Define Additional Outputs in Discrete Manufacturing Work Definitions and Work Orders

Define Additional Outputs in Discrete Manufacturing Work Definitions and Work Orders

Discrete manufacturing processes involving the production of more than one output may require these additional outputs to be either reused in subsequent operations or sold as a separate item. For example, when a manufacturer makes products stamped from a sheet of metal, the remaining metal sheet could be recovered as a by-product and sold as a separate item. Operators currently report ad hoc outputs during work execution from the Review Dispatch List page and complete them to inventory.

With this new update, you can now define additional outputs (co-products and by-products) in new or existing, standard work definitions. These outputs can be added for standard and nonstandard work orders to count point, automatically transact, and optional operations. They can be reported as an output completion transaction into a specified completion subinventory from the Review Dispatch List page. The cost of these additional outputs can be defined as fixed or with allocation percentages, allowing for reuse as supply and inventory. This feature is also available through File-Based Data Import (FBDI) and REST web service - WorkOrderOperationOutput. The Correct Work Orders and Transactions for Import task supports error corrections and resubmissions.

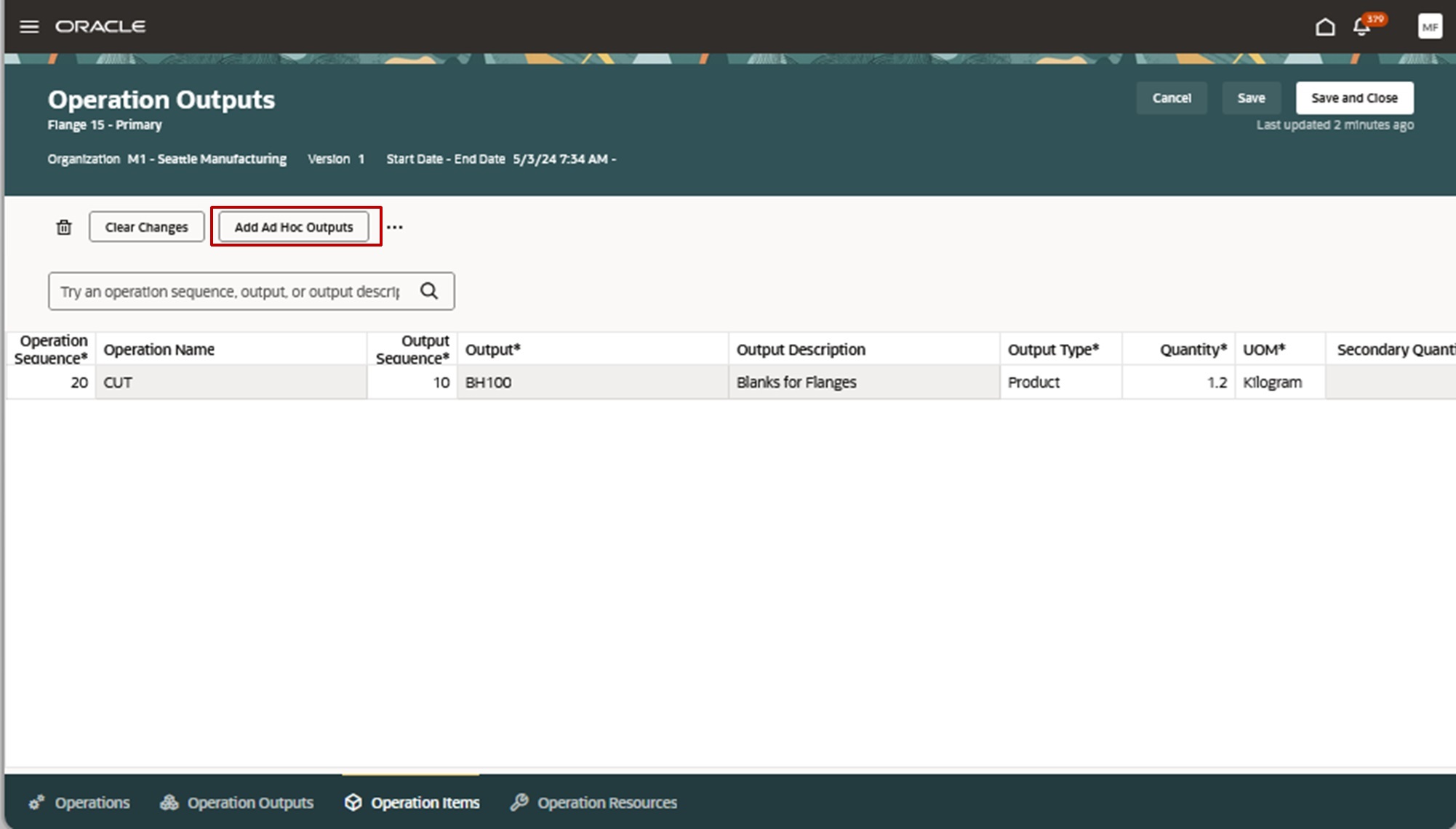

Additional Outputs in Standard Discrete Work Definition

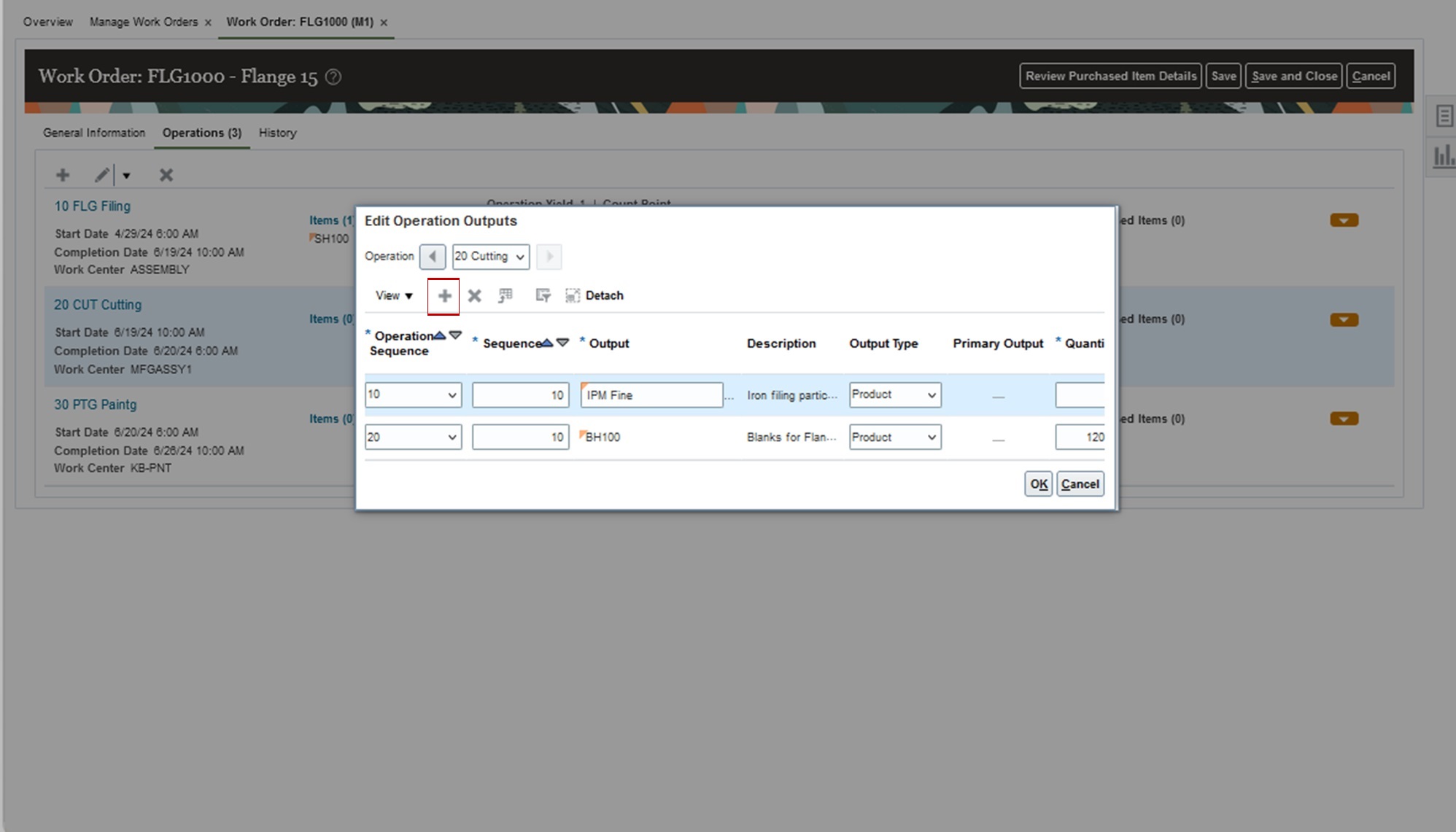

Additional Outputs in Discrete Work Order

File-Based Data Import (FBDI) Changes:

