Integrating Work Orders with a Mobile Device

This topic discusses:

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

Service Operations-General Page |

IB_SERVICE |

Displays a service operation. The synchronous INVENTORY_WO_ISSUES service operation is used for inventory work order issue transactions between PeopleSoft and a mobile device. This service operation invokes the IN_WO_ISSUES_CI component interface. For additional information, see the PeopleTools : PeopleSoft Integration Broker, Creating Component Interface-Based Services topic, Understanding Creating Component Interface-Based Services section. |

|

IB_MESSAGE_BUILDER |

View the fields to be used by the service operation within PeopleSoft Integration Broker. In order to correctly populate the incoming data, review the message definition. |

|

|

CI-Based Services- Review Status Page |

IB_CISERVICES |

Select the IN_WO_ISSUES_CI component interface to expose as a web service. For additional information, see the PeopleTools : PeopleSoft Integration Broker, Creating Component Interface-Based Services topic, Selecting Component Interfaces to Expose as Services section. |

You can use mobile devices to enter information related to your work order and transmit the data to PeopleSoft using a web service. The mobile device is initially updated with current PeopleSoft data needed for the various transactions that are supported; for work order transactions in PeopleSoft Inventory this includes work orders, items, quantities in material storage locations, and other data. This data enables the mobile device to operate disconnected from PeopleSoft. The mobile system requests the data through a web service. The web service calls a PeopleSoft application engine process and the information from the PeopleSoft database is transmitted to the web service using APIs within PeopleSoft Integration Broker. The web service passes the information to the database for the mobile system. The mobile system then updates the mobile devices with the data.

Once the mobile device is up to date with the PeopleSoft information, the user can enter data about the issue or return of items on a work order. When the mobile device records a transaction, such as issuing 10 units to a work order, then the transaction data is passed through the mobile system database to the web service. The web service initiates an API to record the transaction in the PeopleSoft database using a component interface exposed as a service operation.

Note: This section discusses only the PeopleSoft Inventory part of the work order integration. For a complete discussion of the entire work order to mobile devices integration, see the PeopleSoft Maintenance Management .

See Mobile Integration Setup Considerations.

The PeopleSoft Inventory part of the work order integration enables your technician to use a mobile device to:

Issue scheduled parts (items) to a work order.

Issue unscheduled parts (items) to a work order.

Return parts (items) to PeopleSoft Inventory.

Issue parts to a work order based on a pick plan. There are three methods for entering picking results on a mobile device:

Pick Line.

Pick Line as Planned.

Pick Batch as Planned.

Cancelling a picking plan. There are two methods for cancelling a pick batch on a mobile device:

Cancel Pick Batch.

Cancel Pick Line.

This integration point consists of the connection between the PeopleSoft database and a web service. For more information about web services using a component interface and service operation, see the PeopleTools : PeopleSoft Integration Broker, Creating Component Interface-Based Services topic, Understanding Creating Component Interface-Based Services section. For information about the integration between the web service and the mobile device, please see the documentation for the mobile device.

The PeopleSoft Integration Broker provides a method for communications between the web service, PeopleSoft Inventory, and PeopleSoft Maintenance Management using industry standard XML-formatted transactions. These transactions are automatically loaded into the PeopleSoft system by handlers associated with the INVENTORY_WO_ISSUES service operation. Once transactions have been loaded into the PeopleSoft system, the IN_WO_ISSUES_CI component interface (CI) populates the correct PeopleSoft component and saves the transaction.

PeopleSoft delivers the service operations in PeopleSoft Integration Broker with a default status of Inactive. You must activate each service operation before attempting to send or receive data. To set up this service operation use the information in the table below and refer to the setup instructions in the PeopleSoft Supply Chain Management Integrations, "Implementing Integrations" topic, Setting Up Service Operations section.

