Plan for Pick-To-Order Kits

You may have pick-to-order (PTO) kits in your enterprise where two or more items belonging to the kit are packaged together at the time of shipment. Previously, you could plan for PTO kits only in an unconstrained supply plan. With this update, support for PTO kits has been extended for constraint-based plans. This enables you to plan accurately when you express the number of units of demand for PTO kits which is then exploded to derive the demand for the items in the kit.

A kit is a PTO item which consists of a standard list of mandatory components which you pick, pack and ship when you process a customer sales order for that item. An example of a PTO kit is a motor car maintenance kit which consists of essential tools such as wrenches, jack, and spanners.

When a sales order is placed in Oracle Order Management for a PTO kit, sales order lines for the components of the kit are also created by Order Management. The sales orders on the PTO kit and its components are further planned in Supply Planning.

Let’s look into an example:

Use Case 1:

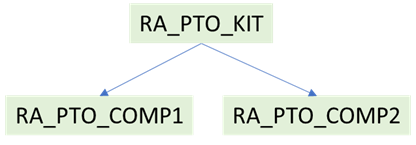

Consider the following PTO kit:

PTO kit

RA_PTO_KIT is a PTO kit and RA_PTO_COMP1 and RA_PTO_COMP2 are its components with usage as 1. There is a sales order on RA_PTO_KIT of quantity 100. Order Management will also create sales order lines for PTO kit components. So, in this case the sales order lines would be:

Sales order on RA_PTO_KIT (quantity 100)

Sales order on RA_PTO_COMP1 (quantity 100)

Sales order on RA_PTO_COMP2 (quantity 100)

To satisfy the sales order on RA_PTO_KIT, a planned order is created by Supply Planning. Constrained supply plan doesn’t explode the planned order that is originating from a sales order on a PTO kit, to its components. In this case, planned order demands are not created for RA_PTO_COMP1 and RA_PTO_COMP2. Separate planned orders are created for each sales order line.

Hence in this example, the following supplies are created:

RA_PTO_KIT (Sales order)

| ______ RA_PTO_KIT (Planned order: quantity 100)

RA_PTO_COMP1 (Sales order)

| ______ RA_PTO_COMP1 (Planned order: quantity 100)

RA_PTO_COMP2 (Sales order)

| ______ RA_PTO_COMP2 (Planned order: quantity 100)

Use Case 2:

If there are forecasts on a PTO kit, the planned orders created to satisfy it are further exploded to its components.

Consider the same setup as of use case 1, there is a sales order on day 5 of quantity 100, and there are forecasts on day 5 and day 10 of quantity 140 and 50 respectively on RA_PTO_KIT. The backward and forward consumption days is set to 1.

The sales order on the PTO kit consumes the forecast and the remaining forecast is exploded by supply planning. This is the case even if the plan option Explode Model Forecasts isn’t selected, because Demand Management doesn’t provide the forecast for standard mandatory components.

In this case, the sales order consumes the forecast on PTO kit on day 5 and remaining forecast is exploded. The forecast on day 10 also explodes to its components.

The following would the demand and supply picture after running a supply plan:

RA_PTO_KIT (Sales order, quantity 100, due date = day 5)

| ______ RA_PTO_KIT (Planned order: quantity 100, due date = day 5)

RA_PTO_COMP1 (Sales order, quantity 100, due date = day 5)

| ______ RA_PTO_COMP1 (Planned order: quantity 100, due date = day 5)

RA_PTO_COMP2 (Sales order, quantity 100, due date = day 5)

| ______ RA_PTO_COMP2 (Planned order: quantity 100, due date = day 5)

On day 5, the forecast of quantity 140 is consumed by the sales order on PTO kit and remaining forecast is planned by supply planning as:

RA_PTO_KIT (Forecast, quantity 40, due date = day 5)

| ______ RA_PTO_KIT (Planned order: quantity 40, due date = day 5)

| ______ RA_PTO_COMP1 (Planned order: quantity 40, due date = day 5)

| ______ RA_PTO_COMP2 (Planned order: quantity 40, due date = day 5)

On Day 10, since there is no consumption of forecast, whole quantity is planned by Supply Planning. The planned order on PTO kit is further exploded into kit components.

RA_PTO_KIT (Forecast, quantity 50, due date = day 10)

| ______ RA_PTO_KIT (Planned order: quantity 50, due date = day 10)

| ______ RA_PTO_COMP1 (Planned order: quantity 50, due date = day 10)

| ______ RA_PTO_COMP2 (Planned order: quantity 50, due date = day 10)

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Supply Chain Planning

Tips And Considerations

If you want to use the Plan for Pick-To-Order Kits feature, then you must opt in to its parent feature: Constraint-Based Planning. If you’ve already opted in to this parent feature, then you don’t have to opt in again.

- The PTO kits are non-stockable and non-transactable and hence any existing supply created on PTO kit is ignored by supply planning. The supplies on components of a PTO kit are considered by supply planning as they are standard items.

- Order modifiers are not respected for PTO kits.

- It is not recommended to create a work definition on PTO kits. If it’s needed for costing purposes, then assign the operation resources with Scheduled flag set to No.

- A PTO kit under a PTO kit parent, or PTO or ATO model is not currently supported.

- This feature is new to constrained supply planning. Planning of PTO kits was already supported in unconstrained supply planning.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Edit Plans (MSC_EDIT_PLANS_PRIV)

- Run Plan with Snapshot (MSC_RUN_PLAN_WITH_SNAPSHOT_PRIV)

- Monitor Supply Planning Work Area (MSC_MONITOR_SUPPLY_PLANNING_WORK_AREA_PRIV)

These privileges were available prior to this update.