Use Pick-Pack Lead Time for Configure-to-Order and Shipment and Arrival Sets

Some organizations need extra time to package and label goods, arrange for transportation, or perform quality checks before shipment. If you need to reschedule configure-to-order items or order lines that are part of a shipment set or arrival set, you can now include this extra "pick-pack lead time." Previously, you could only add extra pick-pack lead time for standard items in Oracle Backlog Management.

You can adjust pick-pack lead time by fulfillment organization, carrier, and destination. Any pick-pack lead time you specify will offset the scheduled ship dates and scheduled delivery dates for order lines fulfilled in those organizations.

Example 1: Impact of Pick-Pack Lead Time on a Shipment Set

Here are the important points for the data shown in this example:

- The system date or plan run date is January 7, 2030.

- The pick and pack lead time is in interlocation shipping networks.

- The organization calendar at the requested ship-from organization is working from Monday through Thursday and isn’t working Friday through Sunday.

- The dates January 7, 2030, and January 14, 2030, fall on a Monday.

- The pick and pack lead time considers the organization’s working calendar.

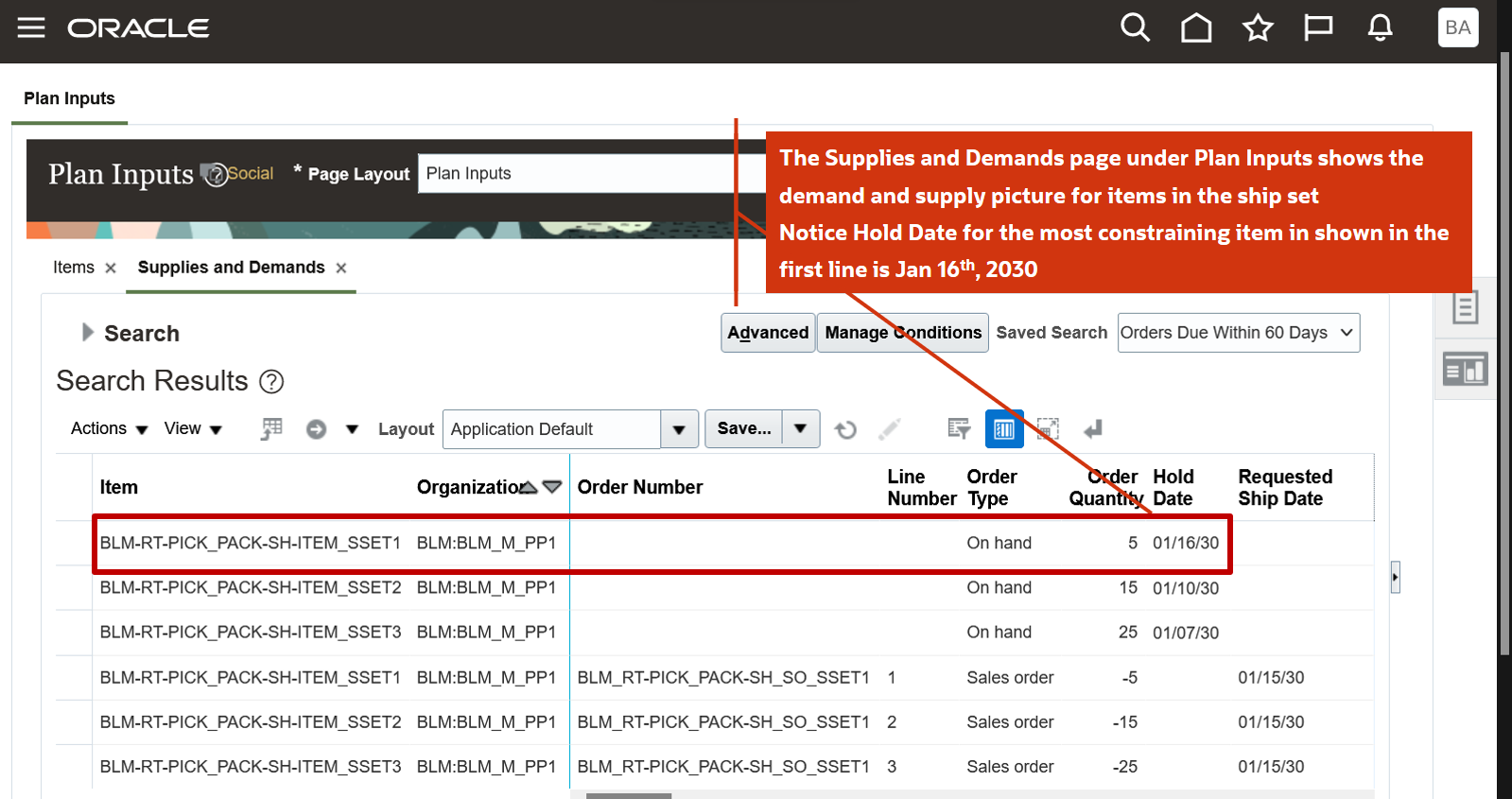

Shipment Set Order and On Hand Supply with Constraining Hold Date

The Supplies and Demands tab on the Plan Inputs page shows lines of a shipment set order and on hand supply that has a hold date of 01/16/30.

