Running the Material Solver

This topic provides an overview of the Material solver and discusses how to define the Material solver.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

PL_MRP_SOLVE |

Define material planning options and run the Material solver. |

The Material solver creates a simple material plan to give an accurate picture of the lead time and materials that are necessary to satisfy all of the top-level demands. It creates supplies just in time to satisfy the demand. Material planning handles supply tasks on a first-come, first-served basis. Before it creates any new planned orders, the solver reschedules nonfrozen supplies or uses existing orders. It creates new supplies only after it uses all of the existing nonfrozen supplies and the demands remain unmet. The Material solver uses existing supply or creates supply for all of the demands in the system. If the demand is beyond the phase-out date, the solver does not create new supplies for the item.

The Material solver has a tolerance setting where a late supply is acceptable for a certain number of days. The ‘Tolerance’ for lateness can be specified for an item in calendar days starting from 0 (default value) up to a maximum of 999 days. If supply order falls inside specified window, existing supply order is considered first before any new supply orders can be created. The Tolerance window Reschedule Tolerance is available under the Solvers link on the Planning tab of the Business Unit/Item attributes page.

You can run the Material solver in regenerative or net change mode. In regenerative mode, the solver considers all of the items. In net change mode, the solver considers only those items with violations, items with a negative quantity at any point at or after the early fence.

This solver uses an item histogram to check for negative projected on-hand quantity at any point. A negative projected on-hand quantity can result from new demands, deleted supply, or unmet demand from the previous run. The Material solver creates planned supplies to meet negative quantity.

If lead time for a planned order pushes the start date before the early fence, the planned order will be scheduled to begin at the early fence. This may result in material shortages for both dependent and independent demands.

Additionally, the Material solver:

Sorts all items in low-level code order.

The Material solver solves for items in the level-code order starting with the lowest-level code. Higher assemblies have lower-level codes.

Deletes all of the nonfrozen planned supplies for the item that is being planned

Sorts all of the demands–sales orders, production components, transfers, forecasts and safety stock, material stock request, and end demand–by target date.

The solver then matches supply and demand, starting with the quantity on hand. The Material solver sums all of the demands that occur at the same time.

Sorts all of the supplies-POs, planned POs, production orders, planned production, and transfers–by date.

Moves existing nonfrozen supplies.

Creates supplies to meet demands.

Cancels remaining nonfrozen supplies.

Note: The Material solver does not consider capacity.

Sourcing Options

The Material solver uses the default sourcing option only, and considers no alternate sourcing options. If the sourcing option is not effective or no default sourcing option is defined, the demands for the item are not met.

Negative Quantity On Hand

First, the Material solver satisfies negative quantity on hand, moving enough supplies to meet the negative quantity on hand. For example, it moves supplies occurring later than the early fence of the item as close to the early fence as possible, and when the total supply quantity that is moved does not satisfy the quantity on hand, it creates new supplies as close to the early fence as possible.

Fixed Periods

The Material solver includes an algorithm that determines the maximum amount that is needed between the first demand and a fixed period amount of time after all of the existing orders have been used. The fixed period is defined as a number of days on the item record. The solver consolidates demands (including safety stock) for the item for a fixed period number of days and creates a single supply.

The Material solver considers the fixed period while planning new supplies only (it does not consider the fixed period when using existing supplies). The fixed period quantity is equal to the sum of all of the demand quantities in the fixed period, plus the maximum safety limit in that period.

