Create a Production Line for Flow Manufacturing

A production line models a physical set of sequential equipment to make a product or similar products. It's common for certain industries to run multiple production lines in a plant with variations in their configuration and scale to accommodate demand changes with production flexibility. Now you can manage production lines to run flow manufacturing using the Redwood user experience:

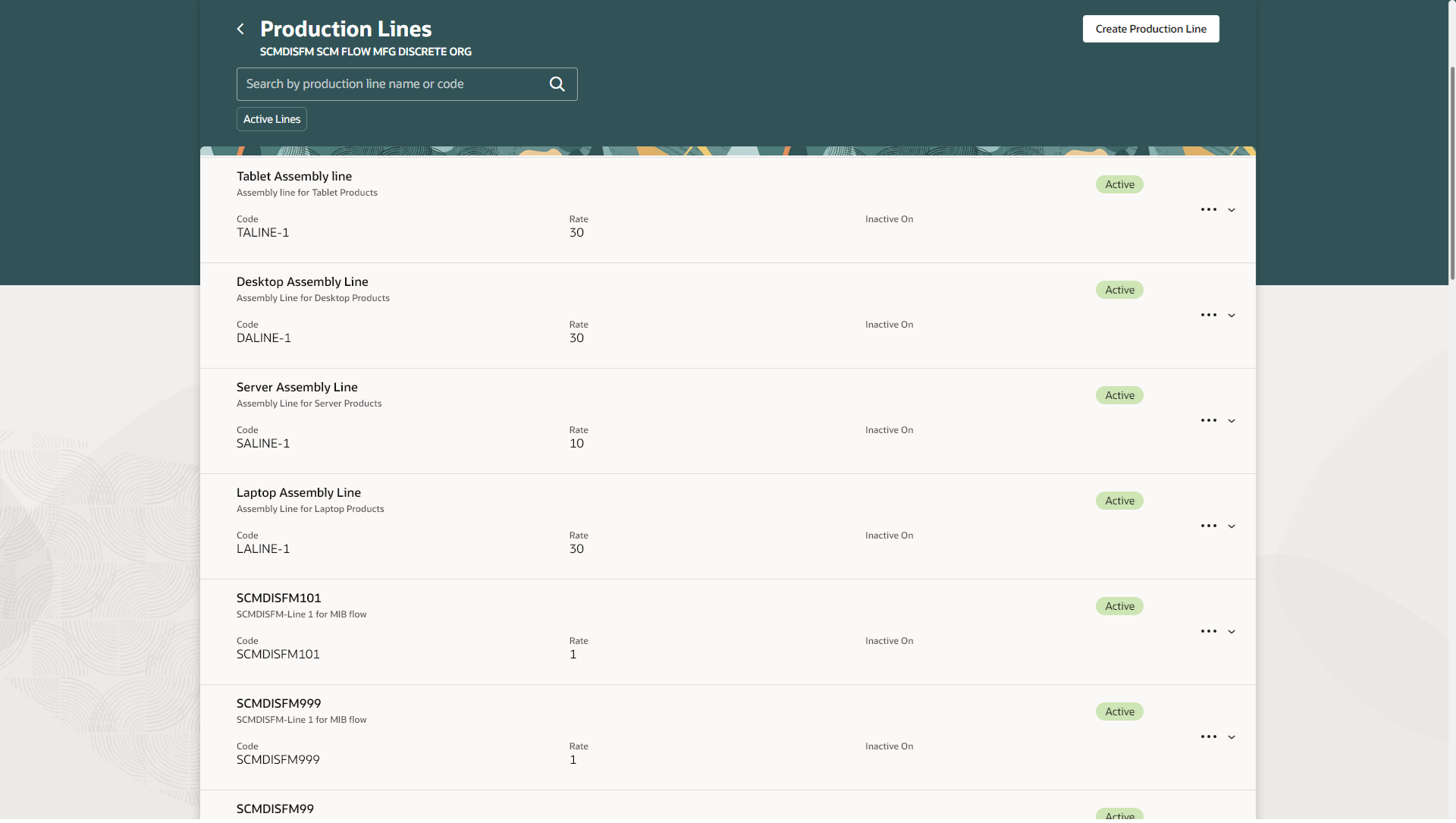

- Search and filter production lines – Quickly find a production line using keywords and filter.

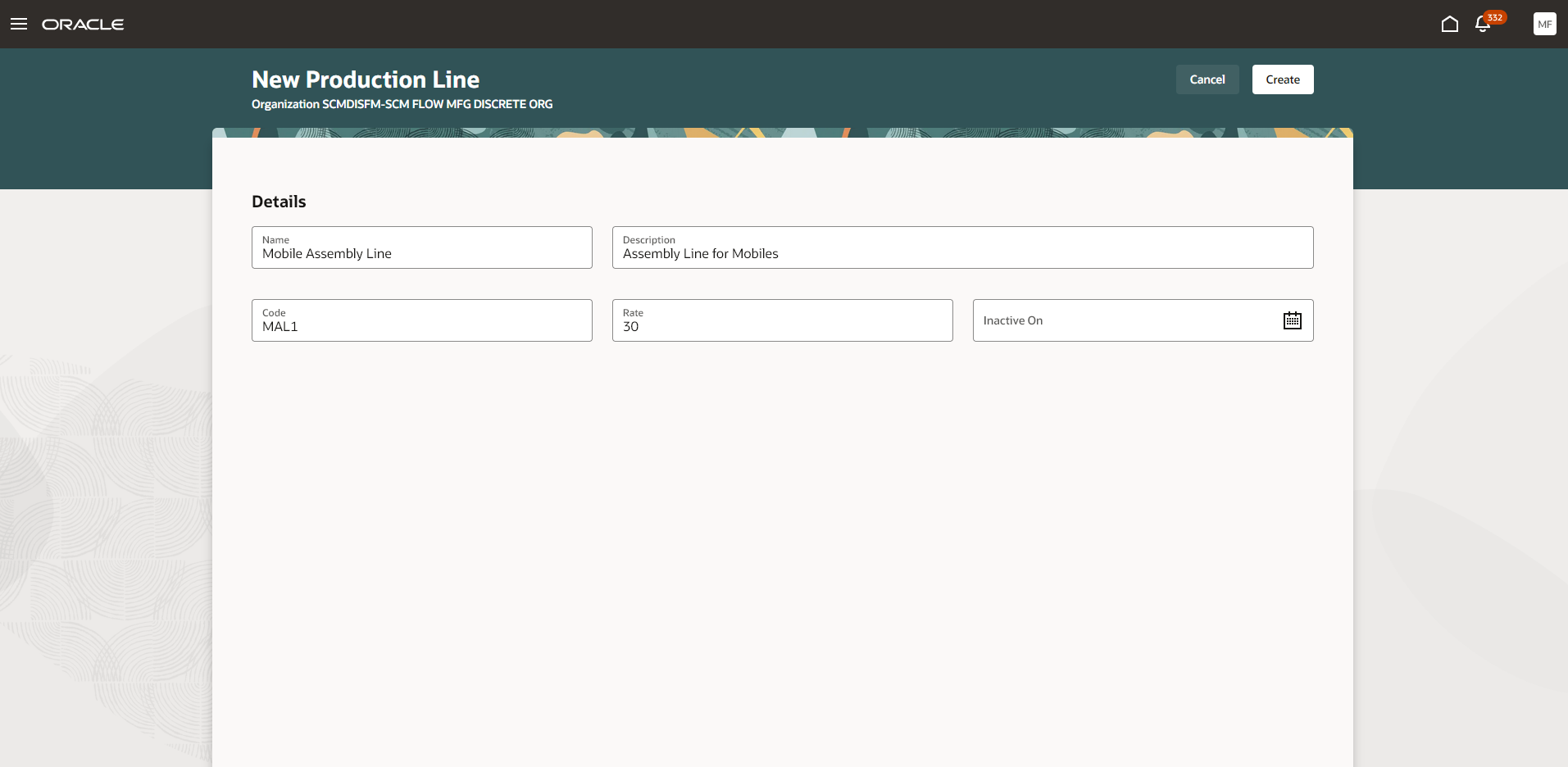

- Create a production line – Define the details for a new production line, including the rate of units produced in an hour.

- Efficiently manage a production line – Take actions to edit or delete a production line details. You can also inactivate a production line by specifying an inactive on date.

Manage Production Lines

Create a Production Line

Using production lines, flow manufacturers can streamline and implement rate-based production based on the line capacity and availability.

Here's the demo of these capabilities:

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- You can use production lines in combination with the following features related to flow manufacturing in 25A:

- Create a Flow Manufacturing Work Definition Associated with a Production Line

- Manage Flow Schedules for Manufacturing Execution on a Production Line

- Execute and Complete Flow Schedules on a Production Line

- You can use production lines to run flow manufacturing for standard and configured products.

- As a recommended practice, prior to creating a production line and work definition for flow manufacturing, you can first design a production line for optimized production flow and minimal waste.

- You can specify the production line rate as the maximum hourly rate that the line can produce. The line rate isn't calculated currently.

- You can't define production line start and stop times. Instead a production line uses the plant calendar to determine its availability.

- You can't define production line operations, equipment resources and their instances, or workstations. Instead create a flow manufacturing work definition that is associated with a production line, add the sequence of operations, and associate its equipment resources. Workstation association to a flow manufacturing line is not supported currently.

- You can't define production line tolerance fences for flow scheduling currently.

- You can't use production lines for discrete manufacturing or process manufacturing work orders, or orderless transactions currently.

Key Resources

- Watch the following demos:

- Create a Production Line for Flow Manufacturing

- Create a Flow Manufacturing Work Definition Associated with a Production Line

- Manage Flow Schedules for Manufacturing Execution on a Production Line

- Execute flow schedules on a production line

Access Requirements

Users who are assigned a configured job role that contains these privileges and codes can access this feature:

- Manufacturing Privileges :

- Manage Production Lines by Service (WIS_MANAGE_PRODUCTION_LINES_SERVICE)

- Get Production Lines by Service (WIS_GET_PRODUCTION_LINES_SERVICE)

These privileges are new in release 25A.

- Guided Journeys : Role Codes

- Use REST Service - Guided Journeys Read Only (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO)

- Use REST Service - Guided Journey Responses (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES)

These roles were available prior to this update.