Generate an Electronic Production Record for a Product

Manufacturers in all industries are increasingly required for regulatory or traceability purposes, to provide the manufacturing records for their products in a digital format that's easily accessible. With the electronic production record (EPR), you can generate such a document that summarizes the complete work order and quality history of a product in a single, auditable record. This document contains the product information as planned and manufactured, including lot and serial information of input material. It also contains quality results for incoming, in process, and final inspection as well as non-conformance, corrective and preventive actions, equipment used, and electronic signatures for any of the business transactions critical to Good Manufacturing Practices (GMP).

You can perform the following tasks with this update:

- Generate the EPR report for completed or closed work orders.

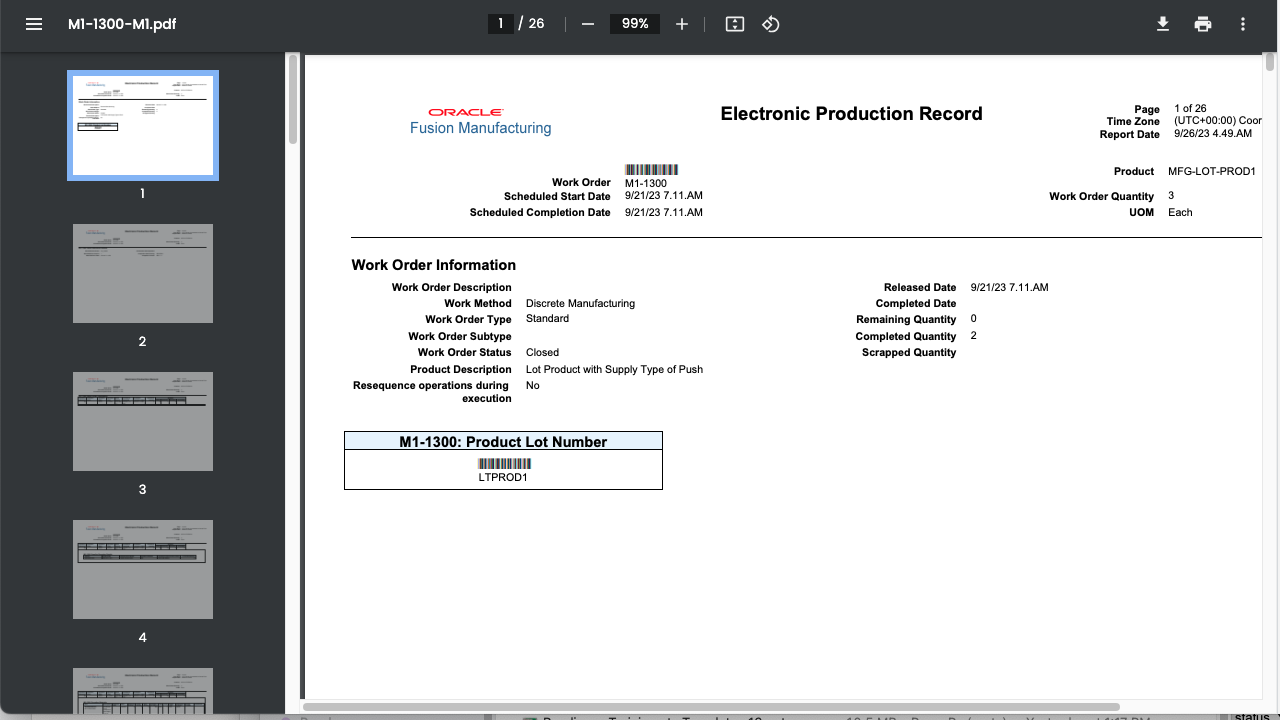

- Generate the EPR report in a PDF format with the following content:

- Work order details, work definition details, operations, materials, and resources

- Operation completion with back flush and inline inspections

- Product with serial and lot details

- Materials issued with serials and lot details

- Labor and equipment resources charged

- Ad hoc quality inspections

- Inspections performed for outside processing or supplier operations

- Inspection of purchased items that are directly procured against the work order