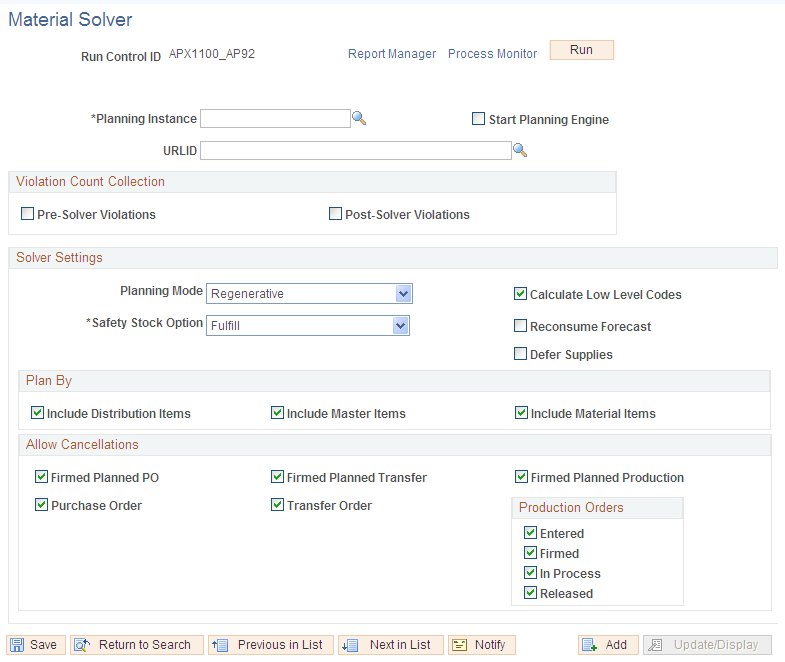

Use the Material Solver page (PL_MRP_SOLVE) to define material planning options and run the Material solver.

Navigation:

This example illustrates the fields and controls on the Material Solver Page . You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Run |

Click to generate a material plan using the PeopleSoft Process Scheduler. |

Planning Instance |

Select a planning instance. Planning instances IDs define a complete set of data analyzed to create a material supply plan |

Solver Settings

Field or Control |

Description |

|---|---|

Planning Mode |

Values are: Regenerative: The Material solver plans for every item in the model. The solver deletes all of the planned orders before planning for each item. Net Change: The Material solver replans only those items that are marked to be planned, only items with violations (items with negative quantity at any point at or after the item's early fence). The solver uses an item histogram to check for projected on-hand quantity at any point. Projected on-hand quantity can become negative as a result of new demands, if supplies are deleted, or if the demand is not satisfied from the previous run. The Material solver considers no new supplies in net change mode (it does not reschedule new supplies to meet new demands), and creates only planned supplies to meet negative quantity. |

Safety Stock Option |

Specify how you want the solver to plan for safety stock levels. Select Ignore to ignore safety-stock constraints. Use this value for what-if scenarios. Select Ignore Prior to First Demand if you want the solver to ignore safety stock demands prior to the first demand. Select Fulfill if you want the solver to plan supply for safety-stock demand as early as possible after the item's early fence. This is the default setting. Note: Once the Planning Instance is selected, the system updates this field with the value on Planning Instance. You can change it at anytime, and save. This new value will remain with the run control, and not copy back to the Planning Instance. |

Defer Supplies |

Select to indicate that supplies should be moved out later to meet a demand. Generally, supplies are moved earlier to meet demands on time. |

Plan By

Use this group box to indicate whether you want the solver to include items that have been defined in the material plan, master plan, distribution plan, or any combination. The solver includes items that are associated with the specified planned-by types only.

Select the Include Distribution Items, Include Master Items, or Include Material Items check box or any combination to items in include in the material plan.

Allow Cancellations

At the start of the solver run, the Material solver deletes planned orders that are not firm and cancels all the excess supplies at the end of the run. You can also use the check boxes in the Allow Cancellations group box to define to the Material solver which orders it can cancel when the supply is not frozen.

The system passes the frozen supply setting from the PeopleSoft Manufacturing system. You can then make the update in PeopleSoft Supply Planning and apply the update back to manufacturing. Frozen orders cannot be cancelled by the Material solver even if the orders are in excess. You can define an order as frozen using pages for each type of order. The system reschedules nonfrozen orders to meet demand on time. If the supplies are frozen and supply cannot be created on time, the system uses late frozen supply. If there is no late supply, then the supply is created in the early fence.

The default value for the check boxes is selected. Click the check box for the type of order or for the firm-planned order that you want to deselect. When you deselect an order, the system deselects the check box and does not allow the cancellation of frozen supplies. Available orders include:

Production Order: Select to allow the cancellation of production orders.

Purchase Order: Select to allow the cancellation of purchase orders.

Transfer Order: Select to allow the cancellation of transfer orders.

Production Order: Select from Production Order statuses for cancellations. The statuses are:

Entered

Firmed

In process

Released

The default is to cancel Production Orders that are excess.

Firmed Planned Production: Select to allow the cancellation of firmed-firmed production. This is a production ID or production schedule that has a quantity, start date, and due date, but the bill of material and routing are frozen and the component and operation lists exist.

Firmed Planned PO: Select to allow the cancellation of firm-planned purchase orders.

Firmed Planned Transfers: Select to allow the cancellation of firm-planned transfers.