|

Service Operation |

Direction and Type |

Handlers |

Chunking Available? |

Integrates With |

|---|---|---|---|---|

|

INVENTORY_WO_ISSUES |

Inbound Synchronous |

REQUESTHDLR |

No |

third-party system |

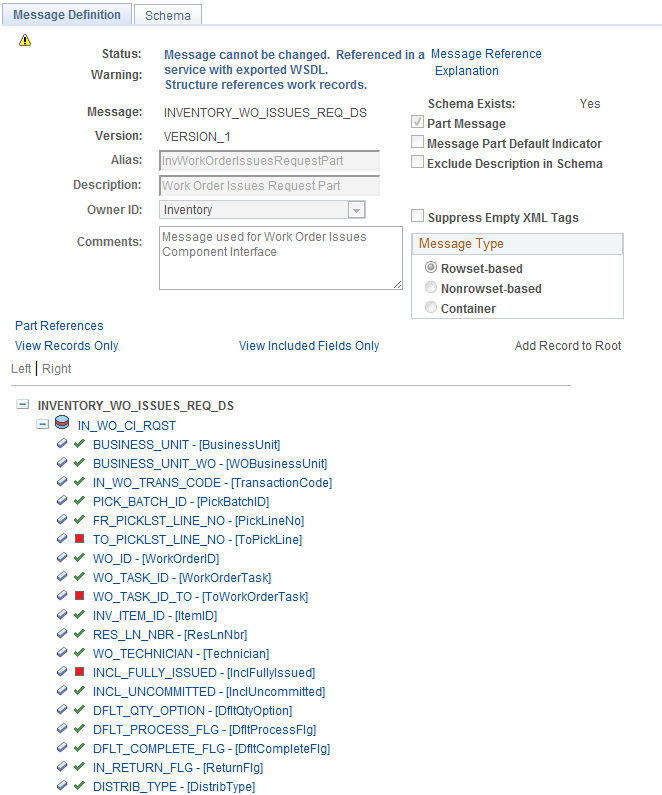

Use the Message Definition page (IB_MESSAGE_BUILDER) to view the fields to be used by the service operation within PeopleSoft Integration Broker.

In order to correctly populate the incoming data, review the message definition.

Navigation:

This example illustrates the fields and controls on the View the fields included in the message used by the INVENTORY_WO_ISSUES service operation (1 or 2). You can find definitions for the fields and controls later on this page.

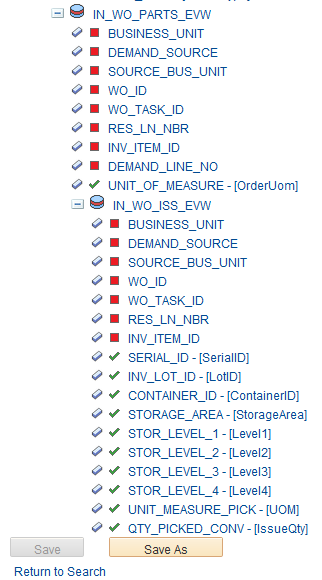

This example illustrates the fields and controls on the View the fields included in the message used by the INVENTORY_WO_ISSUES service operation (2 or 2). You can find definitions for the fields and controls later on this page.

In order to correctly populate the incoming data, review the message definition. Message definitions provide the physical description of the data that is being sent, including; fields, field types, and field lengths. Messages do not contain any processing logic. All processing logic is defined in service operations, using service operation handlers. In this section, consider some important fields in the INVENTORY_WO_ISSUES_REQ_DS message. This message is used by the INVENTORY_WO_ISSUES service operation to load inventory work order issue transactions into the PeopleSoft system. Once transactions have been loaded into the PeopleSoft system, the IN_WO_ISSUES_CI component interface (CI) populates the correct PeopleSoft component and saves the transaction.

For more information about messages, see the Managing Messages topic of the PeopleTools : PeopleSoft Integration Broker.

The INVENTORY_WO_ISSUES_REQ_DS message consists of three sections:

Header section: IN_WO_CI_RQST.

The header section includes information that applies to the entire transaction. It identifies a specific work order, task, transaction code, and material schedule combination applied to the transaction. If the issue is tied to a pick plan, then this header section also contains the pick batch ID, and pick plan line number. There is always only one header row per transaction. For the Issue Scheduled Part (10) and Issue Pick Line (40) transactions, the Default Complete Flag field and the Default Pick Qty Option field allow you to control the processing of the picking transactions.

Level 1 section: IN_WO_PARTS_EVW.

The level 1 section identifies a specific work order demand line. There is always only one level 1 row per transaction.

Level 2 section: IN_WO_ISS_EVW.

The level 2 section identifies the material storage location, quantity, lot, and serial ID of the quantity issued or picked. For each header and level 1 row you specify a row for every material storage location, lot, and serial ID that is issued or picked. For example, for one material schedule row on the work order, you issue 10 units from the material storage location A and 5 units from the material storage location B; therefore, two level 2 rows are included, one for 10 units from location A and another row for 5 units from location B.