- Production exceptions and closure

- Electronic signatures for the previous events, if enabled

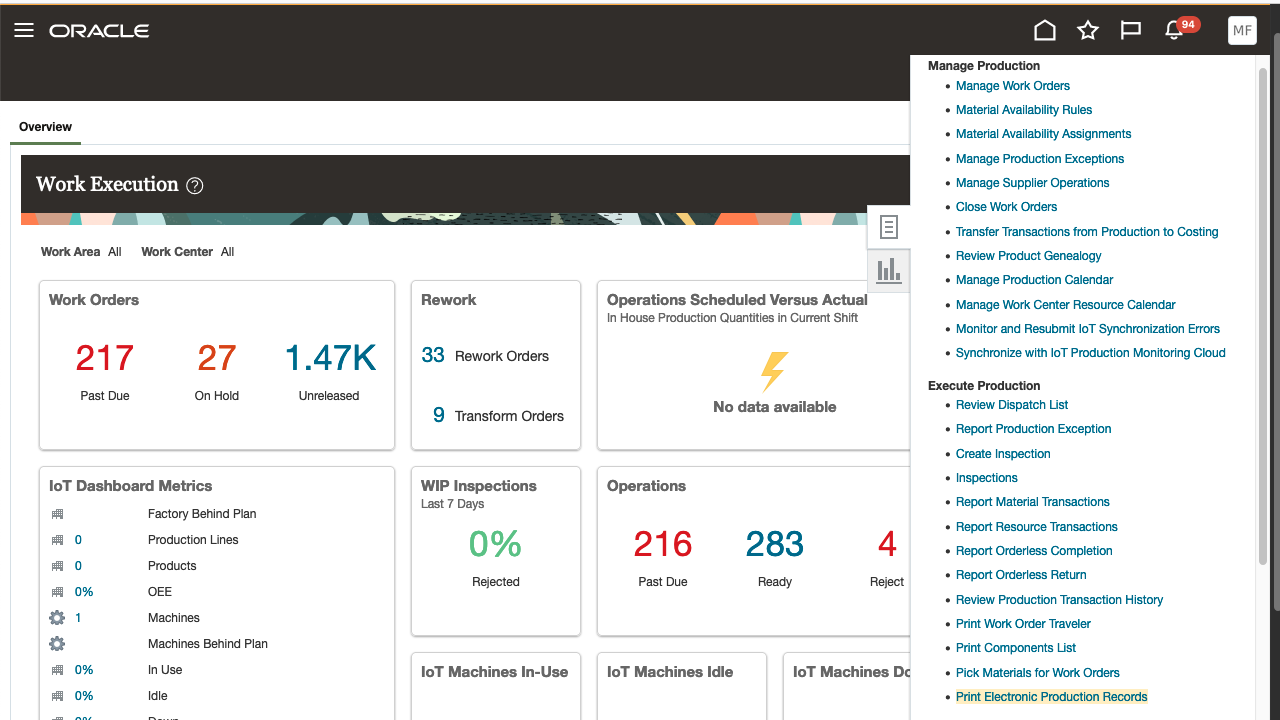

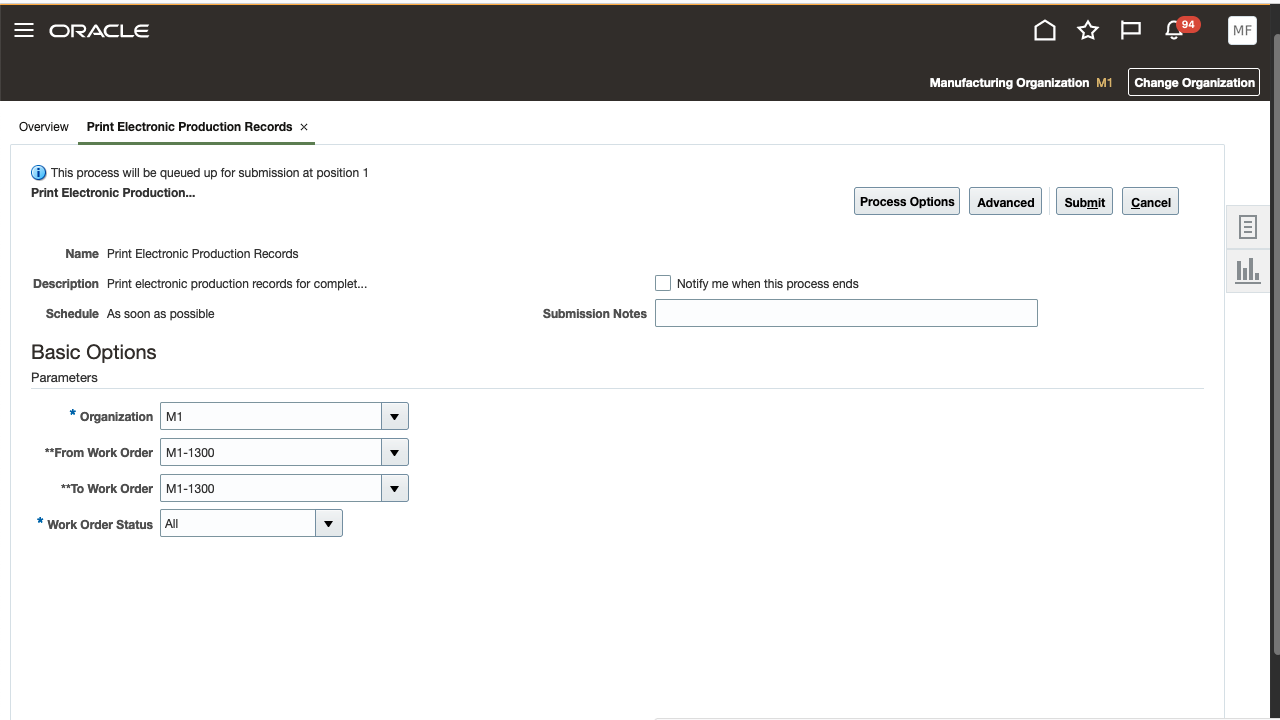

You can generate EPR documents for one or more work orders as shown below from the Manufacturing Work Execution task list.

