Running the Feasible Solver

This topic provides an overview of the Feasible solver and discusses how to define the criteria for initiating the solver run.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

PL_FSBL_SOLVE |

Define criteria for the Feasible solver. |

The Feasible solver is a search-based solver that uses tree-solver technology to resolve material and capacity infeasible tasks. This solver attempts material feasibility for all of the resolvable material violations between the early fence and end of time fence. If you select the Make Plan Capacity Feasible option, available on the Initiate Feasible solver page, the solver attempts capacity feasibility, as well.

Note: If you have frozen tasks, model errors, or insufficient lead time in the planning horizon, the Feasible solver may encounter capacity or material violations that cannot be resolved. In these cases, the solver identifies unavoidable problems and makes the rest of the plan feasible.

Additionally, the Feasible solver:

Considers alternate sourcing options.

Reschedules existing orders that are subject to capacity constraints.

Meets demand due dates and minimizes lateness.

Applies priority for important demands to ensure that they are met on time.

Minimizes excess inventory.

Generates intuitive, feasible MRP type solutions.

Solver Algorithm

When resolving material and capacity infeasible tasks, the Feasible solver deletes all of the nonfrozen planned supplies and retracts (making the supply invisible to the solver until the solver needs supply) all of the other nonfrozen supplies. This solver reschedules demand to the target date and solves for negative on-hand quantities.

Additionally, the Feasible solver sorts independent demand by demand priority, MRP level, and demand target date. Frozen demands are assumed to have the highest priority. Starting with demand that is defined with the highest priority, this solver attempts to supply all of the demand. If it is unable to find supply, it attempts to reschedule the demand for a later date. Failing that, it adds the demand to an exception list and continues to the next demand priority.

Regenerative and Net Change Run Types

When processing regenerative run types, the Feasible solver deletes all of the nonfrozen planned supplies and considers all of the other nonfrozen supply that is available for use. This solver includes frozen supply in the on-hand quantity total.

When processing net change run types, this solver considers nonfrozen supply as available for use. It includes frozen supply in the on-hand quantity total.

Lot for Lot Items

The solver maintains a pegged chain for lot-for-lot items. A lot-for-lot item is an item in which all of the sourcing options are free of order modifiers (in which supply quantities match demand quantities). When you invoke the solver, it checks any current pegging for consistency and maintains that pegging, modifying the pegging structure only when needed to make the plan material and capacity feasible.

If any supply option for an item contains an order modifier, then the solver does not consider the item a lot-for-lot item. For these items, the Feasible solver creates the pegging based on a first-in, first-out (FIFO) basis. When using the FIFO method, the solver first matches demands with the highest demand priority to the available supply.

Supply

The Feasible solver obtains supply in this order:

By rescheduling and using an available existing supply.

For lot-for-lot items, this solver uses existing supply only if an exact supply and demand quantity match exists.

By creating new supply using the sourcing template.

If in this process it creates new, dependant demand, it solves for this demand.

By using available quantity on hand when it is unable to create supply.

For lot-for-lot items, this solver uses quantity on hand only if enough quantity on hand is available to meet the full demand quantity.

Post-Solver Phases

The Feasible solver performs these post-solver Run Lateness and Stock Phase Option processes:

Attempts to minimize permanent excess.

Reduces WIP and solves for safety stock.

This phase enables the Feasible solver to maintain the feasibility of the schedule, while searching for opportunities to reduce excess inventory that occurs between the early fence and end of time fence, and to search for opportunities to satisfy unfulfilled safety-stock requirements.

Performs lateness reduction phase.

This phase maintains the feasibility of the schedule while searching for opportunities to reduce the lateness of demands that have been delayed past their due date. These opportunities can exist due to gaps left behind in capacity or when alternate build options are defined in the model using different bills of material.

Late Supply Calculations

When the Feasible Solver cannot supply on-time quantities for top-level demand which is ordered by demand priority, item low-level code and due date and time, it:

Attempts to use available planned on-hand quantity that's not allocated to other demand or safety stock.

For the remaining demand quantity that's not covered by the first step, attempts to use existing supplies including purchase orders, production process IDs, and transfers.

The order in which the solver selects the supplies is based on the current planned due date and time of the orders. If the selected purchase order, production process, or transfer has a start date and time after the early fence and if the supply is late for the demand, the solver attempts to reschedule it to start at the early fence. The system does not reschedule supplies that start at or before the early fence.

If a transfer order or a production order is selected, the solver checks the order's demand. The solver first attempts to use the available planned on hand quantity, similar to the process described in step 1, to cover the dependent demand. Then, the solver attempts to use existing purchase orders for the demand, similar to the process described in step 2, but the solver does not use existing production ID or transfer supplies. If there is still remaining demand quantity, the solver attempts to create planned supplies using default sourcing options described in step 4.

If there is still remaining demand quantity not covered by step 2, you can select the Transfer Network Onhand check box in the Feasible Solver to indicate that you want to create planned transfers.

Using this functionality, the system creates planned transfers for each transfer option on the sourcing template, ordered by sourcing template priority. The planned transfer is created with the available planned on hand quantity if there are any from the source business unit, starting at the early fence of the source business unit and item. If the available on hand at the source business unit is more than the demand quantity, the solver transfers up to the demand quantity. If the supply is not enough to cover the demand, the solver continues to the next transfer option on the sourcing template until the demand quantity is fully covered or all transfer options are exhausted.

If there are still remaining demand quantity after step 3, the solver attempts to create planned supplies using the default sourcing option.

If there is dependent demand created, such as in the case of planned transfer or production, the solver explodes down each level of the supply chain. For each lower-level dependent demand the solver attempts to use available planned on hand quantity first, then it attempts to use existing purchase orders similar to process described in step 2, but the solver does not use existing production process ID or transfer supplies. If the dependent demand quantity is still not satisfied, the solver creates planned supplies using the default sourcing option.

Finishes the first top-level demand and advances to the next demand by repeating steps 1 to 4.

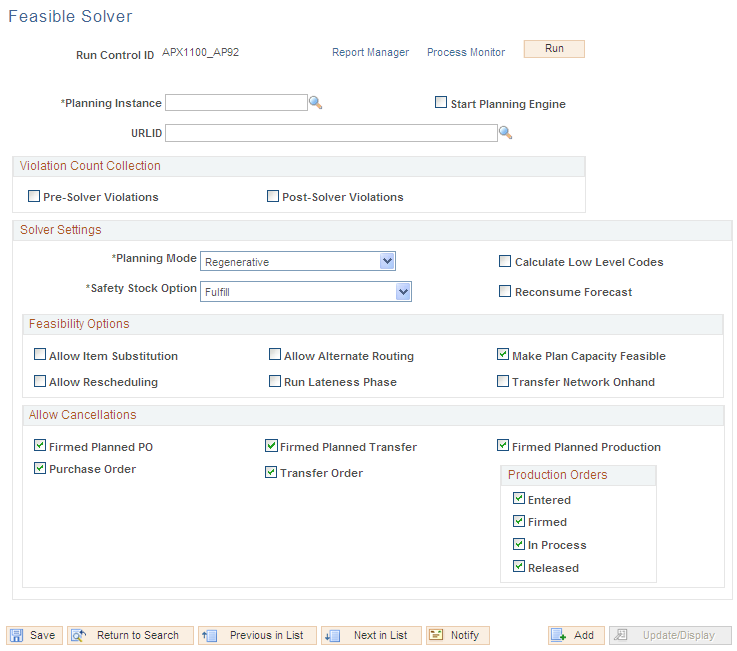

Use the Feasible Solver page (PL_FSBL_SOLVE) to define criteria for the Feasible solver.

