Running the Reserve Materials Process

The Reserve Materials process page submits fulfillment run control requests to the fulfillment engine to soft-reserve stock, promise stock, and move material stock orders and sales orders from an unfulfilled to a releasable state. This process can also soft-reserve stock for a work order line from PeopleSoft Maintenance Management. These fulfillment run control requests are applied directly to the inventory demand tables; the staging tables are not used. Like all run controls, these processes can be scheduled to run one time or on a recurring basis. Any errors in the requests are placed in the Message Log for viewing.

The Reserve Materials process can also be launched from the Order Entry Form component in PeopleSoft Order Management and the Create/Update Stock Request component in PeopleSoft Inventory. To launch from the order entry pages in PeopleSoft Inventory, select the Background option for MSR Entry Reservations on the Setup Fulfillment-Reservation page.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

RUN_IN_FULFILL_RSV |

Define parameters for the Reserve Materials process. |

|

|

Processing Controls |

INV_PROCESS_SEC |

Review or change the fulfillment engine processing options used by the Reserve Materials process. |

|

Fulfillment Engine Options |

INV_FUL_DFLT_BU |

Review the fulfillment engine processing options defined in this run control for the Reserve Materials process. |

Use the Reserve Materials page (RUN_IN_FULFILL_RSV) to define parameters for the Reserve Materials process.

Navigation:

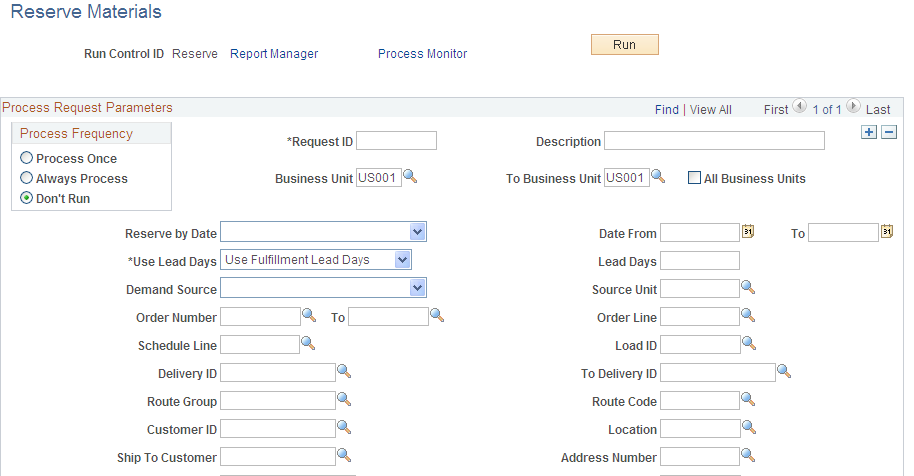

This example illustrates the fields and controls on the Reserve Materials process page (page 1 of 2). You can find definitions for the fields and controls later on this page.

This example illustrates the fields and controls on the Reserve Materials process page (page 2 of 2). You can find definitions for the fields and controls later on this page.

Enter the criteria to soft-reserve stock, promise stock, and move material stock orders and sales orders from an unfulfilled to a releasable state. Leave the fields at their default value to use the values defined on the Setup Fulfillment component. If you enter additional search criteria here, then an order must meet all criteria to be selected for processing.

Field or Control |

Description |

|---|---|

Business Unit and To Business Unit |

If this run control should process one PeopleSoft Inventory business unit, enter the unit in the Business Unit field. If you want to process a range of business units, enter the starting unit in the Business Unit field and the ending business unit in the To Business Unit field. The system processes all Inventory business units, sorted in alphanumerical order, that fall between the starting and ending unit. |

All Business Units |

Select to process all PeopleSoft business units in this run control. |

Reserve by Date |

Select one of the following values to add the additional search criteria based on dates:

|

Use Lead Days |

Determines how this process uses reservation lead days defined on the Setup Fulfillment-Reservation page or the Setup Item Fulfillment page. Values are:

|

Lead Days |

Enter the reservation lead days for this process if you have selected the Override Lead Days option for the Use Lead Days field. The lead days entered here override the reservation lead days defined on the Setup Fulfillment-Reservation page or the Setup Item Fulfillment page. However, you cannot exceed the maximum lead days defined on the Setup Fulfillment-Reservation page. Note: If you use this field to override the reservation lead days, then the Unreserved Demand Lines Report will not include demand lines that were not reserved because the demand lines were outside the lead days window. Select the Unreserved Demand Lines Report check box to generate this report. |

Demand Source |

Select a demand source to restrict the orders selected for processing to one source. The demand sources are:

|

Source Unit |

Enter the business unit where the order originated. |

Order Number and To |

Enter the order number or range of order numbers to be processed. The order can be a sales order from PeopleSoft Order Management, a work order from PeopleSoft Maintenance Management, or a material stock request from PeopleSoft Inventory, Purchasing, Manufacturing, or Supply Planning. If you enter a range of orders using the Order Number and To fields, then the system processes all orders, sorted in alphanumerical order, that fall between the starting and ending order numbers. |