The following fields are used on the INVENTORY_WO_ISSUES_REQ_DS message:

Field or Control |

Description |

|---|---|

IN_WO_TRANS_CODE (Inventory Work Order Transaction Code field) |

Enter a transaction code to define the type of action to be performed. Transaction codes are located in the header section (IN_WO_CI_RQST) of this message. Transaction codes for inventory work order issues are:

|

DFLT_QTY_OPTION (Default Pick Quantity Option field) |

Enter a value of Y or N in this field that is used to control how work order issues process material storage location, lot, and serial ID rows (IN_WO_ISS_EVW rows) that are allocated or pre-allocated. This field is located in the header section (IN_WO_CI_RQST) of this message and is used for the Issue Scheduled Part (10) and Issue Pick Line (40) transactions. |

DFLT_COMPLETE_FLG (Default Complete Flag field) |

Enter a value of Y or N in this field that is used to control when picking is complete for a Pick Line transaction. This field is located in the header section (IN_WO_CI_RQST) of this message and only used for the Issue Pick Line (40) transaction. |

STORAGE_AREA, STOR_LEVEL_1, STOR_LEVEL_2, STOR_LEVEL_3, and STOR_LEVEL_4 |

Select the material storage location for this transaction. This field is located in the level 2 section (IN_WO_ISS_EVW) of this message. |

See the product documentation for PeopleTools: Integration Broker

Your technician can use a mobile device to issue parts to a work order based on a pick plan. These transaction types enable the technician to enter the picking results (feedback) for an existing picking plan and have the system issue the items from inventory. The items have been committed, reserved, and a pick batch ID generated. The technician should have access to a copy of the picking plan; this is not provided in this interface. There are three methods for entering picking results on a mobile device:

Issue Pick Line (transaction code 40)

Pick Line as Planned (transaction code 50)

Pick Batch as Planned (transaction code 55)

The following fields (located in the header section of the transaction) help determine picking completion:

The Default Complete Flag field.

The Default Pick Quantity Option field.

Issue Pick Line (Transaction Code 40)

The Pick Line transaction type (40) enables the technician to enter the picking results (pick line and quantity) for each item picked. A material storage location is entered if the location is different from the location on the pick line. You can use this transaction alone or you can combine it with the Pick Line as Planned and Pick Batch as Planned transactions. Use this transaction to:

Enter all picking results for a pick batch ID with no allocations created (pull pick plan).

Enter any exceptions from a pick batch ID with allocations created (push picking plan).

Enter quantity picked from a pick batch ID with allocations created (push picking plan). Procedural requirements at many sites require that you enter a transaction each time that you pick an item from any material storage location, whether or not you followed the picking plan.

An item that was allocated on the pick batch ID but cannot be picked as planned creates an exception condition. For example, suppose that 20 units were allocated to the material storage location A for an order line on a pick batch ID. Now suppose that you can pick only 15 units from the material storage location A, and you pick the last 5 units from the material storage location B. You must then enter two Pick Line transactions; one for the 15 units from location A, and a second for the 5 units from location B.

You can also use the Pick Line transaction for order lines on a pick batch ID with allocations when there are no exceptions. In fact, procedural requirements at many sites require that you enter a transaction each time that you pick an item from any material storage location, whether or not you followed the picking plan.

Pick Line as Planned (Transaction Code 50)

The Pick Line as Planned transaction type is used to indicate that picking is complete for the pick line. The technician first enters all picking exceptions for the pick line using the Pick Line transaction. Next, the technician sends a Pick Line as Planned transaction from the mobile device to pick the remaining allocations as defined on the pick plan. If the technician picks quantity exactly as the pick line specifies the Pick Line transaction is not needed. The following examples illustrate the use of the Pick Line as Planned transaction:

Example 1: On the picking plan, 10 units of an item are allocated to the material storage location A and the technician picked all 10 units from location A. You can enter a Pick Line as Planned transaction and when the transaction is processed, the 10 units are issued from location A and the pick line is complete.

Example 2: On the picking plan, an item was allocated to two different material storage locations; 10 units from location A and 5 units from location B. Only 7 units are physically stored in material storage location A so the picker picks 7 units from location A and 5 units from location B. You can enter a Pick Line transaction for the 7 units from location A and then enter a Pick Line as Planned transaction. When the transactions are processed 7 units are issued from location A, 5 units are issued from location B, and the pick line is complete.

Pick Batch as Planned (Transaction Code 55)

The Pick Batch as Planned transaction type is used to indicate that picking is complete for the entire pick batch ID. The Pick Batch as Planned transaction is a good way to report the picking activity for environments in which there are very few exceptions to the picking plan. Any exceptions are entered first using the Pick Line transaction and then the Pick Batch as Planned transaction is used.

