Initiating the Close Production Process

After you complete production for the day or for a production ID, you need to close production to any further material or labor transactions. The production status is changed to Closed for Accounting after all related transactions have been completed and potential variances have been analyzed. When the final close for production (the accounting close) occurs, PeopleSoft Manufacturing calculates variances and records them for later posting to the general ledger.

If you have enabled PeopleSoft Workflow, you can use the Production Ready to Close workflow that scans the production data files and notifies appropriate users of any production status that has changed to Pending Complete, Completed, or Closed for Labor.

If you are using production IDs, you can identify costs and variances by discrete order. If you're using production schedules, the system collects costs and variances by day and shift for the production area and item combination.

For standard cost items, the Close Production process (SFS1100) can populate the Production Variance Detail record (SF_VARS_DETAIL) and the Configuration Variance Detail record (SF_CFGVAR_DET ) with detailed information about how each production variance was calculated. This information is displayed on the Production Variance Drilldown component and can be downloaded into a Microsoft Excel spreadsheet. In order to populate the Production Variance Detail record and the Configuration Variance Detail record, you must enable variance drilldown at the business unit level. Select the Enable Variance Drilldown check box on the MFG BU Prdn Options page to capture detailed production variance data.

PeopleSoft Manufacturing provides three options to close a production ID or production schedule:

Field or Control |

Description |

|---|---|

Complete |

This first close prevents any material movement for the production ID or for production on the day or shift selected. This includes component consumption as well as any assembly completions at an operation, to stock, or to another production ID or production area. |

Closed for Labor |

This second close prevents any additional actual labor or machine time recording. |

Closed for Accounting |

This final close completes the production cycle and closes the production ID or production for the shift for accounting purposes. |

After it is closed for accounting purposes, PeopleSoft Manufacturing calculates these standard-cost variances:

Component Yield

Configuration

Labor Lot Size

Material Lot Size

Mix

Outside Processing PPV

Process Routing

Rework Expense

Rework Labor Expense

Teardown Conversion Expense

Teardown Material Expense

Usage

Yield

Production schedules with a status of In Process are automatically set to Pending Complete when the order quantity equals the quantity completed. The system combines material lot size and configuration variances for production schedules.

Note: PeopleSoft Manufacturing reports but does not post Efficiency and Utilization variances.

For more details about the above variances, see the Analyzing Manufacturing topic of the PeopleSoft Cost Management Documentation.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

RUN_SFS1100 |

Change the production status to Complete, Clsd/Labor (closed for labor), or Clsd/Acctg (closed for accounting). |

|

|

RUN_SFS1100A |

Define the production close criteria. |

Use the Production Selection page (RUN_SFS1100) to change the production status to Complete, Clsd/Labor (closed for labor), or Clsd/Acctg (closed for accounting).

Navigation:

Field or Control |

Description |

|---|---|

Report Only Mode |

You can run this process to view the production that may be closed as well as the variances that could be generated as a result of an accounting close. |

Select Production IDs |

Select this check box to close production IDs based on any of these options:

|

All or a Range |

Narrow the production to close by combining any of these options. For example, you can close only those production IDs within a selected production area for a single item. |

Select Production Schedules |

Select this check box to close production schedules based on:

|

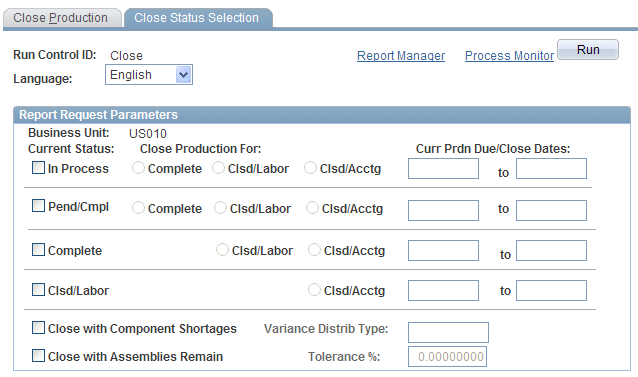

Use the Close Status Selection page (RUN_SFS1100A) to define the production close criteria.