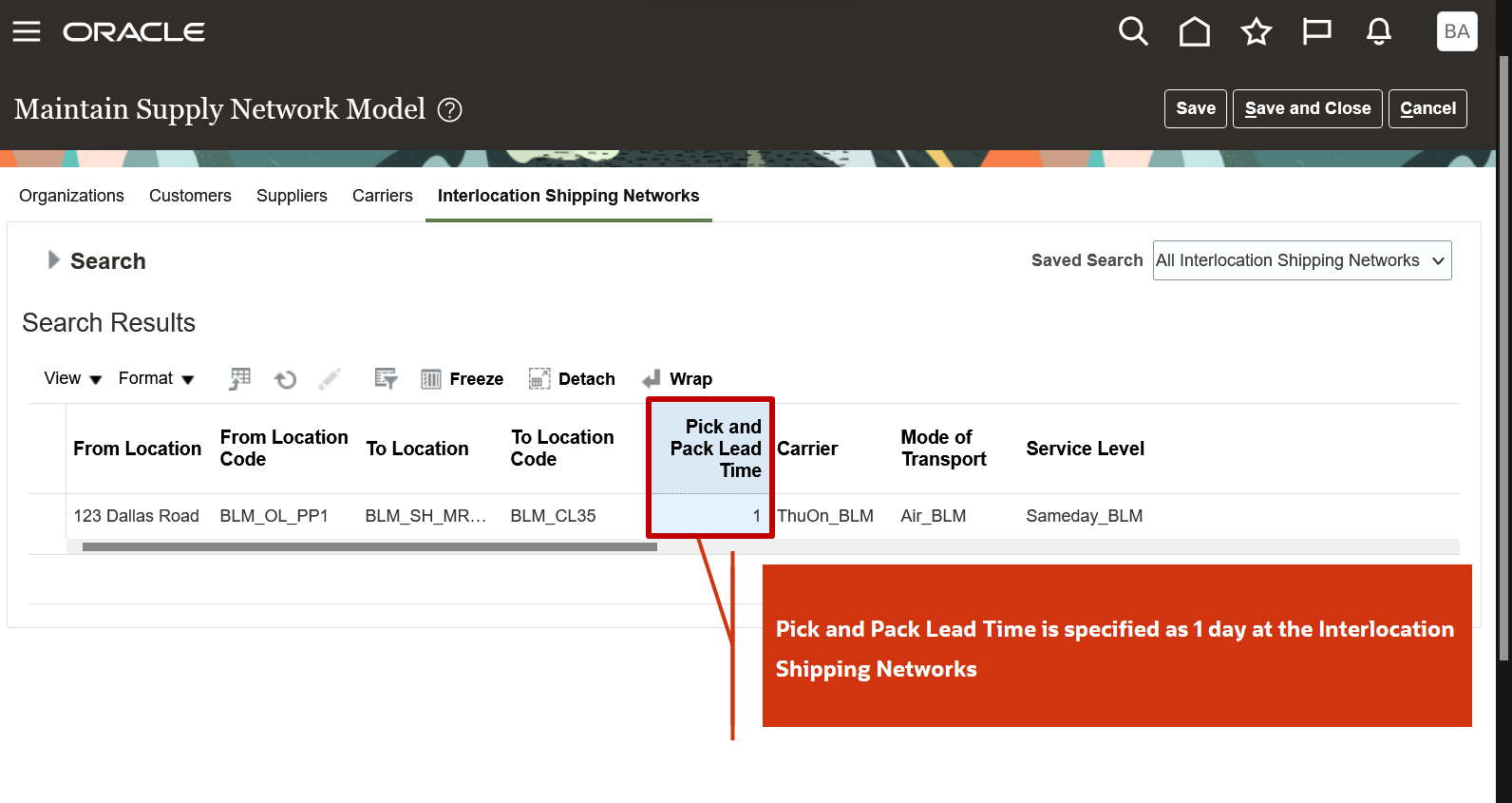

Pick and Pack Lead Time Column on the Interlocation Shipping Networks Tab

To see the pick-pack lead time, from the Plan Inputs or Backlog Management work area, select Maintain Supply Network Model from the task panel tab. Select the Interlocation Shipping Networks tab on the Maintain Supply Network Model page.

