Consigned Inventory

Inventory that is in the possession of the customer (buyer), but is still owned by the supplier is called consigned inventory. Consigned inventory management is a common business process in life sciences, manufacturing, and wholesale and distribution industries.

After establishing an agreement, the supplier places some of their inventory in their customer's possession (in the customer's store or warehouse) and allows them to sell or consume directly from this inventory.

The JD Edwards EnterpriseOne Outbound Inventory Management system provides suppliers the ability to ship goods to a customer's location, but retain ownership until the goods are consumed. After the customer reports usage, the supplier invoices the customer for the consumed goods.

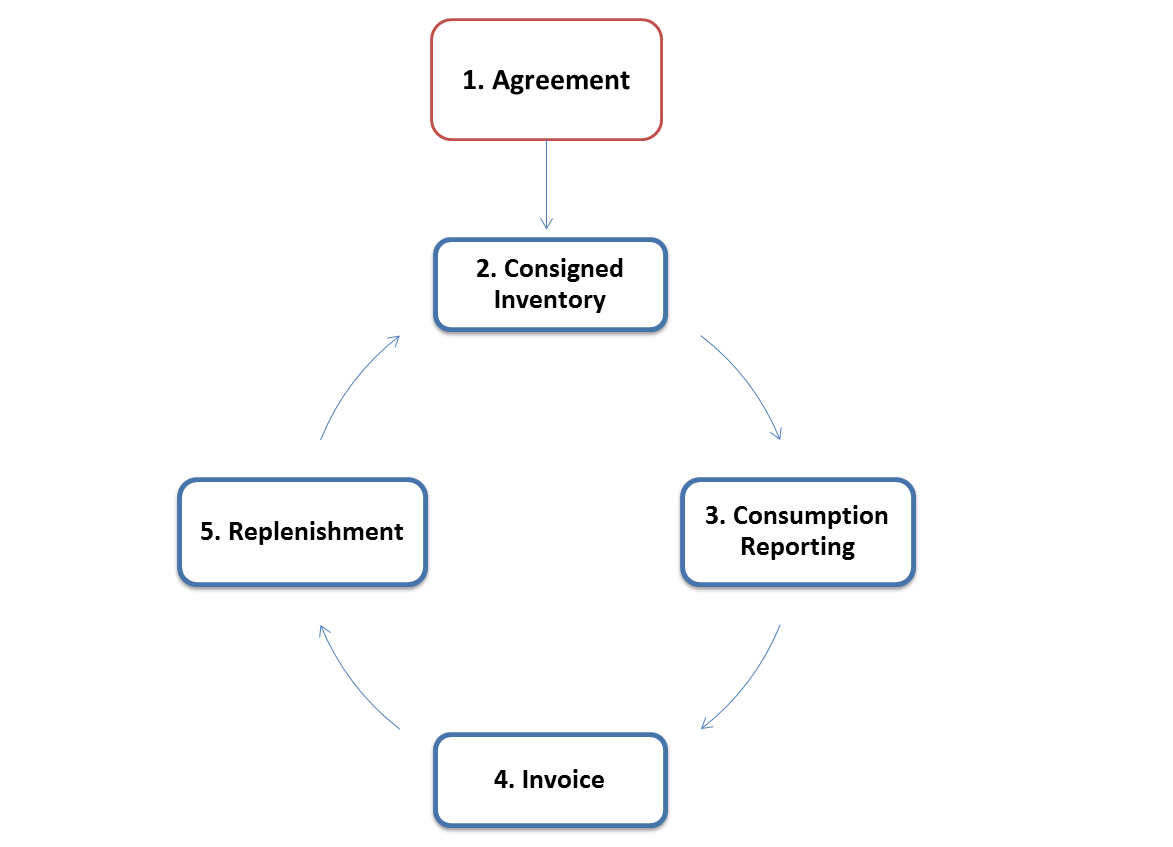

The following diagram describes the process flow for consigned inventory:

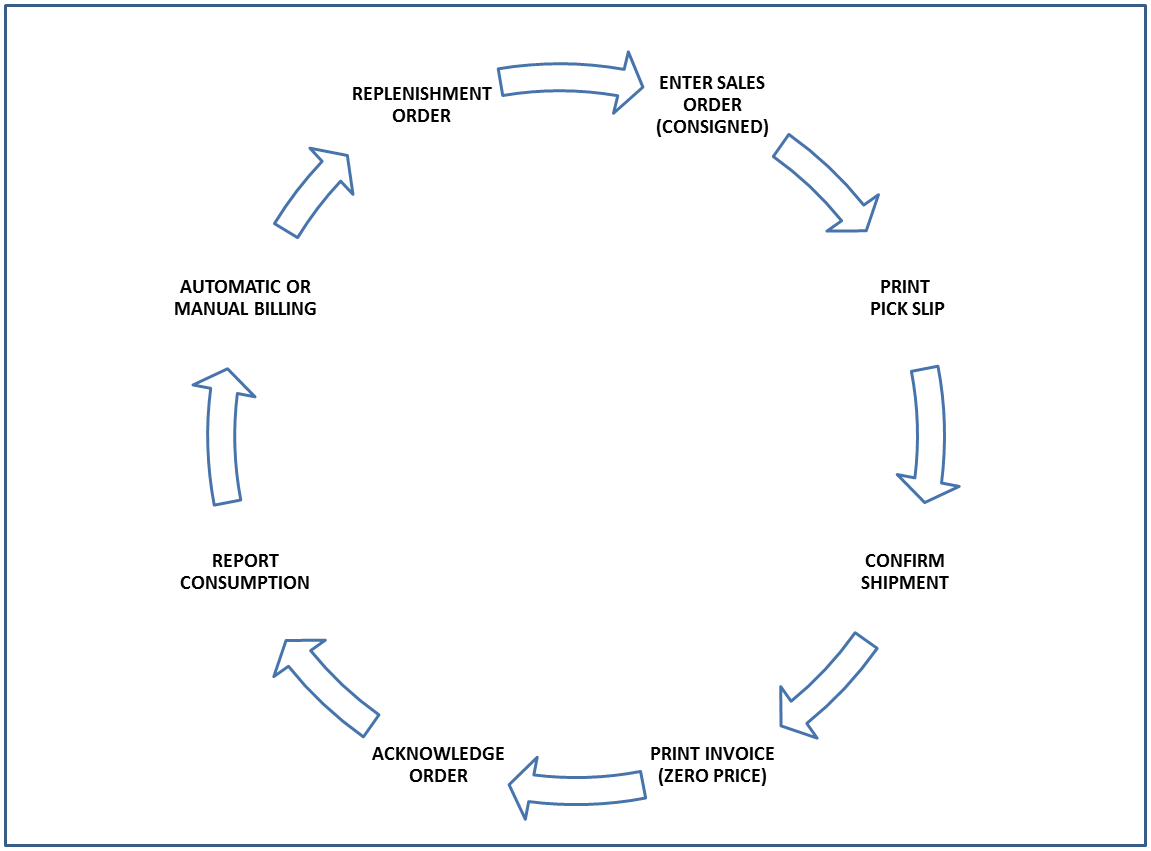

The following diagram illustrates the business process flow used by JD Edwards EnterpriseOne for consigned inventory:

The JD Edwards Outbound Inventory Management system uses the following process for consigned inventory management:

Supplier and customer establish an agreement for shipping and maintaining inventory at the customer's location

Supplier ships inventory to customer's location

Customer acknowledges the receipt of inventory

Customer reports consumption of inventory

Supplier invoices the customer after the customer reports consumption

Supplier replenishes inventory at customer's location based on agreed replenishment method

The JD Edwards EnterpriseOne Outbound Inventory Management system enables the use of the following replenishment methods for consigned inventory:

One-to-one replenishment

Reorder point replenishment