Understanding Automatic Allocations

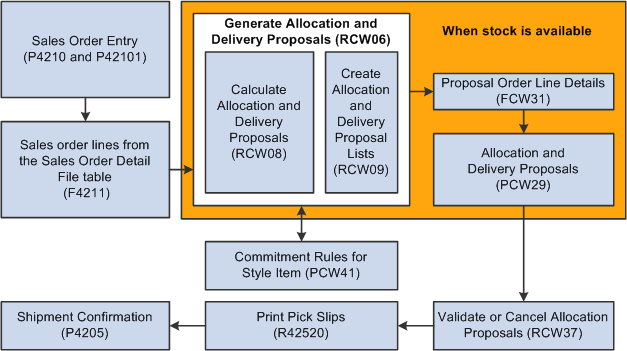

You can perform automatic allocations to fulfill sales orders for style items. Automatic allocations support both allocation proposals and delivery proposals. This diagram illustrates the Automatic Allocations process for style item orders:

You define the parameters for the allocation of products and the primary order to fill. You also define the constraints for delivery. Once the parameters are defined, you run the Generate Allocation and Delivery Proposals program (RCW06) to generate allocation and delivery proposals. You can run both allocation and delivery at the same time. You can also separate the processes to first allocate and commit stock, and then run the Generate Allocation and Delivery Proposals program again to deliver the product.

The Generate Allocation and Delivery Proposals program calls the Calculate Allocation and Delivery Proposals (RCW08) and Create Allocation and Delivery Proposal Lists (RCW09) programs to calculate and create the allocations proposal. A group of sales orders is the input for the reports. You set the data selection based on sales order selection.

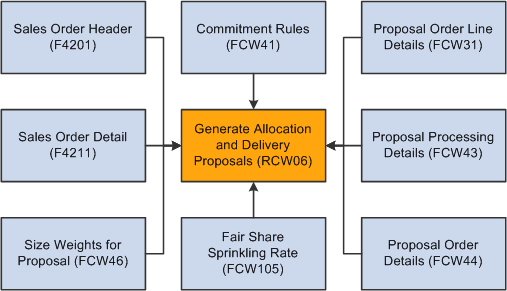

The Generate Allocation and Delivery Proposals (RCW06), Calculate Allocation and Delivery Proposals (RCW08), and Create Allocation and Delivery Proposal Lists (RCW09) programs first extract the sales order lines based on the statuses set in the processing options of the Generate Allocation and Delivery Proposals program. The Generate Allocation and Delivery Proposals program uses order information stored in the Sales Order Header File (F4201) and F4211 tables to prioritize the sales order lines. The Generate Allocation and Delivery Proposals program generates allocation proposals based on the commitment rules defined in the Commitment Rules for Style Item program and stored in the FCW41 table.

The Generate Allocation and Delivery Proposals program then updates the Proposal Order Line Details (FCW31), Proposal Processing Details (FCW43), Proposal Order Details (FCW44), and F4211 tables.

The FCW31 table contains values and other proposal details from the F4211 table plus the priorities applied based on the FCW41 table.

The FCW43 table stores the processing option values of the Generate Allocation and Delivery Proposals program as set at the time the Generate Allocation and Delivery Proposals program is run. The system stores the processing option values because the values can be changed for every run of the program and the values are required later for further processing. The system also stores the proposal name that is equal to the version name of the Generate Allocation and Delivery Proposals program. The FCW43 table stores multiple records and multiple proposals. Each proposal is independent of the others.

The FCW44 table stores values and other proposal details from the F4201 table. The Generate Allocation and Delivery Proposals program updates the FCW44 table.

The Size Weights for Proposal table (FCW46) stores the size weight information for different sizes to be used during the proposal process. This table stores information for both allocation and delivery proposals.

The Fair Share Sprinkling Rate table (FCW105) stores values for the fair share calculation. The Calculate Fair Share for Proposals program (RCW60) adds all quantities to be allocated by item and stores the value in the Fair Share Sprinkling Rate (FCW105) table only if the Available Quantity is greater than 0. The Calculate Allocation and Delivery Proposals program uses the values in the FCW105 table to calculate the fair share.

The F4211 table is updated for order activity rule status and to reflect the other quantity 1 SO.

The quantity in the Soft Committed field is transferred to the Other Quantity 1 SO field for the sales order in the Item Location File table (F41021).

Because the Generate Allocation and Delivery Proposals program updates the Proposed Quantity to the Other Quantity 1 SO field, the other quantity 1 SO should be included in the availability calculation.

During the allocation process, the system calculates item availability based on the availability definition in the branch/plant constants and then uses item availability and allocation constraints to determine the proposed quantity. The system stores the proposed quantity in the Other Quantity 1 SO field.

If the availability definition in the branch/plant constants does not include Other Quantity 1 SO, then the system does not subtract the proposed quantity in the Other Quantity 1 SO bucket from the on hand quantity when calculating item availability. Thus, the item availability calculation is incorrect.

See Prerequisites.

This diagram illustrates the tables used by the Generate Allocation and Delivery Proposals program:

You review the calculated values in the Allocation and Delivery Proposals program (PCW29). You can modify, validate, and cancel proposals using the Allocation and Delivery Proposals program.

The proposals reside in the FCW31 table. The Allocation and Delivery Proposals program processes hard commitments against the validated order lines.

When you validate or cancel proposals, the Allocation and Delivery Proposals program calls the Validate Proposals program (RCW29V) to:

-

Validate a proposal from the Allocation and Delivery Proposals program.

-

Update the status and commitment flag in the F4211 table to a hard commitment.

-

Transfer quantity from the Other Quantity 1 SO field to the Hard Committed Sales field in the F41021 table.

You can also use the Validate or Cancel Allocation Proposals program (RCW37) to validate or cancel an allocation proposal. The Validate or Cancel Allocation Proposals program is run in standalone mode only.