Understanding the PeopleSoft Supply Chain Management Integration with the Supply Chain Business Modeler

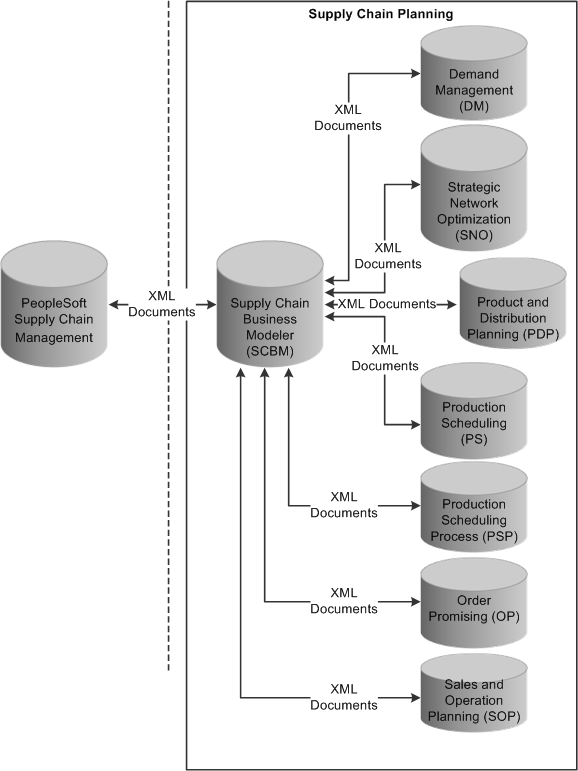

This diagram illustrates the integration between PeopleSoft Supply Chain Management and the Supply Chain Business Modeler. PeopleSoft Supply Chain Management integrates with the Supply Chain Business Modeler (a part of Supply Chain Planning) by passing a wide range of supply chain data to the Supply Chain Business Modeler in the form of XML documents:

Supply Chain Business Modeler

The data that is passed through the XML documents is not planning-model specific but rather a base representation of data that will be used by various planning models. The Supply Chain Business Modeler is a central planning data repository for the Supply Chain Planning Products (Demand Management (DM), Strategic Network Optimization (SNO), Production and Distribution Planning (PDP), Production Scheduling (PS), Production and Scheduling Process (PSP), Order Promising (OP), and Sales and Operation Planning (SOP).

Once the supply chain management data resides within the Supply Chain Business Modeler it is then used to build tactical, operational, or strategic planning models and model partitions. The model partitions are used to generate data needed for specific Supply Chain Planning products. After the Supply Chain Planning products are done with their analysis they then pass their individual information (plans) back to the Supply Chain Business Modeler.

At that point, once again PeopleSoft Supply Chain Management integrates with the Supply Chain Business Modeler by importing that planning data back into PeopleSoft Supply Chain Management and acting upon the recommendations from the planning products.

PeopleSoft Predefined XML Documents

PeopleSoft provides the following predefined XML documents for exporting data from PeopleSoft Supply Chain Management to Supply Chain Business Modeler:

|

XML Document |

Associated Data |

|---|---|

|

Configuration |

Model parameters |

|

Calendar |

Calendar |

|

Base |

|

|

Distribution |

|

|

Supplier |

|

|

Customer |

Customer |

|

Manufacturing |

|

|

Forecasts |

|

|

Sales Orders |

|

|

Sales Order History |

Sales Order History |

|

Transfer Orders |

|

|

Beginning Inventory |

Beginning Inventory |

|

Work Orders |

|

|

Purchase Orders |

|

|

Safety Parameters |

Safety Parameters |

|

Inventory Safety Targets |

Inventory Safety Targets |

PeopleSoft provides the following predefined XML documents for import data from Supply Chain Business Modeler:

|

XML Document |

Associated Data |

|---|---|

|

Purchase Order |

Information for the XML document is extracted from the Supply Chain Business Modeler. Data in this document is used to establish a picture of existing purchase orders sent to the Supply Chain Business Modeler. This picture of the existing orders will be used to populate original order data in the planning instance tables and also be used to identify orders that will be marked as canceled as a result of the optimized plan. Any order sent into the Supply Chain Business Modeler but not received back on a purchase order recommendation out of the Supply Chain Business Modeler will assumed to be canceled. |

|

Transfer Orders |

Information for the XML document is extracted from the Supply Chain Business Modeler. Data in this document is used to establish a picture of existing transfer orders sent to the Supply Chain Business Modeler. This picture of the existing orders will be used to populate original order data in the planning instance and also identify orders that will be marked as canceled as a result of the optimized plan. Any order sent into the Supply Chain Business Modeler but not received back on a net deployment out of the Supply Chain Business Modeler will assumed to be canceled. |

|

Work Orders |

Information for the XML document is extracted from the Supply Chain Business Modeler. Data in this document is used to establish a picture of existing production orders sent to the Supply Chain Business Modeler. This picture of the existing orders will be used to populate original order data in the planning instance and also identify orders that will be marked as canceled as a result of the optimized plan. Any order sent into the Supply Chain Business Modeler but not received back on either a net production requirement or a production schedule out of the Supply Chain Business Modeler will assumed to be canceled. |

|

Enterprise Forecast |

The Enterprise Forecast XML document contains forecast information that was generated by Demand Management (DM). Only inventoried items are sent to the Supply Chain Business Modeler as a part of the standard integration so it is assumed that only Inventory Item forecast will be received out of the Supply Chain Business Modeler. |

|

Net Deployment Requirements |

The Net Deployment Requirements XML document contains information about inventory transfers between two business units and represents results out of the Production and Distribution Planning (PDP). Details for net deployments may contain data for existing transfers as well as new inter unit transfer requirements. |

|

Net Production Requirements |

The Net Production Requirements XML document contains information about production requirements for an item at a given branch and represents the results out of the Production and Distribution Planning (PDP). Details for net production requirements may contain data for existing production as well as new production requirements. |

|

Production Schedules |

The Production Schedule XML document contains detailed production information including specific operations, resources, and material to use in the manufacturing process. Production schedule information can be produced by Production and Distribution Planning and production schedule information can also be produced by Production Scheduling (PS) and Production Scheduling Process (PSP). Production Schedules may contain both existing and new production. |

|

Purchase Order Recommendations |

The purchase order recommendations XML document contains information regarding purchases that need to be made based on predefined supplier/item relationships. Purchase order recommendations can be produced by Production and Distribution Planning. The information may contain both new and existing purchase orders. |