Four-Wall Warehousing Functions in a WMS Integration

This section discusses:

Inventory adjustments.

Storage location transfers (inventory status updates).

Physical inventory (stock quantity snapshots).

Four-wall functions are material management activities bounded by the four walls of a specific warehouse, including performing cycle counts and full physical inventory counts, adjusting quantities for specific material storage locations, replenishing fixed picking locations, and making any other stock transfers between material storage locations. In a WMS integration, all four-wall functions are performed in the WMS and then reported to the PeopleSoft system by using EIPs.

Process Flow for Four-Wall Warehousing Functions in a WMS Integration

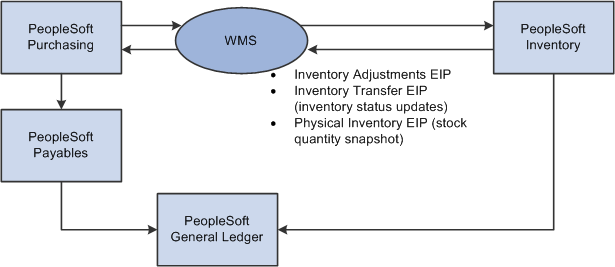

The following diagram shows the process flow for four-wall EIPs in a WMS integration. The WMS performs any wall-to-wall inventory counts or cycle counts and then passes the data to PeopleSoft Inventory using the Physical Inventory service operation. The WMS also performs any warehouse transfers or stock adjustments and passes this information to PeopleSoft using the Inventory Transfer service operation and the Physical Inventory service operation:

The following diagram shows the process flow for four-wall EIPs in a WMS integration.

The EIPs that support the four-wall functions in a WMS integration are based on a number of assumptions. The following sections detail the assumptions for each function.

Inventory quantity adjustment transactions are generated from the WMS using the Inventory Adjustment EIP. The inventory adjustment transaction notifies PeopleSoft Inventory of quantity changes required for defective, found, or lost stock. This transaction is a simple quantity adjustment for an item in a particular material storage location.

Distribution types on the adjustment transaction are used for inventory accounting. Some WMSs have charge codes that match up to the distribution type fields. However, if the WMS charge codes differ from the distribution types established in PeopleSoft Inventory on the Distribution Type page, the WMS charge codes must be converted to match the PeopleSoft distribution types when the transactional data is mapped. If the distribution type field is left blank, the PeopleSoft system uses the default distribution type established for the selected adjustment type on the Default Distribution Type page.

Note: ChartField overrides are not permitted for adjustment transactions.

To notify PeopleSoft Inventory of material transfers between material storage locations, the WMS generates inventory transfer data using the Inventory Transfer EIP. In a typical WMS integration in which quantity balances are tracked only at the business unit level in the PeopleSoft system, the inventory transfer data sent to the PeopleSoft system change the status of the stock to Open or Hold. In PeopleSoft Inventory, two storage locations are defined in the PHYSICAL_INV table: one for quantity with an Open status and another for quantity with a Hold status. Inventory status change transactions originating from the WMS must be translated to map to the EIP by identifying the Open and Hold locations that are used in the PeopleSoft system.

To synchronize quantity balances between the two systems, the WMS uses the Physical Inventory EIP to send PeopleSoft Inventory a stock quantity snapshot transaction that reflects the current stock quantity balances for the business unit. In PeopleSoft Inventory, this data is processed as a physical inventory transaction. You can use the quantity balances in this inbound data to run a reconciliation report and stock quantity update process, just as you would for a cycle or physical count performed for an PeopleSoft Inventory business unit that is not integrated with a WMS.

Because the success of the WMS integration relies on synchronous quantity balances between the two systems, a quantity balance synchronization procedure should be performed as often as feasible.

Synchronizing Quantity Balances

Here are steps for synchronizing quantity balances between PeopleSoft Inventory and a WMS:

In the WMS, perform a counting event and use the Physical Inventory EIP to send PeopleSoft Inventory a transaction that reflects the current quantity count.

A counting event can be for all items in the WMS or for a specific item, lot, or material storage location. Each stock quantity snapshot includes header information for the counting event and lines detailing the count quantity and material storage location information for each item counted. When the data is received, PeopleSoft Inventory loads the counting event data into the electronic data collection transaction tables.

Note: The data sent using the Physical Inventory EIP is used to perform periodic checks of the quantity balance synchronization between the two systems. There is no expectation that an actual cycle count or physical inventory count has occurred in the WMS. The Physical Inventory EIP is not used to communicate quantity balance changes from a physical inventory or cycle counts in the WMS. In these cases, the WMS sends PeopleSoft Inventory an adjustment using the Inventory Adjustments EIP.

Run the Physical Inventory process (INPIPHYS) to move the counting event data to the count table (COUNT_INV) in PeopleSoft Inventory.

Set up run control parameters for the Physical Inventory Load process on the Physical Inventory Process page under the SCM Integrations menu.

Run the Physical Accounting Reconciliation report to detect any discrepancies between the two systems.

Set up run control parameters for the Physical Accounting Reconciliation report on the Reconciliation Report page. If you find a discrepancy and do not want to accept the adjustment, you can use the Item Counts page to change the status of the counting event line to exclude it from the Stock Quantity Update process (INPOPOST).

Run the Stock Quantity Update process to update the quantities in PeopleSoft Inventory.

Set up run control parameters for the Stock Quantity Update process on the Stock Quantity Update Process page.