Plan Considering Yield of Product at a Manufacturing Operation

Plan Considering Yield of Product at a Manufacturing Operation

In various industries, there may be instances where a manufacturing operation doesn’t yield the entire planned quantity. For example, you start to manufacture operation for a quantity of 10 for a particular product. However, due to various manufacturing losses, only a quantity of 9 is expected to be useable for subsequent operations. With this update, the supply planning and production scheduling processes consider the expected operation yield when planning and scheduling subsequent operations. The material required in the subsequent operations is then appropriately scaled down. As a result, manufacturers in environments with significant operation-level yields can ensure the availability of the right quantities of raw materials and finished goods to satisfy demand and begin production.

Previously, the dispatch list and work orders tables in Oracle Production Scheduling displayed the remaining quantity of work orders. If a work order had completions reported, then the remaining quantity in Oracle Production Scheduling reflected these completions, but you couldn’t see the original quantity of the work order.

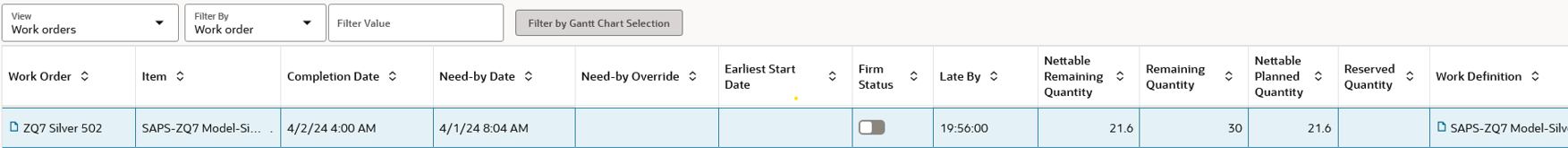

Now, the dispatch list displays the nettable remaining quantity in the dispatch list and both the nettable remaining quantity and the nettable planned quantity in the work orders table. These quantities consider operation yields defined on work definition operations and represent the amount available to meet downstream demand. The nettable planned quantity is the original work order quantity adjusted by the cumulative yield factor, while the nettable remaining quantity also considers any reported completions.

As completions are reported against a work order, the system reduces both the remaining quantity and nettable remaining quantity values over time. However, the nettable planned quantity remains constant, enabling users to track the progress of a work order. For example, if the nettable planned quantity is 100 and the nettable remaining quantity is 50, then users can know the work order is halfway completed.

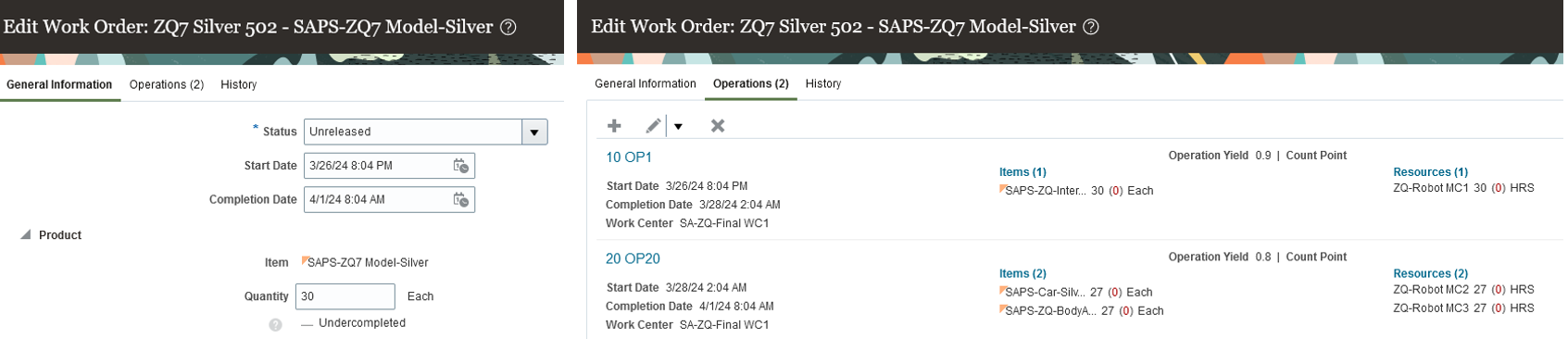

Consider a work order with 2 operations with operation yields defined as 0.9 and 0.8, respectively, see following example. The cumulative yield for the work order is 0.9 x 0.8 = 0.72. If the work order quantity is 30 units, then the nettable planned quantity will be 30 x 0.72 = 21.6 units.

Work Order with Operation Yield

If there are no completions yet as for this work order, then the nettable planned quantity and nettable remaining quantity values displayed in Oracle Production Scheduling are the same.

New Quantity Fields in Work Orders Table Account for Yield

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Supply Chain Planning

Tips And Considerations

If you want to use the Plan Considering Yield of Product at a Manufacturing Operation feature, then you must opt in to its parent feature: Production Scheduling. If you’ve already opted in to this parent feature, then you don’t have to opt in again.

Key Resources

- Visit https://redwood.oracle.com/ for more information about the Redwood experience.

Access Requirements

Users who are assigned a configured job role that contains this privilege can access this feature:

- Edit Production Schedule (MSC_EDIT_PRODUCTION_SCHEDULE_PRIV)

This privilege was available prior to this update.