Checking Item Availability

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

ATP_SUMMARY_INV |

Check the current and projected future quantity available for an item or product. |

|

|

ATP_SRCH_INV |

Enter parameters for an availability check. |

|

|

ATP_DETAIL_INV |

View detailed demand and supply information used to calculate the item's availability. In situations of short supply, use the page to identify orders in danger of missing their scheduled ship dates. |

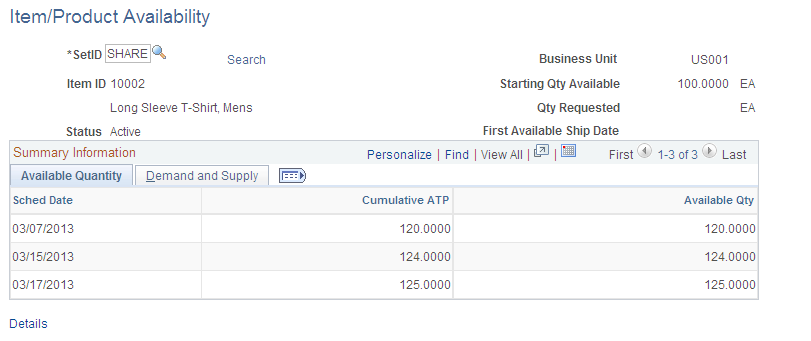

Use the Item/Product Availability page (ATP_SUMMARY_INV) to check the current and projected future quantity available for an item or product.

Navigation:

This example illustrates the fields and controls on the Item/Product Availability page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Starting Qty Available (starting quantity available) |

Calculated using options selected on the Availability Inquiry Selection page. If the Incl WIP in Starting Qty option is not selected, the starting quantity available equals the quantity available of the item at the business-unit level (BU_ITEMS_INV.QTY_AVAILABLE). If the Incl WIP in Starting Qty option is selected, the starting quantity available equals the quantity available of the item at the business-unit level (BU_ITEMS_INV.QTY_AVAILABLE), plus the quantity in WIP storage locations. The WIP quantity is calculated by summing the quantity in all WIP storage locations with an inventory status of Open or an inventory status of Hold or Restricted in a business unit for which the Incl Non-Open in Avail option is selected. |

First Available Ship Date |

The first day on which cumulative ATP is greater than or equal to the quantity requested and on which the date is a valid shipping day based on the business unit calendar. If no date meets these criteria, a message indicates that there is no valid ship date with sufficient quantity to fulfill the requested quantity. Note: If you do not request a quantity on the Availability Inquiry Selection page, the system cannot calculate the first available ship date. In this case, no value appears in either the Qty Requested (quantity requested) or the First Available Ship Date fields. |

Sched Date (schedule date) |

The scheduled date for which orders for expected supply and demand have been summarized. The earliest schedule date is the current date. All supply or demand order lines with schedule dates before the current date are included in the schedule date equal to the current date. The first date listed in the Summary Information grid is always the current date, even if there is no scheduled demand or supply for the current date. |

Cumulative ATP (cumulative available to promise) |

Indicates the cumulative ATP quantity calculated for each schedule date. |

Available Qty (available quantity) |

The running total of the available quantity for each schedule date. The quantity listed as the starting quantity available is used as a starting point. Note: Because quantity in WIP locations is reserved, it is not included in the starting quantity available, unless you select Incl WIP in Starting Qty. |

WIP Available Qty (work-in-process available quantity) |

If you select the Dependent Demand option but not the Incl WIP in Starting Qty option on the Availability Inquiry Selection page, the system subtracts the quantity representing demand due to a production order from the WIP quantity. Once this value reaches 0, dependent demand is fulfilled by the available quantity. This column does not appear if the Dependent Demand option is not selected or the Incl WIP in Starting Qty option is selected. |

Total Demand Qty (total demand quantity) |

The total demand for the schedule date. This field appears if the Dependent Demand option is not selected on the Availability Inquiry Selection page and represents finished good demand (demand from sales orders and other stock requests). If the Dependent Demand option is selected, the Finished Good Demand Qty (finished good demand quantity) and the Dependent Demand Qty (dependent demand quantity) columns replace this one. |

Finished Good Demand Qty (finished good demand quantity) |

If you selected the Dependent Demand option on the Availability Inquiry Selection page, this column tracks the demand quantity for order lines representing total demand from sales orders and other stock requests but not from production orders. In this case, the Total Demand Qty (total demand quantity) column does not appear. |

Dependent Demand Qty (dependent demand quantity) |

If you selected the Dependent Demand option on the Availability Inquiry Selection page, this column summarizes by schedule date the total dependent demand due to a production order. In this case, the Total Demand Qty (total demand quantity) column does not appear. |

Total Supply Qty (total supply quantity) |

Summarizes the expected supply by schedule date. |

Details |

Click to access the Availability Detail page, where you can view detailed demand and supply information. |

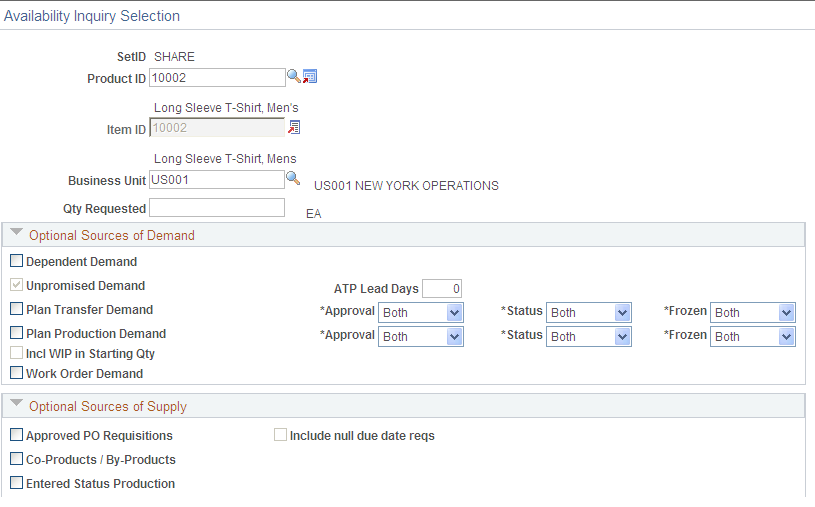

Use the Availability Inquiry Selection page (ATP_SRCH_INV) to enter parameters for an availability check.

Navigation:

Click the Search link on the Item/Product Availability page.

This example illustrates the fields and controls on the Available Inquiry Selection page. You can find definitions for the fields and controls later on this page.

If you do not enter a product ID, you must enter an item ID. You can click the Transfer button next to the Item ID field to access a transfer page of item-related links.

Field or Control |

Description |

|---|---|

Qty Requested (quantity requested) |

Enter a value to use in determining the first available ship date. The value must be in the item's standard UOM. |

Optional Sources of Demand

Select the options in this group box to add additional sources of demand when calculating item availability. The default values come from the Setup Fulfillment- ATP Reservations page.

Field or Control |

Description |

|---|---|

Dependent Demand |

If PeopleSoft Manufacturing is installed, select this check box to include the demand for an item that is sold as part of an assembly in the demand side of the item availability calculation. Dependent demand is derived from the bills of material associated with production orders that are firm, released, or in process. Note: When dependent demand is included in the item availability calculations, it is treated as promised demand. |

Unpromised Demand |

For ATP-reserved items, you can include unpromised demand order lines staged for fulfillment processing in the IN_DEMAND table as a source of demand in the ATP and availability calculation. If the product or item is not an ATP-reserved item, this option is selected by default and cannot be changed. |

ATP Lead Days |

If you select the Unpromised Demand option, you can specify how far in the future to look for unpromised order lines. Unpromised demand lines with schedule dates that fall on or between the current date and the current date, plus the ATP lead days are counted as demand in the ATP and availability calculations. Enter 999 to include all unpromised demand staged in the order fulfillment table (IN_DEMAND) in PeopleSoft Inventory regardless of schedule date. |

Plan Transfer Demand |

If PeopleSoft Supply Planning is installed, select this check box to include planned transfers in the demand side of the item availability calculation. Define which planned transfers should be included based on the Approval, Status (planned, firm planned, or both), and Frozen fields in this row. |

Plan Production Demand |

If PeopleSoft Supply Planning is installed, select this check box to include planned production in the demand side of the item availability calculation. Define which planned production should be included based on the Approval, Status (planned, firm planned, or both), and Frozen fields in this row. |

Incl WIP in Starting Qty (include work-in-process in starting quantity) |

Select if item quantities in WIP storage locations should be considered in the item availability calculation; that is, if item quantities in WIP storage locations is available to fulfill finished good demand. This check box applies to both Dependent Demand and Planned Production Demand. |

Work Order Demand |

If PeopleSoft Maintenance Management is installed, select this check box to include work orders in the demand side of the item availability calculation. |

Optional Sources of Supply

Select the options in this group box to add additional sources of demand when calculating item availability. The default values come from the Setup Fulfillment- ATP Reservations page.

