Performing Crew Capacity Planning

This section presents an overview of crew capacity planning and discusses how to plan crew capacity and create a crew capacity chart.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

WM_CREW_CAPACITY |

Define and update a crew capacity plan. |

PeopleSoft Maintenance Management enables craft supervisors to plan crew capacity for a future scheduling period. They select a crew associated with a business unit and shop, select a future period, and the system calculates total values for the base capacity and adjusted capacity for the crew. The craft supervisor modifies the adjusted capacity values for each craft based on their personal experience and knowledge, which updates the totals. When a scheduler schedules a crew to one or more work orders on the Crew Scheduling Workbench, the crew capacity plan for that crew is updated based on the new crew assignments.

To determine crew capacity, you must set up a schedule pattern and generate schedule periods based on this pattern. Once a crew capacity is tied to the pattern, the user can add new periods with the initial period start date. Typically, the craft supervisor updates each resource's schedule with meetings, appointments, vacation, and more. The system acknowledges these commitments when determining crew availability and capacity. The accuracy of the crew availability and capacity depends upon whether you maintain each resource's calendar and routinely update the resource availability cache record.

Effective dates are important in determining crew capacity. Each resource is assigned to a shop as of an effective date. The crew definition is effective-dated, the shop is effective-dated, and the schedule pattern set up for the crew is based on a date range. If you create a resource on a date falling after the effective date of the crew, the system adds the resource to the shop but it will not add the resource to the crew. For example, if the effective date on the Define Crew page is 3/04/06 and you create an additional resource and associate it with the shop on 3/5/06, then you cannot add this resource to the crew without changing either the effective date of the crew or the effective date of resource's association with the shop.

You create a crew capacity plan for a crew based on a specific schedule period, which is generated from the crew's schedule pattern. The schedule pattern defined in the Crew Definition component is effective-dated, which means that the schedule pattern of a crew might change over time. Therefore, when adding a new crew capacity plan, the system must ensure that only valid schedule periods are used to create the new crew capacity plans. Valid schedule periods are the current and future periods that are valid for the crew schedule pattern as of the start date of the period. When you create a new crew capacity plan, the system calculates specific plan elements, which include:

Base capacity

Base capacity is the crew's calculated total available hours based on the crew resources' weekly shift hours and their capacity allocation percentages in that crew. A crew's total base capacity in hours is the sum of the base capacity calculation for each craft, which appears on the Crew Craft Capacity - Details tab of the Crew Capacity page.

Base Capacity (hours) = Total hours in a crew member's assigned shift * Crew member's capacity %

You assign a capacity percentage to each crew member on the Define Crew page. This percentage represents the time allocated for each crew member to work on a specific crew.

Note: The base capacity does not take holidays into account. For example, the base capacity of the resource for the week of July 4 holiday (07/02/06 through 07/08/06) will be 40 hours, assuming an 8-hour day, Monday through Friday shift. The base capacity will not consider 07/04/06 as a holiday.

This table describes John Clark's time allocation to different crews:

Shop

Crew

Capacity %

Shop A

Crew 1

25

Shop B

Crew 2

25

Shop A

Crew 3

50

Crew members must be listed as resources in the shop associated with their crew. Each resource assigned to a shop is associated with a shift, as shown by this table:

Crew Member/Craft

Shift

% Capacity for Crew 1

Biweekly Base Capacity (hours)

Total Base Capacity/Craft (hours)

#1

Electrician

L1 = 8 hour/day, 5 days/week, 40 hours/week.

100

80.00

80.00

#2

Electrician

L1 = 8 hour/day, 5 days/week, 40.00 hours/week.

50

40.00

120.00

#3

Mechanic

L1 = 8 hour/day, 5 days/week, 40 hours/week.

100

80.00

80.00

Crew 1 Total Base Capacity

200.00

Adjusted capacity (hours, days, headcount)

Adjusted capacity = Base capacity – All commitments (meetings and so on) on the resource's calendar.

The system initially calculates the adjusted capacity for each craft in hours, days, and head count.