The FBDI Discrete Manufacturing Work Definitions Import, WorkDefinitionTemplate.xlsm, has been enhanced to enable reporting of outputs in all standard discrete work definition operations. A new sheet titled, Operation outputs has been added to the template to add outputs at standard discrete work definition operations.

The FBDI Discrete Manufacturing Work Order Import, WorkOrderTemplate.xlsm, has been enhanced to enable reporting of outputs in all discrete work order operations. A new sheet titled, Work Order Operation outputs has been added to the template to add outputs at standard work definition operations. The Output attribute in Work Order Product Lot Numbers and Work Order Serial Numbers sheets is added to enter lot and serial numbers for outputs.

The work orders created through FBDI that failed validations can be corrected and resubmitted through the task - Correct Work Orders and Transactions for Import.

Use the latest FBDI templates after the 24C update.

REST API Changes:

You can now add outputs for standard discrete manufacturing work order operations using the Work Order REST API.

Discrete manufacturers will achieve efficient reuse of items, reduction of waste, and accurate valuation of scrap leading to an optimal manufacturing process flow.

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Manufacturing and Supply Chain Materials Management No Longer Optional From: Update 25A

You must opt in the Report Ad hoc Outputs During Work Order Execution in Discrete Manufacturing feature (11.13.24.04.0) to automatically enable this feature.

Tips And Considerations

- Components can't be defined as outputs in a work definition for an operation.

- Outputs can be optionally enabled as lot or serial-controlled to support product genealogy.