The Default Complete Flag Field

Enter a value of Y or N in the Default Complete Flag field (DFLT_COMPLETE_FLG) that is used to control when picking is complete for a Pick Line transaction. This field is located in the header section (IN_WO_CI_RQST) of this message and only used for the Issue Pick Line (40) transaction. Enter the value of Y (yes) if you do not intend to pick additional quantity for this pick line. When the transaction is processed, all remaining allocations for the pick line are released and the pick batch ID and pick batch line are no longer associated with the work order schedule row. Enter the value of N (no) if you will pick additional quantity for the pick line. When the transaction is processed, remaining allocations are not released and the pick batch ID and pick batch line are still associated with the work order schedule row so additional quantity can be picked at a later time.

The Default Pick Quantity Option Field

Enter a value of Y or N in the Default Pick Quantity Option field (DFLT_QTY_OPTION) that is used to control how work order issues process material storage location, lot, and serial ID rows (IN_WO_ISS_EVW rows) that are allocated or pre-allocated. This field is located in the header section (IN_WO_CI_RQST) of this message and is used for the Issue Scheduled Part (10) and Issue Pick Line (40) transactions. For work order material schedule rows that are allocated on a pick plan, this field works in conjunction with the Default Complete Flag field. If the Default Complete Flag is set to the value of N (no), then the Default Pick Qty Option field is ignored. Only those allocated pick location lines that are included in the transaction are processed. For any allocated pick location lines that are not included, the allocation and the pick batch ID and pick batch line continue to be associated with the work order material schedule row. If the Default Complete Flag is set to the value of Y (yes), then the Default Pick Qty Option field determines how the system will process allocated pick location lines that are not passed. Enter the value of Y (yes) in the Default Pick Qty Option field if you want to use the allocated quantity as the quantity that has been picked for the allocated pick location lines that have not been included in the transaction. Enter the value of N (no) in the Default Pick Qty Option field if you want to use 0 (zero) as the quantity picked for allocated pick location lines that have not been included in the transaction. The system releases the allocated quantity and removes the pick batch ID and pick batch line associated with the work order material schedule row.

For work order material schedule rows that are pre-allocated and not on a pick plan, the Default Pick Qty Option field controls whether the pre-allocations for material storage location, lot, and serial ID rows that are not specified in the transaction are issued or not. If the pre-allocation locations are included in the transaction, then the quantity specified is issued. If the pre-allocation locations are not included in the transaction, then the Default Pick Qty Option field is used to determine the quantity issued. Enter the value of Y (yes) in the Default Pick Qty Option field if you want the pre-allocation quantity to be issued. Enter the value of N (no) in the Default Pick Qty Option field if you want to issue 0 (zero) from the pre-allocation locations. If the pre-allocation locations are included in the transaction, the quantity specified in the transaction is issued to the work order and the Default Pick Qty Option field is ignored.

Example 1: Issue Pick Line (40) transaction with Y in the Default Complete Flag field

The following example illustrates how issue parts to a work order based on a pick plan. For this examples, assume pick batch ID 1000 has one work order and task row and two material schedule rows. For row 1 the pick plan suggests you pick 10 units from material storage location A and 5 units from material storage location B. For row 2 the pick plan suggests you pick 10 units from material storage location B.

In this example, the system is processing a Issue Pick Line (40) transaction with the value of Y (yes) in the Default Complete Flag field. For line 1 the picker finds 0 (zero) units in material storage location A and 15 units in material storage location B. He picks 15 units from location B. For line 2 the picker only finds 8 units in the suggested material storage location. This example displays an abbreviated version of the information sent in the web service and shows two options for recording these transactions.

Option 1: The transaction includes the material storage location, lot, and serial ID information for all rows that are allocated:

|

Segment |

Transaction |

Work Order, Task, and Res Line |

Pick Batch ID |

Line Number |

Material Storage Location |

Issue/Pick Quantity (QTY_PICKED_CONV) |

Default Qty Option |

Default Complete Flag |

|---|---|---|---|---|---|---|---|---|

|

Header (IN_WO_CI_RQST) |

040 |

WO1/1/1 |

1000 |

1 |

Y |

Y |

||

|

Level 1 (IN_WO_PARTS_EVW) |

WO1/1/1 |

|||||||

|

Level 2 IN_WO_ISS_EVW |

WO1/1/1 |

A |

0 (zero) |

|||||

|

WO1/1/1 |

B |

15 |

||||||

|

Header (IN_WO_CI_RQST) |

040 |

WO1/1/2 |

1000 |

2 |

Y |

Y |

||

|

Level 1 (IN_WO_PARTS_EVW) |

WO1/1/2 |

|||||||

|

Level 2 IN_WO_ISS_EVW |

WO1/1/2 |

B |

8 |

For option 1, the transaction does the following:

For WO1/1/1, issue 0 (zero) units from material storage location A and issue 15 units from material storage location B.