The total adjusted capacity amounts that appear for the crew equal the sum of the craft values.

Schedulers can adjust the values in adjusted capacity fields for each craft based on their knowledge of any external circumstances affecting each crew member. The system recalculates total adjustment values for the crew based on any changes to these values that the scheduler enters.

The accuracy of these calculations depends on the timely management of a resources schedule, as well as the timeliness of the PeopleSoft Resource Management Availability Cache Record.

Note: The adjusted capacity takes holidays into account as long as the cache record is updated correctly based on the setup for scheduled holidays. For example, the adjusted capacity of the resource for the week of the July 4 holiday (07/02/06 through 07/08/06) will be 32 hours, assuming an 8-hour day, Monday through Friday shift. The adjusted capacity will consider 07/04/06 as a holiday, as long as the cache is updated.

Adjusted capacity (hours)

Adjusted capacity (hours) = Base capacity – Assigned hours for meetings, appointments, and more in a resource's schedule during the designated period

Adjusted capacity (hours) initially appeared on the Crew Craft Capacity - Details tab.

For example:

The resource schedule for crew member #1 in the previous example indicated one day (8 hours) for vacation, and no additional assignments were scheduled for crew member #2.

The adjusted capacity in hours for the craft Electrician is 120.00 hours – 8.00 hours = 112.00 hours.

Crew member #3 has a 4-hour appointment scheduled.

The adjusted capacity in hours for the craft Mechanic is 80.00 hours – 4.00 hours = 76.00 hours.

The total adjusted capacity in hours for the entire crew equals the adjusted capacity hours for Electricians (112.00 hours) + the adjusted capacity hours for Mechanics (76.00 hours) = 188.00 hours.

Adjusted capacity (days)

The adjusted capacity in days for each craft is the adjusted capacity in hours divided by the standard hours per workday as defined in the shop.

For example:

The adjusted capacity in days for an Electrician = 112.00 (the adjusted capacity in hours) / 8.00 hours (the standard hours per workday defined in shop) = 14.00 days for Electricians.

Mechanics = 76.00 hours / 8.00 hours = 9.50 days

The total adjusted capacity in days for the crew is Electrician (14.00 days) + Mechanic (9.50 days) = 23.50 days.

Adjusted capacity (head count)

The adjusted capacity based on headcount equals the craft's adjusted capacity days divided by the number of work days in the scheduled period.

For example:

For an Electrician, 14.00 days (adjusted capacity days for an Electrician) / 14.00 days (the number of work days in the schedule period) = 1.00 Adjusted capacity headcount for an Electrician.

For a Mechanic = 9.50 days / 14.00 days = .68 Adjusted headcount for a Mechanic.

The total adjusted capacity based on headcount for the crew is Craft 1 (Electrician) headcount (1.00) + Craft 2 (Mechanic) headcount (.68) = 1.68 headcount total adjusted capacity for the crew.

Total cost

Total cost for each craft = Adjusted capacity in hours * Hourly cost rate.

The default hourly cost rate on the Crew Craft Capacity - Potential Cost Revenue tab is derived first from an hourly cost rate set up for the craft entered on the Craft Rates page of the Shop, or the value is derived from the generic labor cost rate specified in the shop or work order business unit.

For example:

The total cost for Electricians = 112.00 (The adjusted capacity in hours) * 150.00 USD Hourly cost rate) = 16,800.00 USD

Because the rate for Mechanics is not specified on the Craft Rates page of the shop: 76.00 hours. (Adjusted capacity in hours) * 100.00 USD (The default labor cost rate from the business unit) = 7,600.00 USD total cost for Mechanics.

Total cost is the sum of each craft's total cost or 16,800.00 USD + 7,600.00 USD = 24,400.00 USD

Total potential revenue

Total potential revenue for each craft = Adjusted capacity in hours * Hourly bill rate)

The default hourly bill rate on the Crew Craft Capacity - Potential Cost Revenue tab is derived first from an hourly bill rate set up for the craft entered on the Craft Rates page of the Shop, or the value is derived from the generic labor bill rate specified in the shop or work order business unit. Total potential revenue for each craft is equal to the adjusted capacity in hours (112.00, Electricians) * Hourly bill rate (200.00 USD) = 22,400.00 USD. * Default labor bill rate from the business unit (110.00 USD) = 8,360.00 USD.