Print Electronic Production Records Task from Manufacturing Work Execution Task List

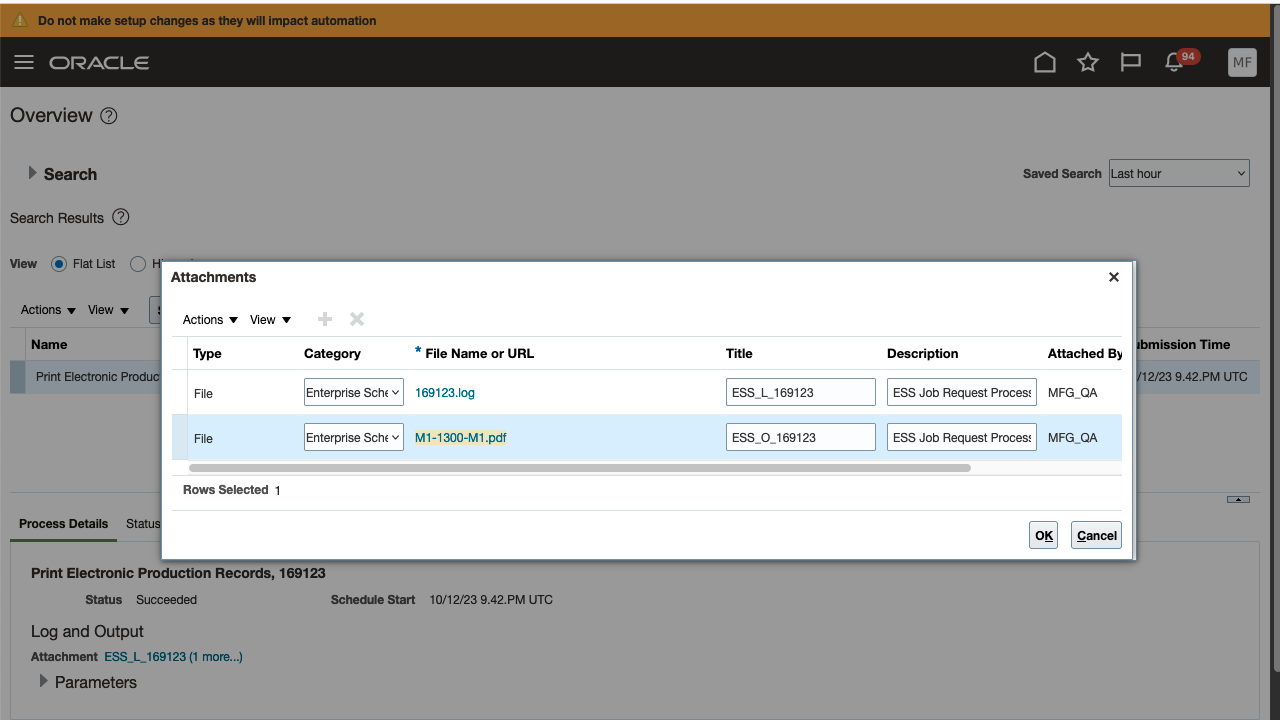

You can also request to generate the electronic production record and view the documents generated for the requests in the Scheduled Processes page under Tools.

EPR Generated as a PDF Document for Each Work Order

Creating an EPR swiftly facilitates a more efficient and streamlined method of collating essential work order information, enhancing the process of compliance documentation of product conformance ensuring audit trails and traceability.

- Risk associated with paperwork errors is mitigated, ensuring that the documentation presented during regulatory audits is both complete and accurate.

- Data is error-free and readily available, significantly aiding in audit processes and ensuring traceability is both seamless and reliable.

- For manufacturers in nonregulated industries, EPRs provide a consolidated report that quickly offers an acceptance record of a product.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- You can't capture the electronic signature for the electronic production record (EPR) at this time.

- The electronic production record is generated using Oracle Business Intelligence Publisher (BIP) and it's an extensible report that allows for the template to be modified.

- With knowledge of the BIP features, administrators can personalize the brand logo, styling, and layout of this report to enhance this further to meet their business needs.

Key Resources

- To learn more about Oracle Business Intelligence Publisher features that can be leveraged to enhance this report, refer to the product documentation

Access Requirements

Users who are assigned a configured job role that contains this privilege can access this feature:

- Print Electronic Production Records (WIP_PRINT_ELECTRONIC_PRODUCTION_RECORDS_PRIV)

This privilege was available prior to this update.