Master Work Order Parts Lists for Style Items

You use the Master Work Order Parts List for Style Items program (PCW50) to create and manage the consolidated parts list at the master work order level. You copy the bill of material for the style item root level 0 to create the parts list for the master work order. The system uses the batch quantity of 0 for the bill of material and routing. You can also run the Work Order Processing for Style Items program (R31F410) to create the parts list. You run the Work Order Processing for Style Items program to protect against performance issues when a master work order contains a significant number of child work orders or deep bills of material.

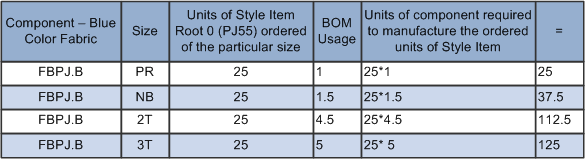

The calculation for the quantity in the Quantity Ordered field on the Master Work Order Parts List Details for Style Items form is (style item root level 0 quantity ordered by attribute) x (bill of material usage for the component) = (quantity of the component required to manufacture the ordered units of the style item).

This diagram shows an example of the quantity-ordered calculation:

Total Quantity of component FBPJ.B = 25 + 37.5 + 112.5 + 125 = 300

You can also use the Master Work Order Parts List for Style Items program to view, modify, and delete parts lists for master work orders. The system stores the parts lists for master work orders in the Style Work Order Parts List table (FCW67). The FCW67 table is a workfile and holds the consolidated view of all the child work order parts lists.

The system also enables the creation of parts lists by means of a batch program. You run the Work Order Processing for Style Items program to create the parts lists by setting data selection over the Work Order Detail for Style Items table (FCW66).

The Master Work Order Parts List for Style Items program generates the standard parts lists for all child style item work orders. Once the child style item work orders are created, transactions and changes to the master work order are pushed down to the parts lists of the individual child style item work orders.

You group the parts lists and enter the exact amount to use. The system prorates the quantities between the different lines to specify the actual amount of material. Changes and additions of components are split over single work orders.

The system enables global changes to the work order parts list of the child style item work orders. You can:

-

Remove a component.

-

Change component quantity.

-

Add a new component.

When entering a new component you should specify a line number of an existing component for the system to base the split off of. Without an existing line number reference, the system cannot append a new component because it does not know how to split the quantity ordered across the single work orders.

The system recalculates the parts list every time you use the Parts List option on the Row menu of the Master Work Order Revisions for Style Items form. The system pushes changes at the child style item work order level up to the master work order.