Navigation:

This example illustrates the fields and controls on the Feasible Solver Page. You can find definitions for the fields and controls later on this page.

Solver Settings

Field or Control |

Description |

|---|---|

Planning Mode |

Values are: Regenerative: Before you run the feasible solver, all nonfrozen planned orders are removed from the planning instance, all independent demands are moved back to their original target dates, and the solve is initiated. Net Change: All supplies are retained and renetted against all demands in the model. |

Safety Stock Option |

Select one of these values:

Note: Once the Planning Instance is selected, the system updates this field with the value on Planning Instance. You can change it at anytime, and save. This new value will remain with the run control, and not copy back to the Planning Instance. |

Feasibility Options

Field or Control |

Description |

|---|---|

Allow Alternate Routing |

Select to enable the Feasible solver to attempt to use additional means of supply as defined on the sourcing template to resolve infeasibilities. The Feasible solver attempts to use alternate purchases, transfers, or production options to resolve a material infeasibility before it tries to reschedule the demand or supply. Select this option if you want the solver to use alternate routings when you also select the Run Lateness/Stock Adjust Phase option. |

Run Lateness Phase |

The Reduce Lateness Phase is a post process that performs a search to determine all of the possible methods to source the end item and meet the end demand on time. It considers late demands in priority order, working on intolerably late orders first. It attempts to meet the demand on time. If it cannot, it attempts to meet the demand as close as possible to the due date. Failing that, it attempts to reduce the lateness of the order as much as possible. The stock adjustment phase attempts to reduce temporary excess by scheduling supplies just in time for their demands while maintaining capacity. In addition, it attempts to restore any missed safety stock periods by scheduling late any demands that are a lower priority than safety stock. |

Make Plan Capacity Feasible |

Select to indicate that you want the Feasible solver to resolve capacity violations between the early fence and capacity fence. If you do not select this option, the solver considers only material feasibility, not capacity feasibility, when you run the plan. Note: The Feasible solver resolves aggregate resource violations, not detailed resource violations. |

Transfer Network Onhand |

Select to indicate that you want to create planned transfers with the available planned on-hand quantity if there are any from the source business unit, starting at the early fence of the source business unit and item. This option is run for each transfer option on the sourcing template in the order of the sourcing template priority. If the available on hand at the source business unit is more than the demand quantity, the system only transfers up to the demand quantity. If the supply is not enough to cover the demand, the system continues to the next transfer option on the sourcing template until the demand quantity is fully covered or all transfer options are exhausted. |

Allow Cancellations

At the start of the solver run, the Feasible solver deletes planned orders that are not firm and cancels all the excess supplies at the end of the run. You can use the check boxes in the Allow Cancellations group box to define to the feasible solver which orders it can cancel.

The system passes the frozen supply setting from the PeopleSoft Manufacturing system. You can then make the update in PeopleSoft Supply Planning and apply the update back to manufacturing.

The default value for the check boxes is selected. Click the check box for the type of order or for the firm-planned order that you want to deselect. When you deselect an order, the system deselects the check box and does not allow the cancellation of frozen supplies.

The default value for the check boxes is selected. Click the check box for the type of order or for the firm-planned order that you want to deselect. When you deselect an order, the system deselects the check box and does not allow the cancellation. Available orders include:

Production Order: Select to allow the cancellation of production orders.

Purchase Order: Select to allow the cancellation of purchase orders.

Transfer Order: Select to allow the cancellation of transfer orders.

Production Order: Select from Production Order statuses for cancellations. The statuses are:

Entered

Firmed

In process

Released

The default is to cancel Production Orders that are excess.

Firmed Planned Production: Select to allow the cancellation of firmed-firmed production. This is a production ID or production schedule that has a quantity, start date, and due date, but the bill of material and routing are frozen and the component and operation lists exist.

Firmed Planned PO: Select to allow the cancellation of firm-planned purchase orders.

Firmed Planned Transfers: Select to allow the cancellation of firm-planned transfers.