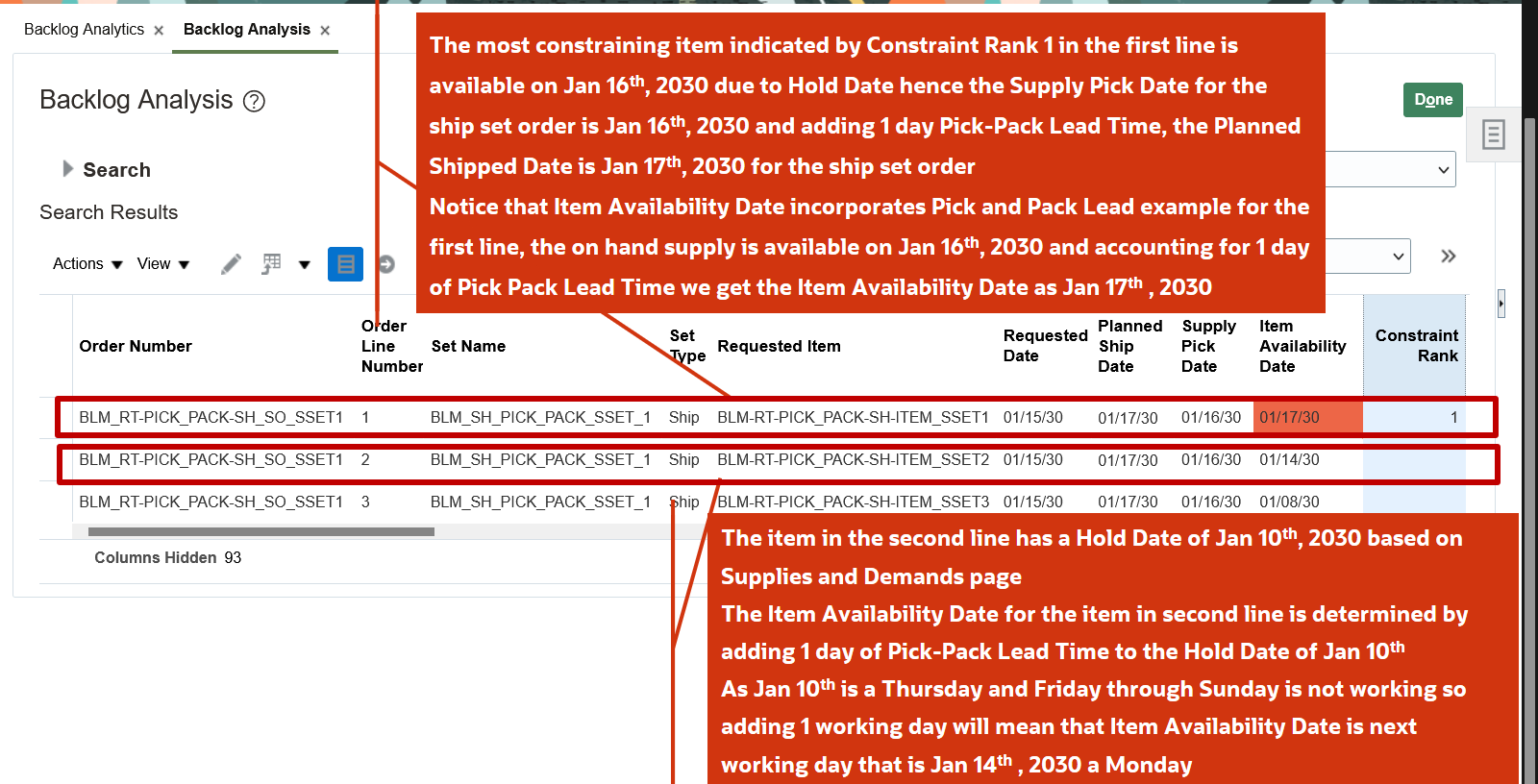

Backlog Analysis Page Shows Some Important Related Attributes for the Shipment Set

You might want to see how the pick-pack lead time affects the shipment set. For example, you can check some important related attributes, such as the Planned Ship Date, Supply Pick Date, and Item Availability Date. You can view these attributes in the Backlog Management work area on the Backlog Analysis page.

