Extend Automated Work Execution by Sending Program Parameters, and Supporting Automatic Quality Inspection and Disposition

Manufacturers are now progressing towards including automation equipment in their manufacturing workflows to support the journey towards end to end automation. Bidirectional communication with automation equipment to the manufacturing execution systems through IoT interface allows automated work execution and eliminates errors while loading program file information in to the automation equipment. This bidirectional communication can be further leveraged to send additional information to the automation equipment and also to automate the quality inspection and disposition process based on information received from the equipment.

With this update, you can extend your current automated work execution with robotic integration to:

- Send program parameters and inspection characteristics in addition to the program file information to an automation equipment resource

- Automatically perform completion and rejection transactions based on inspection results received from automation equipment

The following are key capabilities related to the feature:

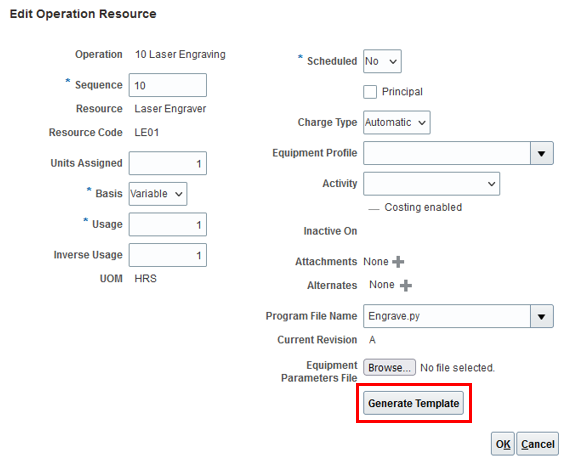

- Generate a equipment parameters file template to associate to work definition operation resource defined as automation equipment

Generation of Equipment Parameters File

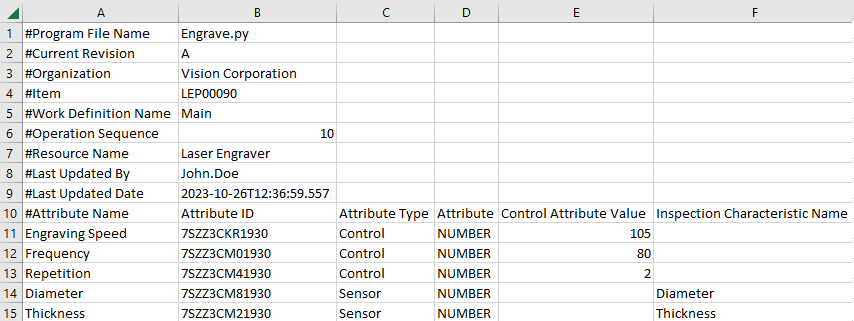

- Enrich the template with input program parameters and inspection characteristic names

Enrichment of the Equipment Parameters File

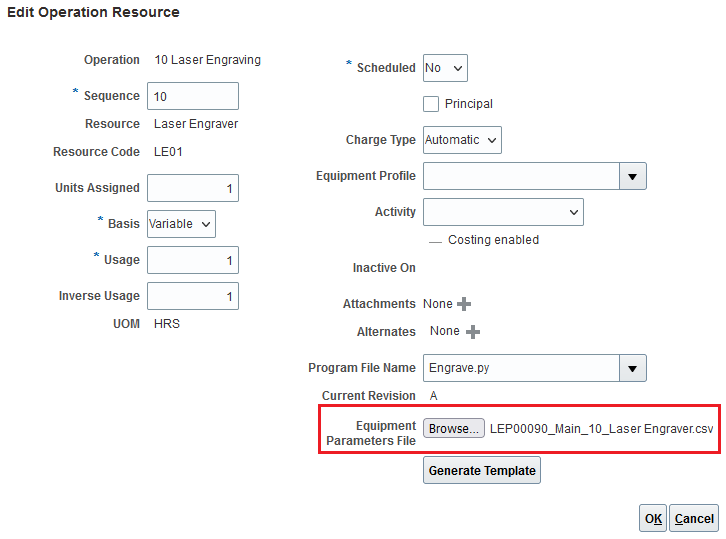

- Save and upload the .csv file to complete association to the work definition operation resource

Equipment Parameters File association to Work Definition Operation

- Send the equipment parameter values, inspection characteristic names, inspection plan identifier along with other details to IoT Production Monitoring upon initiating the start of a work order operation from the dispatch list in Manufacturing.