Navigation:

This example illustrates the fields and controls on the Close Status Selection page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Current Status |

Select one or more of these production statuses:

|

Close Production For |

Select the new production status. Values are:

|

Curr Prdn Due/Close Dates (current production due and close dates) |

Enter the appropriate date ranges. If you are closing any In Process or Pending Complete production, the system closes any production IDs or production schedule quantities whose production due date falls within the date range specified. If you are closing any production IDs or production schedule quantities whose current status is Complete or Closed for Labor, the system closes any production whose close date falls within the range specified. |

Complete with Component Shortages |

Select this check box if you want to close production even if you haven't issued all the scheduled material for the production ID or production schedule. In this instance, the quantity issued to production is less than the current scheduled quantity for the component. |

Variance Distrib Type (variance distribution type) |

(Optional) Displays the variance distribution type, which can be used in conjunction with the transaction group for variances to define the accounting entries to post the variance to the general ledger. The default distribution type for the transaction group (if one was defined) appears, but you can override the distribution type for each accounting close. This field is used only when closing production for accounting. |

Close with Assemblies Remain (close with assemblies remaining) |

Select this check box if you want to close production even though the full production quantity hasn't been completed. Production can close with remaining assemblies only if the production quantity has not been started. Once any quantity is in process, you must complete the assemblies for production to close. |

Tolerance % |

You must indicate a tolerance percentage if you selected the Close with Assemblies Remain check box. Use this field to define what percentage of assemblies can remain uncompleted and still close production with remaining assemblies. For example, if you have a production ID with an order quantity of 100 but have completed only 92 units and enter a tolerance percentage of 5 percent, this production ID will not close because the quantity remaining to be completed is 8 percent of the order quantity. The default is 0 percent. The system closes any production in process, pending complete, complete, or closed for labor if the quantity of assemblies completed and scrapped at each operation equals the quantity started at each operation. |

Run |

Click to run this request. Process Scheduler runs the Close Production process at user-defined intervals. |

Note: If any of the production IDs are for production with one or more subcontracted operations, the system cannot close production if subcontracted purchase orders have not been fully received. To close those production IDs, the material must be received and the subcontracted operation must be recorded as complete.

This process generates the Close Production Request report. If you cannot close a production ID or a production schedule quantity that falls within the selection criteria, the production ID, area, item, and day shift information display as well as the reason why the production could not be closed. Possible reasons include:

Outstanding pick plans.

In this instance, a pick plan has been generated for a production ID or production schedule, but not yet confirmed and released. The picking process must be completed before production can be closed.

Outstanding consumed quantity.

In this instance, a component was consumed during a backflush, but there was not sufficient quantity on hand in the WIP storage area (and the inventory business unit does not allow inventory to go negative) to issue the component to the production ID or production schedule. You haven't decremented the quantity on hand in the WIP location and a nonzero pending issue or pending yield loss quantity exists.

Outstanding component shortages.

If you elected not to complete production with shortages, the system excludes any production ID or production schedule due to be closed that has component shortages. A component is considered short when the issued quantity is less than the current scheduled quantity.

Remaining assemblies in process.

If any assemblies are remaining at an operation (the quantity issued to the location is greater than the quantity completed plus scrapped), they must first be scrapped or completed before you can close production.

Production quantity hasn't been completed.

If the full production quantity hasn't been completed and you haven't selected the Close with Assemblies Remain check box, you cannot close the production ID or production schedule. Additionally, if you've selected the option to close with assemblies remaining but the remaining assembly quantity exceeds the tolerance percentage, the production cannot be closed.

Production quantity remaining uncompleted exceeds tolerance.

If you have selected the Close with Assemblies Remaining check box, but the remaining amount exceeds the tolerance percentage, the production ID or production schedule will not be closed. For example, if you have an order quantity of 100, 80 of which are completed, and you enter a tolerance of 5 percent, production will not be closed because at least 95 assemblies must be completed.

Subcontracted purchase order quantity outstanding.

If the quantity of assemblies sent to the supplier is not equal to the quantity of scrapped and completed assemblies received back from the supplier, then you cannot close production. The outstanding assemblies must be reconciled before you can close production.

Important! Be aware that if you are closing a serial genealogy production ID with a status of Complete, you cannot close the production ID if there are outstanding serial IDs that have been associated but have not been completed or scrapped. All serial IDs that have been associated with the production ID must be accounted for; either they have been completed or scrapped.

After displaying the list of production that you cannot close, the report lists production that has been successfully closed. It also details the variances incurred, categorized by variance type.

If you are running this process in update mode (that is, you didn't select the Report Only Mode check box), the status is set to Complete, Clsd/Labor (closed for labor), or Clsd/Acctg (closed for accounting), depending on the Close Production For group box level selected. The close date and time is updated with the current date and time for those production IDs or production schedules that you could close.

PeopleSoft Manufacturing records variances for production IDs and production schedules that you've closed for accounting. The system also posts these variances to the general ledger during the accounting line generation and journal generator processes.

When production is closed and an operation has costing post production time that hasn't yet been earned, the closing process calculates the earned labor and machine post production costs and updates the Earned Conversion Cost record accordingly.