Order Line and Schedule Line |

Enter a specific order line to restrict processing to one order line. Enter a specific order line and shipment schedule line to restrict processing to one demand line. These fields are based on the Order Number field. |

Load ID |

Enter to select orders assigned to a single load ID. |

Delivery ID and To Delivery ID |

Enter a single delivery ID or range of delivery IDs to select order lines assigned to delivery IDs. Deliveries are logical groupings of order lines that can be shipped together. PeopleSoft Inventory and Order Management can use these groupings for pricing sales orders, adding freight charges, and packing shipping containers. Each delivery is assigned a unique delivery ID. See Understanding PeopleSoft Delivery Management and Freight Calculations. |

Route Group and Route Code |

Enter to select orders grouped together for a particular transportation grouping and transportation route for delivery of the order. |

Customer ID and Location |

Enter to select orders to process that were entered for a particular customer or customer location. |

Ship To Customer and Address Number |

Identify the shipping location for the customer. |

Carrier ID |

Enter to select orders to ship with one carrier. |

Ship Method |

Enter to select orders to ship using one shipping method (ship via code). |

Parent Product ID |

Enter a product kit ID to select demand lines containing the kit components. |

Item ID |

Enter an item ID to select demand lines by item. |

Priority |

Enter a inventory priority rank to select demand line of a particular priority. Inventory priority ranks can be assigned to order line based on rules established on the Priority Rule Definition page. |

Product ID |

Enter a product ID from a sales order in PeopleSoft Order Management. |

Auto Release Option |

Select the auto processing option to move your orders downstream to the desired state. Options include:

The Auto Release Option field is not applied to work orders from PeopleSoft Maintenance Management. |

Release Run Control |

Select a run control for the Order Release Request process page. This run control contains the parameters to be used when auto-processing orders after the Reserve Materials process. The Auto-Processing Option field on the Order Release Request determines how far downstream the orders will be sent. Auto Release will only advance lines to a released state if a release run control is provided, either through the defaults or in this field. The Release Run Control field is not applied to work orders from PeopleSoft Maintenance Management. |

Processing Options |

Click to access the Processing Controls page, where you can view and override some of the fulfillment engine processing options defined at the business unit or SetID level. Initially this page displays the current fulfillment engine options that are defined in your environment at the business unit level (in the Setup Fulfillment component) or at the SetID level (in the Fulfillment Engine Options page). The fields available on this page are determined by the selection of the Allow Processing Overrides check box in the fulfillment engine options. |

View Process Defaults |

Click to access the Fulfillment Engine Options page where you can view the fulfillment engine processing options defined at the business unit level. |

Note: If the business unit requires closure calendar validation and processing for shipping activities as defined on the Closure Calendar page, and the reservation lead days include closure dates, the system adds one day for every number of closed days to the number of reservation lead days to compare against the scheduled ship date. Therefore, the lead days include only open business days.

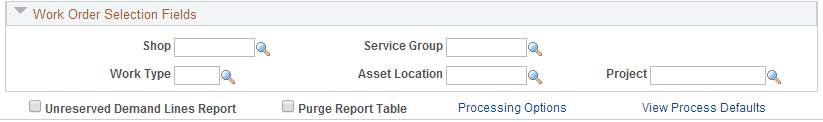

Work Order Selection Fields

Work Order Selection Fields group box is only available if PeopleSoft Maintenance Management is installed. Work Orders from PeopleSoft Maintenance Management can place demand for items into the PeopleSoft Inventory business unit. You can use the Work Order Selection Fields group box to refine your search for the work order demand lines that you wish to soft-reserve within the Inventory business unit. To pick up both committed and not yet committed work orders lines, the Reserve Materials process searched for demand lines meeting the selection criteria in both the IN_DEMAND table in PeopleSoft Inventory and the Work Order Parts List table in PeopleSoft Maintenance Management.

Field or Control |

Description |

|---|---|

Shop, Service Group, Work Type, Asset Location, and Project |

Enter work order selection criteria to narrow the work order demand lines selected by the Reserve Materials process. A business unit must be entered in the Source Unit field above in order access a list of values for these fields. |

If the Demand Source field is blank and any of the following field have values then work order demand lines are not selected: Load ID, Route Group, Route Code, Customer ID, Location, Ship To Customer, Address Number, Carrier ID, Ship Method, or Product ID.

Unreserved Demand Lines Report

Field or Control |

Description |

|---|---|

Unreserved Demand Lines Report |

Select this check box to generate the Unreserved Demand Lines report (INS6400) when the Reserve Materials process is run. This report displays all demand lines that were not reserved and the reason they were not reserved. The default value entered on this page is derived from the Setup Fulfillment-Reservation page for this business unit. Note: Before selecting this check box consider the impact on system performance. The Unreserved Demand Lines report examines all demand lines in the unfulfilled state, including lines outside the reservation lead days. The report could pick up a large number of demand lines which can slow down performance of the Reserve Materials process. |

Purge Report Table |

Select to purge the report table (IN_FUL_RSV_RPT) used to build the Unreserved Demand Lines report after each run (process instance). The default value entered on this page is derived from the Setup Fulfillment-Reservation page for this business unit. |