-

Perform automatic quality inspection and disposition through the integration with Oracle Quality Management, based on the sensor data received from automation equipment.

-

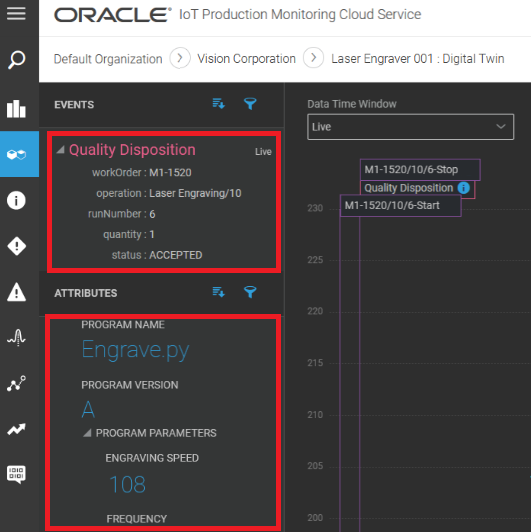

Monitor execution status real-time with contextual execution details, telemetry, and transactional data from the automation equipment. In the execution details section of attributes, the user can view the current work order, operation, quantity, program name, version, and user defined program parameters. In addition to execution details, if inspection events have been performed by the machine, inspection event results are also presented in the digital twin view of the machine.

Digital Twin View of Automation Equipment in IoT Production Monitoring Displaying Quality Disposition Details and Program Parameters

-

Create completion and rejection transactions automatically in Manufacturing based on the disposition details received from Quality Management.

While integrating automation equipment in native manufacturing workflows, providing relevant information to the equipment allows for faster transition into end to end automation.

- Sending program parameters in addition to program file information to an automation equipment eliminates errors that may be caused due to manual input into the machine. This provides flexibility to maintain a common program file to perform an operation, but parse item specific parameters for different item variants.

- Leveraging inspection results provided by the automation equipment in the form of telemetry data through IoT communication eliminates the need to manually acceptance and rejections of units produced by automation equipment during work order execution.

Steps to Enable

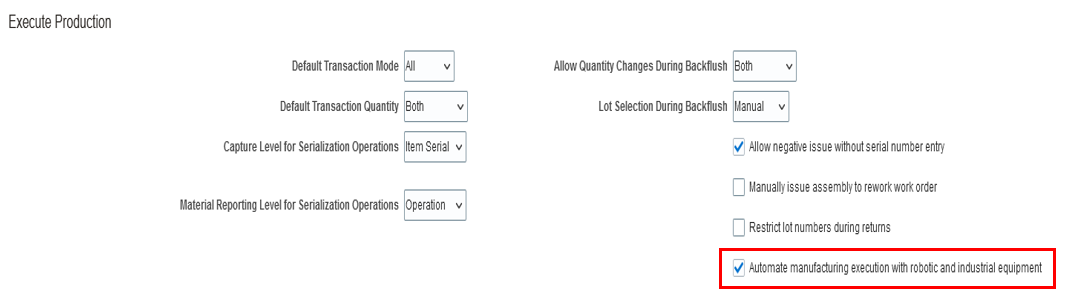

Enable the Enable synchronization to IoT Production Monitoring plant parameter, and then enable the Automate manufacturing execution with robotic and industrial equipment parameter to be able to use this feature.

Plant Parameter to Automate Manufacturing Execution Through Bidirectional Communication with Robotic and Industrial Equipment

Tips And Considerations

- The inspection characteristic names in the equipment parameters file associated to a work definition operation resource must be entered in the local language of the user that's configured in Production Monitoring for Manufacturing Cloud integration.

- If quantities were automatically reported as rejected based on inspection results received from the automation equipment, further disposition of the rejected quantities to scrap or completion must be done by the operator manually from the Review Dispatch List page.

Key Resources

- Refer to the What's New of the 23D feature: Automate Manufacturing Execution Through Bidirectional Communication with Robotic and Industrial Equipment as a starting point for this 24A feature

- Refer to the Extend Automated Work Execution by Sending Program Parameters and Supporting Automatic Quality Inspection and Disposition readiness training