Example 2: Impact of Pick-Pack Lead Time on an Assemble-to-Order Order

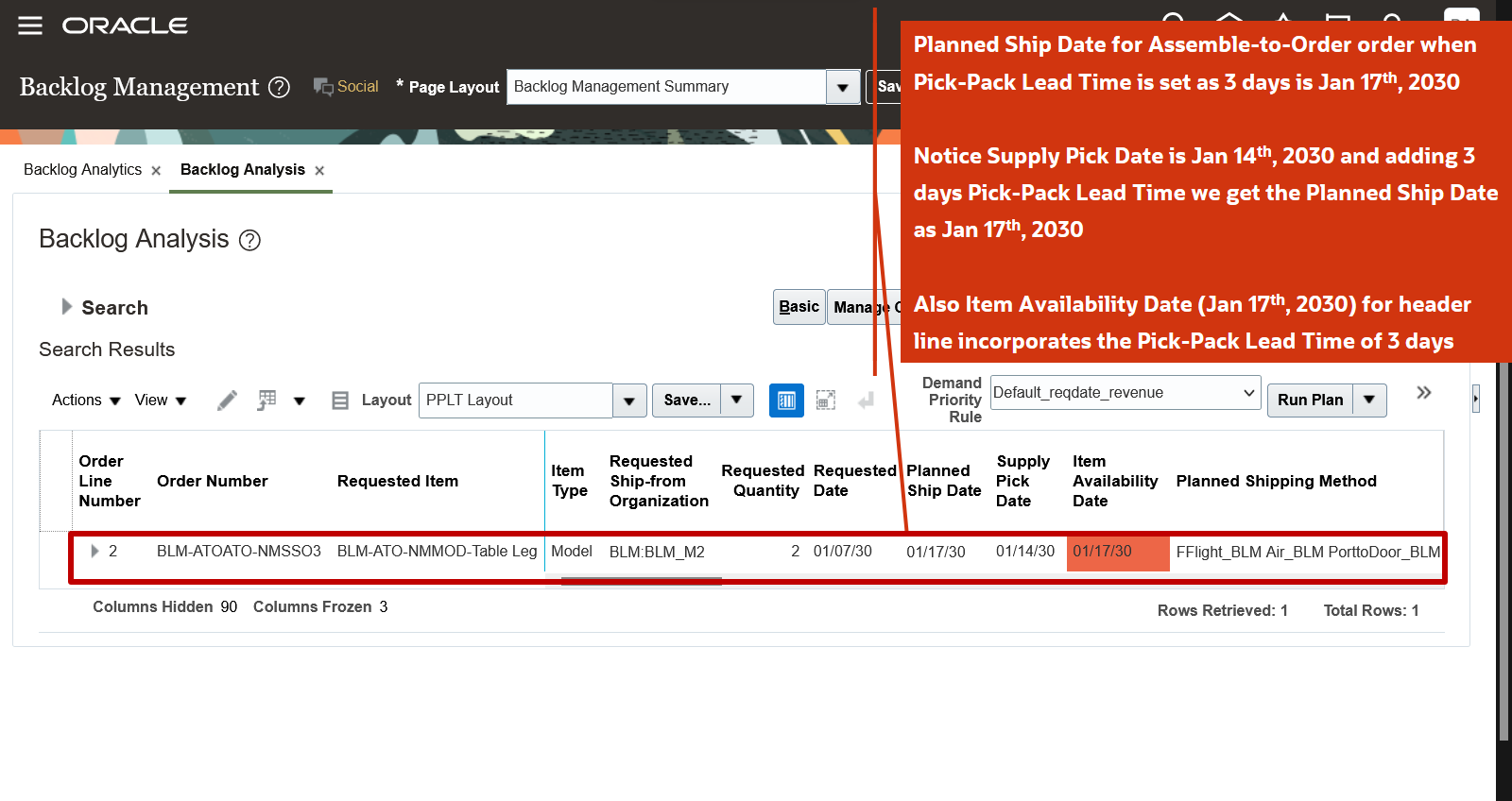

Here are the important points for the data shown in this example:

- The system date or plan run date is January 7, 2030.

- The pick-pack lead time is specified only at the carrier level.

- The organization calendar at the requested ship-from organization is working Monday through Friday.

- January 14, 2030, is on a Monday.

- The pick-pack lead time considers the organization's working calendar.

