Promise Only After You Release Holds On Lots

Promise Only After You Release Holds On Lots

An item might need to pass inspection or mature before you can use it in your manufacturing process or ship it to your customer. You can put the on-hand lot that you need to make or ship the item on hold and exclude that lot from promising. You can set a release date, and Oracle Global Order Promising will use it to determine when it can start using that supply and fulfill the sales order. The release date might change during fulfillment depending on how long it takes to inspect or mature the item.

Use supplies from your on-hand lot to meet demand on or after the hold date. You can use these supplies even for each component of an assembly that you manufacture.

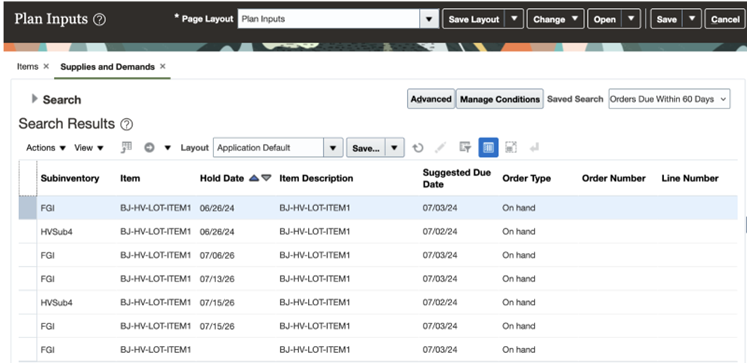

Here's an example from the Supplies and Demands tab of the Plan Inputs page.

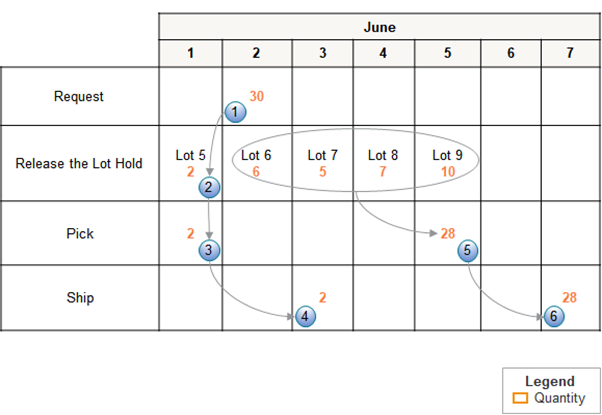

Example 1: Promise When You Hold the Lot's Date

Assume:

- You release on-hand supply from different lots on different dates.

- You place sales orders on different dates and each order has a different quantity.

- You specify a value in the lot's Hold Until Date attribute in Oracle Inventory Management. For background, see How the Dates in Lot Attributes Are Calculated.

- You set the Pick and Pack Lead Time attribute to 2 days. For background, see Add Lead Time So You Can Pick and Pack.

- You enable the Split Order When Supply Becomes Available option and you set the Minimum Quantity for Splitting attribute to 1 on your ATP rule.

Promising will consume supply from your on-hand lot:

Assume Promising splits your sales order into part 1 and part 2. It will promise the first part of that split when it has enough on-hand supply to meet part 1, and it will promise part 2 when it has enough supply to promise part 2:

- You submit a sales order with a quantity of 30 on June 2.

- 2 units are available on June 1 in lot 5.

- Promising sets the pick date to June 1, and then consumes 2 units for part 1 from lot 5.

- Promising sets the scheduled ship date to June 3 for part 1 (June 2 pick date plus 2 days pick and pack lead time equals June 3).

- Promising sets the pick date to June 5, and then consumes 28 units for part 2 from lots 6, 7, 8, and 9.

- Promising sets the scheduled ship date to June 7 for part 2.

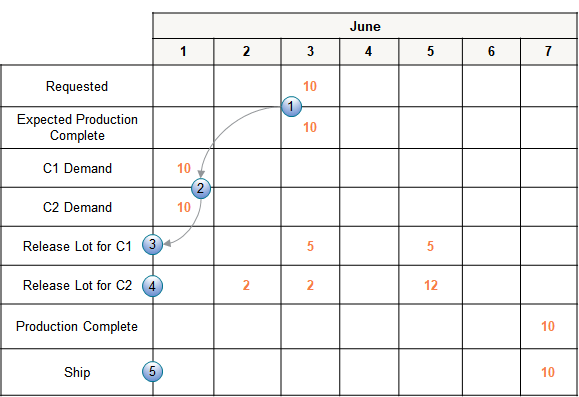

Example 2: Promise an Assembly's Components

Assume you need component C1 and component C2 to build an assembly.

- You release on-hand supply from different lots on different dates.

- You set the Processing Lead Time to 2 days and the Post Processing Lead Time for the assembly to 0.

- You submit a sales order on June 3 for 10 units. Promising uses the lead times to determine that it expects production to be done on June 3.

- Promising places demand for C1 and C2 on June 1.

- Promising uses the on-hand supply that you release on June 3 and June 5 to meet C1's demand.

- Promising uses the on-hand supply that you release on June 2, June 3, and June 5 to meet C2's demand.

- Production is done on June 7, so Promising sets the sales order's scheduled ship date to June 7, with a delay of four days.

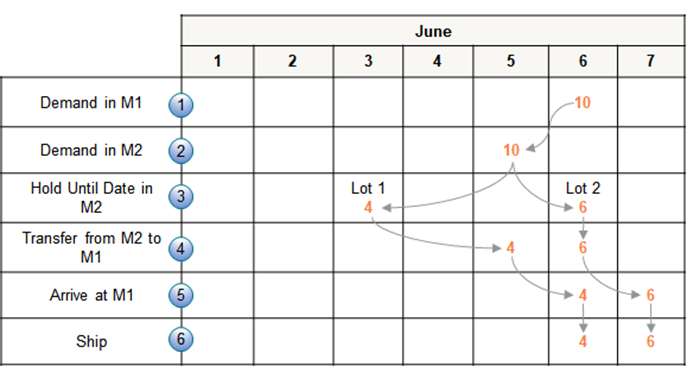

Example 3: Promise with Transfer Orders

Assume you ship a sales order from your M1 organization.

- You release on-hand supply from your upstream M2 organization from different lots on different dates.

- You set up transfer rules that transfer supply from M2 to M1.

- You set the Transit Lead Time from M2 to M1 to 1 day. For background, see Transit Times.

- You don't set any value for the Pick and Pack Lead Time attribute on the ATP rule or for the item's Postprocessing Lead Time attribute in the Product Information Management work area.

- You enable the Split Order When Supply Becomes Available option and you set the Minimum Quantity for Splitting attribute to 1 on your ATP rule.

- You submit a sales order in M1 on June 6 for 10 units.

- Promising places demand for 10 units in M2 on June 5. It sees that there isn't enough supply to meet demand, so it splits the original order line into two lines.

- Promising examines M2's hold until dates. It consumes 4 units of M2's supply from lot 1 on June 3, and 6 units from lot 2 on June 6.

- Promising transfers supply from M2 to M1. It transfers 4 units from lot 1 on June 5, and 6 units from lot 2 on June 6.

- Lot 1's supply arrives at M1 on June 6. Lot 2's supply arrives at M1 on June 7.

- Promising sets the scheduled ship date to June 6 for 4 units to meet demand from the original line, and sets it to June 7 for 6 units to meet demand for the split line.

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Supply Chain Planning No Longer Optional From: Update 25B

Enable the Promise Only After You Release Holds On Lots opt-in feature in the Global Order Promising offering. Promising will come predefined with this feature automatically enabled starting in Update 25B.

Tips And Considerations

- If you specify a value in the lot's Hold Until Date attribute, then Promising will assume that supply is available on or after the date that you specify. If you don't specify it, then Promising uses the supply that's currently available.

- If you specify a value in the Pick and Pack Lead Time attribute, then Promising will use the supply that's available on the Hold Until Date on or before the supply's pick date. The item must be ready before you can pick it. For example, production must be done, quality checks must be done, and so on.

- If the Hold Until Date happens in the future, then Promising sets the Scheduled Ship Date to the Hold Until Date plus the Pick and Pack Lead Time. If it happens in the past, then Promising sets the Scheduled Ship Date to the current date plus Pick and Pack Lead Time.

- Promising doesn't apply postprocessing lead time to on-hand supply, but it does apply that lead time for future supply that you get through a transfer order, purchase order, or work order. If you use the item's postprocessing lead time to add the time that you need to do a quality check, then you must make sure the Hold Until Date provides enough time to finish postprocessing.

- Promising considers your manufacturing calendar or your organization's calendar to help determine the date that supply is available. If Hold Until Date happens on a nonwork day, then Promising will assume the supply's due date is the calendar's next work day.

- Promising applies the Hold Until Date for on-hand supply for each component of an item that you manufacture.

- If you allocate, then Promising allocates supply each week. You can use the Supply Allocation Report to view the allocated supply for the week when the Hold Until Date releases supply. Promising consumes supply for each sales order according to your calendar. The report includes the supply the Promising consumes during the week and illustrates where it consumed supply. These values might be different from the values that you specified when you allocated supply. For example, supply becomes available on Saturday, a nonwork day, but Promising doesn't consume it until Monday, the next work day.

- You can use this feature with source promising. For background, see Source Promising.

- If you specify an ATP time fence, and if the lot's Hold Until Date happens within the fence, then Promising will use the fence. If the Hold Until Date happens after the fence, then Promising will give capable-to-promise supply higher priority.

- Promising doesn’t recognize supply that you reserve from a lot. If Promising encounters a collected sales order that has reserved, on-hand supply, and if the Hold Until Date happens in the future, then Promising will consume supply on the Hold Until Date.