For Electricians, the total potential revenue = 112.00 hours. (The adjusted capacity in hours) * 200.00 USD (The hourly bill rate) = 22,400.00 USD total potential revenue for Electricians.

Because the rate for Mechanics is not specified on the Craft Rates page of the shop, the default bill rate from the business unit is used: 76.00 hours. (The adjusted capacity in hours) * 110.00 USD (The default bill rate) = 8,360.00 USD total potential revenue for Mechanics.

The total potential revenue is the sum of each craft's total potential revenue: 22,400.00 USD (Electricians) + 8,360.00 USD (Mechanics) = 30,760.00 USD

Total workdays

Total workdays equal the total number of days the shop is open based on the schedule period. For example, if the schedule period is weekly and the standard operating hours of the shop as defined on the Shop Definition page indicate that the shop is open on Monday for 8 hours, Tuesday for 8 hours, and Wednesday for 4 hours, then the Total Workdays equals 3 days for the weekly schedule period. Even though the shop is only open for 4 hours on Wednesday, it is counted as one workday.

Average target load percentage

This figure is the weighted average of the target load percentage of each craft associated with the crew. The target load percentage for a craft is determined by the scheduler based on the scheduler's knowledge of any unscheduled or emergency works that might come in during the scheduling period. After the initial creation of a crew capacity plan, the scheduler can enter a target load percentage for each craft, which is used to calculate the target hours for each craft.

For a craft: Target load % * Adjusted capacity in hours = Craft's target hours.

For example:

A scheduler enters a target load percentage of 10.00, the target hours will equal to 11.20 hours, then 10.00% * 112.00 hours (Adjusted capacity in hours for Electricians) = 11.20 target hours for Electricians.

This table shows how the average target load percentage is calculated:

Craft

Qty Resources

Target Load %

Qty * Target Load %

Average Target Load % = SUM of (Qty * Target Load %) / Total Qty Resources

Electrician

2

95.00

2 * .95 = 1.90

Plumber

1

100.00

1 * 1.00 = 1.00

Carpenter

5

80.00

5 * .80 = 4.00

SUM:(1.90 + 1.00 + 4.00)/ 8 = 86.3% Average Target Load %

You can add crafts that are not part of a crew to a crew capacity plan, and you do not have to add these crafts to the crew. You also can copy from an existing crew capacity plan.

The confirmed scheduled hours and the total scheduled hours for a crew capacity plan are automatically updated when you assign and confirm the work order task requirements against the capacity plan in the Crew Scheduling Workbench by using the Confirm Metrics action.

Note: You can add or remove crew members regardless of whether or not a crew capacity plan exists. To add a crew member, insert a new effective-dated row on the Define Crew page.

Copying a Crew Capacity Plan

The system does not allow overlapping crew capacity plans where the start period date for a new crew capacity plan falls within the period range of an existing crew capacity plan. However, users can copy a crew capacity plan from the current period to a future period. Because the crew is effective-dated and can change from one period to another, the system asks if you want to override the current capacity plan. If you indicate that you do want to override the crew capacity plan, the process will replace the capacity plan for each matched craft, but it will not change the target quantity and base capacity amounts. If the source capacity plan does not have a match for a given craft and the craft is not a crew craft, the system will insert the non-matching, non-crew craft to the target capacity plan.