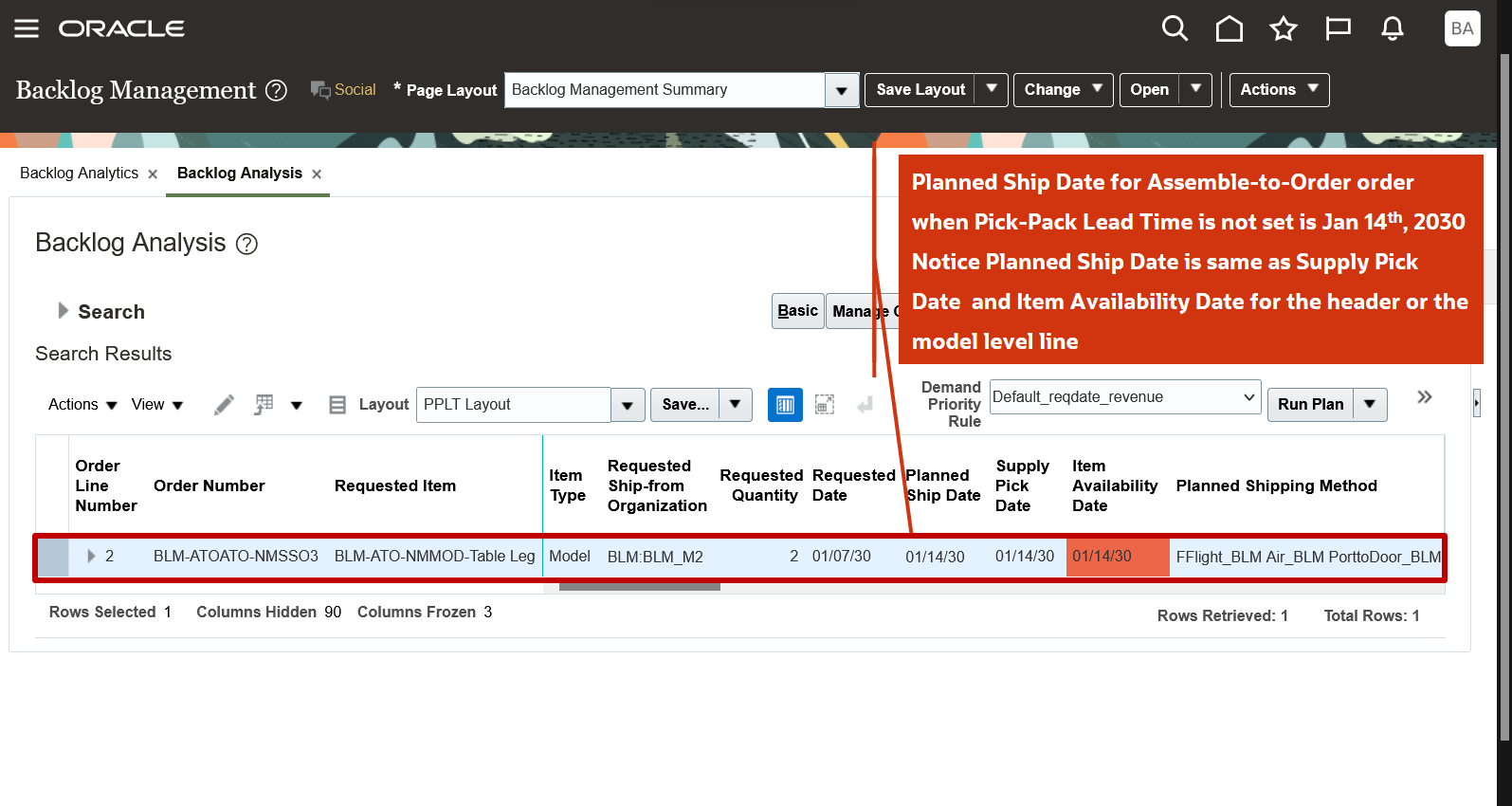

You can see what happens when the pick-pack lead time isn’t set. From the Backlog Management work area, open the Backlog Analysis page to see some important related attributes, like Planned Ship Date, Supply Pick Date, and Item Availability Date.

Backlog Analysis Page Shows Important Related Attributes for the Assemble-to-Order Order

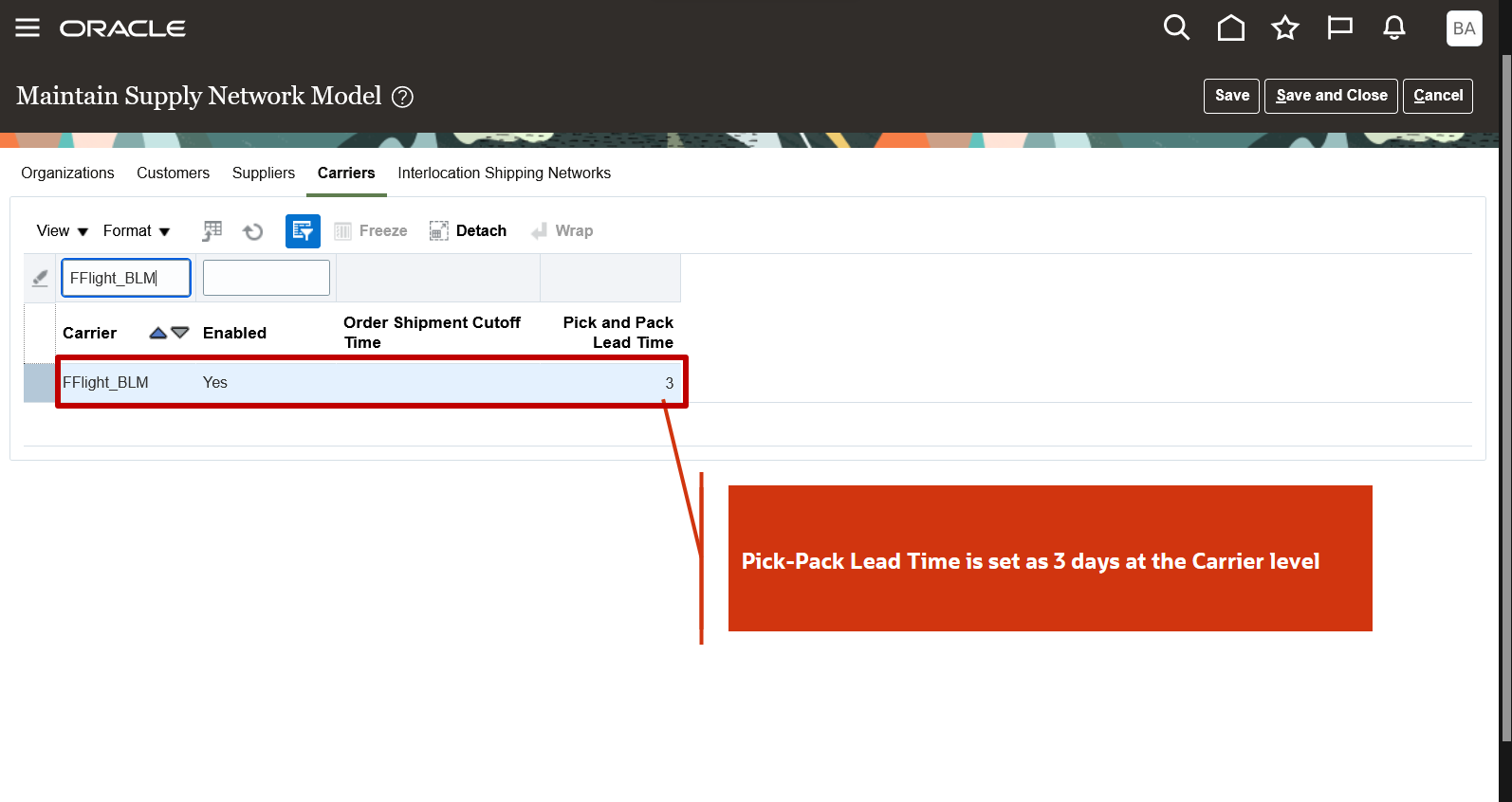

In the following figure, you can see that the Pick and Pack Lead Time is 3 days on the Carriers tab. To see your Pick and Pack Lead Time, open the Plan Inputs work area and select the Maintain Supply Network Model from the Tasks panel tab. Then select the Carriers tab.

Pick and Pack Lead Time Column Specified on the Carriers Tab

You can see in the following figure how the 3-day pick-pack lead time affects the Planned Ship Date, Supply Pick Date, and Item Availability Date. To find the values for your environment, go to the Backlog Management work area and open the Backlog Analysis page.

Backlog Analysis Page Shows Important Attributes for an Assemble-to-Order Order

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Supply Chain Planning

If you want to use the Pick-Pack Lead Time for Configure-to-Order and Shipment and Arrival Sets feature, then you must opt in to its parent feature: Order Backlog Management. If you’ve already opted in to this parent feature, then you don’t have to opt in again.

Additional steps you must take for Backlog Management to plan sales order lines using this feature:

-

Select the Maintain Supply Network Model from the Tasks panel tab in the Plan Inputs work area.

-

On the Maintain Supply Network Model page, select one of these tabs depending on your use case:

-

The Interlocation Shipping Networks tab to provide a value for the Pick and Pack Lead Time column for a source, destination, and carrier combination.

-

The Carriers tab to provide a pick-pack lead time for a shipping method.

-

The Organization tab to provide a pick-pack lead time for an organization.

-

