UX One: Maintenance Reliability Page

The Maintenance Reliability page (P13003X|W13003XC) enables users to receive alerts regarding overdue work orders and preventive maintenance records that require attention. The page also provides analytical data about the reliability of the equipment used by the maintenance team.

To access the UX One Maintenance Reliability page, log in to the EnterpriseOne system using the Maintenance Operations Manager role. When you log in with this role, the system automatically displays the Maintenance Operations Manager page. Click the Maintenance Reliability task on the springboard to access the Maintenance Reliability page.

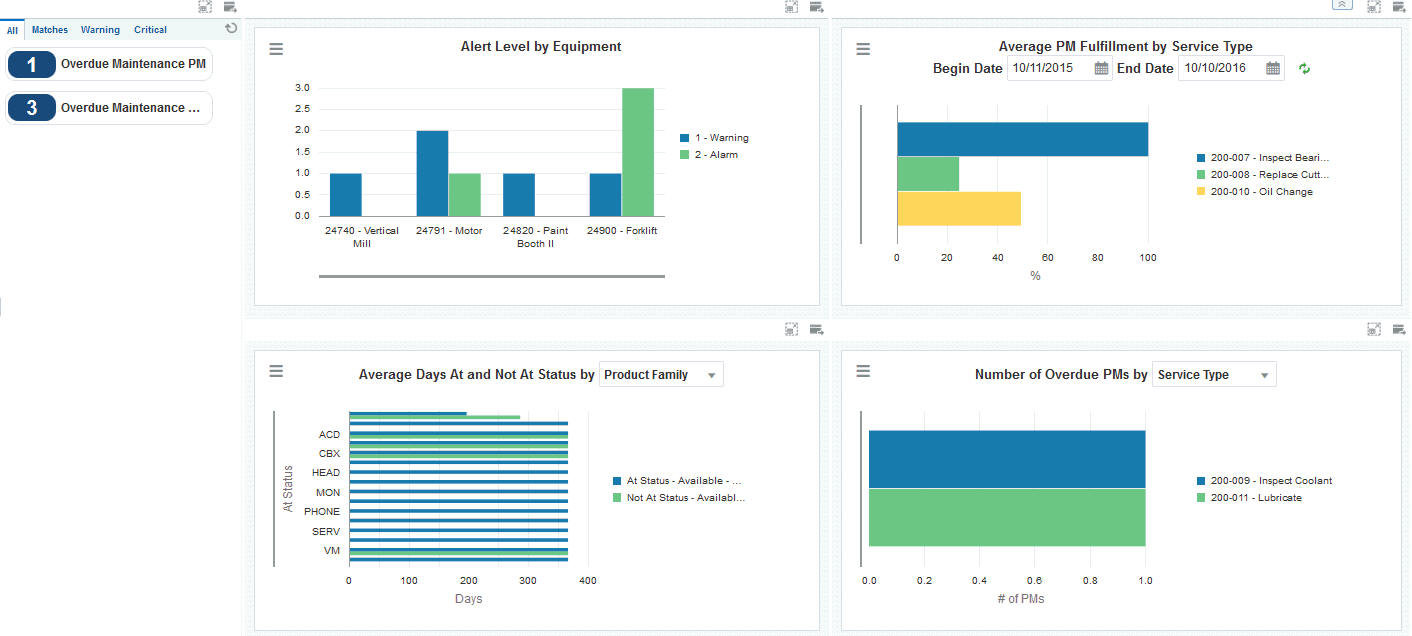

This graphic illustrates the Maintenance Reliability page:

Watchlist Alerts

These alerts are based on EnterpriseOne programs. By default, the alerts are set up to use queries that are based on delivered demo data. Each of these queries is associated with a specific program version. To use a different query or call a different program version, you can modify these queries or create new queries that better meet your requirements. Additionally, these watchlists have been set up with specific warning and critical threshold values. You can adjust these values to meet your requirements.

This table lists and describes the watchlist alerts that are available on the Maintenance Reliability page:

Watchlist Alert |

Description |

|---|---|

Overdue Maintenance PMs |

This alert tells users how many preventive maintenance records are currently overdue. This alert is based on the Preventive Maintenance Backlog program (P12071). When you click the alert, the system displays the PM Backlog form. The following form layout is available:

The following grid format is available:

|

Overdue Maintenance WOs |

This alert tells users how many work orders are currently overdue. This alert is based on the Planning Workbench program (P13700). When you click the alert, the system displays the Search for Equipment Work Orders form. |

For additional information about the programs associated with these watchlist alerts, see:

Working with Condition-Based Alerts in the JD Edwards EnterpriseOne Applications Condition-Based Maintenance Implementation Guide.

Creating Work Orders Using the Planning Workbench Program (P13700) in the JD Edwards EnterpriseOne Applications Capital Asset Management Implementation Guide.

Working with Preventive Maintenance Schedules in the JD Edwards EnterpriseOne Applications Capital Asset Management Implementation Guide.

Charts

These charts are based on EnterpriseOne programs. By default, the charts are set up to render using queries that are based on delivered demo data. Each of these queries is associated with a specific program version. To use a different query or call a different program version, you can modify these queries or create new queries that better meet your requirements.

This table lists and describes the charts that are available on the Maintenance Reliability page:

Component Title |

Description |

|---|---|

Alert Level by Equipment (P1310X|W1310XA) |

Use this chart to view the alert level for each piece of equipment. This chart is based on the Condition-Based Alerts Workbench program (P1310). |

Average PM Fulfillment by Service Type (P13570X|W13570XC) |

Use this chart to view average preventative maintenance fulfillment data by service type. This chart is based on the One View PM Analysis program (P13570). Additionally, you can use the Begin Date and End Date fields to adjust the date range for the chart. |

Average Days At and Not At Status (P13400X|W13400XA) |

Use this chart to view the number of days that equipment items have been at or not at a specified status. This chart is based on the One View Equipment Status Inquiry program (P13400). Additionally, you can use the drop-down menu on the top of the chart to change the data that the system displays. You can select one of these options:

|

Number of Overdue PMs (P13570X|W13570XA) |

Use this chart to view the number of overdue preventative maintenance there currently are. This chart is based on the One View PM Analysis program (P13570). You can select one of these options:

|

For additional information about the programs associated with these charts, see these topics in the JD Edwards EnterpriseOne Applications One View Reporting User Guide:

Additionally, see Working with Condition-Based Alerts in the JD Edwards EnterpriseOne Applications Condition-Based Maintenance Implementation Guide.