Automatically Assign Item Structure Components to Work Definition Operations

Automatically Assign Item Structure Components to Work Definition Operations

Today coordinating item structure changes to work definitions requires a multistep process of reviewing and approving changes to implement. Specifically, the assignment of components to operations needs to be finalized before the work definition can be used for production, supply planning, and cost planning. In the item structure, the suggested operation sequence records a design engineer's suggestion for the operation sequence of components in a manufacturing work definition.

Using the Redwood user experience, you can now create or copy a discrete or process manufacturing work definition for a standard item with its components automatically assigned to operations based on the suggested operation sequence in the item structure. In addition, you can run the Process Item Changes to Work Definitions scheduled process to support the following scenarios:

- Automatically assign an added structure component to the corresponding manufacturing work definitions in the existing and Redwood user experiences.

- Receive a notification of an updated, suggested operation sequence for review and possible actions such as versioning, update, or correction.

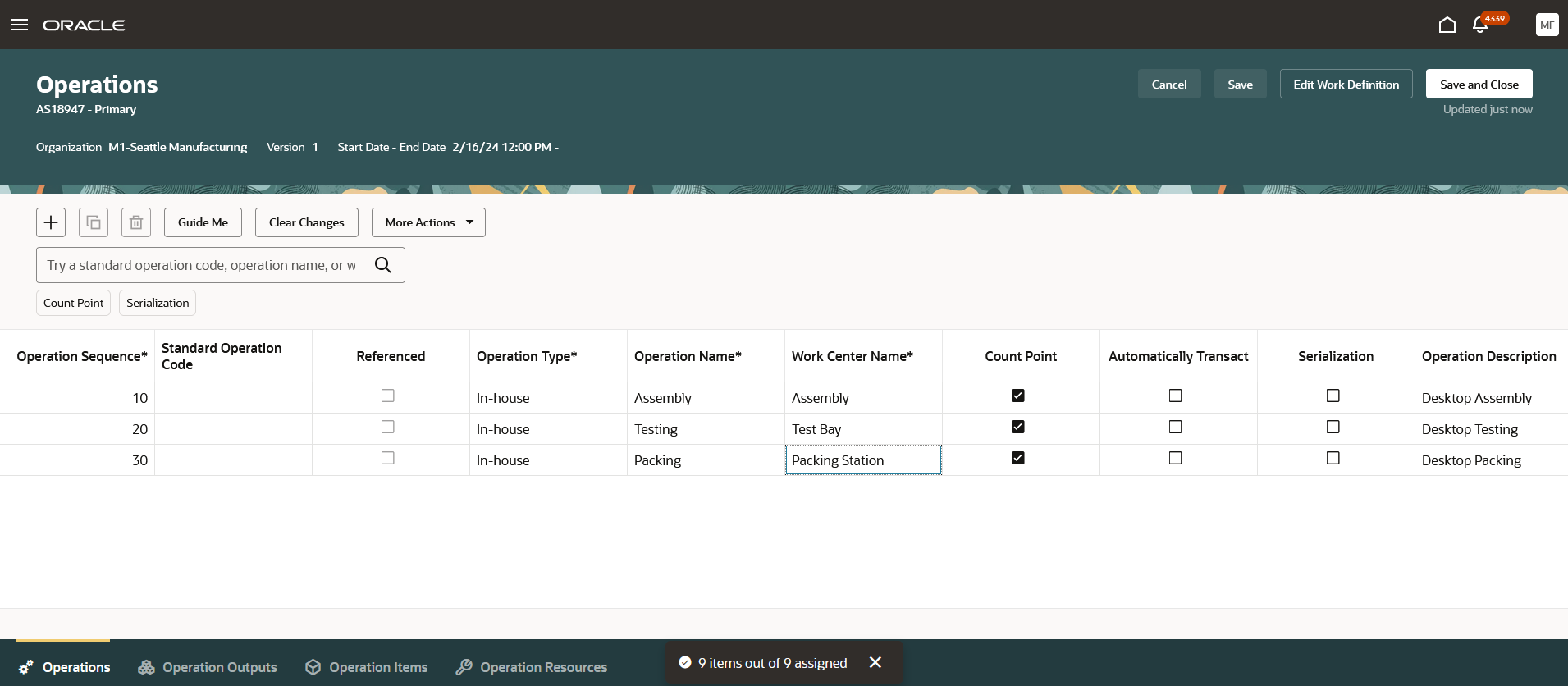

Automatic Assignment of Item Structure Components While Creating a Work Definition

