Specify Fixed and Variable Lead Times for Your Assembly Operations

Your manufacturing process might need a fixed lead time to prepare for, set up, and inspect the results of an assembly operation, and a variable lead time to assemble each item. Starting with Update 24C, Oracle Global Order Promising can include both a fixed and a variable lead time in the bill of resources, so you can schedule each of your assembly operations more accurately. Your capable-to-promise flow will multiply the number of items on the order line by the variable lead time, and then add the fixed lead time to schedule the operation's total lead time.

Promising uses this equation to calculate lead time:

Lead Time = [Fixed Lead Time + (Order Quantity) * Variable Lead Time] + Postprocessing Lead Time

Promising applies logic differently depending on whether you have availability constraints on resources and components:

|

Don't Have Constraints |

Have Constraints |

|

Promising will apply the lead time so it can offset the requested date and determine manufacturing's start date and end date. |

Promising will find manufacturing's earliest start date according to when components and resources are available and that can meet the lead time's constraints for components and resources. |

Overview of the Examples

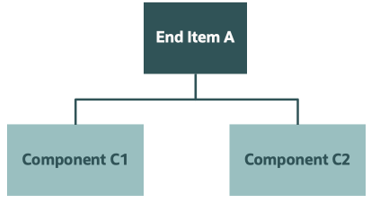

Assume your sales order has a quantity of 10 for your AS54888 Desktop Computer item, and you consume one unit each of components C1 and C2 to create the AS54888.

Assume you have these values:

|

Attribute |

Value in Days |

|

AS54888's Fixed Lead Time |

9 |

|

AS54888's Variable Lead Time |

0.1 |

|

System Date |

1 |

|

Postprocessing Lead Time |

0 |

Assume your current supply for components and resources can meet demand, and you don't have any other constraints for these components and resources on the calendar.

Here's the item's hierarchy:

Example 1: Requested Date Happens in the Future with No Constraints

Assume the Requested Ship Date is Day 17 for sales order 57984 and it happens in the future. Here's how Promising will calculate the lead time for this example:

Lead Time = [9 + (10) * 0.1] + 0 = 10 days

Assume your bill of resources has these values for the AS54888 item:

Component Requirement According to Bill of Resources

|

Required Quantity |

Lead Time in Bill of Resources |

|

|

C1 |

10 |

1 |

|

C2 |

10 |

1 |

Promising will disregard these lead time values from the bill of resources, and instead will calculate the lead times according to the values that you specify in the Fixed Lead Time attribute and the Variable Lead Time attribute for the AS54888 in the Product Information Management work area.

There aren't any availability constraints on resources or components, and there aren't any other calendar constraints in this example, so Promising will use 10 days for the lead time when it determines the promised dates:

|

Requested Date |

Calculated Date |

Value |

|

Day 17 |

Manufacturing Start Date |

Day 7 |

|

Manufacturing End Date |

Day 17 |

|

|

Scheduled Ship Date |

Day 17 |

Promising will start to look for component supplies on Day 7. Components and resources are available, so Promising will set the Schedule Ship Date to the Requested Ship Date.

Example 2: Requested Date is the System Date with No Constraints

Assume the requested date happens on the system date for sales order 57984, and the Requested Ship Date is Day 1. Here's how Promising will calculate the lead time for this example:

Lead Time = [9 + (10) * 0.1] + 0 = 10 days

Promising determines that it needs a quantity of 10 for component C1 and also 10 for C2.

There aren't any availability constraints on resources or components, and there aren't any other calendar constraints, so Promising will use 10 days for the AS54888's lead time when it determines the promised dates:

|

Requested Date |

Calculated Date |

Value |

|

Day 1 |

Manufacturing Start Date |

Day 1 |

|

Manufacturing End Date |

Day 10 |

|

|

Scheduled Ship Date |

Day 10 |

Promising starts to look for component supplies on Day 1, finds that components and resources are available, and then uses the lead time to set the Schedule Ship Date to Day 10.