For WO1/1/2, issue 8 units from material storage location B.

Since the Default Complete Flag field is set to the value of Y (yes), the allocations are released for both WO rows: 10 units from WO1/1/1 and 2 units for WO1/1/2. In addition, the pick batch ID and line number are no longer associated with the work order material schedule rows.

Option 2: The transaction includes the material storage location, lot, and serial ID information for only the locations in which quantity was picked:

|

Segment |

Transaction |

Work Order, Task, and Res Line |

Pick Batch ID |

Line Number |

Material Storage Location |

Issue/Pick Quantity (QTY_PICKED_CONV) |

Default Qty Option |

Default Complete Flag |

|---|---|---|---|---|---|---|---|---|

|

Header (IN_WO_CI_RQST) |

040 |

WO1/1/1 |

1000 |

1 |

N |

Y |

||

|

Level 1 (IN_WO_PARTS_EVW) |

WO1/1/1 |

|||||||

|

Level 2 IN_WO_ISS_EVW |

WO1/1/1 |

B |

15 |

|||||

|

Header (IN_WO_CI_RQST) |

040 |

WO1/1/2 |

1000 |

2 |

Y |

Y |

||

|

Level 1 (IN_WO_PARTS_EVW) |

WO1/1/2 |

|||||||

|

Level 2 IN_WO_ISS_EVW |

WO1/1/2 |

B |

8 |

For option 2, the transaction does the following:

For WO1/1/1, issue 15 units from material storage location B and since the Default Quantity Option field has a value of N (no) and the material storage location A is not included in the message, then the transaction issues a quantity of 0 (zero) units from location A.

For WO1/1/2, issue 8 units from material storage location B.

Since the Default Complete Flag field is set to the value of Y (yes), the allocations are released for both WO rows: 10 units from WO1/1/1 and 2 units for WO1/1/2. In addition, the pick batch ID and line number are no longer associated with the work order material schedule rows.

Example 2: Issue Pick Line (40) transaction with N in the Default Complete Flag field

The following example illustrates how issue parts to a work order based on a pick plan. For this examples, assume pick batch ID 1000 has one work order and task row and two material schedule rows. For row 1 the pick plan suggests you pick 10 units from material storage location A and 5 units from material storage location B. For row 2 the pick plan suggests you pick 10 units from material storage location B.

In this example, the system is processing a Issue Pick Line (40) transaction with the value of N (no) in the Default Complete Flag field and all material storage locations included in the transaction. For pick line 1, the picker picks 10 units in material storage location A and 5 units in material storage location B. For pick line 2, the picker picks 4 units from material storage location B and plans to pick the remaining 6 units in a few hours. This example displays an abbreviated version of the information sent in the web service and shows two options for recording these transactions.

|

Segment |

Transaction |

Work Order, Task, and Res Line |

Pick Batch ID |

Line Number |

Material Storage Location |

Issue/Pick Quantity (QTY_PICKED_CONV) |

Default Qty Option |

Default Complete Flag |

|---|---|---|---|---|---|---|---|---|

|

Header (IN_WO_CI_RQST) |

040 |

WO1/1/1 |

1000 |

1 |

Y |

Y |

||

|

Level 1 (IN_WO_PARTS_EVW) |

WO1/1/1 |

|||||||

|

Level 2 IN_WO_ISS_EVW |

WO1/1/1 |

A |

10 |

|||||

|

WO1/1/1 |

B |

5 |

||||||

|

Header (IN_WO_CI_RQST) |

040 |

WO1/1/2 |

1000 |

2 |

Y |

N |

||

|

Level 1 (IN_WO_PARTS_EVW) |

WO1/1/2 |

|||||||

|

Level 2 IN_WO_ISS_EVW |

WO1/1/2 |

B |

4 |

The transaction does the following:

For WO1/1/1, issue 10 units from material storage location A and 5 units from material storage location B.

For WO1/1/2, issue 4 units from material storage location B.

Since the Default Complete Flag field is set to the value of N (no), the pick batch ID and line number are still associated with WO1/1/2 and the remaining 6 units are still allocated. The picker can pick the remaining 6 units at some other time.