Field or Control |

Description |

|---|---|

Approved PO Requisitions (approved purchase order requisitions) |

If PeopleSoft Purchasing is installed, select this check box to include approved requisitions in the supply side of the item availability calculation. Only approved requisitions that specify the PeopleSoft Inventory business unit and a due date are counted. |

Co-Products/By-Products |

If PeopleSoft Manufacturing or PeopleSoft Supply Planning are installed, select this check box to include co-products and by-products in the supply side of the calculation. This includes both production and planned production as sources of supply.

Waste by-products are always excluded. |

Entered Status Production |

If PeopleSoft Manufacturing is installed, select this check box to include production orders in the Entered status in the supply side of the calculation. |

Plan Purchase Orders |

If PeopleSoft Supply Planning is installed, select this check box to include planned purchase orders in the supply side of the calculation. Define which planned purchase orders should be included based on the Approval, Status (planned, firm planned, or both), and Frozen fields in this row. |

Plan Transfer Supply |

If PeopleSoft Supply Planning is installed, select this check box to include planned transfer orders in the supply side of the calculation. Define which planned transfers should be included based on the Approval, Status (planned, firm planned, or both), and Frozen fields in this row. |

Plan Production Supply |

If PeopleSoft Supply Planning is installed, select this check box to include planned production orders in the supply side of the calculation. Define which planned production should be included based on the Approval, Status (planned, firm planned, or both), and Frozen fields in this row. |

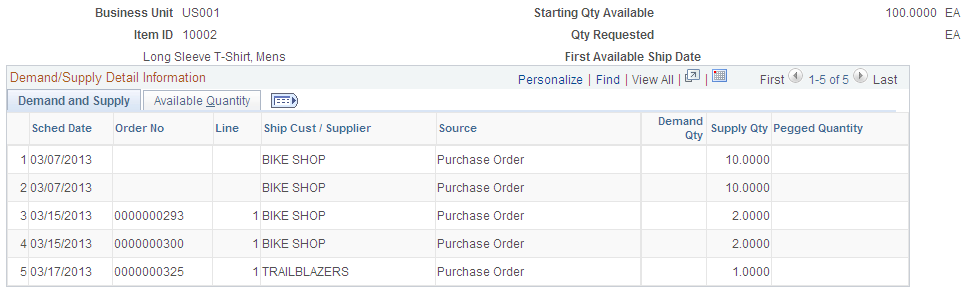

Use the Availability Detail page (ATP_DETAIL_INV) to view detailed demand and supply information used to calculate the item's availability.

In situations of short supply, use the page to identify orders in danger of missing their scheduled ship dates.

Navigation:

Click the Detail link on the Item/Product Availability page.

This example illustrates the fields and controls on the Availability Detail page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Sched Date (schedule date) |

The date the item or product is to be issued from the business unit (for demand) or is to arrive at the business unit (for supply). |

Order No (order number) |

The sales order number in PeopleSoft Order Management, the material stock request in PeopleSoft Inventory, the purchase order or requisition number in PeopleSoft Purchasing, or the production ID for production orders in PeopleSoft Manufacturing. |

Line |

The order line number for the sales order, material stock request, purchase order, or requisition. |

Ship Cust/Vendor (ship to customer/vendor) |

For demand, this field indicates the customer, internal department, or business unit that requested the order, if applicable. For supply, this field indicates the vendor that is fulfilling the order or the business unit that requested the order, if applicable. |

Source |

The demand source for both demand and supply orders. Returns are not counted as supply. |

Demand Qty (demand quantity) |

The amount to be shipped or issued from the business unit in the item's standard UOM. This amount is subtracted from the available quantity. |

Supply Qty (supply quantity) |

The amount scheduled to arrive at the business unit in the item's standard UOM. This quantity is added to the available quantity. |

Available Qty (available quantity) |

The running total of the available quantity for each schedule date. The quantity listed in the Starting Qty Available field is the starting point. A negative available quantity for a finished good demand line (that is, a sales order or material stock request line) indicates that the order is in danger of missing its scheduled ship date. Note: Because quantity in WIP locations is reserved, it is not included in the starting quantity available, unless you select the Incl WIP in Starting Qty option. |

Pegged Quantity |

The amount pegged to demand for the business unit, in the item's standard UOM. This quantity is subtracted from the available quantity. |

WIP Available Qty (work-in-process available quantity) |

If you select the Dependent Demand option, but not the Incl WIP in Starting Qty option on the Availability Inquiry Selection page, this column displays the running balance of WIP quantity; once this value reaches 0, dependent demand is fulfilled by the available quantity. |