Steps to Enable

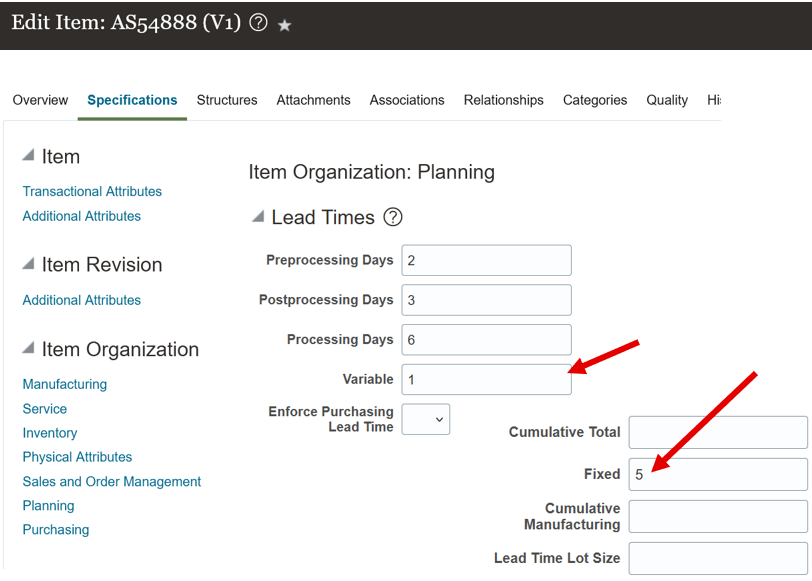

Set up the item:

- Go to the Product Information Management work area, then click Tasks > Manage Items.

- Search for the AS54888 item, then open it for editing.

- On the Edit Item page, click Specifications > Planning.

- In the Lead Times section, set the values.

Attribute

Value

Variable

1

Fixed

5

For example:

Item

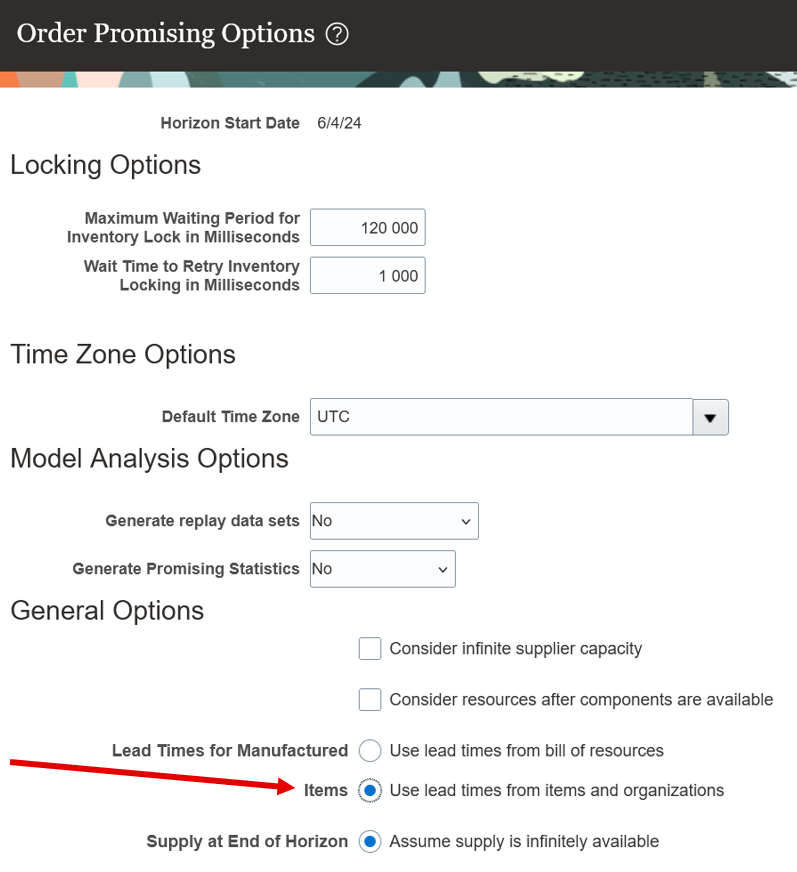

Set up Promising:

- Go to the Global Order Promising work area, click Tasks > Order Promising Options, then enable the Use Lead Times from Items and Organizations option:

Set up Promising:

Tips And Considerations

- Promising disregards lead times in your bill of resources when you use this feature.

- Promising will continue to consider the bill of resources as the source of truth for all other work definitions and structural details.

- Promising will consider the item's Fixed Lead Time attribute and its Variable Lead Time attribute for assembly and subassembly items.

- You can use the item's Post Processing Lead Time attribute. If you set it, then Promising considers it when promising.

- We recommend that you mark all subassemblies as critical so your bill of resources will include them. This helps to make sure that Promising considers each manufactured item's lead times.

- Fixed lead time and variable lead time apply to standard items and to assemble-to-order configured items.

- As an option, you can also set up Promising so it considers resources after components are available. For more, see Consume Resources Only After Components Are Available.

Key Resources

- Assignments and Promising Rules

- Guidelines for Using Lead Time Mode

- Support Capable-to-Promise for Manufactured Items 22A Global Order Promising Training

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Schedule Fulfillment Line (MSP_SCHEDULE_ORCHESTRATION_ORDER_FULFILLMENT_LINE_PRIV)

- Edit Bills of Resources (MSC_EDIT_BILLS_OF_RESOURCES_PRIV)

- View Bills of Resources (MSC_VIEW_BILLS_OF_RESOURCES_PRIV)

These privileges were available prior to this update.