Entering Return Material Authorizations

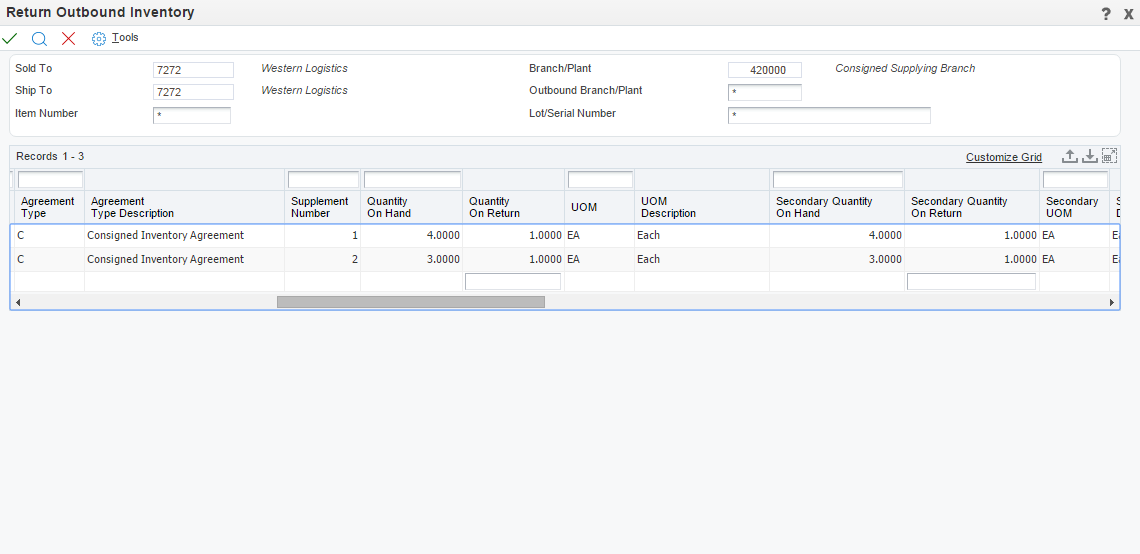

To return outbound inventory using RMA, use the Return Outbound Inventory application (P42I01). You search for items using Sold To, Ship To, Item Number, Outbound Branch/Plant and Lot. The system then displays the list of items that are available for return. You can return both quantity-on-hand and quantity-on-hold. The system also enables you to enter quantity-to-return in both primary and secondary units.

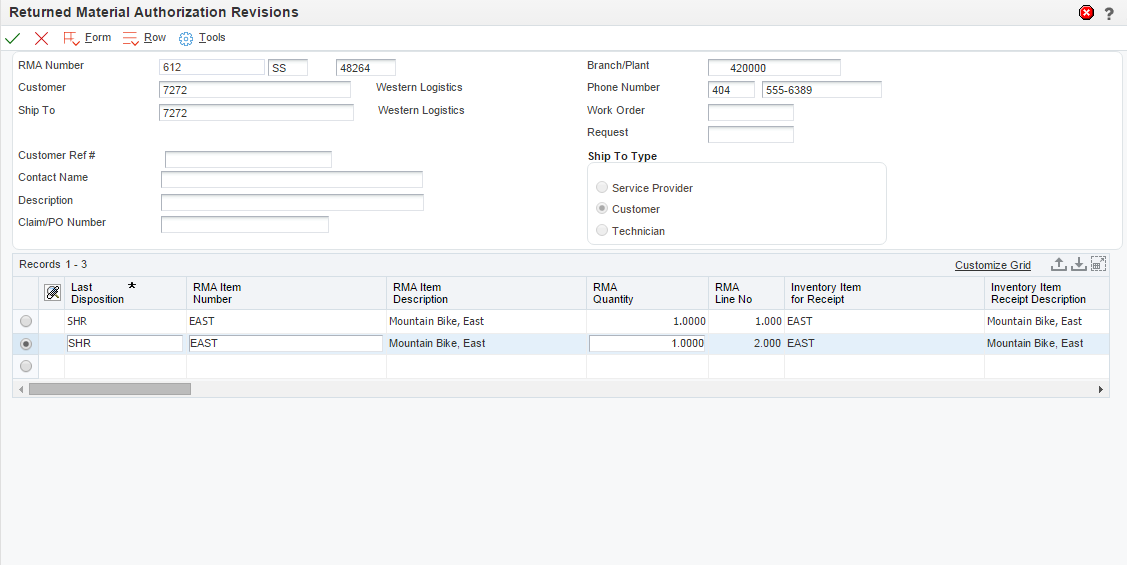

You access the Return Outbound Inventory application from the Form menu on the Returned Material Authorization Revisions application. After you complete the fields on the Return Outbound Inventory application, the system redirects you to the Returned Material Authorizations Revisions application and populates the values you entered in the Return Outbound Inventory application.

For returning outbound inventory transactions, you can use the following processes to create RMAs:

Create a credit order

Create a credit order and purchase order

Create a purchase order

Create sales order with zero price

Create sales order with zero price and a purchase order

Create a sales order with price

Create a sales order with price and a purchase order

Access the Returned Outbound Inventory program.

Form Name |

Form ID |

Navigation |

|---|---|---|

Returned Material Authorization Revisions |

W400511E |

Daily Work Order Processing (G1712) or Additional Order Processes (G4212), Returned Materials AuthorizationClick Add on the Work with Return Material Authorization form. Select Outbound Inventory from the Form menu. |

On the Return Outbound Inventory form, complete the following fields to filter records:

- Item Number

Enter the item number of the item you want to return.

- Outbound Branch/Plant

Enter the outbound branch/plant where the inventory was originally shipped.

- Lot/Serial

Enter the lot number for the items you want to return.

Click the Find button. The system displays the following information based on your search criteria:

Item number and description

Outbound item group and description

Agreement information

Quantity on-hand and on-hold

Outbound location and outbound location type

After filtering records, complete the following fields in the grid on the Return Outbound Inventory form:

- Quantity On Return

Enter the on-hand quantity you want to return. This quantity is expressed in the primary unit of measure.

- Secondary Quantity On Return

Enter the on-hand quantity you want to return. This quantity is measured in the secondary unit of measure.

- Shipping Branch/Plant

Enter the branch/plant from where the item will be shipped.

After completing the fields, click the OK button. The system displays the Returned Material Authorization Revisions form.

On the Returned Material Authorization Revisions form, verify or complete the following fields:

- Customer

Verify the customer number for creating the RMA.

- Customer Ref # (customer reference number)

Use to cross-reference a customer number with the RMA.

- Branch/Plant

Enter the branch/plant that the system uses when creating the sales order and purchase order.

- Last Disposition

Enter a value from UDC 40/RN that indicates the current status of a Returned Material Authorization line. The special handling code for the Last Disposition field determines whether a purchase order, sales order (or credit order), or both are created when you enter the last disposition on an RMA line.

The special handling codes are:

1: Purchase order only.

2: Sales order only.

5: Purchase order and sales order.

7: Purchase order and credit order.

- RMA Item Number

Verify the item number for the item to be returned.

- RMA Quantity

Verify the quantity that you enter through the Return Outbound Inventory application.

- RMA Type

Enter a value from UDC 00/DT that indicates the document type of the RMA records.