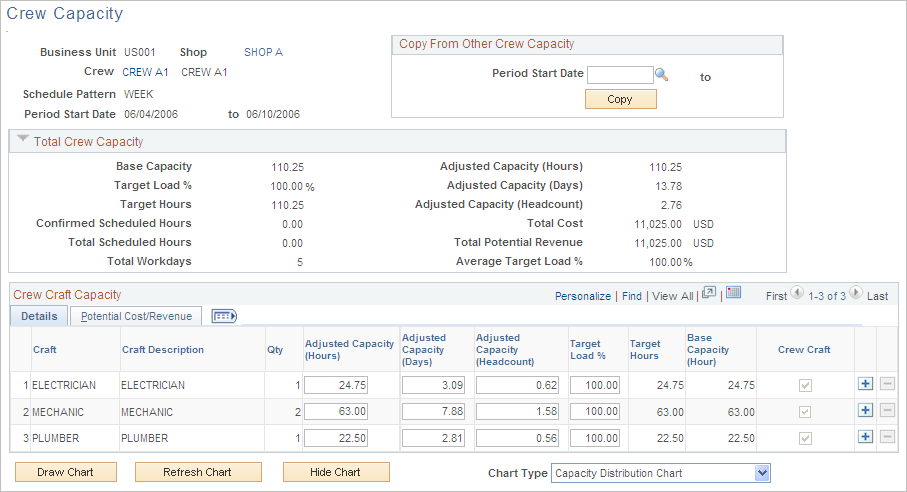

Use the Crew Capacity page (WM_CREW_CAPACITY) to define and update a crew capacity plan.

Navigation:

This example illustrates the fields and controls on the Crew Capacity page. You can find definitions for the fields and controls later on this page.

Note: To create a crew capacity plan, select a work order business unit, shop, crew, and a period start date on the Add a New Value page.

Field or Control |

Description |

|---|---|

Shop |

Click the shop name link to access the Define Shop component for this shop. |

Crew |

Click the crew name link to access the Define Crew component for this crew. |

Total Crew Capacity

Field or Control |

Description |

|---|---|

Base Capacity |

Displays the total resource base capacity for the crew, which is derived from the hours in each resource's shift times the total capacity percentage of each resource assigned to this crew on the Define Crew page. Note: If the crew resources are associated with different shifts, the system calculates this value based on the different shifts. |

Adjusted Capacity (Hours) |

Displays the total adjusted capacity in hours for the entire crew. Total Adjusted Capacity = (Base capacity – All commitments) * Capacity allocation percentage of the each resource in the crew. This value cannot be negative. If a negative value is calculated, the system enters zero as the value. Schedulers can modify this value manually for each craft based on their knowledge of the technician's working hours for the period. Modify this value on the Details tab. Note: The accuracy of this calculation depends on the calendar entries of the resources for the specified schedule period and the currency of the resource management availability cache record. |

Target Load % (target load percentage [total crew]) |

Displays total target load percentage value for the crew (calculated at the crew level) = Total target hours / Total adjusted capacity hours Total load % = Total target hours / Total adjusted capacity hours. |

Adjusted Capacity (Days) |

Displays the total adjusted capacity in days for the crew. Total adjusted capacity days = Total adjusted capacity hours / standard hours per workday defined on the Shop Definition page. |

Target Hours |

Displays the total target available hours for the crew for the schedule period. Total target hours for the crew = Total target load percentage * Total adjusted capacity hours. Note: This value is used to schedule a crew. |

Adjusted Capacity (Headcount) |

Displays the total adjusted capacity in headcount for the crew. Total adjusted capacity headcount for the crew = Total adjusted capacity days / Total workdays in the schedule period. Note: The total workdays for a schedule period is based on the operating hours of the crew shop. |

Confirmed Scheduled Hours |

Displays the total confirmed number of hours scheduled for the crew on the Crew Scheduling Workbench, which means that the Confirm Metrics action was performed against the crew schedules. |

Total Cost |

Displays the total cost for the crew. Total cost for the crew = Sum of the hourly cost rate for each craft * Total adjusted capacity hours for each craft |

Total Scheduled Hours |

Displays the total number of scheduled hours of all of the crafts listed for the crew. This value is updated when you assign a work order task requirement to a crew for the schedule period on the Crew Scheduling Workbench, or when you change the period on the Crew Scheduling Workbench and save the page. |

