Understanding Routing Instruction Creation for Style Items

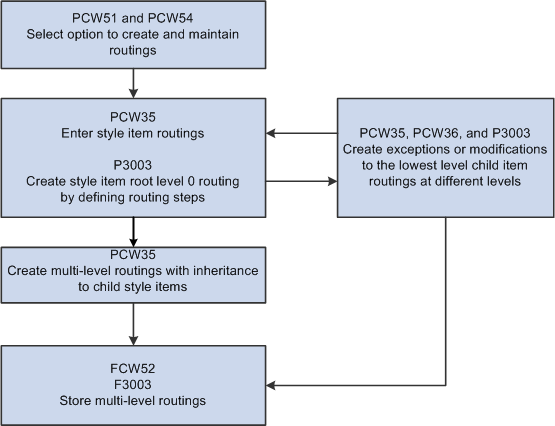

Routing instructions are the sequence of operations carried out in the process of manufacturing a style item. You use the Work With Style Routing Master program (PCW35) and Enter/Change Routing (P3003) to define the routing for the style item root level 0. The style item root level 0 is always passed into the Work With Style Routing Master program regardless of the level from which it is called in the Style Item Master (PCW51) or Style Items by Collection (PCW54) program.

The routings for the lowest-level child style items are copied from the style item root level 0. In the JD Edwards EnterpriseOne Apparel Management system, the routing typically remains the same for the style item root level 0 as well as the child style items.

Routing instructions do not depend on attributes such as color or size. For example, the process for the production of a blue jacket is no different from that for a green jacket. The process also remains the same in regard to size because the process does not change for a jacket size of small (S) versus medium (M). Thus, child style items inherit the routing of the style item root level 0.

The system enables review and modification of child style item routings. You use the Routing Exception program (PCW36) to override the style item root level 0 routing at the child level through exception processing. The child style item has the same routing as the style item root level 0 except when:

-

One material is not used for a color or a size.

For example, a skirt lining is not used for the black color.

-

Manufacturing times differ for bigger versus smaller sizes.

For example, the number of hours required for the stitching operations.

The system provides visual assistance on the Work With Style Routing form as color coding in the column headings. The color of the column headings changes according to the following statuses:

-

Blue is status 0

The color is blue after you create the routing for the style item root level 0 or any level of the style item but you have not yet created routings for the child style items.

-

Red is status 2

The color is red after you change the routing for the style item root level 0 or any level of the style item without re-creating the routings for the child style items.

-

Black is status 9

The color is black when all updates to the style item root level 0 or any level of the style item routing have been proliferated to the child style items.

The system stores routing information in the Style Routing Master File (FCW52) and Routing Master File (F3003) tables.

This diagram illustrates the routing creation process for style items:

Once the routing is created, the system uses standard JD Edwards EnterpriseOne functionality.

If you use the Work With Style Routing Master program to delete a routing, then the system deletes the routings for the style item root level 0 or any level of the style item. The system deletes the routing records from the FCW52 and F3003 tables.

The system enables the use of outside operations for which a particular operation is outsourced to a vendor. For example, manufacturers in the apparel industry might outsource such manufacturing tasks as dyeing, cutting, and sewing. A specific operation sequence in the routing instructions is identified as an outside operation. After defining the routing steps, the system creates the required documents, such as a purchase order, for the outside operations.