Understanding the PDX Integration

You can use PeopleSoft Manufacturing to receive item, revision, and manufacturing bill of material (BOM) information from external applications. This integration uses the product data exchange (PDX) version 1.0 XML format.

Note: The term PDX refers to the XML files containing change order information that is sent from the product life cycle management application to PeopleSoft.

PeopleSoft Manufacturing integrates with PLM applications enabling you to send item, revision, and manufacturing BOM information using change orders.

Specifically, the PeopleSoft system integrates with engineering change order (ECO) and manufacturer change order (MCO) subclasses of PDX to support inbound item (part) and BOM information into PeopleSoft Manufacturing. This integration is one-way only (inbound to PeopleSoft), and supports one PLM system to one PeopleSoft system (single business unit).

In general, implementing a PLM integration implies that the PLM system is the master data source for items, revisions, and BOMs instead of PeopleSoft. Therefore, when this integration is implemented, use PeopleTools security to severely restrict access (disallow changes) to item, revision, and BOM maintenance functions within PeopleSoft. Generally, these maintenance functions should only be done in PeopleSoft for the data elements that are not maintained through the PLM system, for example, costing, purchasing or planning attributes on the Item Master. This maintenance depends on the specific implementation of the PLM application, as well as any modifications that you have made.

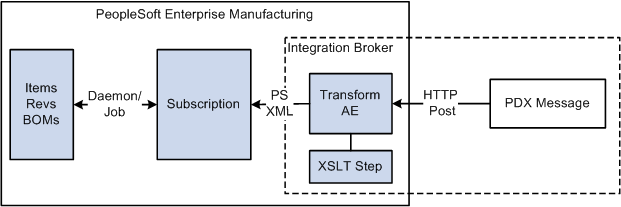

This diagram illustrates the flow of data between PeopleSoft Manufacturing and a PDX message using the PeopleSoft Integration Broker to transform the HTTP data to PeopleSoft-formatted XML data and apply the item changes, revisions, and BOM changes to PeopleSoft Manufacturing:

This section discusses:

PeopleSoft Manufacturing.

The integration checklist.

PeopleSoft Manufacturing

Once you have defined usage of a valid life cycle status within the product life cycle management application, you can then set up PeopleSoft Manufacturing by defining default and mapping information within the Installations Options - Manufacturing page. These mappings look for custom fields in the XML as a system such as Agile™ would write them within the PDX 1.0 standard.

In addition, certain PeopleSoft Integration Broker and messaging information is also required, which enables PeopleSoft to receive the service operation in the PDX 1.0 format.

Within PeopleSoft, you also set up a Daemon program and related job designed to process inbound change orders (within the PDX 1.0 service operations) for items and BOMs sent in PDX format into PeopleSoft master tables.

Integration Checklist

Use this checklist to configure the PDX integration:

|

PeopleSoft Manufacturing Setup Tasks |

Description |

|---|---|

|

1. Set up PeopleSoft Installation Options. |

Create basic life cycle mappings, defaults, and other basic mappings for data not delivered in standard PDX 1.0 XML. |

|

2. Set up the PeopleSoft messaging gateway. |

Activate service operations — for services BOM_SYNC and ITEM_SYNC The service operation version itself has a status and there is an individual status for each handler and routing. |

|

3. Turn off Flag 1 within Data Maint Setup pages for ITEM and BOM transaction types. |

Flag 1 in this setup page indicates that you do not want to auto-process inbound service operations as they are received. This is important for the integration to control the flow and updating of change orders. |

|

4. Set up the PDX Alert and PDX_DMON Daemon group for processing inbound service operations. |

a. Set up the run control for the PDX Alert. The PDX Alert enables you to notify a specific user by using email when exceptions occur within PeopleSoft due to the processing of inbound changes. b. Set up the Daemon to process inbound changes. The PDX_DMON Daemon group must be set up and running for a process scheduler to monitor inbound — PDX service operations and start the PDX_JOB when needed. |