Total Potential Revenue |

Displays a value, which is derived by multiplying the hourly bill rate for each craft times the adjusted capacity (hours) for each craft. This value equals the potential revenue for each craft. Add these figures together to obtain the total potential revenue for the crew. |

Total Workdays |

Displays total number of workdays, which is derived from the total number of workdays in the shift associated with the shop based on the schedule period. For example: If the schedule period is biweekly and the shift associated with the shop is 8 hours per day, 5 days per week, then the total workdays for this crew is 10. |

Average Target Load % (average target load percentage) |

Displays a weighted average of the target load percentage. Average Target Load % = SUM (Number of resources in each craft) * Target Load % of the craft) / Total number of resources in the crew capacity plan |

Copy from Other Crew Capacity

Select the Copy From Other Crew Capacity group box.

The Copy button does not appear once the work is scheduled for this crew capacity plan. To copy this source crew capacity plan to a target crew capacity plan, select:

Field or Control |

Description |

|---|---|

Period Start Date |

Select or enter the start date for the future period for the target crew capacity plan. |

Copy |

Click the Copy button to display a page containing this message: Would you like the system to override the current capacity plan? The system will copy each craft to the target capacity plan that matches a craft on the source capacity plan. However, it does not copy the quantity and the base capacity fields of the source capacity plan. If the system does not find a match for a source capacity plan craft in the target capacity plan and if the craft is not associated with a crew, then the system will insert the craft into the target capacity plan. If the non-matching craft is a crew craft, it will not be added to the target capacity plan. If the quantity of the target capacity plan is equal to the quantity of the source capacity plan for the crew's craft, the adjusted capacity value on the target capacity plan will be set to the adjusted capacity value on the source capacity plan. If these values are not equal, then the system will not change the adjusted capacity value in the target capacity plan. Click:

|

Crew Craft Capacity Details

Access the Crew Craft Capacity - Details tab.

Field or Control |

Description |

|---|---|

Craft |

Displays one or more crafts based on the list of crafts associated with each resource on the Define Crew page. |

Qty (quantity) |

Displays the number of resources on the Define Crew page associated with a craft. |

Adjusted Capacity (Hours) |

Displays the adjusted capacity hours for the total number of resources in a craft. Adjusted Capacity hours (craft) = Base capacity for total number of craft resources – All commitments * Capacity allocation percentage of the craft resources Schedulers can modify this value manually based on their knowledge of the technician's working hours for that period. This adjustment is reflected in the total Adjusted Capacity (Hours) field in the Total Crew Capacity group box. Note: The accuracy of this calculation is determined by the calendar entries of the resources for the specified schedule period and the currency of the Resource Management Availability Cache Record. |

Adjusted Capacity (Days) |

Displays the adjusted capacity in days for a craft. Adjusted Capacity (Days) for a craft = Adjusted capacity hours / Standard Hours per Day (Shop Definition) A scheduler can adjust this value. This figure changes when the scheduler adjusts the adjusted capacity (hours) value. Note: Adjustments to one value automatically adjusts the values in the other fields. |

Adjusted Capacity (Headcount) |

Displays the adjusted capacity headcount for a craft. Adjusted capacity headcount for each craft = The adjusted capacity (days) / The total number of workdays based on the schedule period and the shop's operating hours A scheduler can adjust this value. This value changes if the adjusted capacity (hours or days) value changes. |

Target Load % (target load percentage) |

Enter the workload percentage for this crew taking into account any unscheduled or emergency work that might come up during this schedule period. This percentage is used to calculate the target hours for this craft. |

Target Hours |

Displays the target hours for each craft. Target hours for each craft = Target load percentage for the craft * Adjusted capacity hours for the craft |

Base Capacity (Hours) |

Displays the base capacity hours for each craft. Base capacity hours for each craft = SUM of the resource's weekly shift hours * Capacity percentage specified for the resource on the Define Crew page |

Crew Craft |

A check mark appears in the check box as display only if the listed craft is associated with this crew. Note: The system selects and deselects this check box depending on whether you associate a craft with a crew. |

Crew Craft Capacity Potential Cost Revenue

Select the Crew Craft Capacity - Potential Cost Revenue tab in the Crew Capacity component.