Enter values for the Pick and Pack Lead Time column in whole number format.

-

Click Save.

Tips And Considerations

- If the pick-pack lead time is defined in multiple tabs, Backlog Management will use the following hierarchy for pick-pack lead time:

- The source destination and carrier combination

- The carrier

- The organization

- The pick-pack lead time is applicable to different types of supplies, including on hand, transfer orders, purchase orders, and work orders.

- This feature isn't applicable to drop ship flows.

- Order cutoff times will be recognized by this feature.

- If the pick-pack lead time at the most granular level is null, then the pick-pack lead time at the second most granular level is considered, and so on.

- If the pick-pack lead time at the most granular level is 0, then 0 is considered as the pick-pack lead time, and Backlog Management doesn’t check it at higher levels of granularity.

- The Item Availability Date incorporates, includes, or encapsulates the Pick and Pack Lead Time.

- You’ll need to determine the levels where the pick-pack lead time needs to be defined, and whether it’s for an organization, carrier, or a combination of shipping method, destination, and organization.

Key Resources

-

Watch the Use Pick-Pack Lead Time for Configure-to-Order and Shipment and Arrival Sets demo

- Recommended related training:

- Use Pick-Pack Lead Time in Backlog Management (update 24A) Readiness Training

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Monitor Backlog Management Work Area (MSC_MONITOR_BACKLOG_MANAGEMENT_WORK_AREA_PRIV)

- Edit Supply Network Model (MSC_EDIT_SUPPLY_NETWORK_MODEL_PRIV)

These privileges were available prior to this update.