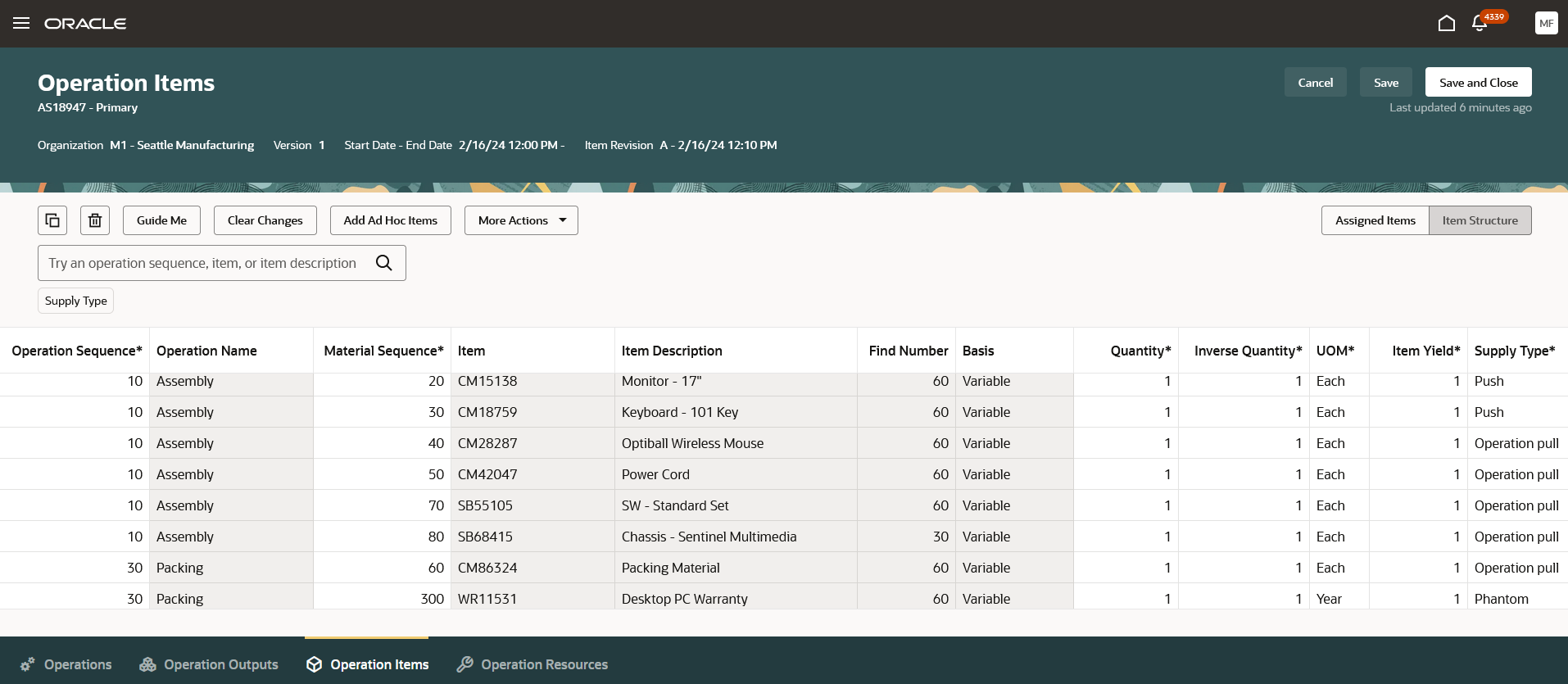

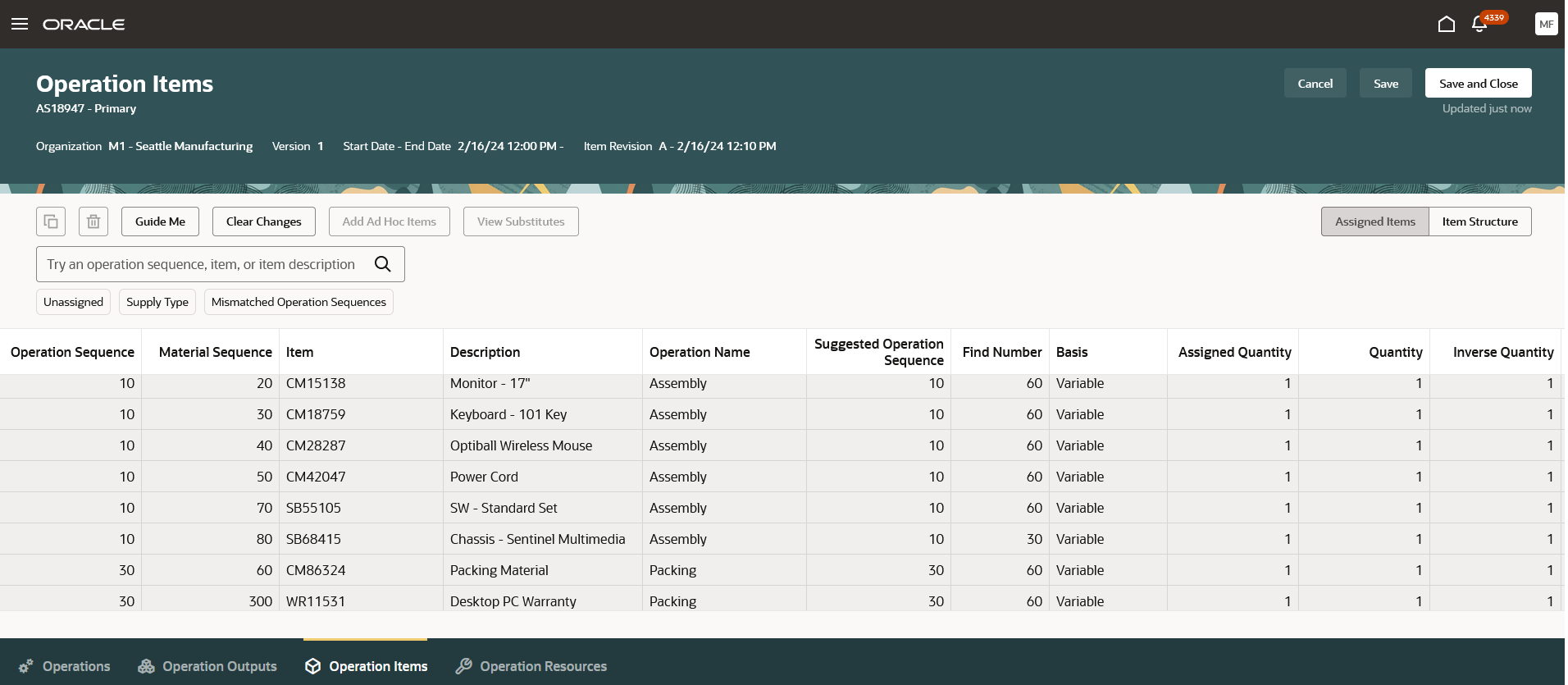

The Operation Items page displays the item structure components that are automatically assigned to work operations based on the suggested operation sequence defined in the item structure. The Assigned Items view in the Operation Items page displays the item structure components automatically assigned to work order operations, The Item Structure view in the Operation Items page displays the suggested operation sequence that's used as a basis to automatically assign item structure components. It also provides a means to identify mismatched operations and manually assign the components to the intended operation sequence.

Assigned Items View in the Operation Items Page

Item Structure View in the Operation Items Page

The automatic operation assignment of item structure components to work definition operations enables better synchronization in the design-to-manufacturing digital thread without manual intervention.