Field or Control |

Description |

|---|---|

Hourly Cost Rate |

Displays the hourly cost rate for a craft if it is specified on the shop's Craft Rates page. If the crew capacity plan has more than one craft and if one or more of the crafts does not have a cost and bill rate specified on the Craft Rates page of the shop, then the rate is derived either from the shop or the work order business unit, depending on the setup. |

Hourly Bill Rate |

Displays the hourly bill rate for a craft if it is specified on the shop's Craft Rates page. If the crew capacity plan has more than one craft and if one or more of the crafts does not have a cost and bill rate specified on the Craft Rates page of the shop, then the rate is derived either from the shop or the work order business unit depending on the setup. |

Total Cost |

Displays a value that equals the adjusted capacity (hours) for the craft multiplied by the hourly cost rate. |

Total Potential Revenue |

Displays a value that equals the adjusted capacity (hours) for the craft multiplied by the hourly bill rate. |

Currency Code |

Displays the default value derived from the work order business unit. |

Use the Crew Capacity page (WM_CREW_CAPACITY) to define and update a crew capacity plan.

Navigation:

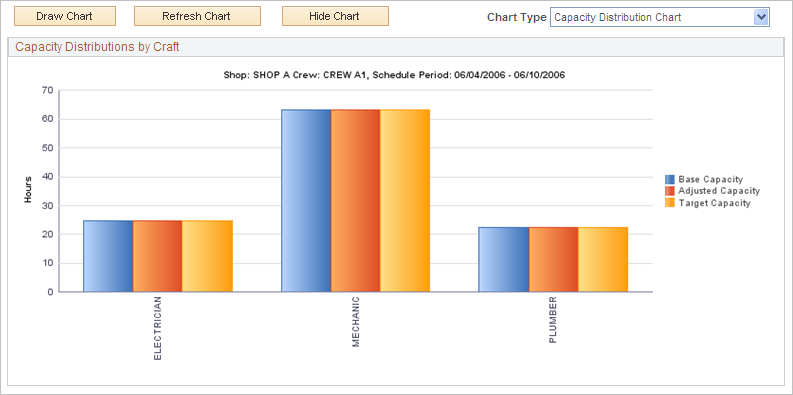

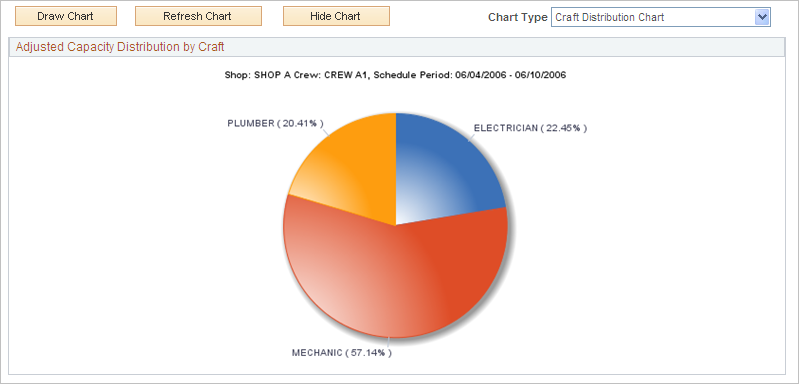

This example illustrates the fields and controls on the Crew Capacity page (1 of 2). You can find definitions for the fields and controls later on this page.

This example illustrates the fields and controls on the Crew Capacity page (2 of 2). You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Draw Chart |

Click this button to display the crew capacity chart based on the crew capacity data for the schedule period. The system saves the page before displaying the chart. |

Refresh Chart |

Click this button to refresh the crew capacity chart based on changes that you made to the crew capacity data. |

Hide Chart |

Click this button so that the chart is not visible on the page. |

Chart Type |

Select the type of chart that you want to appear. Chart types are:

|