Report Material Transactions for a Work Order Operation Executed at a Workstation

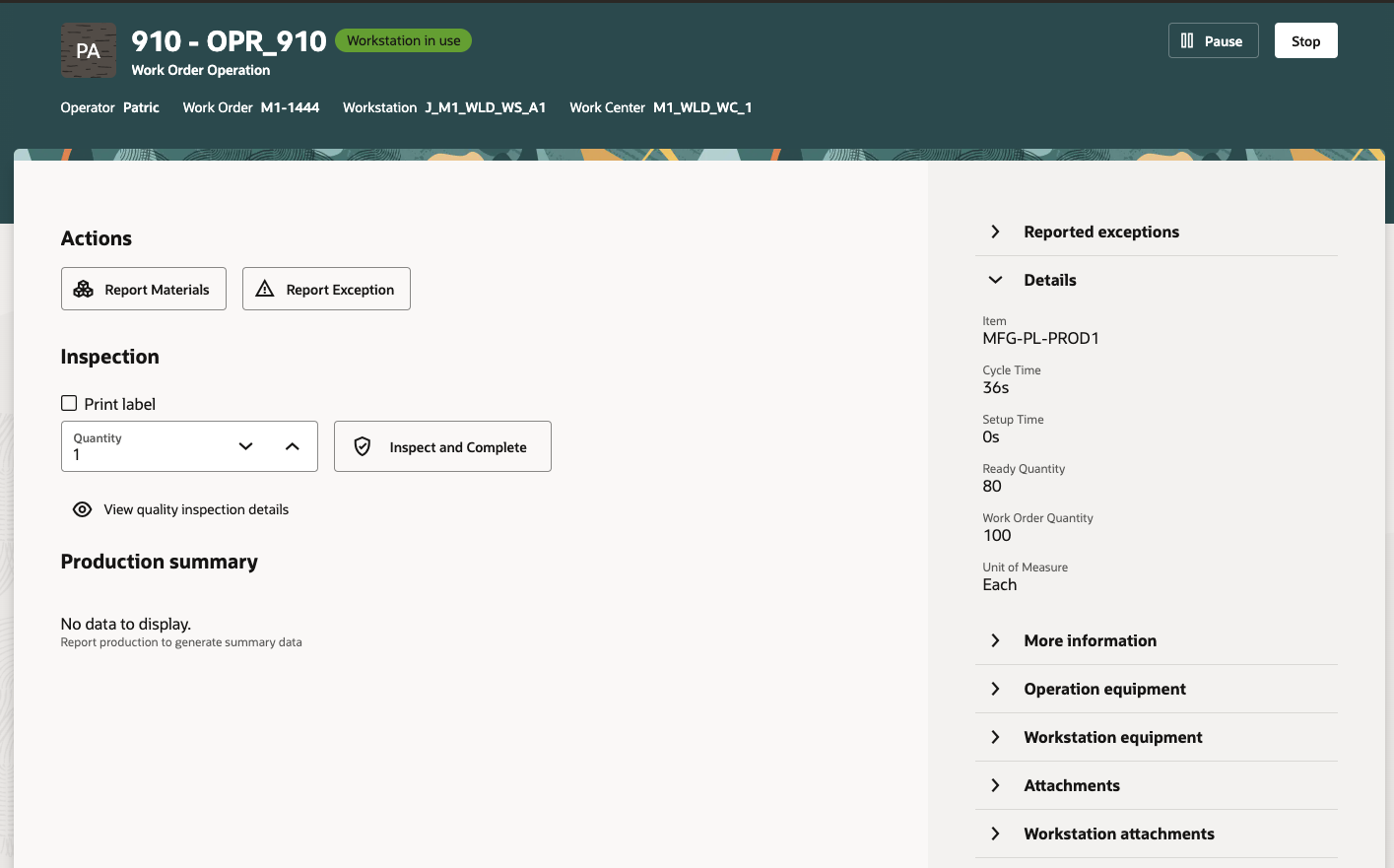

When performing the execution of a work order operation at a workstation, you may need to issue materials that are either serial controlled, lot controlled or non-controlled, and of different supply types. With this update, you can:

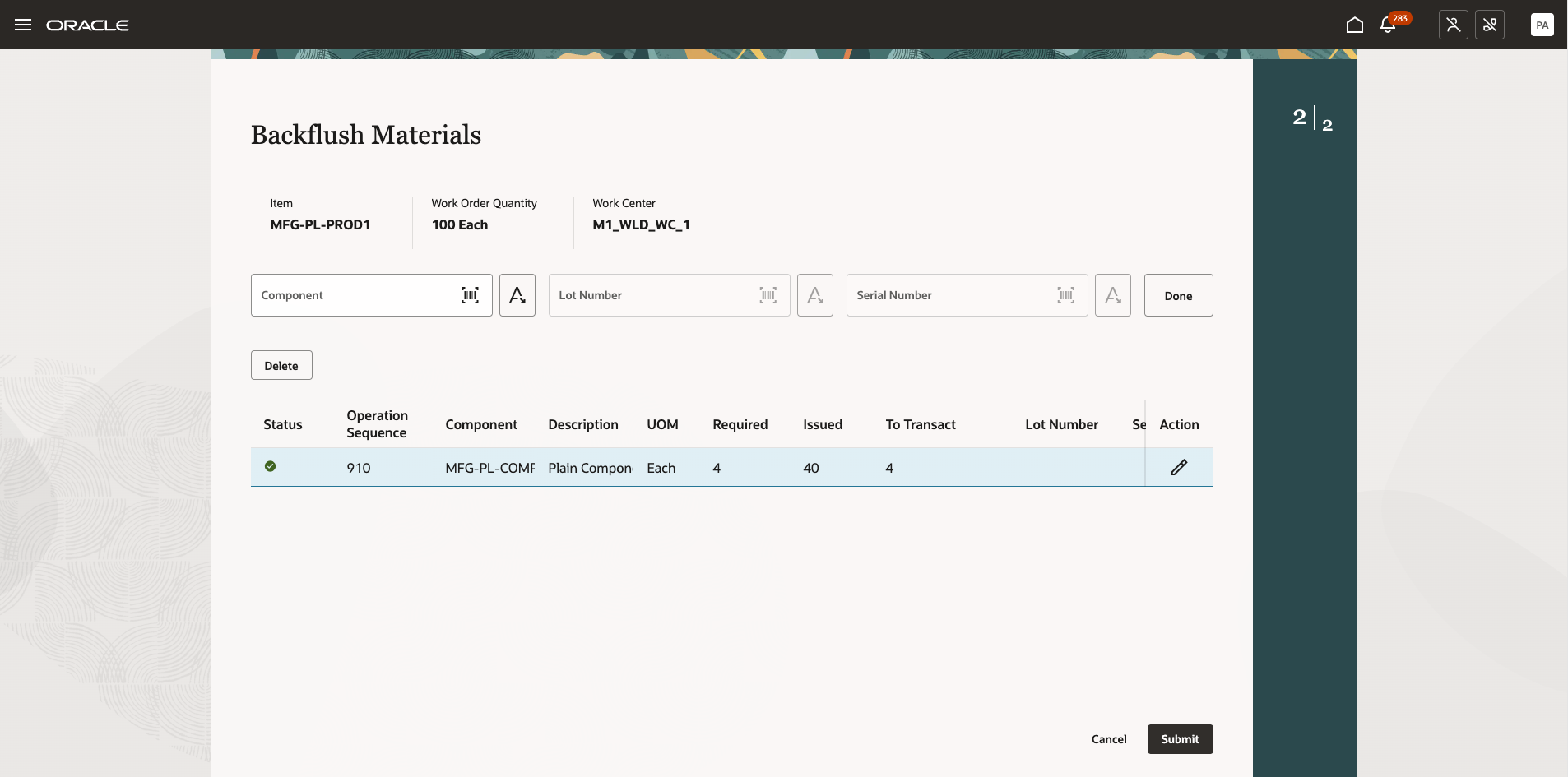

- Scan or enter the lot and serial information of supply types push and operation pull.

- Report material quantities consumed for the work order operation quantity.

- Report ad hoc materials for a work order operation.

- Enter serial and lot information during material backflush for serial-controlled components, before operation completion.

You can enable guided journeys to help user perform this task by providing videos, images, and best practices.

Report Material at a Workstation

Report Backflush Materials During Execution

Manufacturers can maintain accurate traceability of controlled or non-controlled components. Manufacturers can ensure compliance with quality and production standards without spending additional time on manual record management.

Here's the demo of these capabilities:

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Manufacturing and Supply Chain Materials Management No Longer Optional From: Update 25B

You must opt in the Complete Work Order Operations with Details at Workstations feature (24D) to automatically enable this feature.

Tips And Considerations

- You can't report materials for work order operations in organizations with project tracking, country of origin tracking for inventory, or with warehouse management integration at this time.

- You can't view material reservations while reporting material transactions at this time.

- You can report material from the workstation before starting a work order operation execution, during execution, or while completing the quantities that require materials to be backflushed.

Key Resources

- Watch the Report Material Transactions for a Work Order Operation Executed at a Workstation Demo.

- Watch the Report Material Transactions for a Work Order Operation Using the Redwood User Experience Demo.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these privileges can use this feature:

- Report Material Transactions (WIP_REPORT_MATERIAL_TRANSACTIONS_PRIV)

- Execute Production at a Workstation (WIP_EXECUTE_WORKSTATION)

- Edit Inspection Results (QA_EDIT_INSPECTION_RESULTS_PRIV)

- View Inspection Results (QA_VIEW_INSPECTION_RESULTS_PRIV)

Guided Journeys : Role Codes

- Use REST Service - Guided Journeys Read Only (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO)

- Use REST Service - Guided Journey Responses (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES)

These privileges were available prior to this update.

In addition to the preceding privileges, you should have the following data security configured for your role and user:

-

Manufacturing plant data security: Set the security context value for the manufacturing plant to the manufacturing organization.

-

Item class data security: Set the View Item Basic action to allowed.