Steps to Enable

Follow these steps to enable or disable this feature:

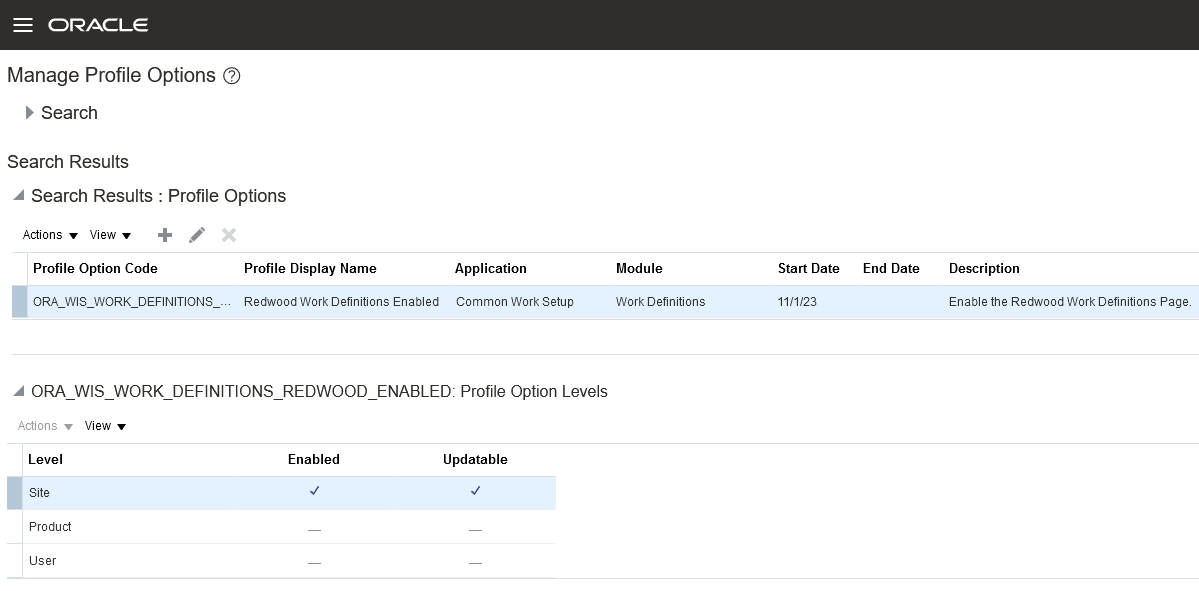

- In the Setup and Maintenance work area, search for and select the Manage Administrator Profile Values task.

- On the Manage Administrator Profile Values page, search for and select the ORA_WIS_WORK_DEFINITION_REDWOOD_ENABLED profile option code.

- In the Profile Values section, set the Site level to Y or N. The default value of the profile option is N.

- Y = enables the feature

- N = disables the feature

- Click Save and Close. Changes in the profile value will affect users the next time they sign in.

You'll have the option to enable or disable this feature from 24B update.

Profile Option for Accessing Work Definitions Using Redwood Experience

Tips And Considerations

- You can leave the suggested operation sequence blank for an item structure component to disable the automatic assignment to a work definition operation.

- A best practice is to include a manufacturing engineer in the Change Order approval process to coordinate changes to the suggested operation sequence for item structure components.

- It's recommended to use a unique combination of suggested operation sequence and find number to distinguish duplicate component instances in an item structure. The alternative approach of splitting the item structure component quantity across multiple operations in the work definition doesn't support the following:

- Automatic synchronization of item structure changes to impacted work definitions through a scheduled process

- Automatic assignment of item structure components to work definition operations based on the suggested operation sequence

For more information, refer to the 24A features in Oracle Fusion Product Lifecycle Management and Oracle Fusion Manufacturing, respectively:

- You can't view the substitutes for item structure components that are automatically assigned to work definition operations at this time.

- You can't automatically assign item structure components when creating or copying manufacturing work definitions for standard items in the following scenarios:

- The existing work definition user interface

- Application Development Framework Desktop Integration (ADFdi)

- File Based Data Import (FBDI)

- REST API

- Electronic records and electronic signatures are enabled

- You can't automatically synchronize subsequent changes to the suggested operation sequence for item structure components to the impacted work definitions. It's a one-time automatic operation assignment when creating a manufacturing work definition or adding an item structure component. Instead, you will receive a notification for review and action.

Key Resources

- Refer to the Oracle Fusion Cloud SCM: Using Manufacturing guide, available on the Oracle Help Center.

- Refer to the Oracle Fusion Cloud SCM: Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these privileges can use this feature:

- View Work Definitions (WIS_VIEW_WORK_DEFINITIONS_PRIV)

- Manage Work Definitions (WIS_MANAGE_WORK_DEFINITIONS_PRIV)

These privileges were available prior to this update.