- Multiple outputs from the same work definition will be considered as supply by Supply Planning.

- Negative component quantities in work definition and work order operations will be considered as removed components during work execution and can't be reported as outputs. To know more about negative component quantities, refer to the 23C feature: Remove a Component During Discrete Manufacturing Work Execution.

- You can report ad hoc material output transactions during work execution. To know more about ad hoc material outputs, refer to the 24B feature: Report Ad hoc Outputs During Work Order Execution in Discrete Manufacturing.

- You can create OTBI reports and analyses, and use BICC views to include multiple outputs in discrete manufacturing work orders and output transactions.

Key Resources

- Watch the Define Additional Outputs in Discrete Manufacturing Work Definitions and Work Orders Demo.

- Refer to the Oracle Fusion Cloud SCM: Using Manufacturing guide, available on the Oracle Help Center.

- Refer to the Oracle Fusion Cloud SCM: Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains this privilege can associate outputs to work definition operations:

- Manage Work Definitions (WIS_MANAGE_WORK_DEFINITIONS_PRIV)

Users who are assigned a configured job role that contains these privileges can associate outputs to work order operations:

- Manage Work Order Headers (WIP_MANAGE_WORK_ORDER_HEADERS_PRIV) and

- Manage Work Order Operations (WIP_MANAGE_WORK_ORDER_OPERATIONS_PRIV)

Users who are assigned a configured job role that contains this privilege can report multiple outputs during operation completions:

- Report Operations Transactions (WIP_REPORT_OPERATION_TRANSACTIONS_PRIV)

These privileges were available prior to this update.