Master Work Order Processing for Style Items

You use the Master Work Order Processing for Style Items program (PCW49) to create, process, and maintain master work orders for style items. After you create the master work order, you run the Work Order Processing for Style Items program (R31F410) to attach the parts lists and routing instructions for each child work order.

The Work Order Processing for Style Items program updates the Work Order Parts List (F3111) and Work Order Routing (F3112) tables.

The source data for the Work Order Processing for Style Items program comes from three tables: Work Order Detail for Style Items (FCW66), Work Order Master File (F4801), and Work Order Master Tag File (F4801T). The FCW66 table stores the cross-reference between the master work order and its child work orders. The cross-reference information enables processing of all child style item work orders based on the master work order number.

Based on the data selection in the Work Order Processing for Style Items program, the system runs the Work Order Processing for Style Items program (R31F410) for each child work order of the master work order. The Work Order Processing for Style Items program calls the Order Processing program (R31410), which processes the work orders to attach parts lists and routing instructions.

If you attach the parts list and routing instructions interactively, you can use the Work Order Processing for Style Items program to generate and print the shop paperwork. The system prints the parts list and routing instructions, shop packet summary, and shortage report based on the processing option settings of the Order Processing program. The system prints all the child work orders together in one output.

After all child work orders are processed, the master work order status is updated if the Master Work Order Detail processing option on the Edits tab is set to a value of 1. The system updates the status of the master work order with the status of the first child work order. Although a child work order is at status 10, the first child work order is at status 45 so the master work order will be at status 45. You use the Manufacturing Work Order Processing program (P48013) to review the child work orders. You can also select a child work order on the Master Work Order Revisions for Style Items form and then select Update Child WO from the Row menu to launch the Manufacturing Work Order Processing program.

The Additional Style Item Information Work File table (FCW63) stores the master work order number derived from a next number bucket.

During master work order processing, the system uses the Work Order Header for Style Items table (FCW65) to enable data selection for outside operations. The system groups the outside operations.

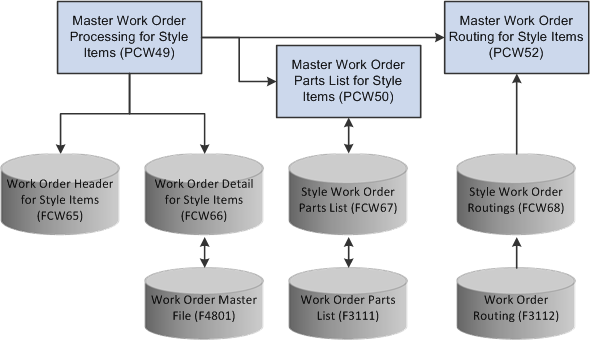

This diagram illustrates the master work order process: