Pinpoint Root Cause of Late Demands Due to Material and Capacity Constraints

When a plan determines that a particular demand, whether it is a forecast or sales order, can’t be fulfilled on time, it’s essential that your planners understand what the root cause is so they can evaluate mitigation actions. Planners can use the data on the Analyze Late Demand page in the Supply Planning work area to facilitate this analysis.

With this update, the logic behind the Analyze Late Demand page has been enhanced to pinpoint the root cause of late demands to the actual supply at any level of the bill causing a demand to be late. The logic now factors in additional scenarios previously not considered. These enhancements help you understand the plan results so you can take mitigation actions when feasible.

With this update, the following scenarios were enhanced:

- Scenario 1: Identify the supply that isn’t in the pegging chain of an end demand but is causing it to be late because of a shared supply downstream pegged to an end demand.

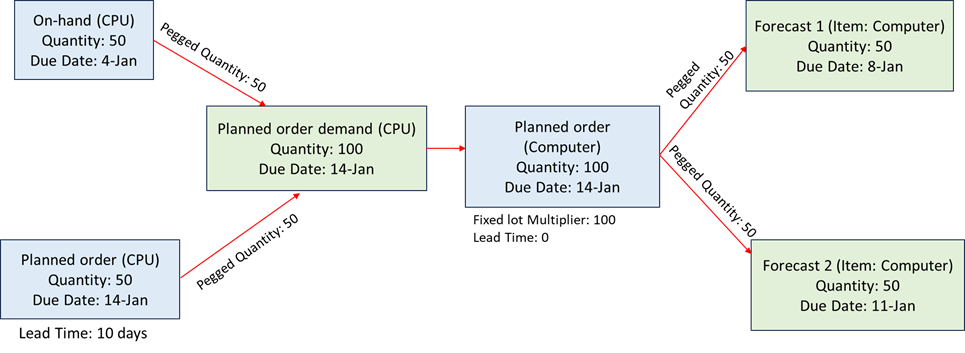

Consider the following example. The plan run date is 04-Jan in this scenario.

Example of Late Demand Analysis

In this use case, the Computer item is the final assembly with 0 days lead time, and its item structure has a CPU component with 10 days lead time.

The pegging structure of both forecasts is:

Forecast 1 (Computer), Qty 50, 8-Jan Forecast 2 (Computer), Qty 50, 11-Jan

-- Planned order (Computer), Qty 100, 14-Jan -- Planned order (Computer), Qty 100, 14-Jan

-- On-hand (CPU), Qty 50, 04-Jan -- Planned order (CPU), Qty 50, 14-Jan

Forecast 1 is satisfied late in this case because the planned order of the Computer item has a due date of 14-Jan. However, the planned order of the Computer assembly item is delayed because the planned order of the CPU component item has a lead time of 10 days.

Prior to this update, the Late Demand Analysis view for Forecast 1 stopped the constrained supply path at the planned order (Computer) because the component planned order (CPU) was-n’t in the pegging chain of Forecast 1. As a result, the planner couldn’t correctly identify the reason for Forecast 1’s delay.

After this update, the planned order (CPU) will also be shown in the constrained supply path of Forecast 1. This will help you correctly identify the supply that caused the delay, and you can take mitigating action.

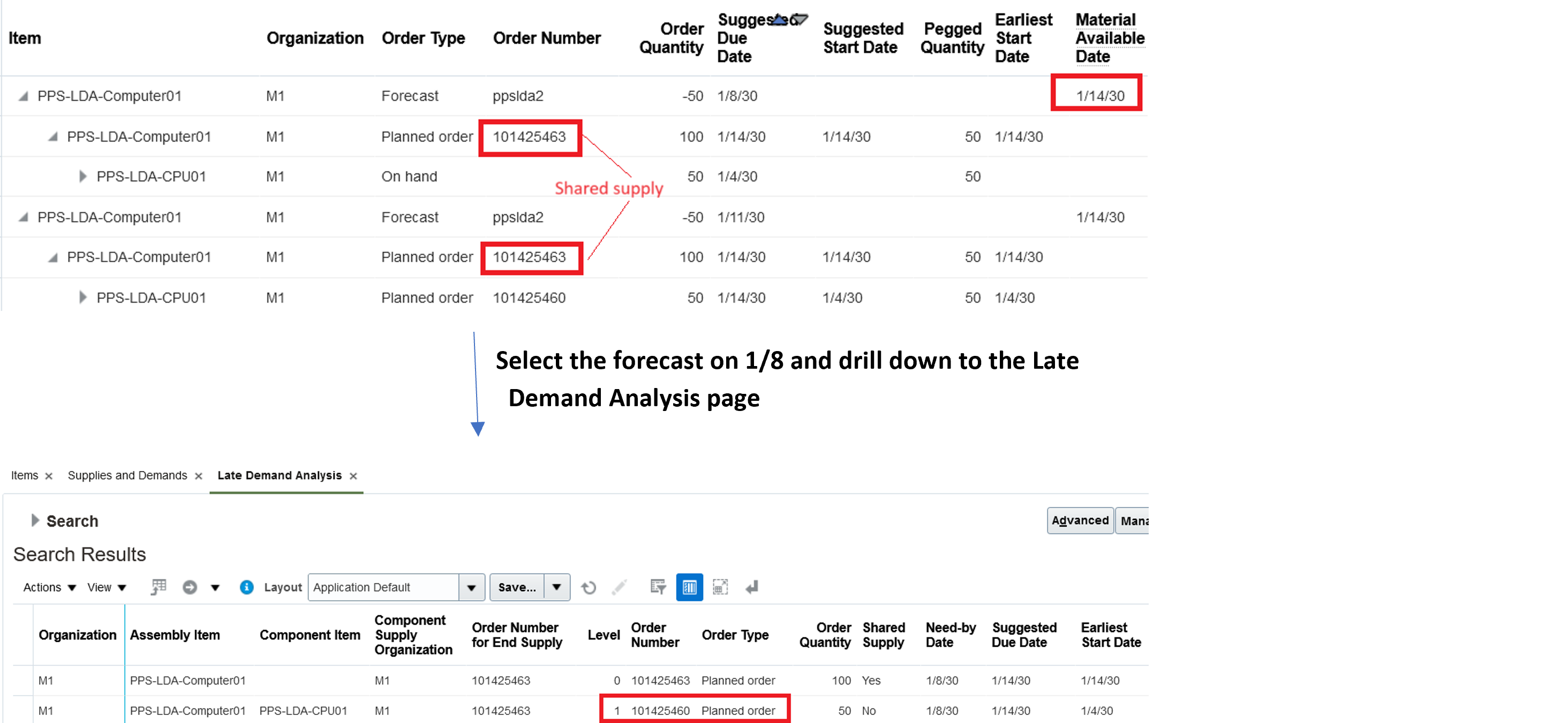

Demands are satisfied late, as shown on the Supplies and Demands page. The Material Available Date is later than the due date of the demand.

Example of Analyzing a Late Demand

The forecast on 1/8 is delayed because the planned order supply of component item PPS-LDA-CPU01 is available only on 1/14 due to lead time constraints. This planned order is not in the pegging chain of forecast demand but has a shared supply downstream.

- Scenario 2: If purchasing lead times have been compressed when the Enforce Purchasing Lead Time item attribute has been set to No, those compressed purchased supplies don’t show on the Late Demand Analysis page.

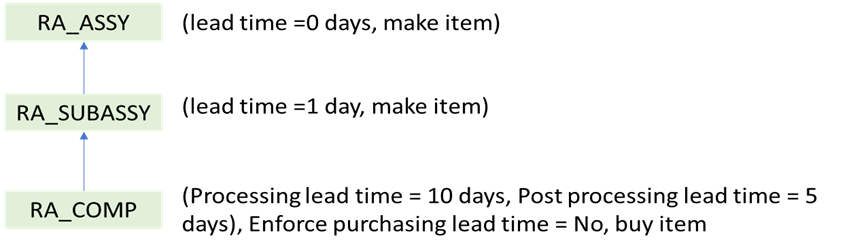

Consider the following example:

-

- RA_ASSY is the final assembly with 0 days lead time.

- RA_SUBASSY is a sub-assembly item with a 1-day lead time.

- RA_COMP is a purchased part with the Enforce Purchasing Lead Time attribute set to No.

Item Structure of Final Assembly RA_ASSY

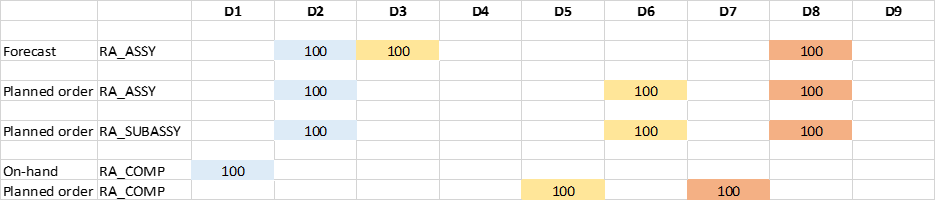

The following screenshot shows the supply demand:

Example of the Demands and Its Supply Chain

In this use case, the demand on day 2 (D2) is satisfied on time because it’s pegged completely to onhand supply. The demand on day 3 (D3) is satisfied late due to the purchased component's lead time. The post-processing lead time is a hard constraint even if the Enforce Purchasing Lead Time item attribute is set to No. The demand on day 8 (D8) is satisfied on time. The processing lead time for the purchased component is compressed (EPLT=No), and component demand is outside the post-processing lead time.

Before this update, the Late Demand Analysis page showed the end demands for days 3 (D3) and 8 (D8). The late demand analysis has considered the total lead time of the purchased component even though the Enforce Purchasing Lead Time attribute was set to No and demand was satisfied on time.

With this update, the Late Demand Analysis page shows only the demand for day 3 (D3). In scenario 2, the planned orders for RA_COMP on day 5 (D5), RA_SUBASSY on day 6 (D6), and RA_ASSY on day 6 (D6) are on the constrained supply path. None of the supplies pegged to end demand on day 8 (D8) are on the constrained supply path.

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Supply Chain Planning

Tips And Considerations

If you want to use the Pinpoint Root Cause of Late Demands Due to Material and Capacity Constraints feature, then you must opt in to its parent feature: Constraint-Based Planning. If you’ve already opted in to this parent feature, then you don’t have to opt in again.

- The late demand analysis view provides the list of supplies that can cause delays to an end demand. The constrained supply path is not the pegging tree of an end demand.

- A compressed upstream supply can still be on the constrained supply path for cases other than scenario 2 mentioned previously, for example, if it is pegged to a firm downstream supply and its latest start date is earlier than the earliest start date.

- There are a couple of changes to the user interface:

- The Pegged Quantity column is removed because the supply in a constrained path may not be directly pegged to the end demand.

- A new Parent Supply Order Number column is available. This column shows the supply order number of the immediate downstream supply. In cases with multiple parent downstream supplies, the order number of the latest supply is shown.

-

This feature is supported for both constrained plan types, Enforce Demand Due Date and Enforce Capacity Constrained.

Key Resources

-

Watch the Pinpoint Root Cause of Late Demands Due to Material and Capacity Constraints demo.

- Refer to the feature Identify Which Supplies are Causing Demands At Risk (update 22a) for the initial design.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Edit Plans (MSC_EDIT_PLANS_PRIV)

- Run Plan with Snapshot (MSC_RUN_PLAN_WITH_SNAPSHOT_PRIV)

- Edit Demands and Supplies (MSC_EDIT_DEMANDS_AND_SUPPLIES_PRIV)

- Monitor Supply Planning Work Area (MSC_MONITOR_SUPPLY_PLANNING_WORK_AREA_PRIV)

- Exceptions view (MSC_MANAGE_PLANNING_EXCEPTIONS_PRIV)

These privileges were available prior to this update.