Understanding Master Work Orders for Style Items

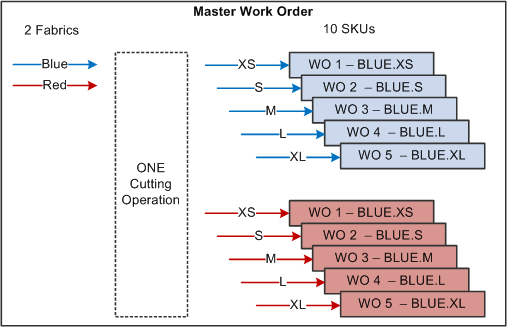

A master work order is a comprehensive work order that corresponds to one or several style item root level 0 items. A master work order encompasses a group of related standard manufacturing work orders that correspond to the child style items. A master work order is not a parent work order.

The system calls the Matrix Entry program (PCW10) when you enter a style item root level 0 on the master work order.

You can view the availability of selected style items at the parent level (style item root level 0) or child level (intermediate item level) for a branch/plant or all branch/plants on the Matrix Entry form. To view style item availability on the Matrix Entry form, you must embed the Style Item Availability form on the Matrix Entry form, and map the Selected Style Item field of the Matrix Entry form to the Style Item field of the Style Item Availability form.

See "Creating Embedded EnterpriseOne Form Content" in the JD Edwards EnterpriseOne Tools Composite Application Framework (CafeOne) User's Guide.

You manage everything at the master work order level. You group your parts lists and enter the exact quantities to use. The system prorates the quantities between the different lines in the master work order to specify the actual amount of material required for each child work order.

The master work order has corresponding child work orders, such as numbers 1, 2, 3, and so on, for the child style items.

The Work Order Detail for Style Items table (FCW66) ties the master work order of the style item root level 0 to the standard work orders for the child style items.

This diagram illustrates a master work order and standard work orders for the associated child style items: