have a demand for 28 and the multiple is 10, then the system generates a planned supply order for 30. |

Use the Exceptions - Effectivity Date Exceptions page (PL_RVW_EXCP_EFFTV) to review additional information about the effectivity date exceptions.

Navigation:

Click any link in the Filtered or Total column in the Effectivity Date Exceptions group box on the Exceptions page.

Field or Control |

Description |

|---|---|

Order Type |

Displays the type of supply order. |

Order ID |

Click any value in this column to access the corresponding Refine Plan Details page for the order type. For example, suppose that the order type is Material Stock Request, you can click the Order ID value to access the Refine Plan - Stock Requests page, where you can maintain information about internal and external demand orders on an inventory business unit, such as planning parameters, dates, and quantities. |

Frozen |

Select to indicate that the status of the order is frozen; the system does not reschedule frozen demand when solving for material plans. |

Start Date/Time and End Date/Time |

|

Item ID |

Click any value in this column to access the Material Workbench - Summary page, where you can analyze the material plan for the item, navigate to the order maintenance page for the corresponding order, and resolve item violations manually. |

BOM Code |

Displays the BOM identifier for the production option. Production options can be predefined or created based on the defaults specified for the item attributes according to unit level. |

Routing Code |

Displays the routing identifier for the production option. If the corresponding item uses lead time instead of production routings, the system does not populate this field with a value. |

Use the Exceptions - General and Policy Exceptions page (PL_RVW_EXCP_INVBOM) to review general and policy violation details.

Navigation:

Click a link in the Filtered or Total column in the General and Policy Exceptions group box on the Exceptions page.

Field or Control |

Description |

|---|---|

Item ID |

Click any value in this column to access the Material Workbench - Summary page, where you can analyze the material plan for the item, navigate to the order maintenance page for the order, and resolve item violations manually. |